What is a VFFS Packaging Machine? Complete Guide to Vertical Form Fill Seal Technology

- What is a VFFS Packaging Machine?

- Key Components of a VFFS Machine

- How Does a VFFS Packaging Machine Work?

- 1. Film Transport & Unwinding

- 2. Film Tension Management

- 3. Printing (Optional)

- 4. Film Tracking & Positioning

- 5. Bag Forming

- 6. Filling & Sealing

- 7. Bag Discharge

- Advantages of VFFS Packaging Machines

- Factors to Consider When Choosing a VFFS Machine

- Kenwei’s Advanced VFFS Packaging Systems

- Conclusion

A VFFS packaging machine, or Vertical Form Fill Seal machine, is an automated packaging system that transforms a roll of film into sealed bags filled with products. Known for speed, accuracy, and efficiency, VFFS machines are widely used in food, pharmaceutical, and industrial packaging.

What is a VFFS Packaging Machine?

A Vertical Form Fill Seal (VFFS) machine is an advanced packaging system that forms bags from a roll of film, fills them with product, and seals them—all in one continuous vertical process. Its efficiency, precision, and automation make it a preferred choice for high-volume packaging operations.

Key Components of a VFFS Machine

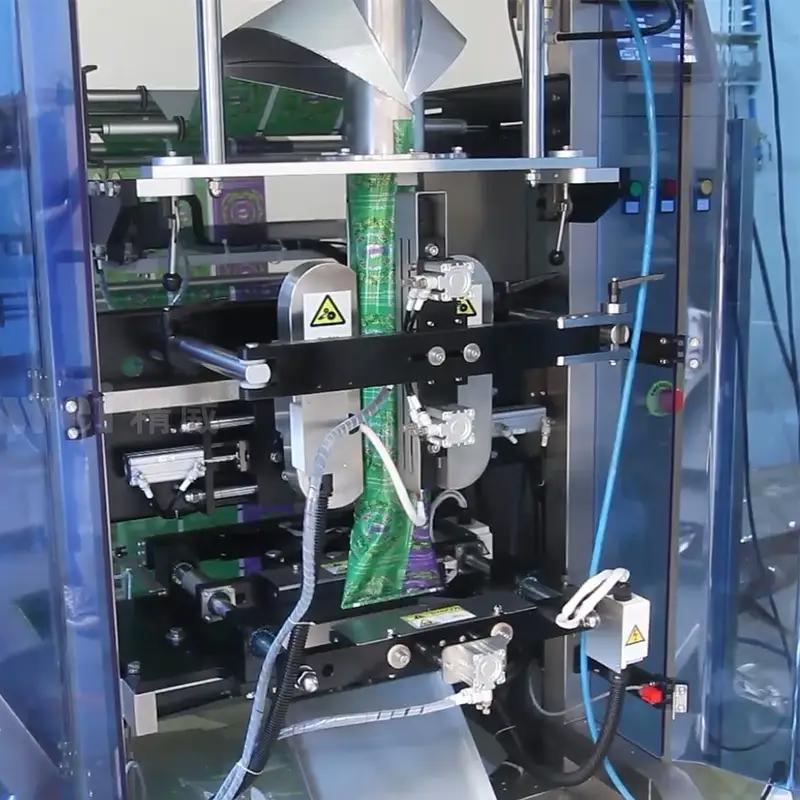

A typical VFFS machine consists of several integrated systems:

-

Film Roll – Supplies the packaging material.

-

Forming Tube – Shapes the flat film into a vertical tube.

-

Sealing Jaws – Apply heat or ultrasonic sealing to close the film edges.

-

Filling Mechanism – Accurately dispenses product into the bag.

-

Cutting Mechanism – Cuts individual bags after sealing.

-

Sensors & Control Systems – Ensure alignment, accuracy, and efficiency.

How Does a VFFS Packaging Machine Work?

The VFFS packaging process involves multiple stages:

1. Film Transport & Unwinding

Packaging material is unwound from a roll and guided into the forming tube.

2. Film Tension Management

Rollers and dancer arms maintain smooth film tension and prevent misalignment.

3. Printing (Optional)

Date codes, barcodes, or branding are printed before forming the bag.

4. Film Tracking & Positioning

Sensors ensure precise alignment and cutting accuracy.

5. Bag Forming

The film is shaped into a cylinder around the forming tube and sealed vertically.

6. Filling & Sealing

Products are dispensed into the bag while sealing jaws form the top and bottom seals.

7. Bag Discharge

Finished bags are cut, sealed, and discharged onto a conveyor for further processing.

Advantages of VFFS Packaging Machines

Businesses across industries choose VFFS packaging machines for their many benefits:

-

High-Speed Production – Up to 160 bags per minute.

-

Versatility – Suitable for films, laminates, and biodegradable materials.

-

Cost-Effectiveness – Reduces labor costs and material waste.

-

Compact Design – Saves valuable floor space in factories.

Factors to Consider When Choosing a VFFS Machine

When investing in a vertical form fill seal machine, consider:

-

Material Compatibility & Sealing Technology – Match sealing to film type.

-

Production Speed & Bag Styles – Align with business output needs.

-

Product Type & Filling Accuracy – Ensure precision for powders, liquids, or solids.

-

Integration – Compatibility with current systems and automation lines.

-

Maintenance & Support – Choose reliable service and easy-to-maintain equipment.

Kenwei’s Advanced VFFS Packaging Systems

Kenwei Intelligent Machinery Co., Ltd. offers state-of-the-art VFFS machines with unmatched accuracy, speed, and durability. Designed with modular structures and intuitive controls, Kenwei’s solutions feature:

-

High-performance multihead weighers and linear weighers.

-

Customizable sealing technology for various industries.

-

Strong, stable construction for long-term reliability.

-

User-friendly operation with professional after-sales support.

Kenwei’s VFFS packaging systems are trusted worldwide in food, pharmaceuticals, hardware, and consumer goods manufacturing.

Conclusion

A VFFS packaging machine is a powerful investment for businesses looking to improve efficiency, reduce costs, and achieve high-quality packaging results. With their speed, flexibility, and precision, VFFS systems remain essential in modern packaging operations.

For companies seeking cutting-edge packaging solutions, Kenwei’s VFFS machines deliver industry-leading technology and tailored options to meet diverse needs. Contact Kenwei today to explore how our solutions can transform your packaging process.

About After Sales Support

How about the after-sales service?

Warranty :2 years

About Solution suggestions

Can Kenwei solutions be adapted for different product packaging types?

Yes, Kenwei solutions can handle a variety of packaging types, including bags, boxes, pouches, and bottles. We can customize machines to suit your packaging format, ensuring compatibility with your packaging equipment.

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

About Cooperation Process

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

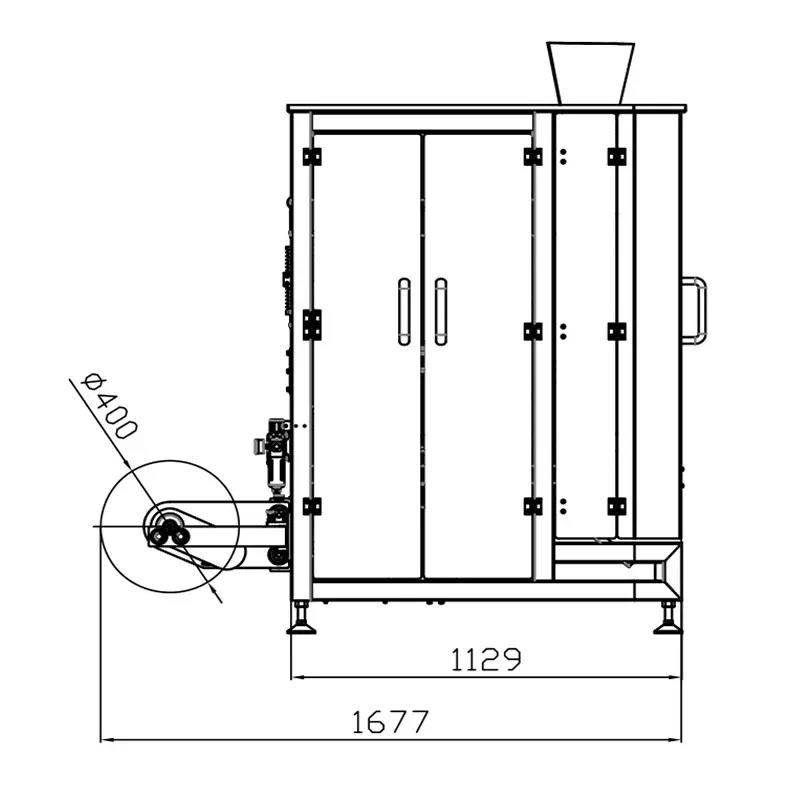

The Fully Automatic High-Speed Vertical Double Filling Form-Fill-Seal (VFFS) machine features a compact design and a complete range of packaging machines and auxiliary equipment, making it adaptable to various materials and space-efficient. It can handle a wide variety of laminated films, single-layer PE films, film thicknesses ranging from 0.04mm to 0.09mm, and paper membrane packaging. This VFFS machine is widely used in food, pharmaceutical, and chemical industries for packaging snacks, powders, liquids, and granular products. The machine forms bags from flat film rolls, fills them with products, and seals them vertically, improving packaging efficiency and ensuring consistent, high-quality production.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei