Troubleshooting common issues with a 14 head multihead weigher

- Troubleshooting common issues with a 14 head multihead weigher

- Overview: Why troubleshooting a 14 head multihead weigher matters for pickles

- Product snapshot: 14 Heads Vertical Single Screw Feeding Pickles Weigher backups

- Common issue #1: Inaccurate weights or wide weight distribution (14 head multihead weigher)

- Common issue #2: Product bridging and jams in the vertical single screw feed

- Common issue #3: Weigher sensitivity to moisture and brine

- Common issue #4: Electrical/control faults, HMI errors and PLC communication

- Common issue #5: Mechanical wear, misalignment and bucket malfunction

- Sanitation, washdown and CIP considerations for pickle lines

- Data-driven troubleshooting: monitor, record and analyze

- Troubleshooting quick-reference table

- When should you call technical service or replace parts (backups)

- Preventive maintenance checklist tailored for pickles

- Operational tips for better performance with pickles on a 14 head multihead weigher

- Brand advantages: why the 14 Heads Vertical Single Screw Feeding Pickles Weigher backups stands out

- FAQs (Frequently Asked Questions)

- Contact & Call to Action

- Authoritative references

- Final notes

Troubleshooting common issues with a 14 head multihead weigher

Overview: Why troubleshooting a 14 head multihead weigher matters for pickles

The 14 head multihead weigher is a high-speed, high-accuracy machine widely used in food packaging. When set up for wet, irregular products like pickles, it requires tailored settings and focused maintenance. For businesses using the 14 Heads Vertical Single Screw Feeding Pickles Weigher backups, understanding specific failure modes and their practical remedies reduces downtime, improves yield, and protects product quality. After resolving common faults, attention often shifts to performance improvement. Learning how to optimize speed and accuracy on 14 head multihead weighers for pickles allows producers to increase throughput without sacrificing weight precision.

Product snapshot: 14 Heads Vertical Single Screw Feeding Pickles Weigher backups

Product name: 14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Common issue #1: Inaccurate weights or wide weight distribution (14 head multihead weigher)

Symptoms: Packages are over or under target weight, frequent rejections at checkweigher, high giveaway or product loss.

Root causes and immediate checks:

- Calibration drift — check last calibration date and perform a quick calibration sequence using certified test weights.

- Hopper dosing inconsistency — inspect individual feed hoppers and weigh buckets for sticky residues from pickle brine that change flow behavior.

- Incorrect feed timing — the vertical single screw feed may be delivering inconsistent product slices; confirm screw pitch, speed, and stroke settings.

- Environmental vibrations — nearby equipment or floor resonances can affect readings; place vibration dampers under the machine if necessary.

Quick fixes:

- Run a calibration cycle and zero-check the load cells.

- Clean hopper surfaces and weigh buckets to remove brine buildup.

- Adjust screw speed and microfeed settings for steady dosing.

Long-term prevention: implement scheduled calibration checks (daily quick checks, weekly full calibration), maintain a cleaning SOP focused on brine removal, and keep a log of weight distributions to spot trends early.

Common issue #2: Product bridging and jams in the vertical single screw feed

Symptoms: Intermittent stops, uneven hopper loading, or mechanical overload alarms on the feeder.

Root causes:

- Pickles can bridge or cluster in the screw due to size variability, brine viscosity, or pieces sticking together.

- Worn or incorrect screw geometry for the pickle size and pack style.

- Insufficient agitation at feed inlet causing irregular supply.

Practical solutions:

- Use a gentle vibratory or paddle agitator at the feed hopper inlet to separate pieces before the screw.

- Inspect and change the screw to a profile optimized for whole or sliced pickles; consider a variable-pitch screw if product mix varies.

- Increase screw rpm slightly or implement short reverse cycles if your controller supports it to clear occasional clogs.

Common issue #3: Weigher sensitivity to moisture and brine

Symptoms: Corrosion on components, sticky residues reducing movement, electrical faults from moisture ingress.

Root causes:

- Brine splashes from product or washdown procedures reach bearings, load cells, or electronics.

- Condensation inside control cabinets due to cool product and warm ambient air.

Recommended actions:

- Use protective covers and splash guards around vulnerable areas; IP-rated enclosures for electrical components are essential.

- Specify and use washdown-rated components (stainless steel, IP66 cabinets, marine-grade connectors).

- Install condensation heaters or ventilation for control enclosures in high-humidity environments.

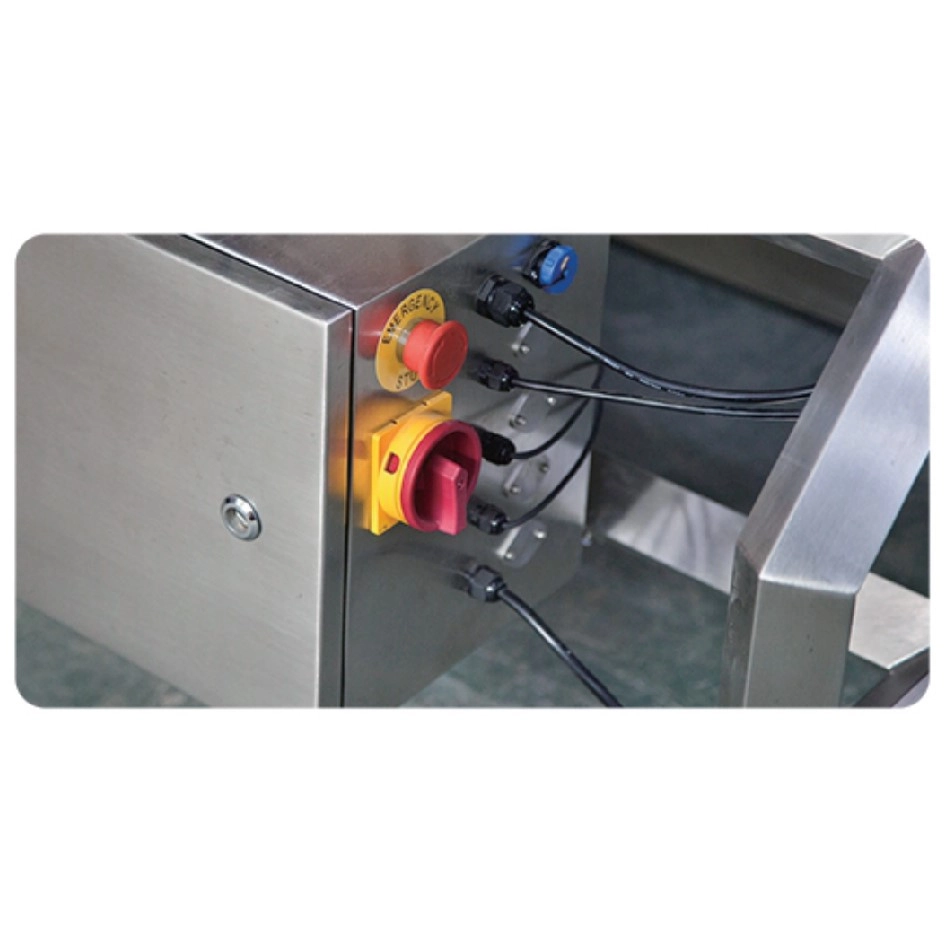

Common issue #4: Electrical/control faults, HMI errors and PLC communication

Symptoms: Random alarms, frozen HMI screens, inconsistent cycle times, or lost recipes.

Causes and fixes:

- Loose or corroded connectors: perform visual and torque checks on all terminal blocks and connectors. Replace corroded connectors with sealed types.

- Outdated firmware or corrupted recipe files: keep controller firmware updated and maintain versioned backups of recipes/parameters off-machine.

- Power quality issues: fit surge protection and a stable UPS for PLC/HMI to prevent corruption during brief outages.

Operational best practice: keep a 'golden copy' of all machine settings on a secure server and document any changes with an authorized operator log.

Common issue #5: Mechanical wear, misalignment and bucket malfunction

Symptoms: Uneven bucket closing, increased noise, reduced cycle speed, or repeatable weighing errors on certain heads.

Diagnosis and solutions:

- Inspect cams, bearings, and bucket lifters for wear — replace worn parts before they cause head imbalance.

- Check load cell mounts for cracks or loose fasteners; even small misalignments cause measurable weight variance.

- Perform a head-by-head static check: block all other heads and test each head to isolate failing units.

Sanitation, washdown and CIP considerations for pickle lines

Pickles are processed in a wet environment and often require frequent cleaning. Poor cleaning protocols cause bacterial risk and mechanical issues.

Recommendations:

- Design SOPs that specify cleaning frequency (e.g., daily clean for contact surfaces) and acceptable cleaning agents for seals and sensors.

- Use quick-release covers and tool-less access points to reduce cleaning time and avoid makeshift methods that can damage the machine.

- Validate cleaning with ATP swabs or microbiological testing where required by food safety programs.

Data-driven troubleshooting: monitor, record and analyze

Modern weighers provide diagnostic logs, weight histograms and rejection data. Use those tools:

- Enable continuous statistical logging of weight distributions to spot drift or trends before they become failures.

- Correlate changes in weight distribution with production parameters (screw rpm, feed hopper level, ambient temperature).

- Use the machine's head-by-head data to identify single-head issues early and swap out a problematic head or bucket during scheduled downtime.

Troubleshooting quick-reference table

| Issue | Likely Cause | Immediate Fix | Long-term Fix | Estimated Downtime |

|---|---|---|---|---|

| Inaccurate weights | Calibration drift / brine on buckets | Recalibrate / clean buckets | Scheduled calibration & cleaning | 15–60 minutes |

| Feeder jams | Bridging in screw / wrong screw pitch | Clear jam / run reverse cycle | Install agitation / change screw | 10–120 minutes |

| Moisture-related faults | Brine ingress / condensation | Dry and protect electronics | IP-rated enclosures, protective guards | 30–240 minutes |

| Electrical/PLC errors | Corroded connectors / firmware | Check connectors / reboot | Firmware updates / backups / UPS | 15–180 minutes |

When should you call technical service or replace parts (backups)

If an issue repeats after basic fixes, or if a head consistently shows variance despite calibration, escalate to factory service. Maintain a small inventory of critical spares (load cells, buckets, screws, bearings, seals) so you can replace parts quickly. The product name, 14 Heads Vertical Single Screw Feeding Pickles Weigher backups, implies provision for backups—keep at least one spare feed screw and a set of weigh buckets on-site for rapid exchange.

Preventive maintenance checklist tailored for pickles

- Daily: visual inspection, quick clean of hoppers and buckets, confirm no alarms, log production batch info.

- Weekly: full washdown of product-contact areas, check screw wear, torque-check fasteners.

- Monthly: load cell accuracy check, firmware and backup verification, review weight histograms and reject rates.

- Quarterly: replace wear items as recommended by OEM, lubrication of bearings (food-grade), inspect electrical connectors.

Operational tips for better performance with pickles on a 14 head multihead weigher

1) Standardize product feed size and moisture level wherever possible — uniform product promotes repeatable dosing. 2) Adjust target combination strategies in the weigher software to prefer more heads with smaller contributions if the product is highly variable. 3) Use adaptive algorithms or recipe presets for different pickle formats (whole, slices, spears) to reduce set-up time and errors.

Brand advantages: why the 14 Heads Vertical Single Screw Feeding Pickles Weigher backups stands out

Specialization: built specifically for pickles, this model integrates a vertical single screw feed that minimizes product damage while delivering steady flows for each of the 14 heads. Reliability: backup strategy and spare-ready design reduce mean time to repair. Sanitation-friendly design: stainless steel construction and quick-access panels reduce cleaning time and risk of contamination. Serviceability: heads and feed components are designed for easy swap-out which pairs well with an on-site spare parts policy. These advantages reduce downtime, lower giveaway and improve packaging throughput for pickle lines.

FAQs (Frequently Asked Questions)

Q1: How often should I calibrate my 14 head multihead weigher?

A: Perform a quick zero/offset and test-weight check at the start of each shift. Full calibration with certified test weights is recommended weekly or whenever weight drift is detected.

Q2: Can I run multiple pickle formats without heavy retooling?

A: Yes—use recipe presets for each format and keep interchangeable screws and hopper guides available. Minor adjustments to screw speed and head contributions are usually sufficient.

Q3: What spare parts should I stock for fast recovery?

A: At minimum, keep 2–3 spare weigh buckets, one spare screw (vertical feed), a spare load cell, a set of seals/gaskets, and common fasteners/connectors. The product backups strategy emphasizes this spare approach.

Q4: How do I prevent brine-related electrical issues?

A: Use IP-rated enclosures, sealed cable glands and corrosion-resistant connectors. Ensure washdown procedures avoid direct spray on control panels and dry enclosures after cleaning.

Q5: When should I call OEM service rather than local maintenance?

A: If load cells need replacement, major firmware recovery is required, or repeated head imbalance persists after head swaps, call OEM service. Also contact OEM for warranty-covered component failures.

Contact & Call to Action

For tailored advice, spare parts, or to schedule a service visit for your 14 Heads Vertical Single Screw Feeding Pickles Weigher backups, contact our technical team today. We provide remote diagnostics, on-site troubleshooting, and a stocked spare-parts program to minimize downtime. Click to contact our sales and service team or view the full product specification sheet.

Authoritative references

- Weighing scale — Wikipedia: https://en.wikipedia.org/wiki/Weighing_scale

- Food and Drug Administration (FDA) — Food safety and manufacturing guidance: https://www.fda.gov/food

- Codex Alimentarius — International food standards: http://www.fao.org/fao-who-codexalimentarius/en/

- European Hygienic Engineering & Design Group (EHEDG) — Hygienic design guidance: https://www.ehedg.org/

- Ishida (industry reference for multihead weighers) — https://www.ishida.com/

- European Food Safety Authority (EFSA) — Food safety science: https://www.efsa.europa.eu/

Final notes

Maintaining a 14 head multihead weigher on a pickle line requires attention to moisture control, proper feed handling via the vertical single screw, and a disciplined maintenance regimen. Using the product-specific practices outlined here will reduce downtime, decrease giveaway, and keep your line compliant with food safety expectations.

Top 10 Metal Detector Models for High-Speed Packaging Lines

How Food Metal Detectors Prevent Contamination in Production

Selecting Good Metal Detectors for High-Speed Production Lines

Best Food Packing Machine Brands for Multihead Weigher Systems

About Product choice

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

About products customization

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

About Solution suggestions

Can Kenwei machines handle products with irregular shapes or sizes?

Yes, multi-head weighers are particularly effective for handling products with irregular shapes and sizes.

About Cooperation Process

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Combined Check Weigher and Metal Detector for Food Industrial Weighing and Sorting

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei