Kenwei's Competitive Advantages in Waterproof and Stable Packaging Machinery Design

- Kenwei’s Technical Edge: Waterproof, Stable, and Built to Last

- ✅ 1. Fully Enclosed Stainless Steel Housing for Easy Cleaning

- ✅ 2. Waterproof Welded Structure for Long-Term Use

- ✅ 3. Reinforced Waterproof Housing

- ✅ 4. Fewer Connectors = More Stability

- ✅ 5. High-Speed Parallel Communication System

- ✅ 6. Sensor and Motor Welding for Greater Stability

- Conclusion:

Kenwei packaging machinery leads the industry in durability and stability with waterproof welded enclosures, reduced connector points, and reliable parallel communication. Designed for long-term use in harsh environments, Kenwei minimizes failure risks while maximizing customer confidence.

Kenwei’s Technical Edge: Waterproof, Stable, and Built to Last

In the demanding world of packaging machinery, Kenwei stands apart by prioritizing durability, reliability, and design precision. Unlike many competitors focused on ease of maintenance, Kenwei’s approach centers on minimizing failure risk—especially in wet, aquatic, or corrosive production environments.

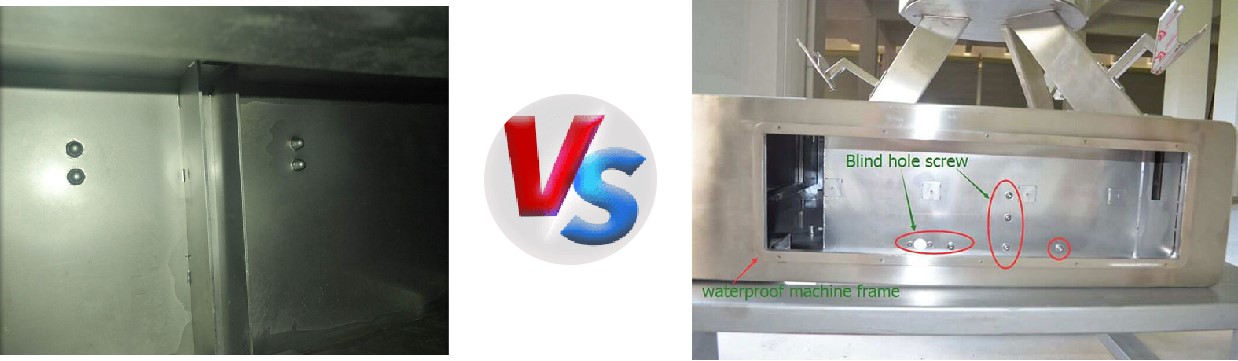

✅ 1. Fully Enclosed Stainless Steel Housing for Easy Cleaning

Kenwei Advantage:

-

Uses a seamless stainless steel shell with no external screws or steps, ideal for high-hygiene environments and frequent cleaning.

Market Comparison:

-

Other companies use aluminum enclosures that exaggerate blind hole functions, which are not durable in aquatic environments.

-

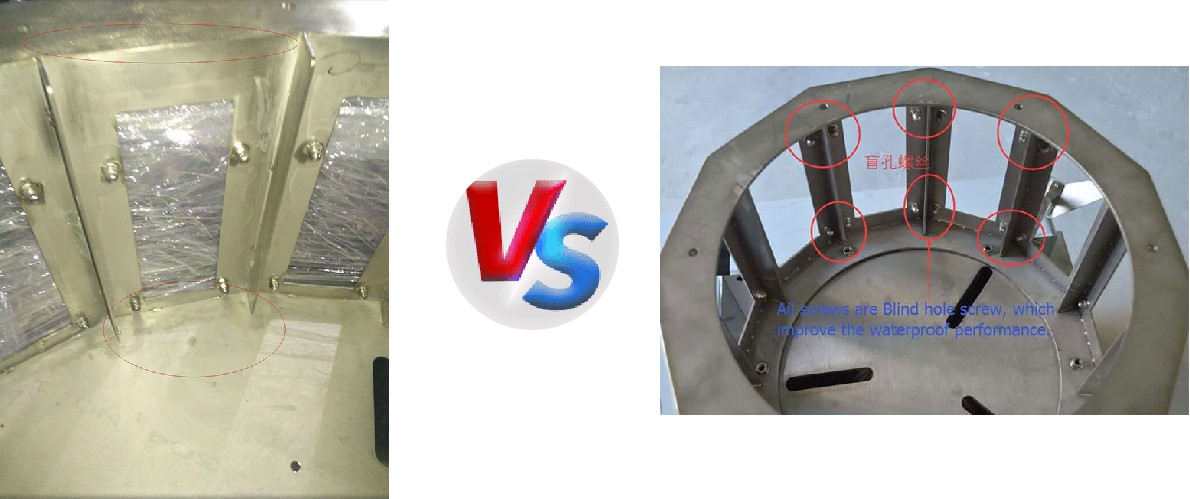

✅ 2. Waterproof Welded Structure for Long-Term Use

Kenwei Advantage:

-

Integral welded body enhances waterproof performance and overall reliability.

Market Comparison:

-

Some competitors still use a split structure, increasing risk of water ingress and system failure.

-

✅ 3. Reinforced Waterproof Housing

Kenwei Advantage:

-

Waterproof shells are not only sealed but mechanically strengthened for extra durability.

Market Comparison:

-

Others may provide waterproofing but lack structural reinforcement, leading to faster wear.

-

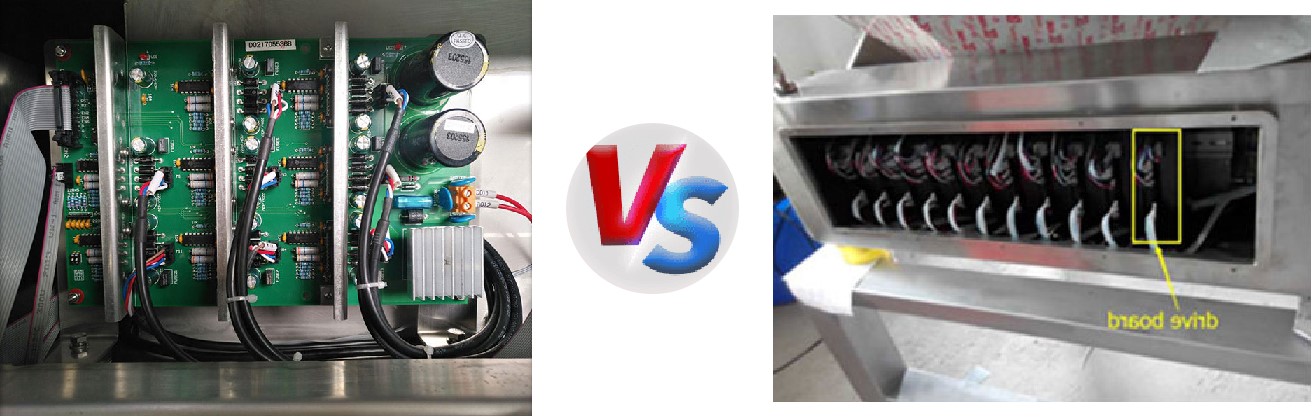

✅ 4. Fewer Connectors = More Stability

Kenwei Advantage:

-

Reduced connector count and centralized power supply make the system more stable and reliable.

Market Comparison:

-

Some brands use separate modules with excessive connectors, increasing contact failure risk over time.

-

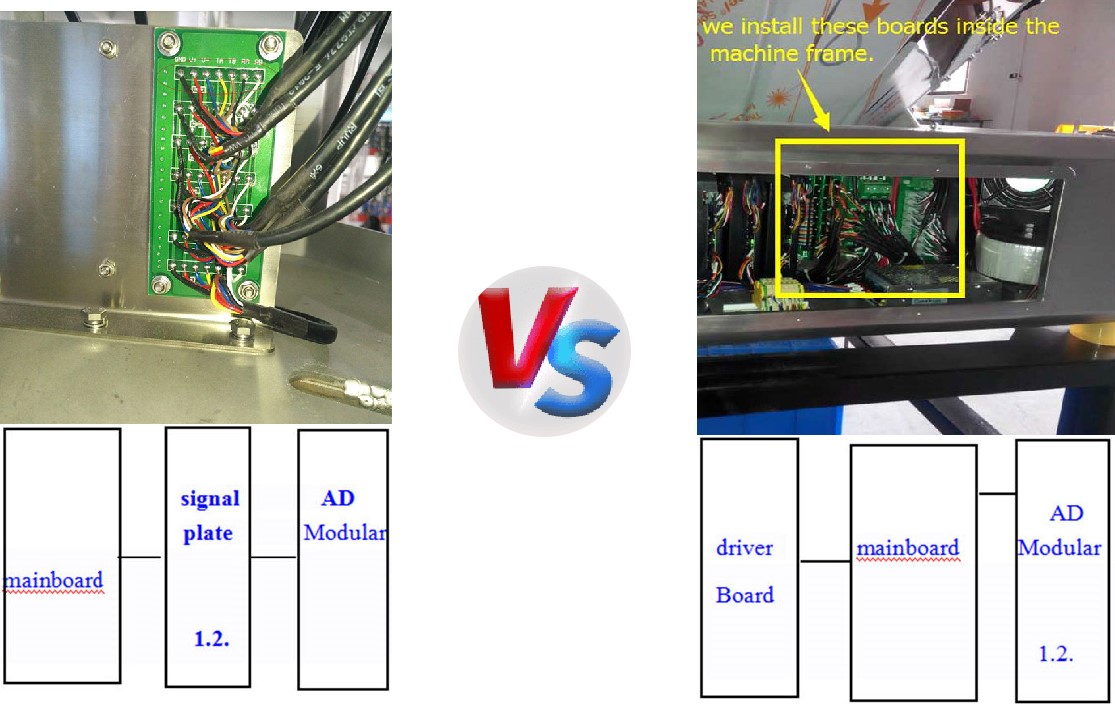

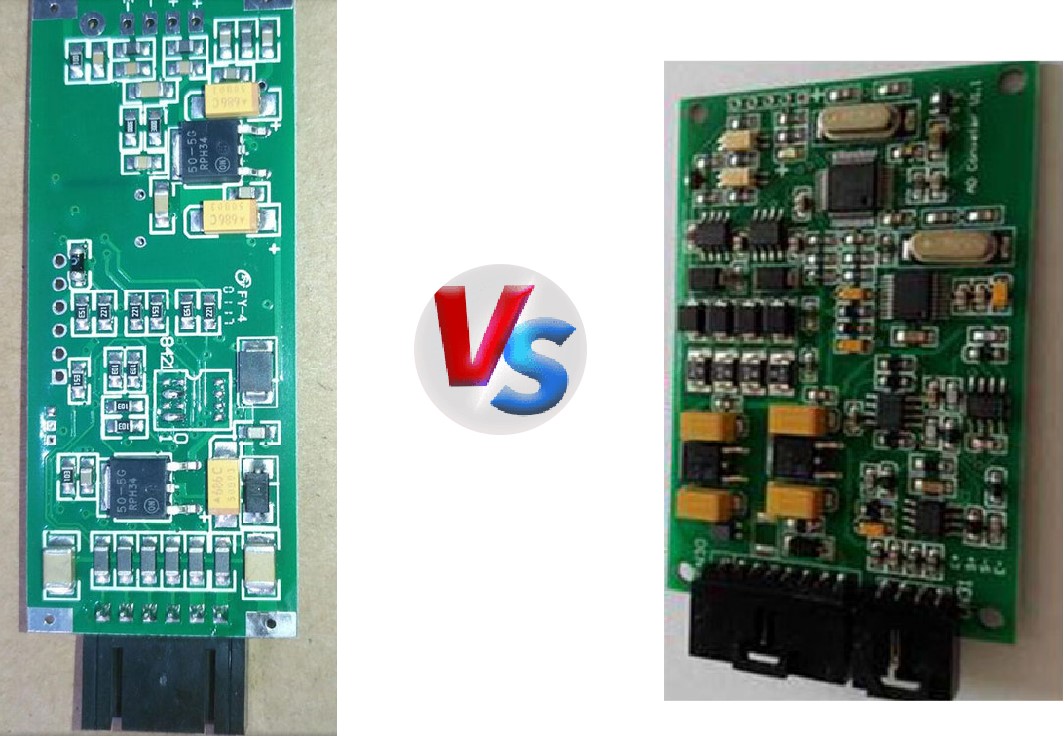

✅ 5. High-Speed Parallel Communication System

Kenwei Advantage:

-

Employs parallel communication: direct link between the mainboard and AD module, ensuring faster signal transmission with fewer failure points.

-

All weak signal components use welded technology—stable and consistent.

Market Comparison:

-

Other systems use serial communication with signal boards in between, adding more complexity and failure points.

-

✅ 6. Sensor and Motor Welding for Greater Stability

Kenwei Advantage:

-

Sensors and motors are welded directly, significantly reducing the risk of poor contact and signal loss.

Market Comparison:

-

Competitors often add connectors for convenience, which increases the risk of poor contact and long-term faults.

-

Conclusion:

While many small manufacturers prioritize easy maintenance, Kenwei builds for long-term reliability and stability. With continuous innovation—like second-generation modular panels, stainless or aluminum housings without extra holes, and direct board communication—Kenwei minimizes risk and ensures peak performance across industries.

Choose Kenwei. Choose long-term reliability.

About products customization

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

About Solution suggestions

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

About Cooperation Process

Can Kenwei customize equipment to meet my specific needs?

Yes! We offer customized solutions for all of our machines. Our team will work closely with you to understand your specific requirements and create a solution that meets your needs in terms of size, functionality, speed, and other factors.

About Product choice

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

About After Sales Support

How do I claim warranty service?

To claim warranty service, please contact our customer support team with your machine’s product code and a description of the issue. If applicable, we may request photos or videos of the issue to facilitate troubleshooting.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei