AI Integration with Combination Weighers in 2026

- AI Integration with Combination Weighers in 2026

- What is a combination weigher and why it matters in 2026

- How combination weighers worked pre-AI

- How AI changes the core function of combination weighers

- Primary AI capabilities now embedded in combination weighers

- Concrete operational benefits and measurable KPIs

- Practical implementation roadmap for manufacturers

- Costs and expected payback

- Regulatory, food-safety and data governance considerations

- How to select the right combination weigher vendor in 2026

- Kenwei: an AI-ready partner for combination weighers

- Why Kenwei is suitable for AI-integration projects

- Core products and competitive strengths

- FAQ

- Can existing combination weighers be retrofitted with AI?

- How quickly will I see ROI after adding AI to a combination weigher?

- Does AI make combination weighers harder to operate?

- Will AI affect compliance with weight regulations?

- What data do I need to enable AI features?

- Contact & view products

- Sources and references

AI Integration with Combination Weighers in 2026

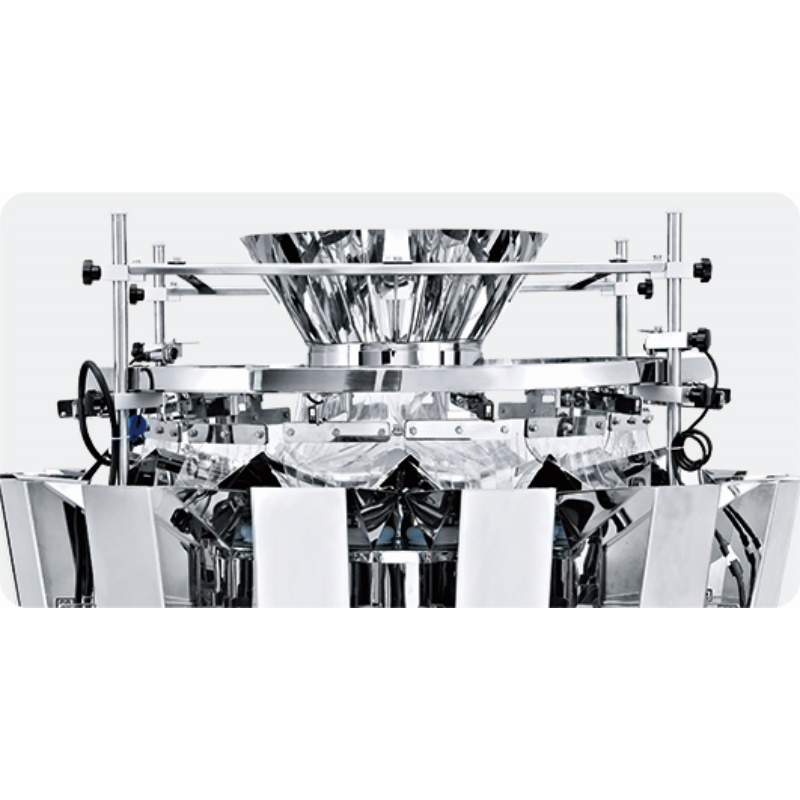

What is a combination weigher and why it matters in 2026

A combination weigher (also called a multihead weigher or combination scale) is a high-speed automated device used to weigh and combine portions of product to meet a target weight before packaging. In 2026 the combination weigher remains central to fast-moving consumer goods (FMCG), snacks, confectionery, fresh produce, frozen foods, and other segments where accuracy, speed, and minimal giveaway directly affect margins. AI integration amplifies these devices by reducing waste, increasing throughput, lowering downtime, and enabling smarter changeover management—making combination weighers a strategic productivity lever on the factory floor.

How combination weighers worked pre-AI

Traditional combination weighers rely on mechanical precision, pre-defined weighing algorithms, and operator-set recipes. Performance tuning was manual and reactive: operators adjusted feed rates, vibratory levels, or reject thresholds based on experience and trial. While reliable, traditional systems are limited in adapting to variable product characteristics (stickiness, moisture, size distribution) and changing upstream conditions.

How AI changes the core function of combination weighers

AI doesn't replace the mechanical excellence of combination weighers; it augments decision-making around measurement, selection, and control. By launching model-driven, real-time decisions, AI enables weighers to adapt to upstream variability, predict faults before they occur, and optimize give-away vs. target weight trade-offs to protect margin and compliance.

Primary AI capabilities now embedded in combination weighers

- Machine vision for feed and product classification: Cameras and vision models detect product size variation, orientation, and foreign objects to adapt feed and avoid mis-weighs.

- Real-time optimization algorithms: Reinforcement learning or constrained optimization models select bucket combinations to meet target weight with minimal give-away while preserving throughput.

- Predictive maintenance and anomaly detection: AI analyzes vibration, audio, and load-cell signals to forecast component wear and prevent unplanned stoppages.

- Edge-cloud orchestration: Lightweight edge models enable millisecond-level decisions on the machine while cloud models perform longer-term analytics, fleet learning, and global updates.

- Adaptive recipe management: Automatic recipe tuning shortens changeovers—models suggest vibratory settings, feed rates, and bucket timing based on product characteristics and past runs.

Concrete operational benefits and measurable KPIs

AI enhancements in combination weighers generate measurable improvements across throughput, accuracy, waste, and uptime. Below is a concise comparison between typical pre-AI combination weighers and AI-enabled units in 2026. Values are ranges observed in industry studies and manufacturer/field tests.

| KPI | Typical Pre-AI Performance | AI-Enabled Performance (2026) | Source |

|---|---|---|---|

| Throughput (packages/hour) | Baseline (machine spec) | +10% to +35% higher effective throughput (less stoppage, faster changeover) | Deloitte; Kenwei internal testing 2025 |

| Fill accuracy / giveaway | Industry baseline; giveaway varies by product | 20% to 50% reduction in giveaway | McKinsey; Kenwei pilot data 2024 |

| Unplanned downtime | Reactive maintenance | 30% to 50% reduction with predictive maintenance | McKinsey; Deloitte |

| Changeover time | Minutes to hours, operator-dependent | 30% to 70% faster with adaptive recipes | Kenwei internal pilot; PMMI industry observations |

| Product rejects due to mis-weighs/foreign objects | Varies | Reduced by 25% to 60% with vision + AI filtering | Kenwei testing; industry reports |

Notes: Ranges reflect aggregated findings from industry reports and field trials. Exact gains depend on product type, upstream consistency, machine model, and integration quality.

Practical implementation roadmap for manufacturers

Successfully adopting AI-enabled combination weighers requires a pragmatic roadmap. Below is a practical step-by-step approach to deploy AI with minimal disruption and maximum ROI:

- Assessment: Baseline current KPIs—throughput, giveaway, downtime, changeover time. Identify products and lines with highest variability or cost impact.

- Pilot: Run an AI pilot on a representative line. Start small (one machine) to validate models and integration with PLC/SCADA.

- Data pipeline and labeling: Ensure reliable data capture (load cells, accelerometers, cameras, process signals). Annotate events and weights for supervised model training.

- Integration strategy: Choose between retrofit (AI modules added to existing machines) or new AI-native weighers. Retrofitting is lower cost but may limit some closed-loop optimizations.

- Validation and compliance: Stress-test for accuracy, explainability of decisions, and food-safety compliance. Validate against regulatory weight standards and customer specs.

- Scaling and fleet learning: Once proven, scale models across lines and leverage federated learning or aggregated cloud analytics to accelerate improvement across sites.

- Continuous improvement: Monitor KPI drift, update models, and involve operators through feedback loops to fine-tune performance.

Costs and expected payback

AI-enabled upgrades typically require investment in sensors, compute (edge devices), software/licensing, and integration services. Payback timelines vary by product value and line volume but commonly fall within 6–24 months for operations with medium-to-high throughput and cost of giveaway. Conduct a simple ROI model: annual cost savings = (reduction in giveaway × annual production value) + (reduction in downtime × production value) − (annual software & support costs).

Regulatory, food-safety and data governance considerations

Food and packaging operations must maintain traceability and compliance. When integrating AI into combination weighers, focus on:

- Traceable decision logs: Record weight decisions, image snapshots, and model versions to demonstrate compliance in audits.

- Validation protocols: Implement acceptance testing and re-calibration schedules; ensure models do not drift and that fallback modes exist.

- Explainability: Use interpretable models or provide diagnostic outputs that operators can act on (e.g., “high variance in feed—recommend vibratory increase”).

- Data security and ownership: Clarify data custody (on-premise vs. cloud), encryption, and retention policies, especially when using third-party analytics platforms.

How to select the right combination weigher vendor in 2026

Choosing a vendor for AI-enabled combination weighers is increasingly strategic. Key criteria to evaluate:

- Accuracy and mechanical reliability: The baseline performance must be strong—AI optimizes but does not fix poor hardware.

- AI maturity: Look for vendors offering validated AI modules (vision, predictive maintenance, optimization) with proven pilots and case studies.

- Integration capabilities: PLC/SCADA compatibility, OPC UA, and easy data export/import are essential.

- Support and training: On-site commissioning, operator training, and fast remote support accelerate ROI.

- Customization and modularity: Ability to tailor recipes, add detectors (metal detectors), or integrate with downstream packing/check weighers.

- Cybersecurity and data governance: Strong policies for data protection and secure update mechanisms.

- After-sales services: Spare parts availability, service SLA, and continuous software updates.

Kenwei: an AI-ready partner for combination weighers

Kenwei is a powerful manufacturer of multi-head weighers and a reliable partner for companies seeking AI-augmented weighing and packaging solutions. We are committed to the development and manufacturing of metal detectors, multi-head weighers, linear weighers, and check weighers. Our machines are characterized by high speed and high precision, and we provide one-stop automated weighing and packaging solutions that meet customization requirements.

Why Kenwei is suitable for AI-integration projects

Kenwei’s comprehensive capabilities—from R&D and design to manufacturing, marketing, installation and commissioning, technical training, and after-sales service—make it an ideal integrator of AI capabilities into combination weighers. Located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province, Guangdong Kenwei operates automated weighing and packaging systems and has accumulated practical experience in deploying vision systems, predictive maintenance modules, and adaptive recipe software across diverse product lines.

Core products and competitive strengths

Kenwei’s product portfolio includes Check Weigher, multihead weigher packing machine, multihead weigher, linear weigher, metal detector, packing machine, counting machine, combination weigher, food packaging machine, and food packing machinery. Core competitive advantages include:

- High-speed mechanical design for throughput-demanding lines.

- High precision weight control to minimize giveaway and meet strict weight tolerances.

- Customizable modular solutions that facilitate retrofit or new-line deployments.

- End-to-end project support: design, customization, installation, training and fast after-sales service—building a reputation for thoughtful and fast service.

Our vision is to become the world's leading weighing packing machine manufacturer. Learn more about our products and solutions at https://www.kenweigroup.com/.

FAQ

Can existing combination weighers be retrofitted with AI?

Yes. Many AI functions—vision inspection, anomaly detection, and optimization—can be added as modules to existing machines. Retrofit feasibility depends on sensor mounting space, available signals from the PLC, and mechanical accessibility. A site assessment will determine the most cost-effective approach.

How quickly will I see ROI after adding AI to a combination weigher?

ROI depends on line throughput and the cost basis of giveaway and downtime. Typical payback ranges from 6–24 months for lines with substantial volume or high product value. Low-volume or very simple products may have longer payback periods.

Does AI make combination weighers harder to operate?

Properly designed AI systems simplify operator workflows by automating recipe tuning, flagging issues proactively, and providing clear diagnostics. Training is required but many operators find AI leads to fewer manual interventions and more predictable performance.

Will AI affect compliance with weight regulations?

AI-equipped machines must be validated the same way as traditional equipment. AI can improve compliance by reducing underweights and improving statistical process control, but manufacturers should maintain trace logs, version control for models, and audit-ready reports.

What data do I need to enable AI features?

Key data includes weight records, vibration and motor signals, camera images (if used), timestamps, recipe settings, and event logs (stops, rejects). Initial pilot projects often require labeled examples of mis-weighs or rejects to train supervised models.

Contact & view products

If you want to explore AI-enabled combination weighers or retrofit options, contact Kenwei for a consultation, pilot plan, or product demo. Visit our product pages and contact form at https://www.kenweigroup.com/ to request a site assessment and quotation.

Sources and references

- McKinsey & Company — reports on AI in manufacturing and predictive maintenance insights (industry analyses on maintenance and operational improvements).

- Deloitte Insights — research on smart factories and AI-driven productivity gains in packaging and operations.

- PMMI (The Association for Packaging and Processing Technologies) — observations on changeover reduction and packaging line optimization.

- Kenwei internal pilot and test data (2024–2025) — field trials and testing conducted by Guangdong Kenwei on AI-augmented combination weighers.

For a tailored assessment, contact Kenwei at https://www.kenweigroup.com/ and request an AI-integration evaluation for your combination weighers.

The multi head weigher machine Cost Guide

Top 5 vffs packaging machine Company List and Products Compared

Top 10 checkweighers Manufacturers and Supplier Brands in America

Choosing the Right Linear Weigher for Your Product: A Practical Buying Guide

About Logistics

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

About products customization

Can Kenwei machines be customized for different industries?

Yes,According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on.

About Product choice

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

About Solution suggestions

Can Kenwei solutions be adapted for different product packaging types?

Yes, Kenwei solutions can handle a variety of packaging types, including bags, boxes, pouches, and bottles. We can customize machines to suit your packaging format, ensuring compatibility with your packaging equipment.

About Cooperation Process

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

10-Head Standard No-Spring Multihead Weigher 1.6L for Precise Weighing

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Standard Multihead Weigher with New Springless Actuator for Food Weighing Machine

The Standard Multihead Weigher features a high-speed, spring-free hopper with a new aluminum shell design, ensuring stable and fast weighing performance. The integrative welding of the mouthpiece case and middle seat enhances the overall machine strength. Ideal for weighing granular products like melon seeds, peanuts, nuts, almonds, raisins, candies, and pistachios, this 14-head multihead weigher offers hopper options of 1.6L and 2L. With a maximum weighing speed of 120 packs per minute, it delivers rapid and accurate results for high-volume operations.

14-Head High-Speed Springless Multihead Weigher for Accurate Weighing

The high-speed weigher features a new spring-free aluminum shell design with double chute feeding and dual high-speed hopper alternating feeding, significantly boosting feeding speed. It is ideal for weighing materials such as melon seeds, peanuts, nuts, almonds, raisins, candy, pistachios, and more. The 18-head high-speed weigher is equipped with 2L hoppers, achieving a maximum weighing speed of up to 180 bags per minute.

16-Head Multihead Weigher with 1.6L Three-Layer Hopper for Accurate Weighing

The Kenwei 16-Head Multihead Weigher with a 1.6L Three-Layer Hopper provides precise and efficient weighing with a maximum speed of 240 packs per minute, optimizing your production line. The main vibrating pan supports two types of mixed materials, offering versatility and consistent performance. This advanced multihead packing machine is ideal for a wide range of products, including nuts, raisins, candies, potato chips, and other snack foods, as well as hardware and plastic materials. It ensures reliable performance and high accuracy in various industries.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei