Top 10 checkweighers Manufacturers and Supplier Brands in America

- Top 10 Checkweighers Manufacturers and Supplier Brands in America

- 1. Kenwei: Innovative Multi-Head Weighers and Checkweighers

- 2. Mettler Toledo: Precision and Advanced Technology

- 3. Ishida: Reliable and Efficient Weighing Systems

- 4. Anritsu: Versatile Checkweighers with Custom Solutions

- 5. CSM Checkweighers: Accuracy Meets Industrial Durability

- 6. MOCOM: User-Friendly and High-Speed Checkweighers

- 7. Process Control Corporation (PCC): Customizable Checkweighing Solutions

- 8. Safeline: Integrated Metal Detection and Checkweighing

- 9. WeighPack Systems: Flexible and Scalable Checkweighers

- 10. Ishida Americas: Comprehensive Checkweighing Technologies

- Top 10 Checkweighers Manufacturers - Product Comparison

- Conclusion: Choosing the Right Checkweigher Manufacturer

Top 10 Checkweighers Manufacturers and Supplier Brands in America

Checkweighers play a crucial role in quality control and packaging efficiency across many industries. If you’re seeking high-quality, reliable checkweighers, this article introduces the top 10 manufacturers and suppliers in America, including industry leader Kenwei. We’ll explore their strengths, product ranges, and innovations to help you make informed decisions.

1. Kenwei: Innovative Multi-Head Weighers and Checkweighers

Kenwei is a powerful player in the weighing machinery industry, committed to manufacturing high-speed, high-precision checkweighers alongside multi-head weighers, linear weighers, and metal detectors. Located in Zhongshan City, Guangdong Province, Kenwei provides tailored automated weighing and packaging solutions. Their checkweighers stand out for accuracy and speed, making Kenwei a top choice for American companies seeking trustworthy and customizable equipment.

2. Mettler Toledo: Precision and Advanced Technology

Mettler Toledo is a global leader offering advanced checkweighers with precise weighing capabilities and user-friendly interfaces. Their products integrate seamlessly with production lines, delivering real-time data analytics and efficient quality control for food, pharmaceutical, and industrial sectors.

3. Ishida: Reliable and Efficient Weighing Systems

Ishida is renowned for its robust checkweighers and multihead weighers. Their American branch serves a wide range of industries, focusing on accuracy, speed, and hygiene standards particularly suited for food packaging.

4. Anritsu: Versatile Checkweighers with Custom Solutions

Anritsu provides high-performance checkweighers focusing on adaptability in packaging lines. They offer flexible integration options, making them ideal for diverse product types requiring strict weight control.

5. CSM Checkweighers: Accuracy Meets Industrial Durability

CSM delivers robust checkweighers with industrial-grade components designed for high-volume manufacturing environments. Their models emphasize durability and consistent performance, suitable for heavy-duty operations.

6. MOCOM: User-Friendly and High-Speed Checkweighers

MOCOM’s checkweighers are known for combining ease of use with high throughput. Their equipment supports quick changeovers and simple programming, streamlining production workflows for packaging lines.

7. Process Control Corporation (PCC): Customizable Checkweighing Solutions

PCC focuses on providing fully customized checkweighers tailored to specific industrial needs. Their systems integrate advanced controls and networking options, enhancing automation efficiency.

8. Safeline: Integrated Metal Detection and Checkweighing

Safeline combines metal detection technology with checkweighers to ensure product safety and quality. Their solutions are widely used in food and pharmaceutical sectors where contamination prevention and weight accuracy are critical.

9. WeighPack Systems: Flexible and Scalable Checkweighers

WeighPack offers a range of checkweighers designed to fit varying production scales. Their modular approach allows for easy upgrades and integration with existing packaging lines.

10. Ishida Americas: Comprehensive Checkweighing Technologies

Separate from its Japanese headquarters, Ishida Americas tailors advanced checkweighing technology specifically for American manufacturing demands. Their solutions deliver precise weight measurements and compliance with industry standards.

Top 10 Checkweighers Manufacturers - Product Comparison

| Manufacturer | Product Speed | Accuracy | Customization | Integrated Solutions | Industry Focus |

|---|---|---|---|---|---|

| Kenwei | High-speed | High precision | Full customization | Weighing & packaging automation | Food, pharma, packaging |

| Mettler Toledo | High-speed | Ultra-precise | Modular options | Data-driven QC integration | Food, pharma, industrial |

| Ishida | Fast | Accurate | Standard to customized | Multihead weighers & checkweighers | Food packaging |

| Anritsu | Moderate | High | Flexible | Integration capabilities | Food, pharmaceuticals |

| CSM | High | Reliable | Limited | Durable industrial design | Heavy-duty industries |

| MOCOM | Very high | High | Easy setup | User-friendly controls | Packaging lines |

| PCC | Variable | Custom accuracy | Highly customizable | Advanced automation | Specialized industrial |

| Safeline | Moderate | High | Standard | Metal detection + checkweighers | Food, pharma |

| WeighPack | Scalable | Accurate | Modular | Flexible solutions | Various industries |

| Ishida Americas | High-speed | Precise | Customized for market | QC & weighing tech | American manufacturing |

Conclusion: Choosing the Right Checkweigher Manufacturer

Selecting the right checkweighers manufacturer depends on your industry needs, required accuracy, production speed, and customization preference. Kenwei leads with high-speed and high-precision solutions combined with comprehensive customer service and turnkey packaging automation. However, other brands also offer specialized advantages such as integrated metal detection, customizable software, or scalable machinery suitable for different production lines.

Invest in a brand that aligns with your operational goals and ensures efficient quality control for your products. Leveraging the right checkweighers will not only help maintain compliance with regulatory standards but also optimize throughput and reduce waste.

Frequently Asked Questions

What is a checkweigher and why is it important?

A checkweigher automatically checks the weight of packaged goods to ensure compliance with weight specifications. It helps maintain quality control, avoid underweight penalties, and reduce waste.

Can checkweighers handle different product types?

Yes, advanced checkweighers are designed to handle a wide range of product types, including food, pharmaceuticals, and industrial items, with varying shapes and sizes.

How does Kenwei compare with other checkweigher brands?

Kenwei offers high-speed, high-precision machines with full customization and integrates weighing with packaging automation. This positions Kenwei as a comprehensive supplier compared to brands focusing on niche aspects.

Is after-sales service important in checkweigher selection?

Absolutely. Reliable after-sales service ensures that machines stay calibrated and operational, reducing downtime and maintaining production efficiency.

Are checkweighers compatible with automated packaging lines?

Yes, most modern checkweighers are designed to seamlessly integrate into automated production and packaging lines for real-time weight monitoring and control.

Calculating ROI: Is a Linear Weigher Worth It?

Compliance Matters: Food Safety for Powder Packing Machines

The latest trends for automatic check weighing equipment

Confectionery Packing: Using Multihead Weighers Effectively

About Cooperation Process

How to operate it?

Many languages are available for global markets. There are not only detailed instructions, but also machine video for reference learning.

About Price and payment

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

About Logistics

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

About After Sales Support

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

C2000 High-Speed Check Weigher for Precise and Fast Weight Testing

C2000 High-Speed Check Weigher machine is a crucial component of production lines, especially in industries like food and pharmaceuticals. This specialized equipment ensures products meet the required weight specifications, helping manufacturers maintain quality control, adhere to regulations, and minimize product giveaways. The checkweigher automatically weighs each product as it moves along the production line. If a product falls outside the acceptable weight range, the machine can trigger actions such as diverting it for manual inspection, adjusting the fill level, or halting production to prevent non-compliant products from reaching consumers.

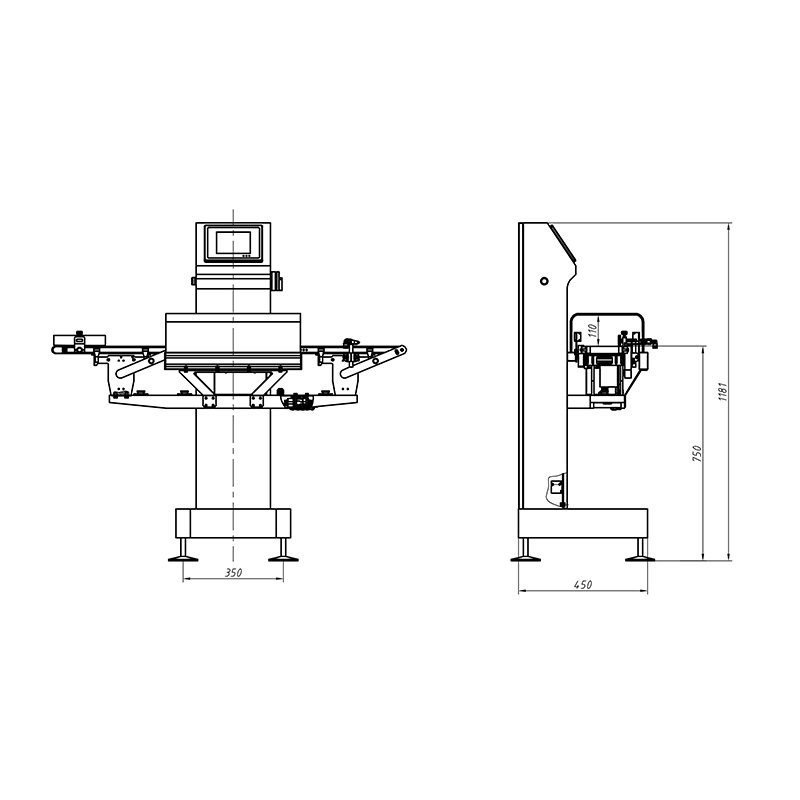

Double Column Check Weigher for Accurate Material Weight Testing and Automatic Sorting

The equipment is equipped with two independent conveyor lines, which do not interfere with each other in measurement. It adopts a new modular control system with an accuracy of up to 0.2g and a fault alarm text prompt. The conveyor structure is designed to be easily disassembled for easy cleaning and maintenance. At the same time, it provides comprehensive production quality statistics, including weight distribution bar graphs, total weight, number of qualified packages, qualified rate, number of unqualified packages and corresponding time, etc., to improve production management efficiency.

30KG Check weigher with pneumatic pusher

The JW-C30000 sorting checkweigher is designed to move products using conveyor belts or rollers, ensuring accurate weight control in manufacturing and packaging lines. This high-precision checkweigher automatically verifies whether each product falls within the specified weight range, helping to eliminate underweight or overweight items before they reach the market.

With a maximum inspection weight of 30 kg, it offers a wide weighing range, high speed, and consistent accuracy. Ideal for bulk paper bags, plastic bags, cartons, metal film packaging, and other rigid packages, this checkweigher system supports both belt and roller transport options. As a reliable tool for quality assurance, it provides stable performance and is widely used across various industries for efficient weight checking.

200g High Precision Food Checkweigher in Food Packaging and Processing

Discover the Kenwei 200g High Precision Food Checkweigher—ideal for accurate weight inspection in food packaging and processing. Our checkweigher ensures reliable results and efficiency. Choose Kenwei checkweighers for advanced quality control solutions.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei