Kenwei Unveils High-Speed Rhombus Timing Hopper for Next-Gen Packaging Efficiency

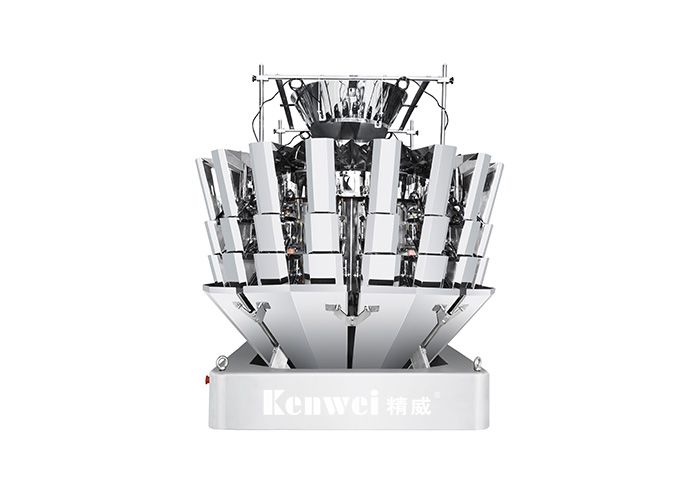

At ProPak China 2021, Kenwei showcased its groundbreaking high-speed rhombus timing hopper, designed for fast and efficient packaging of small-weight granules. When paired with the fourth-generation 18-heads weigher, the system increases production speed by 50%, ensuring material integrity and packaging precision.

To meet the growing demand for efficient and rapid small-weight packaging, Guangdong Kenwei proudly presented its cutting-edge high-speed rhombus timing hopper at ProPak China 2021 (Shanghai)—a powerful innovation engineered to enhance the performance of vertical packaging lines.

This advanced hopper, when paired with Kenwei’s fourth-generation three-layer 18-heads standard combination weigher, delivers an impressive output of up to 160 packs per minute. Compared to traditional multihead weighing systems, this solution increases filling speed by over 50%, making it ideal for high-speed quantitative production of small granular materials.

Ensuring Speed Without Compromising Product Integrity

One of the standout features of the rhombus timing hopper is its ability to preserve material integrity even at high speeds. As the weighed product is transferred through the hopper into a vertical packaging machine, the system ensures a smooth, uninterrupted flow.

This not only reduces the adjustment time of the packaging machine, but also accelerates the final output of finished products. The result is a highly adaptive system that can meet the stringent demands of modern high-speed production environments.

A Perfect Fit for All High-Speed Vertical Packaging Machines

Whether you're packaging snacks, small candies, seeds, or granules, the synergy between the high-speed timing hopper and the 4th-gen 18-head weigher offers unmatched flexibility. Together, they form a complete high-efficiency packaging solution that helps businesses:

-

Maximize throughput

-

Save on operational costs

-

Improve overall packaging consistency

With customer needs at the core of its innovation, Kenwei continues to lead the way in intelligent, automated, and high-speed packaging technology. This new system is a testament to that commitment—delivering value, precision, and speed for a competitive manufacturing future.

About products customization

Can Kenwei machines be customized for different industries?

Yes,According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on.

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

About Logistics

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

About Product choice

Are Kenwei’s products suitable for small-scale or large-scale operations?

Yes! We offer machines that are scalable to meet the needs of both small and large-scale operations.

About After Sales Support

How about the after-sales service?

Warranty :2 years

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei