Sustainable Packaging: Combination Weighers Role in 2026

- Sustainable Packaging: Combination Weighers' Role in 2026

- Why sustainable packaging matters—and where weighing fits in

- What is a combination weigher and why it matters for sustainability

- How combination weighers reduce waste, greenhouse gases and costs

- Comparison: Combination Weigher vs Other Weighing Systems (Sustainability Focus)

- Practical metrics: How much impact can precise weighing deliver?

- Data on packaging and food waste that frame the opportunity

- Integrating combination weighers into sustainable packaging lines

- Cost-benefit considerations: ROI and sustainability KPIs

- Case study snapshot (anonymized example)

- Operational best practices for maximizing sustainable gains with combination weighers

- Kenwei: Partnering for sustainable, automated weighing and packaging solutions

- Kenwei's advantages for sustainable packaging projects

- Selecting the right combination weigher model for 2026 needs

- Barriers and how to overcome them

- Future outlook: combination weighers and sustainable packaging in 2026 and beyond

- Frequently Asked Questions (FAQ)

- Q: What is the main sustainability benefit of using a combination weigher?

- Q: Can combination weighers handle fragile or irregular products?

- Q: How quickly can a combination weigher pay for itself?

- Q: Are combination weighers compatible with lightweight or recyclable packaging formats?

- Q: How does a combination weigher fit into an Industry 4.0 strategy?

- Contact Kenwei / View products

- References

Sustainable Packaging: Combination Weighers' Role in 2026

Why sustainable packaging matters—and where weighing fits in

Global pressure from regulators, retailers and consumers is forcing food and consumer goods manufacturers to reduce packaging waste, lower carbon footprints, and optimize material use. Sustainable packaging choices often involve using less material, shifting to recyclable or mono-materials, and redesigning packs so that primary packaging serves multiple functions (protection, display, barrier). However, lighter or thinner packs increase the need for precise filling and portion control to maintain consumer trust and regulatory compliance. That's where industrial weighing equipment—most notably the combination weigher—plays a critical role.

What is a combination weigher and why it matters for sustainability

The combination weigher is a multi-head weighing system that combines the output of multiple heads to reach a target weight with minimal overfill. Compared with single-head or linear systems, a combination weigher determines combinations of weigh-head outputs to reach the required weight more precisely, thereby reducing giveaway (overfill) and product waste. When product giveaway decreases, manufacturers use less product per pack on average—directly lowering material throughput requirements, energy consumption in processing and packaging, and overall cost. The combination weigher therefore addresses both environmental and commercial objectives.

How combination weighers reduce waste, greenhouse gases and costs

Combination weighers contribute to sustainability in several measurable ways:

- Reduced giveaway: Accurate weight control means brands pack closer to the declared weight without risking underfill, reducing the percentage of product overfilled across large runs.

- Less scrap and rework: Consistent weighing reduces product rejects and the need to rework under- or overfilled packs.

- Optimized packaging design: When fill accuracy is high, packaging engineers can safely reduce pack size or material thickness, lowering material consumption and transport weight.

- Energy and CO2 savings: Lower material usage and fewer rejects reduce energy use across production, transport and end-of-life processes—contributing to smaller scope-1 and scope-3 emissions.

Meeting sustainability targets often requires both equipment improvement and process changes; combination weighers provide a technical lever with immediate ROI and environmental benefit.

Comparison: Combination Weigher vs Other Weighing Systems (Sustainability Focus)

Choosing the right weighing technology is critical when sustainability is a target. The table below summarizes typical performance characteristics relevant to sustainable packaging decisions.

| Attribute | Combination Weigher | Multihead Weigher (standard) | Linear Weigher |

|---|---|---|---|

| Accuracy / Minimizing giveaway | High — optimizes head combinations to closely hit target | High — fast and accurate for many products, but less combinatorial optimization | Medium — single-stream accuracy, higher chance of overfill to ensure compliance |

| Speed (packs/min) | High — designed for high throughput, depends on model and product | Very High — commonly fastest for free-flowing products | Medium — suitable for bulk continuous dosing |

| Flexibility (product types) | High — handles a broad range including irregular shapes when combined with improved algorithms | Medium-High — versatile but can struggle with very fragile or sticky items | Low-Medium — best for homogenous, free-flowing products |

| Suitability for lighter/eco packs | Excellent — enables reduced tolerance and smaller headspace with confidence | Good — suitable but may require conservative fills for some pack types | Fair — often requires extra safeguards leading to more overfill |

| Typical use cases that aid sustainability | High-value snacks, confectionery, frozen veggies, pet food — where minimal giveaway equals major material savings | Snack bags, cereals, chips — large volume where speed and reasonable accuracy matter | Bulk sauces, grains where continuous dosing is required |

Sources: industry product literature and trade publications summarized in References.

Practical metrics: How much impact can precise weighing deliver?

Quantifying savings depends on product value, pack size, and production volume. To illustrate, consider a conservative hypothetical example:

- Production: 100 million packs per year

- Declared weight: 100 g

- Average giveaway reduced by implementing combination weighers: 0.5 g per pack (0.5% of pack weight) — a conservative operational improvement for many manufacturers

Outcome: 0.5 g × 100,000,000 packs = 50,000 kg less product used per year. Depending on the product, this reduces raw material consumption, packaging-per-unit CO2, transport weight and associated costs.

Note: Exact figures will vary by operation. Many manufacturers track giveaway reduction in grams-per-pack as a key KPI to estimate annual savings and carbon reduction.

Data on packaging and food waste that frame the opportunity

Understanding the broader context helps prioritize investments in weighing and packaging. Relevant global figures include:

- Food loss and waste: The UN Food and Agriculture Organization (FAO) estimates that roughly one-third of food produced for human consumption is lost or wasted globally. Better portioning and packing can reduce some categories of food waste at the packing and retail level.

- Consumer demand: Surveys show growing consumer preference for brands that minimize waste and use recyclable or reduced packaging.

Sources listed in References.

Integrating combination weighers into sustainable packaging lines

Installing a combination weigher is not simply a machine swap. To maximize sustainability returns, manufacturers should:

- Map current giveaway and waste: Measure grams over the declared weight, rejects, and rework rates before investment.

- Define packaging goals: Decide whether target is reduced material, smaller formats, or switching to mono-materials that require tighter fill control.

- Upgrade upstream processes: Ensure product feed, pre-dosing and conveying systems match the weigher's characteristics to avoid variability.

- Use data and automation: Leverage recipe management, real-time analytics and adaptive algorithms to maintain performance across product changes.

- Validate with trials: Pilot new pack formats and weights on the line to verify performance before full rollout.

Combining mechanical upgrades with digital controls enhances both sustainability and operational resilience.

Cost-benefit considerations: ROI and sustainability KPIs

Investment decisions should consider both direct financial ROI and less tangible sustainability KPIs (reduced material use, lower transport emissions, brand compliance). Typical evaluation steps include:

- Calculate annual product savings from expected reduction in giveaway (grams per pack × annual volume × product cost).

- Estimate reduction in packaging material if pack downsizing is feasible due to tighter fill control.

- Quantify energy and CO2 reductions downstream (transport, handling, storage) tied to lower pack weight and fewer rejects.

- Compare to capital and operating cost of the combination weigher, including installation, integration, and maintenance.

Manufacturers often find payback periods of 12–36 months for high-volume lines when giveaway and rework reductions are realized. Exact payback depends on product margin and volume.

Case study snapshot (anonymized example)

A mid-sized snack producer replaced a legacy linear weighing system with a modern combination weigher on a 150 g bag product. Key results after three months:

- Giveaway reduced by 0.4 g/pack

- Annual raw material savings equivalent to ~30 metric tons

- Rework/pack rejects decreased by 60%

- Estimated payback: 18 months (equipment + integration)

These results are typical when lines are optimized end-to-end and operators are trained to use the combination weigher's features.

Operational best practices for maximizing sustainable gains with combination weighers

To extract continuous benefit from a combination weigher, focus on:

- Routine calibration and preventative maintenance to keep accuracy high.

- Operator training on recipe changes, cleaning procedures, and troubleshooting to minimize downtime.

- Data logging and analytics to track giveaway, rejects, and head performance, enabling incremental improvements.

- Integration with check weighers and metal detectors to ensure full-line quality control while avoiding unnecessary rework.

These steps protect both product quality and sustainability outcomes over the machine lifecycle.

Kenwei: Partnering for sustainable, automated weighing and packaging solutions

Kenwei is a powerful manufacturer of multi-head weighers. We are committed to the development and manufacturing of metal detectors, multi-head weighers, linear weighers, and check weighers. Our machines are characterized by high speed and high precision. We also provide our customers with one-stop automated weighing and packaging solutions to meet our customers’ customization requirements. Guangdong Kenwei is located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province. The company is equipped with an automated weighing and packaging system and has comprehensive capabilities in design and development, manufacturing, marketing, installation and commissioning, technical training, and after-sales service. It has established a good brand image and a reputation for thoughtful and fast service in the packaging machinery industry. Our vision is to become the world's leading weighing packing machine manufacturer. Our website is https://www.kenweigroup.com/

Kenwei's advantages for sustainable packaging projects

Kenwei combines high-speed, high-precision machines with services that reduce time-to-value for sustainability initiatives:

- Comprehensive product portfolio: Check Weigher, multihead weigher packing machine, multihead weigher, linear weigher, metal detector, packing machine, counting machine, combination weigher, food packaging machine, and other food packing machinery.

- Customization capability: One-stop automated solutions tailored to pack sizes, materials and sustainability targets.

- Engineering and service: In-house R&D, local installation & commissioning, operator training and responsive after-sales support.

- Proven performance: Equipment designed to minimize giveaway and maximize throughput—key drivers of reduced material use and cost.

For manufacturers targeting reduced packaging footprint and lifecycle impacts, Kenwei provides both the machines and the implementation support required to achieve measurable sustainability results.

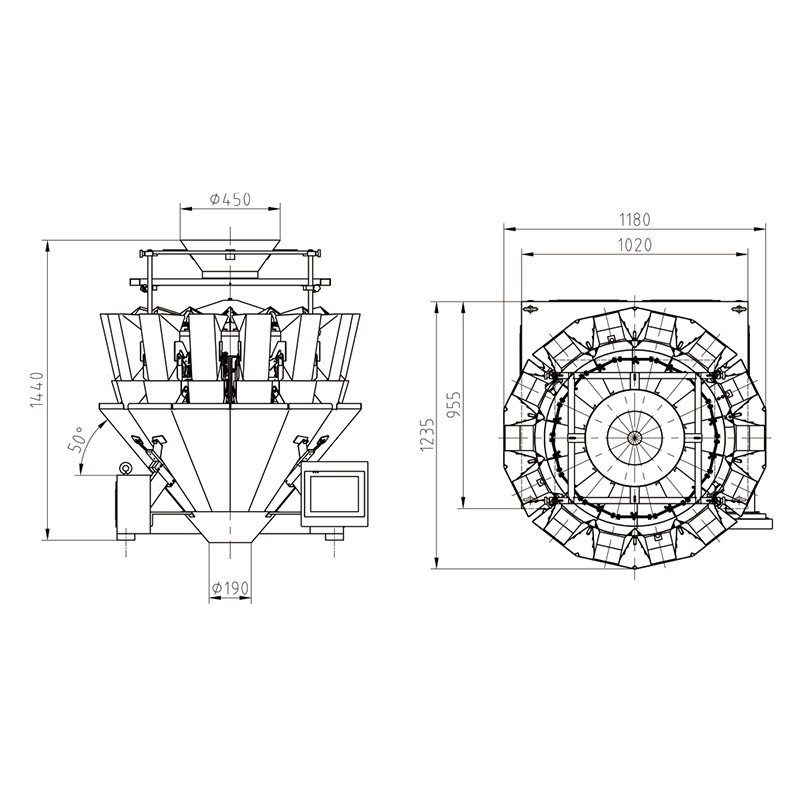

Selecting the right combination weigher model for 2026 needs

When choosing a combination weigher, evaluate:

- Throughput capacity matched to your production peaks.

- Accuracy specs and algorithm sophistication for minimal giveaway.

- Sanitary design for easy cleaning—especially important for reduced water and chemical use in cleaning operations.

- Compatibility with your packaging machinery, including vertical form fill seal (VFFS) or pre-made pouch lines.

- Software and Industry 4.0 readiness for data collection and remote support.

Kenwei's product range offers scalable options for manufacturers moving from traditional heavier packs to lighter, recyclable formats without compromising compliance or consumer satisfaction.

Barriers and how to overcome them

Common barriers to adopting combination weighers for sustainability include upfront capital, line integration complexity, and operator resistance. Overcome these by:

- Running pilot projects to demonstrate ROI and sustainability gains.

- Working with machine suppliers (like Kenwei) that provide end-to-end support: design, commissioning, training and after-sales service.

- Building cross-functional teams (R&D, packaging engineering, operations, sustainability) to align technical and environmental goals.

Future outlook: combination weighers and sustainable packaging in 2026 and beyond

By 2026, expect combination weighers to be more tightly integrated with digital platforms (cloud analytics, AI-assisted recipe optimization) and to support new packaging trends such as reduced-headspace fill, mono-material pouches, and micro-dosing for high-value ingredients. These capabilities will amplify their role in lowering material use, waste and greenhouse emissions—making combination weighers a strategic investment in both productivity and sustainability.

Frequently Asked Questions (FAQ)

Q: What is the main sustainability benefit of using a combination weigher?

A: The primary benefit is reduced giveaway—more accurate fills mean less product is overfilled per pack. That reduces raw material use, packaging needs per unit of product sold, and downstream energy and transport impacts.

Q: Can combination weighers handle fragile or irregular products?

A: Yes. Modern combination weighers are designed with gentle product handling and can be configured (hopper design, head type, vibration control) to handle fragile, irregular or mixed-product applications while maintaining accuracy.

Q: How quickly can a combination weigher pay for itself?

A: Payback depends on production volume, product value, and current giveaway levels. Many manufacturers report paybacks between 12 and 36 months when giveaway and rework reductions are realized—especially on high-volume lines.

Q: Are combination weighers compatible with lightweight or recyclable packaging formats?

A: Yes. Their improved accuracy allows brands to reduce headspace and material thickness safely. Integration trials are recommended to validate pack performance and seal integrity with new materials.

Q: How does a combination weigher fit into an Industry 4.0 strategy?

A: Modern machines offer recipe management, real-time monitoring and data export for analytics. This enables continuous optimization of giveaway, uptime and maintenance—key metrics for sustainable operations.

Contact Kenwei / View products

If you are planning to reduce packaging waste, optimize material use or upgrade to smarter, more accurate filling systems, Kenwei can help. Visit our product pages and request a line assessment at https://www.kenweigroup.com/ or contact our sales team to arrange a pilot or demo. Our specialists will help model expected savings and sustainability impacts for your specific product and packaging formats.

References

- Food and Agriculture Organization of the United Nations (FAO) — reports on food loss and waste.

- WRAP (UK) — guidance and studies on packaging, waste reduction and food waste prevention.

- Packaging World and Food Engineering trade publications — industry articles discussing weighers, accuracy and giveaway reduction.

- Kenwei product literature and corporate materials — for machine capabilities, product range and services (https://www.kenweigroup.com/).

Note: Data examples in this article are illustrative. Manufacturers should run site-specific trials to quantify exact savings and sustainability benefits.

Top 10 multi head packing machine Manufacturers and Supplier Brands

best multihead weigher choices for confectionery lines 2026

Top 10 Metal Detectors for Aluminum Foil in Food Plants

What are the application scenarios of vffs packaging machine?

About Logistics

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

About Cooperation Process

How to operate it?

Many languages are available for global markets. There are not only detailed instructions, but also machine video for reference learning.

About Solution suggestions

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

About Price and payment

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

About Product choice

Are Kenwei’s products suitable for small-scale or large-scale operations?

Yes! We offer machines that are scalable to meet the needs of both small and large-scale operations.

10-Head Standard No-Spring Multihead Weigher 1.6L for Precise Weighing

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Standard Multihead Weigher with New Springless Actuator for Food Weighing Machine

The Standard Multihead Weigher features a high-speed, spring-free hopper with a new aluminum shell design, ensuring stable and fast weighing performance. The integrative welding of the mouthpiece case and middle seat enhances the overall machine strength. Ideal for weighing granular products like melon seeds, peanuts, nuts, almonds, raisins, candies, and pistachios, this 14-head multihead weigher offers hopper options of 1.6L and 2L. With a maximum weighing speed of 120 packs per minute, it delivers rapid and accurate results for high-volume operations.

14-Head High-Speed Springless Multihead Weigher for Accurate Weighing

The high-speed weigher features a new spring-free aluminum shell design with double chute feeding and dual high-speed hopper alternating feeding, significantly boosting feeding speed. It is ideal for weighing materials such as melon seeds, peanuts, nuts, almonds, raisins, candy, pistachios, and more. The 18-head high-speed weigher is equipped with 2L hoppers, achieving a maximum weighing speed of up to 180 bags per minute.

16-Head Multihead Weigher with 1.6L Three-Layer Hopper for Accurate Weighing

The Kenwei 16-Head Multihead Weigher with a 1.6L Three-Layer Hopper provides precise and efficient weighing with a maximum speed of 240 packs per minute, optimizing your production line. The main vibrating pan supports two types of mixed materials, offering versatility and consistent performance. This advanced multihead packing machine is ideal for a wide range of products, including nuts, raisins, candies, potato chips, and other snack foods, as well as hardware and plastic materials. It ensures reliable performance and high accuracy in various industries.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei