How Food Metal Detectors Prevent Contamination in Production

- How Food Metal Detectors Prevent Contamination in Production

- What a metal detector for food industry actually does

- How food metal detectors work: the detection principle

- Common contaminant types and detection capability

- Introducing the Food Metal Detector Manufacturer For Reject Defective Products G5020

- Why multi-frequency metal detectors matter in the food industry

- Installation and integration: making metal detectors part of your HACCP plan

- Validation, calibration and routine testing

- Comparison: Metal detector vs X-ray inspection

- Common challenges and practical solutions

- Operational processes that maximize metal detector effectiveness

- How the G5020 supports compliance and minimizes contamination risk

- Brand advantages: why choose our G5020 for your food line

- Cost justification: reducing recall and warranty risk

- FAQ — Frequently Asked Questions

- Contact us / View product

- References and further reading

How Food Metal Detectors Prevent Contamination in Production

What a metal detector for food industry actually does

Metal detectors are a frontline defense in food safety systems. They detect unwanted metallic contaminants (ferrous, non-ferrous and some stainless steels) that can enter food during processing and packaging. By identifying contaminated items on the production line and automatically rejecting them, these systems reduce the risk of consumer injury, product recalls, and brand damage. In short, a correctly selected and maintained metal detector turns an invisible hazard into a controllable operational step. Understanding how food metal detectors prevent contamination in production is only the first step. To achieve full-line efficiency, manufacturers also need to focus on seamless equipment coordination, which is why integrating metal detectors with multihead weighers becomes a critical best practice in modern food processing lines.

How food metal detectors work: the detection principle

Metal detectors for food industry use electromagnetic fields to identify conductive and magnetic materials. A transmitter coil generates an alternating field; when a metal object passes through, it disturbs that field and induces signals in receiver coils. Signal processing electronics analyze the disturbance to determine the presence and approximate size of a contaminant. Modern systems use multi-frequency processing and digital filtering to improve sensitivity in difficult products (those with varying moisture, salt or density), reducing false rejects and missed contaminants.

Common contaminant types and detection capability

Typical contaminants include fragments of processing equipment (e.g., screws, weld splashes), packaging materials, or foreign objects introduced in handling. Detection sensitivity varies by metal type and product: ferrous metals are easiest to detect, while non-ferrous metals (aluminum, copper) and certain stainless steels are harder. Product characteristics (e.g., wet vs dry, homogeneous vs heterogeneous) also affect detection ranges. Properly configured systems and validation programs ensure consistent detection performance.

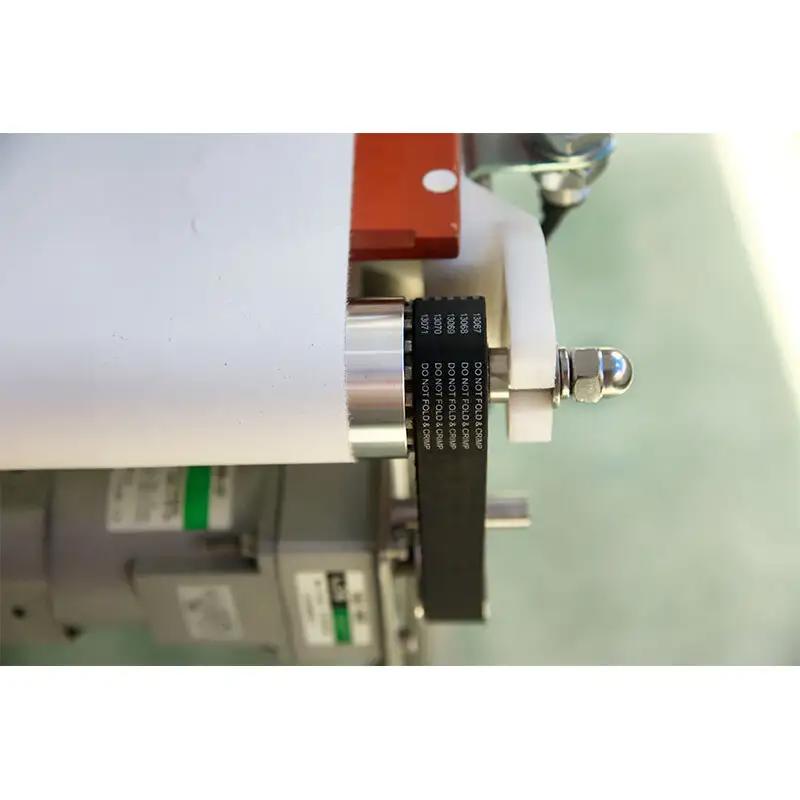

Introducing the Food Metal Detector Manufacturer For Reject Defective Products G5020

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Why multi-frequency metal detectors matter in the food industry

Multi-frequency detectors sweep or operate on several frequencies simultaneously. This capability is important because different frequencies respond better to different metal types and product effects. For example:

- Low frequencies better detect larger ferrous items and are less affected by product mineralization.

- High frequencies improve detection of small non-ferrous contaminants in low-conductivity products.

By combining frequencies (as with the G5020), the system balances sensitivity and stability, improving detection in mixed and challenging products common in food lines.

Installation and integration: making metal detectors part of your HACCP plan

Installing a metal detector correctly is crucial. Key considerations include conveyor speed and stability, product presentation (single-file vs bulk), grounding, and the proximity of motors or other electromagnetic noise sources. A metal detector should be placed after all metal-forming operations and before final packing to maximize the chance of detecting process-generated debris. Integration into your Hazard Analysis and Critical Control Points (HACCP) or Food Safety Plan should define rejection logic, record-keeping, alarm responses, and corrective actions.

Validation, calibration and routine testing

To ensure ongoing performance, follow a documented validation and verification program. Typical steps include:

- Initial sensitivity validation using industry-standard test pieces representing ferrous, non-ferrous and stainless contaminants at known sizes.

- Daily or shift-start product tests (e.g., test pieces passed through the detector) recorded in logs for audit purposes.

- Periodic calibration and environmental noise checks, plus re-validation when process changes (new product, conveyor changes) occur.

Maintaining traceable test records supports compliance with food safety standards (BRCGS, SQF, ISO 22000) and helps during audits.

Comparison: Metal detector vs X-ray inspection

Many food manufacturers use metal detectors and X-ray systems together because they complement each other. The table below summarizes strengths and trade-offs.

| Feature | Metal Detector | X-ray Inspection |

|---|---|---|

| Best for | Metal contaminants (ferrous, non-ferrous, some stainless) | Dense contaminants (stone, glass, high-density foreign matter), some plastics |

| Sensitivity to small metal pieces | Very high (particularly multi-frequency systems) | Lower than metal detectors for thin small metals |

| Effect of product effect (wet/salty/mineralized) | Can be significant; multi-frequency reduces impact | Less affected by product effect |

| Cost | Generally lower CAPEX and OPEX | Higher CAPEX and maintenance costs |

| Typical use | Primary metal screening on lines | Final check for dense non-metallic contaminants and complex packages |

Sources for the comparison are industry whitepapers and regulatory guidance (see citation list below).

Common challenges and practical solutions

Manufacturers often face these issues:

- False rejects caused by product effect — mitigate by using appropriate frequency profiles, product compensation and stable conveyor design.

- Missed contaminants due to poor product presentation — ensure consistent single-file presentation or stable bulk flow and correct conveyor aperture size.

- Electromagnetic interference (EMI) — route motors and power cables away from detector head, and ensure correct earth grounding.

- Poor record-keeping — use detectors with integrated data-logging and network connectivity for audit trails.

Design choices like the G5020’s specialized conveyor belt and easy disassembly directly address many of these practical problems by improving product presentation, hygiene, and maintenance access.

Operational processes that maximize metal detector effectiveness

To get the most from a metal detector for food industry use, implement these operational controls:

- Standard Operating Procedures (SOPs) for startup, end-of-shift checks, and after maintenance.

- Daily test-piece routines with records retained for audits.

- Training programs for line operators and maintenance staff on sensitivity settings, reject verification and basic troubleshooting.

- Routine preventive maintenance: belt cleaning, mechanical alignment, and software backups.

These steps reduce downtime and ensure sustained detection performance across product runs.

How the G5020 supports compliance and minimizes contamination risk

The Food Metal Detector Manufacturer For Reject Defective Products G5020 is designed with production realities in mind. Its multi-frequency electronics improve detection across a wide range of product types. The conveyor is optimized to minimize product interference and to be easily removed for cleaning—reducing cross-contamination risk. Built-in reject mechanisms and data logging help manufacturers meet regulatory and retail compliance requirements by providing traceable records of rejected product events and system checks.

Brand advantages: why choose our G5020 for your food line

When selecting a supplier, reliability, after-sales service, and proven performance are decisive. Key brand advantages include:

- Industry-tailored design — the G5020 was engineered specifically to address the typical contamination sources and operational needs of food, pharma and spice processors.

- Multi-frequency detection technology — improved sensitivity in challenging products and reduced false rejects.

- Hygienic, easy-to-maintain mechanics — fast disassembly reduces downtime and supports GMP cleaning routines.

- Comprehensive documentation and validation support — we provide test certificates, SOP templates and training to help you pass audits and meet standards like BRCGS, SQF and ISO 22000.

- Global support network — spare parts availability and local service technicians to minimize production interruptions.

Cost justification: reducing recall and warranty risk

Investing in reliable metal detection can be cost-effective. A single contamination-related recall can cost hundreds of thousands to millions of dollars depending on the size of the recall, product type and regulatory fines. By preventing contaminated product from reaching consumers, metal detectors protect revenue and brand value. When evaluating ROI, include avoided recall cost, reduced returns, lower insurance High Qualitys, and improved retailer confidence in supplier audits.

FAQ — Frequently Asked Questions

Q: What sizes of metal can the G5020 detect?

A: Detection size depends on metal type (ferrous, non-ferrous, stainless), product characteristics and conveyor aperture. During installation we validate sensitivity using standardized test pieces to determine exact detection thresholds for your products.

Q: Can metal detectors find non-metal contaminants?

A: No — metal detectors are optimized for metallic contaminants. Use X-ray inspection alongside metal detectors to detect dense non-metallic contaminants (glass, stone) and certain plastics.

Q: How often should we test and calibrate?

A: Daily functional checks using test pieces are industry best practice. Full calibration and re-validation should occur after maintenance, product changes, or as part of scheduled preventive maintenance (typically quarterly or semi-annually depending on production intensity).

Q: Will product moisture or salt content cause false rejects?

A: High moisture and salt can cause product effect that raises the baseline signal. Multi-frequency systems like the G5020 and proper product compensation reduce false rejects. Site-specific tuning during installation is crucial.

Q: Is the G5020 suitable for pharmaceutical or spice lines?

A: Yes. The G5020 is suitable for food, pharmaceuticals, spices and other industries listed in the product description. Its hygienic design and validation support make it appropriate for regulated environments.

Contact us / View product

If you want to minimize contamination risk and improve compliance, contact our sales team to schedule a line survey, request a demo, or receive a quotation for the Food Metal Detector Manufacturer For Reject Defective Products G5020. For immediate assistance, email sales@example.com or call +1-800-000-0000. To view full product specifications and datasheets, request a product pack from our team.

References and further reading

- U.S. Food & Drug Administration (FDA) — Food Safety Modernization Act (FSMA) and Preventive Controls guidance: https://www.fda.gov/food

- Mettler-Toledo Safeline — Metal Detection Guide and Whitepapers (industry reference on metal detector principles and validation): https://www.mt.com

- BRCGS — Global Standard for Food Safety (guidance on foreign body control and validation): https://www.brcgs.com

- Codex Alimentarius — general food safety principles and HACCP guidance: http://www.fao.org/fao-who-codexalimentarius

Note: Specific detection performance (e.g., minimum detection diameter for each metal type) should be validated on-site with your actual product, conveyor geometry and production speed. Our team will help perform these tests and provide written validation documentation.

The B2B Buyer’s Guide to snack packaging machine

Top 10 multihead weighing machine Manufacturers and Supplier Brands in America

The latest trends for linear scale weigher

Everything You Need to Know About food metal detector

About Product choice

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

About Cooperation Process

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

About After Sales Support

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

About Logistics

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

About products customization

Can Kenwei machines be customized for different industries?

Yes,According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on.

Dropped Metal Detector for Powder Granules For Food Industry

Enhance food safety with Kenwei’s Dropped Metal Detector for Powder Granules. This advanced food metal detector ensures precise detection in the food industry, safeguarding products and maintaining high quality standards throughout processing.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei