Packaging Material Compatibility for Vertical Packaging Machines

- Packaging Material Compatibility for Vertical Packaging Machines

- Introduction: Why material compatibility matters for vertical packaging machine performance

- Product spotlight: Economic vertical form fill seal packing machine (VFFS)

- Core material categories compatible with vertical packaging machines

- Sealing mechanisms and what they require from film

- Practical table: Common films and VFFS compatibility

- Key film properties to evaluate for vertical packaging

- How thickness and film stiffness affect the Economic VFFS operation

- Sealing best practices and machine settings

- Testing and validation you must perform

- Regulatory and food-contact compliance

- Modified Atmosphere Packaging (MAP) and barrier films

- Addressing recyclable and compostable materials

- Troubleshooting common material-related issues on vertical packaging machines

- Operational recommendations for reliable production

- Brand advantages: why the Economic vertical form fill seal packing machine (VFFS) helps materials compatibility

- FAQ — Packaging Material Compatibility for Vertical Packaging Machines

- Contact us / View product

- Authoritative references and further reading

- Closing notes

Packaging Material Compatibility for Vertical Packaging Machines

Introduction: Why material compatibility matters for vertical packaging machine performance

Choosing the right packaging material is as important as selecting the right vertical packaging machine. The interaction between film properties and machine sealing/drawing mechanics determines seal integrity, appearance, throughput, and product shelf life. For food, pharmaceutical, and industrial parts applications, mismatch between film and machine settings can cause poor seals, film tearing, frequent downtime, or compromised product safety. This article concentrates on practical guidance for materials and settings that work well with a vertical packaging machine—especially with an Economic vertical form fill seal packing machine (VFFS)—to help packaging engineers, production supervisors, and purchasing teams make informed decisions. With material compatibility confirmed, manufacturers can fully realize productivity gains by understanding how economic VFFS improves line efficiency and throughput.

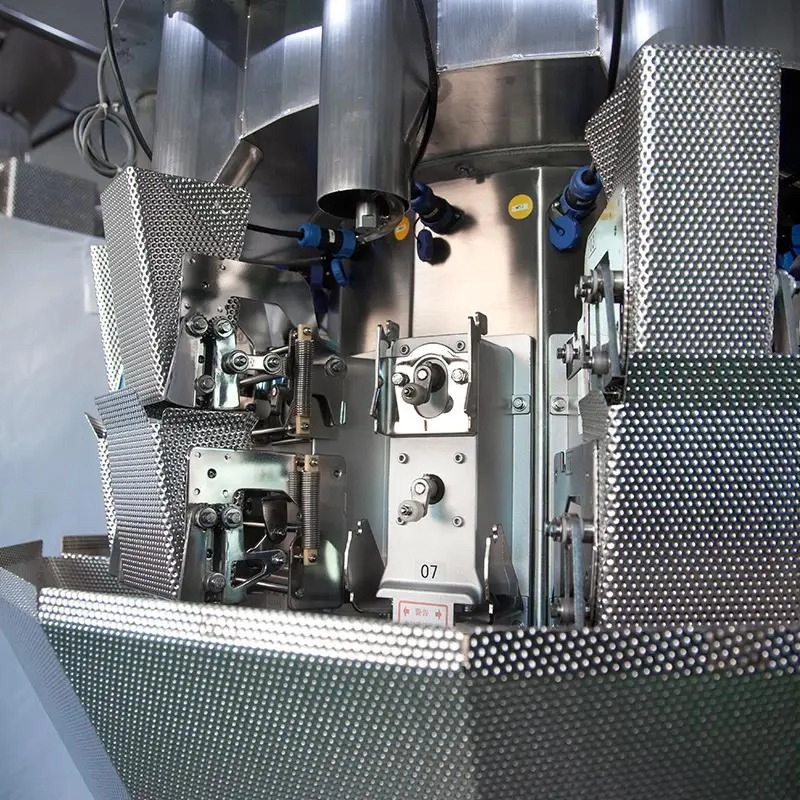

Product spotlight: Economic vertical form fill seal packing machine (VFFS)

The economical vertical form fill seal (VFFS) packaging machine offers a variety of models designed with a sturdy 304 stainless steel frame. It is equipped with safety door protection and supports multiple bag types, including pillow bags, angle belt bags, printed bags, and triangle bags. This versatile machine is ideal for packaging a wide range of materials, such as snacks, frozen foods, coffee beans, oats, sugar, salt, rice, small hardware components, and more. Affordable and cost-effective, it provides reliable performance and efficiency for diverse packaging needs.

Core material categories compatible with vertical packaging machines

Most VFFS machines, including the Economic VFFS, are engineered to run a broad set of flexible films. Common categories include single-polymer films (PE, PP), oriented films (OPP, OPA), multi-layer laminates (PET/PE, PET/AL/PE), and coated or metallized films. Each type behaves differently in forming tubes, heat sealing, cold-sealing, and when exposed to draw tension. Understanding these behaviors is the first step to specifying the right film for your product.

Sealing mechanisms and what they require from film

Vertical packaging machines use several sealing methods: continuous heated jaw sealing, impulse sealing, ultrasonic sealing, and cold-seal coatings (for low-temperature food items). The Economic VFFS commonly uses heated jaws or impulse sealers. Films must have a compatible heat-seal layer (sealant) such as low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), or specially formulated sealant resins. Sealant layer melting point and coefficient of friction affect dwell time, seal strength, and film handling. For example, PE-based sealant layers are forgiving and widely used; EVOH or aluminum layers provide barriers but require a compatible outer sealant layer.

Practical table: Common films and VFFS compatibility

Use the table below to quickly assess common film choices for a vertical packaging machine like the Economic VFFS.

| Film Type | Typical Structure | Compatibility with VFFS | Benefits | Considerations / Drawbacks |

|---|---|---|---|---|

| PE (LDPE/LLDPE) | Single layer or sealant layer | High — excellent heat-sealability | Flexible, low-cost, good seals | Low barrier to oxygen/water vapor |

| PP (BOPP) | Oriented PP, often heat-sealable coated | Good if sealant coated | High clarity, stiffness, printable | Requires sealant coating; oriented films can be brittle |

| PET / PET-based laminates | PET/PE, PET/AL/PE | High when sealant present | Excellent strength, printability, barrier options | Higher cost, needs correct sealant layer |

| Aluminum foil laminates | PET/AL/PE | High — widely used for barrier packs | Superior barrier, light protection | Stiffer; require controlled tension to avoid wrinkling |

| EVOH barrier laminates | PE/EVOH/PE or PET/EVOH/PE | Good — with compatible sealant | Excellent oxygen barrier, clarifies MAP use | Moisture-sensitive during extrusion; must control process |

| Paper and coated paper | Paper/PE, Paper/PLA | Moderate — requires strong sealant | Good consumer perception, recyclable overlays | Lower puncture resistance; print and seal variability |

| Compostable / Biobased films | PLA blends, PBAT coatings | Variable — heat-sealing profiles differ | Environmentally friendly option | May need higher sealing temp or different dwell times |

Key film properties to evaluate for vertical packaging

When selecting film for a VFFS line evaluate: sealant chemistry and melting point, film thickness (gauge), tensile strength and elongation, friction coefficient, puncture resistance, barrier values (OTR and MVTR), printability, and machinability (weld line formation). Practical performance testing on the actual VFFS is essential — vendor data sheets are starting points but not substitutes for line trials.

How thickness and film stiffness affect the Economic VFFS operation

Film gauge affects film draw, forming tube behavior, and sealing. Very thin films (<30 µm total) can wrinkle or tear under high film tension; very thick films (>150 µm) require more power to form and may slow throughput. Stiffer films (oriented films, foil) may not form cleanly into small-diameter forming tubes without a larger former. The Economic VFFS offers adjustable forming and tensioning, but choose a film thickness range that matches the machine’s forming tube diameter and drive capability.

Sealing best practices and machine settings

Optimize sealing by adjusting: jaw temperature, dwell time, jaw pressure, and the frequency (for impulse). Start with the film supplier’s recommended seal profile, then run seal strength tests (peel and shear) at production line speed. Typical actions when troubleshooting seals:

- Weak seals: increase temperature or dwell time; verify jaw cleanliness.

- Film sticking to jaws: lower temperature, adjust release coating, or use Teflon covers.

- Wrinkled seals: reduce draw tension or lower forming tube vacuum.

- Blackened/burnt edges: reduce temperature or dwell time.

Testing and validation you must perform

Before full production, perform these tests to reduce risk:

- Seal Strength (ASTM F88/F2824 or equivalent): peel and shear analysis.

- Burst/Headspace Integrity Tests: ensure resistance to pressure changes.

- OTR and MVTR measurements: confirm shelf-life target.

- Migration and food-contact compliance testing (for food): per FDA/EU requirements.

- Line trials for throughput and visual quality at target speeds.

Regulatory and food-contact compliance

If packaging food, pharmaceuticals, or products with stringent safety needs, choose films that comply with local regulations. In the U.S., the FDA regulates food-contact substances; in the EU, Commission Regulation (EU) No 10/2011 covers plastic materials. Confirm documentary evidence from your film supplier (declarations of compliance), and if necessary, run migration tests for specific product/formulation interactions.

Modified Atmosphere Packaging (MAP) and barrier films

For products sensitive to oxygen or moisture (coffee beans, snacks), use barrier laminates (EVOH, metallized films, foil laminates) and ensure your Economic VFFS supports MAP capability (gas flushing and good seal integrity). Barrier films need compatible sealant layers and may require slower dwell times or higher heat due to their stiffer structure. Verify residual oxygen levels post-seal and run shelf-life trials.

Addressing recyclable and compostable materials

Demand for recyclable packaging is rising. Monomaterial PE-based laminates are more recyclable than mixed-material laminates. Compostable films (PLA/PBAT blends) are an option for some brands, but they often require different sealing temperatures and may be less puncture-resistant. Evaluate environmental claims against local recycling infrastructure and ensure your VFFS sealing system can adapt to the different seal profiles these materials need.

Troubleshooting common material-related issues on vertical packaging machines

Typical symptoms and fixes:

- Poor seal: check film sealant compatibility, increase temperature/dwell, clean jaws.

- Film tearing: lower tension, use thicker gauge, inspect forming tube for sharp edges.

- Inconsistent bag length: verify encoder and film perforation/pull alignment.

- Static and film cling: install ionizing bars or anti-static devices.

- Wrinkled film in seal: reduce film tension and optimize former geometry.

Operational recommendations for reliable production

To ensure consistent results on your Economic VFFS:

- Always validate a new roll of film using a short run with full QA testing.

- Maintain spare forming tubes and sealing jaws matched to the film type.

- Keep a documented matrix: film SKU → machine settings (temperature, dwell, pressure) → expected seal strength.

- Train operators on quick-changeover procedures and basic troubleshooting.

- Work closely with film suppliers to obtain processing windows and trial support.

Brand advantages: why the Economic vertical form fill seal packing machine (VFFS) helps materials compatibility

The Economic VFFS platform is designed for flexibility and repeatable performance. Key advantages that help material compatibility include a robust 304 stainless frame for hygiene and durability, adjustable forming and tensioning controls to handle different film gauges, and safety door protection for operator access during adjustments. Its support for multiple bag styles (pillow, angle belt, printed, triangle) and compatibility with common sealing technologies make it straightforward to trial a range of films and configurations without major capital changes.

FAQ — Packaging Material Compatibility for Vertical Packaging Machines

Q: Can I run compostable films on an Economic VFFS?

A: Often yes, but compostable films can need unique sealing temperatures and may reduce throughput. Validate through line trials and adjust seal profiles accordingly.

Q: How do I know if a film's sealant is compatible with my VFFS?

A: Ask your film supplier for recommended seal temperature, dwell time, and jaw pressure. Run a calibration batch with ASTM-style seal tests at production speed.

Q: What barrier films are best for snack products on VFFS lines?

A: PET/AL/PE and PET/EVOH/PE laminates provide strong barriers. Choose a laminate with a PE sealant layer for reliable heat sealing on standard VFFS machines.

Q: Why are seals failing intermittently?

A: Intermittent failures often point to inconsistent film web tension, contaminated jaws, or variable film thickness between rolls. Implement a corrective checklist: clean jaws, check tensioners, and test film uniformity.

Q: Can I use metalized films for printed bags?

A: Yes — metalized films can be printed and used on VFFS. Ensure film stiffness is compatible with the forming tube and that the sealant layer tolerates heat sealing.

Contact us / View product

If you need help selecting a film or want to schedule a line trial on the Economic vertical form fill seal packing machine (VFFS), contact our sales engineering team for sample testing, machine demonstrations, and recommended spare parts. Click to contact sales or request a quote today.

Authoritative references and further reading

For regulatory and technical standards, consult these sources:

- Form-fill-seal — Wikipedia: https://en.wikipedia.org/wiki/Form-fill-seal

- FDA Food Contact Substances (FCS): https://www.fda.gov/food/packaging-food-contact-substances-fcs

- European Commission — Food contact materials: https://ec.europa.eu/food/safety/chemical_safety/food_contact_materials_en

- Packaging Machinery Manufacturers Institute (PMMI): https://www.pmmi.org

Closing notes

Material compatibility is a combination of correct film selection, optimized machine settings, and rigorous testing. The Economic vertical form fill seal packing machine (VFFS) provides the flexibility and control needed to run a wide range of films reliably. Partnering with film suppliers and running comprehensive line trials will minimize risk, reduce downtime, and protect product quality and shelf life.

Troubleshooting common issues with a 14 head multihead weigher

Multihead Weigher Technology Trends 2026

Integration with Production Line Controls and Traceability

Where to Buy checkweighers

About Product choice

Are Kenwei’s products suitable for small-scale or large-scale operations?

Yes! We offer machines that are scalable to meet the needs of both small and large-scale operations.

About products customization

Can Kenwei machines be customized for different industries?

Yes,According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on.

About Logistics

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

About After Sales Support

How do I claim warranty service?

To claim warranty service, please contact our customer support team with your machine’s product code and a description of the issue. If applicable, we may request photos or videos of the issue to facilitate troubleshooting.

About Solution suggestions

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

Automatic Multi-Function Pouch Weighing and Packing Machine – 65 BagsMin for Efficient Packaging

The mini combined weighing and packaging machine integrates a miniature multi-head scale with a vertical packaging machine, all controlled by an advanced PLC program. This fully automatic system handles metering, filling, bag-making, date printing, and packaging output. Ideal for weighing small particles such as Chinese herbal medicine, tea, seeds, monosodium glutamate, chicken essence, coffee beans, chocolate, and more. With its affordable price, low maintenance costs, and high efficiency, the mini combined weighing and packaging machine is an economical choice for small-scale operations.

Mini Combined Weighing and Packing Machine with Multihead Weigher for Tea Powder, Coffee Beans, and More

The mini combined weighing and packaging machine integrates a compact multi-head scale with a vertical packaging machine, all controlled by an advanced PLC program. This fully automated system handles precise metering, filling, bag-making, date printing, and packaging output. Ideal for weighing small particles such as Chinese herbal medicine, tea, seeds, monosodium glutamate, chicken essence, coffee beans, chocolate, and more. The mini combined weighing and packaging machine is cost-effective, economical, and offers low maintenance costs, making it an excellent choice for small-scale packaging operations.

Standard Vertical Weighing And Packaging Machine For Granules Puffy Foods JW-B1

Discover Kenwei’s Standard Vertical Weighing And Packaging Machine For Granules Puffy Foods. This efficient vertical packaging machine accurately weighs and packs a variety of foods, making it the ideal weighing and packaging machine for granules and puffy snacks.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei