Integrating Metal Detectors with Multihead Weighers: Best Practices

- Integrating Metal Detectors with Multihead Weighers: Best Practices

- Why integrating a metal detector for food industry lines is essential

- Product spotlight — Food Metal Detector Manufacturer For Reject Defective Products G5020

- Key integration objectives when pairing a metal detector with a multihead weigher

- Line layout and mechanical best practices for reliable metal detector performance

- Electrical and control integration: communications and synchronized control

- Reject systems and verification strategy for metal detector + multihead weigher lines

- Calibration, routine testing and audit readiness

- Software, data and quality systems integration

- Comparing inspection technologies — metal detector vs X-ray (quick reference)

- Common integration pitfalls and how to avoid them

- Brand advantages — why choose the Food Metal Detector Manufacturer For Reject Defective Products G5020 for integration

- Implementation checklist — step-by-step

- FAQ — Common questions about metal detector integration with multihead weighers

- Q: Where should I place the metal detector relative to a multihead weigher?

- Q: How often should the detector be tested and calibrated?

- Q: Can metal detectors detect stainless-steel fragments?

- Q: How to reduce false rejects after integration?

- Q: Do metal detectors work with all food types?

- References

Integrating Metal Detectors with Multihead Weighers: Best Practices

Why integrating a metal detector for food industry lines is essential

In modern food production, combining a metal detector with a multihead weigher is a common and highly effective approach to protect consumers and brands. A properly integrated system helps ensure that products leaving the packing line are free of metal contaminants while meeting throughput, accuracy and regulatory requirements. This guide explains best practices for integrating a metal detector for food industry applications with multihead weighers, highlighting practical steps, testing regimes, rejection strategies and design considerations using the Food Metal Detector Manufacturer For Reject Defective Products G5020 as a real-world reference. Once integration is optimized, operators should clearly understand what they are detecting. Our guide on common metal contaminants and detection techniques in food explains the types of ferrous, non-ferrous, and stainless steel particles that metal detectors are designed to identify.

Product spotlight — Food Metal Detector Manufacturer For Reject Defective Products G5020

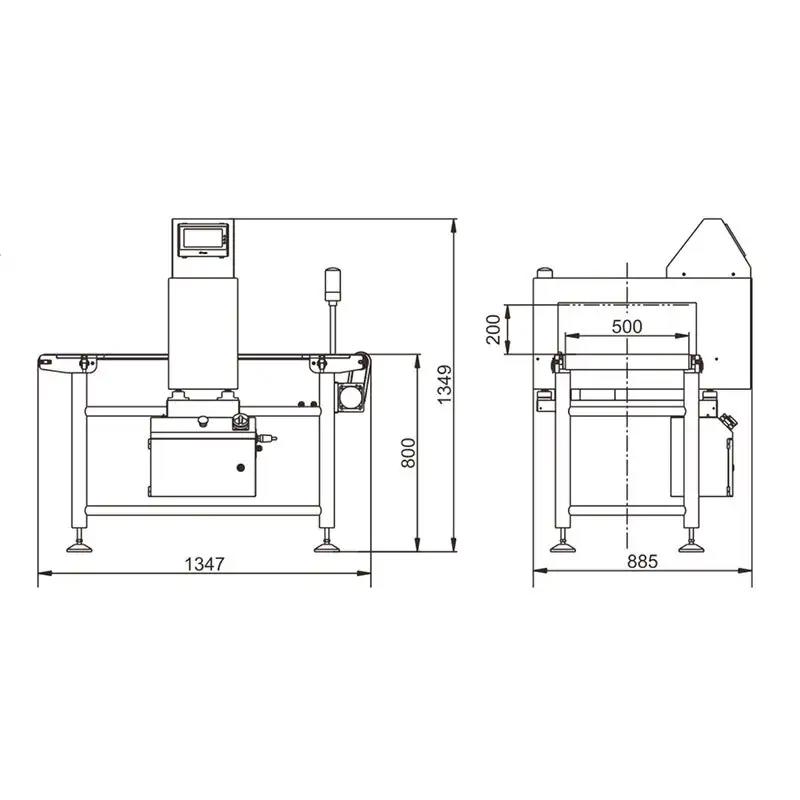

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Key integration objectives when pairing a metal detector with a multihead weigher

Before integration begins, clarify the primary objectives — safety (remove metallic contaminants), compliance (meet regulatory and retailer standards), productivity (maintain line speed and yield), and traceability (record rejects and events). Common objectives include:

- Detect and reliably reject ferrous, non-ferrous and stainless-steel contaminants at defined sensitivities.

- Maintain target throughput of the multihead weigher without excessive false rejects.

- Provide audit-ready logs for quality teams and traceability for recalls or supplier investigations.

- Allow fast maintenance and hygienic cleaning with minimum downtime.

Line layout and mechanical best practices for reliable metal detector performance

Mechanical integration affects detection sensitivity and false reject rates. Follow these practical rules when placing a metal detector for food industry lines alongside a multihead weigher:

- Placement: Install the metal detector after the multihead weigher and any dynamic infeed sections, but before final pick-and-pack or enrobers, so the detector inspects the final product configuration. If upstream operations (mixers, grinders) can introduce contamination, consider additional detectors earlier in the line.

- Conveyor stability and product presentation: Ensure consistent product presentation. Irregular product piling or overlapping can reduce sensitivity. Use dedicated conveyor widths and guides to center product under the detector aperture.

- Distance from vibration sources: Position the detector away from heavy vibration sources (pumps, motors, nearby packaging machines). Mechanical vibration can increase noise in detector signals and trigger false rejects.

- Hygienic design: Use stainless-steel frames, sloped surfaces for drain-off and quick-release conveyors (as with the G5020) to allow cleaning without dismantling electronics. EHEDG-aligned design reduces contamination risk and shortens cleaning downtime.

- Synchronize product transfer: Minimize gaps and product collisions between weigher discharge and detector infeed. Use short, controlled transfer belts, gentle chutes or product accumulators to prevent product damage and presentation inconsistency.

Electrical and control integration: communications and synchronized control

Seamless electrical and PLC integration ensures detection events are logged and rejects are reliably coordinated with the multihead weigher’s discharge cycle. Key best practices:

- Protocol compatibility: Confirm communication protocols (Ethernet/IP, Modbus TCP, ProfiNet, digital I/O). Many modern detectors including models like the G5020 support common industrial protocols for direct integration with the line PLC and MES systems.

- Event tagging and recipe handling: Map detector events to product recipes in the weigher’s control system so the detector uses the correct sensitivity and reject logic per SKU. This reduces false positives when product backgrounds change between recipes.

- Time-stamping and traceability: Ensure the detector outputs event data (time, product SKU, sensitivity used, reject count) to the line historian or cloud service for audit trails and trend analysis.

- Fail-safe interlocks: Design interlocks so that a fault in the detector or communications results in a safe, controlled line stop or divert to a secondary inspection point rather than allowing contaminated product to pass unchecked.

Reject systems and verification strategy for metal detector + multihead weigher lines

Reject systems must be matched to line speed and product type to avoid jams or incorrect disposal of good product. The combination of the G5020 metal detector and a robust reject mechanism is a common approach.

- Reject mechanisms: Options include pneumatic air blasts, diverter arms, drop gates, and retractable belts. Choose a method that handles your product delicately enough to avoid breakage but decisively enough to remove contaminants at full speed.

- Verification loop: Implement a verification check after the reject station (for example, a second short detector or camera system) to confirm the reject actually occurred and that the remaining stream is clear. This is essential when the reject mechanism is downstream from the multihead weigher.

- Sorting strategy: Use conditional logic to divert suspect items into a quarantine lane for inspection rather than immediately discarding them. This saves product and provides samples for root cause analysis without contaminating good product streams.

- Logging and reporting: Record each reject event with the reason (metal detected, mechanical fault), images (if available), and timestamp to support corrective action and supplier feedback.

Calibration, routine testing and audit readiness

Maintaining detection sensitivity over time requires documented procedures and training. Best practices include:

- Daily start-up checks: Use manufacturer-recommended test pieces (ferrous, non-ferrous, stainless) to verify detection. Place test pieces on the product stream at defined locations and log results.

- Scheduled calibration: Follow the detector manufacturer’s calibration intervals and retain certificates for audits. Multi-frequency detectors like the G5020 should be validated after major maintenance or firmware updates.

- False reject analysis: Track false reject rates and investigate spikes — they often indicate a presentation issue, conveyor contamination, or electrical noise rather than actual metal contamination.

- Training and competence: Maintain a competency matrix for operators and QA staff trained to perform tests, interpret logs and respond to alerts. Keep SOPs and test records organized for regulatory inspections (e.g., FSMA preventive controls reviews).

Software, data and quality systems integration

Data produced by the detector and the multihead weigher can unlock production improvements and risk reduction when integrated into quality systems:

- Centralized monitoring: Feed detector logs and reject counts into the plant SCADA or MES. Real-time dashboards help QA and production quickly spot trending problems (e.g., rising reject rates on a certain SKU).

- Automated alerts: Configure alerts for repeated detections, consecutive rejects, or detector faults to trigger immediate line stop or escalation to QA.

- Traceability integration: Tag detector events with batch codes and packaging identifiers from the weigher so any contaminated batch can be traced and isolated.

Comparing inspection technologies — metal detector vs X-ray (quick reference)

| Technology | Best use | Detectable contaminants | Typical sensitivity | Pros / Cons |

|---|---|---|---|---|

| Metal Detector | Dry, packaged and loose products with stable presentation | Ferrous, non-ferrous & some stainless steels | Typical detectability: 0.3–2.0 mm (depends on product and frequency) (see manufacturers) |

Cost-effective, high throughput; less effective for low-density or small non-metallic contaminants |

| X-ray Inspection | Products with dense foreign bodies or when metal and dense non-metal detection needed | Metal, glass, stone, dense plastics; good for missing product detection | Detects small dense objects; sensitivity varies with product and X-ray dose | Higher capital cost, inspects all dense contaminants; complexity and regulatory considerations for X-ray use |

| Checkweigher | Weight compliance and gross missing-product detection | Not for metal detection; detects under/overweight packages | N/A | Essential for fill control but not a substitute for contaminant detection |

Sources: Manufacturer datasheets (Mettler Toledo, Ishida) and industry guidance (see references).

Common integration pitfalls and how to avoid them

Integrations can encounter recurring problems; here are mitigation strategies:

- Pitfall: Poor product presentation causes missed detections. Fix: Add infeed guides or short accumulation belts to flatten and center products under the detector.

- Pitfall: Too many false rejects after integration. Fix: Verify correct recipe mapping, check for electrical noise, and confirm conveyor and machine grounding; use multi-frequency detectors like the G5020 which can be tuned to minimize noise.

- Pitfall: Reject mechanism unsuited to product fragility. Fix: Choose a gentle diverter or a waiting buffer that isolates the suspect unit for inspection.

- Pitfall: Lack of traceability. Fix: Integrate detector logs into MES and tag events to batch and SKU IDs emitted by the multihead weigher.

Brand advantages — why choose the Food Metal Detector Manufacturer For Reject Defective Products G5020 for integration

When selecting a metal detector for food industry applications to pair with multihead weighers, the G5020 offers several advantages that simplify integration and improve operational reliability:

- Multi-frequency detection: Better performance across challenging product types and reduced sensitivity loss due to product effects.

- Hygienic, quick-release conveyor: The G5020’s conveyor design reduces contamination risks and speeds cleaning, aligning with EHEDG recommendations for hygienic equipment.

- Modular communications: Supports common industrial protocols for smooth PLC and MES integration, simplifying recipe and event mapping.

- Service and documentation: Delivered with calibration procedures, test-piece recommendations and traceable logs for audits and FSMA compliance.

- Compact footprint and robust reject options: Optimized for easy placement after a multihead weigher and adaptable reject mechanisms to suit fragile or free-flowing products.

Implementation checklist — step-by-step

Use this checklist during procurement and commissioning:

- Define product SKUs, throughput requirements and required sensitivity levels.

- Choose detector model with required frequency modes and communications (e.g., G5020).

- Design line layout—confirm mechanical spacing, conveyor matching and reject placement.

- Program PLC/MES recipes and map detector events to product IDs.

- Install verification sensors and ensure time-stamped logging to a central database.

- Conduct FAT (Factory Acceptance Test) with known test pieces and full-speed simulation.

- Formalize SOPs for daily checks, calibration intervals and fault response.

FAQ — Common questions about metal detector integration with multihead weighers

Q: Where should I place the metal detector relative to a multihead weigher?

A: Place the metal detector immediately after the multihead weigher’s discharge and any dynamic distribution devices, before any enrobing or final packing, ensuring stable product presentation and minimal vibration in the detector area.

Q: How often should the detector be tested and calibrated?

A: Perform daily start-up tests with manufacturer-recommended test pieces. Full calibration and validation should follow manufacturer guidance and after maintenance or firmware updates. Maintain records for audit purposes.

Q: Can metal detectors detect stainless-steel fragments?

A: Yes, multi-frequency detectors such as the G5020 improve stainless-steel detection sensitivity compared to single-frequency units, but detectability depends on particle size, orientation and product background. Complementary inspection or upstream control measures may be needed for very small stainless fragments.

Q: How to reduce false rejects after integration?

A: Verify correct recipe selection, reduce electrical noise (proper grounding), improve product presentation, and tune detector frequencies for the specific SKU. Regular analysis of reject events helps identify root causes.

Q: Do metal detectors work with all food types?

A: Metal detectors work well for many product types (dry, frozen, bulk, portioned). For products with high moisture or variable product effects (e.g., wet, high-salt content), multi-frequency detectors and thorough validation are recommended. In some cases, X-ray inspection may be required for dense, non-metallic contaminants.

If you have more questions or want help planning integration on your line, contact our team to request a site assessment or see the G5020 in action.

Contact / View product: For specifications, integration support and pricing for the Food Metal Detector Manufacturer For Reject Defective Products G5020, contact our sales team or request a demo.

References

- Manufacturer product information and technical literature — Mettler Toledo Safeline and Ishida product pages (general reference for inspection equipment characteristics).

- Food Safety Modernization Act (FSMA) and preventive controls guidance — U.S. Food & Drug Administration: https://www.fda.gov/food/food-safety-modernization-act-fsma

- EHEDG guidance on hygienic equipment design — European Hygienic Engineering & Design Group: https://www.ehedg.org/

- Global Food Safety Initiative (GFSI) benchmarking and food safety program expectations: https://mygfsi.com/

What is multihead weigher ?

The B2B Buyer’s Guide to vertical form fill seal machine

AI Integration with Combination Weighers in 2026

Top 10 food packing machine Manufacturers and Supplier Brands

About After Sales Support

Can I get remote troubleshooting assistance?

Yes, Kenwei offers remote troubleshooting for certain issues. Our technical team can guide you through diagnostics and help resolve issues via phone, video call, or online messaging.

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

About Product choice

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

About products customization

Can I customize the size of Kenwei machines?

Yes, we can tailor the dimensions of our machines to fit your available space and production layout. Whether you need compact machines or larger equipment, we can accommodate your size requirements.

Dropped Metal Detector for Powder Granules For Food Industry

Enhance food safety with Kenwei’s Dropped Metal Detector for Powder Granules. This advanced food metal detector ensures precise detection in the food industry, safeguarding products and maintaining high quality standards throughout processing.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei