Top 5 vffs packaging machine Company List and Products Compared

- Advantages of Ishida's VFFS Machine

- Disadvantages of Ishida's VFFS Machine

- Technical Points of Ishida's VFFS Machine

- Applications of Ishida's VFFS Machine

- 2. Company Introduction: Yamato

- Advantages of Yamato's VFFS Machine

- Disadvantages of Yamato's VFFS Machine

- Technical Points of Yamato's VFFS Machine

- Applications of Yamato's VFFS Machine

- 3. Company Introduction: MULTIVAC

- Advantages of MULTIVAC's VFFS Machine

- Disadvantages of MULTIVAC's VFFS Machine

- Technical Points of MULTIVAC's VFFS Machine

- Applications of MULTIVAC's VFFS Machine

- 4. Company Introduction: PFM Packaging Machinery

- Advantages of PFM's VFFS Machine

- Disadvantages of PFM's VFFS Machine

- Technical Points of PFM's VFFS Machine

- Applications of PFM's VFFS Machine

- 5. Company Introduction: Kenwei

- Advantages of Kenwei's VFFS Machine

- Disadvantages of Kenwei's VFFS Machine

- Technical Points of Kenwei's VFFS Machine

- Applications of Kenwei's VFFS Machine

- Comparison Table of Top 5 VFFS Packaging Machine Companies and Products

- Conclusion

- FAQ

- What is a VFFS packaging machine?

- How do I choose the best VFFS packaging machine for my business?

- What are the advantages of using a VFFS packaging machine?

- Can VFFS machines handle different types of products?

- What is the typical lifespan of a VFFS packaging machine?

- Does Kenwei offer after-sales support for their VFFS machines?

Ishida

Ishida is a renowned name in the packaging industry, particularly known for its cutting-edge technology and reliable performance.

Advantages of Ishida's VFFS Machine

- High-speed operation ensures efficient production lines.

- Robust construction and reliable performance.

- User-friendly interface for easy operation and maintenance.

Disadvantages of Ishida's VFFS Machine

- Higher initial investment compared to some competitors.

- May require specialized training for full utilization.

Technical Points of Ishida's VFFS Machine

- Capable of speeds up to 150 bags per minute.

- Features advanced weighing and sealing technologies.

- Integrates seamlessly with other Ishida equipment.

Applications of Ishida's VFFS Machine

- Suitable for food, pharmaceuticals, and pet food industries.

- Ideal for packaging snacks, powders, and granular products.

2. Company Introduction: Yamato

Yamato is another heavyweight in the packaging industry, known for its precision and versatility in VFFS machines.

Advantages of Yamato's VFFS Machine

- High precision in weighing and packaging.

- Versatile applications for various product types.

- Excellent after-sales support and service.

Disadvantages of Yamato's VFFS Machine

- Can be complex to set up and configure initially.

- Slightly higher energy consumption compared to some competitors.

Technical Points of Yamato's VFFS Machine

- Offers speeds up to 140 bags per minute.

- Advanced control systems for accurate weighing and sealing.

- Modular design for easy maintenance and upgrades.

Applications of Yamato's VFFS Machine

- Widely used in food, confectionery, and frozen products.

- Suitable for packaging both solid and liquid products.

3. Company Introduction: MULTIVAC

MULTIVAC is a global leader in packaging solutions, offering a wide range of VFFS machines designed for various industries.

Advantages of MULTIVAC's VFFS Machine

- Highly customizable to meet specific packaging needs.

- Robust and durable construction for long-term use.

- Excellent integration with other MULTIVAC packaging equipment.

Disadvantages of MULTIVAC's VFFS Machine

- Higher cost for specialized customizations.

- May require more space in the production line.

Technical Points of MULTIVAC's VFFS Machine

- Can achieve speeds up to 180 bags per minute.

- Features advanced vacuum and modified atmosphere packaging options.

- User-friendly HMI for easy operation and adjustments.

Applications of MULTIVAC's VFFS Machine

- Ideal for meat, cheese, and ready meals.

- Suitable for both fresh and processed food products.

4. Company Introduction: PFM Packaging Machinery

PFM Packaging Machinery offers reliable and efficient VFFS machines tailored to meet the demands of various industries.

Advantages of PFM's VFFS Machine

- Cost-effective solutions with excellent performance.

- Compact design suitable for smaller production spaces.

- Quick changeover times for different packaging formats.

Disadvantages of PFM's VFFS Machine

- Lower maximum speeds compared to some High Quality models.

- Limited customization options compared to top-tier competitors.

Technical Points of PFM's VFFS Machine

- Operates at speeds up to 100 bags per minute.

- Features a simple yet effective control system.

- Easy to maintain and service.

Applications of PFM's VFFS Machine

- Suitable for snacks, cereals, and other dry goods.

- Ideal for small to medium-sized businesses.

5. Company Introduction: Kenwei

As a leading manufacturer of multihead weighers, Kenwei offers comprehensive VFFS packaging solutions that combine speed, precision, and reliability.

Advantages of Kenwei's VFFS Machine

- High-speed and high-precision performance.

- Customizable solutions to meet specific customer needs.

- Comprehensive after-sales support and service.

Disadvantages of Kenwei's VFFS Machine

- May have a higher initial cost due to advanced technology.

- Requires some technical expertise for optimal operation.

Technical Points of Kenwei's VFFS Machine

- Capable of speeds up to 200 bags per minute.

- Advanced multihead weighing technology for accurate filling.

- Integrated control system for seamless operation.

Applications of Kenwei's VFFS Machine

- Ideal for food, pharmaceuticals, and agricultural products.

- Suitable for both solid and liquid packaging needs.

Comparison Table of Top 5 VFFS Packaging Machine Companies and Products

| Company | Speed (Bags/Min) | Precision | Customizability | Cost | Ideal Applications |

|---|---|---|---|---|---|

| Ishida | Up to 150 | High | Medium | High | Food, Pharma, Pet Food |

| Yamato | Up to 140 | Very High | High | High | Food, Confectionery, Frozen Products |

| MULTIVAC | Up to 180 | High | Very High | High | Meat, Cheese, Ready Meals |

| PFM | Up to 100 | Medium | Low | Low | Snacks, Cereals, Dry Goods |

| Kenwei | Up to 200 | Very High | Very High | High | Food, Pharma, Agriculture |

Conclusion

Choosing the right VFFS packaging machine is crucial for ensuring efficiency and quality in your production line. Each of the top 5 companies offers unique advantages and features, catering to different industry needs and budgets. As a leading manufacturer in the multihead weigher industry, Kenwei stands out with its high-speed, high-precision VFFS machines, providing customizable solutions and comprehensive support. Consider your specific requirements and compare the pros and cons of each machine to make the best decision for your business.

FAQ

What is a VFFS packaging machine?

A VFFS packaging machine, or Vertical Form Fill Seal machine, is used to create bags from a flat roll of film, fill them with product, and seal them. It is widely used in various industries for efficient and automated packaging.

How do I choose the best VFFS packaging machine for my business?

Consider factors such as speed, precision, customizability, cost, and the specific needs of your industry. Assess the pros and cons of each machine and choose one that aligns best with your production requirements and budget.

What are the advantages of using a VFFS packaging machine?

VFFS machines offer high-speed packaging, consistent quality, flexibility in packaging sizes and types, and reduced labor costs. They are essential for businesses looking to increase efficiency and productivity.

Can VFFS machines handle different types of products?

Yes, VFFS machines can handle a wide range of products, including solids, liquids, powders, and granules. Different machines may have specific capabilities, so it's important to choose one that suits your product type.

What is the typical lifespan of a VFFS packaging machine?

With proper maintenance and care, a VFFS packaging machine can last up to 10-15 years. Regular servicing and using genuine parts can significantly extend the lifespan of the equipment.

Does Kenwei offer after-sales support for their VFFS machines?

Yes, Kenwei provides comprehensive after-sales support, including installation, commissioning, technical training, and maintenance services to ensure the optimal performance of their VFFS machines.

Located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province, Kenwei is committed to the development and manufacturing of metal detectors, multihead weighers, linear weighers, and check weighers. Our vision is to become the world's leading weighing packing machine manufacturer, and we provide one-stop automated weighing and packaging solutions to meet our customers' customization requirements. Visit our website at https://www.kenweigroup.com/ to learn more about our offerings and how we can help your business thrive.

The latest trends for automatic check weighing equipment

The food packing machine for small business Cost Guide

Top 10 food metal detector Manufacturers and Supplier Brands

The latest trends for combination mulithead weigher

About Price and payment

How is the price of Kenwei machines determined?

The price of Kenwei machines depends on several factors, including the type of machine, customization requirements, production volume, and any additional features or integrations. We provide tailored quotes based on your specific needs and requirements.

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

About After Sales Support

Can I get remote troubleshooting assistance?

Yes, Kenwei offers remote troubleshooting for certain issues. Our technical team can guide you through diagnostics and help resolve issues via phone, video call, or online messaging.

About Solution suggestions

What are Kenwei’s primary solutions for industrial weighing and packaging?

Kenwei provides comprehensive solutions for automated weighing and packaging, including multi-head weighers, linear weighers, check weighers, metal detectors, and packing machines. These solutions are tailored to improve speed, accuracy, and efficiency in various industries such as food, pharmaceuticals, and chemicals.

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

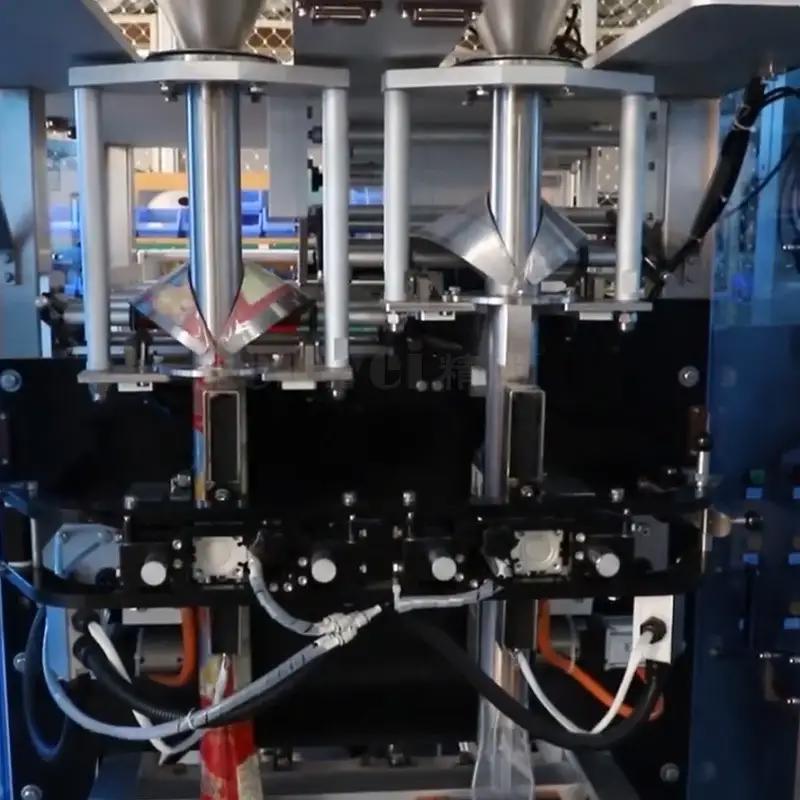

Double Filling VFFS Packaging Machine for Efficient Dual Product Packaging

The Fully Automatic High-Speed Vertical Double Filling Form-Fill-Seal (VFFS) machine features a compact design and a complete range of packaging machines and auxiliary equipment, making it adaptable to various materials and space-efficient. It can handle a wide variety of laminated films, single-layer PE films, film thicknesses ranging from 0.04mm to 0.09mm, and paper membrane packaging. This VFFS machine is widely used in food, pharmaceutical, and chemical industries for packaging snacks, powders, liquids, and granular products. The machine forms bags from flat film rolls, fills them with products, and seals them vertically, improving packaging efficiency and ensuring consistent, high-quality production.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei