What are the application scenarios of vffs packaging machine?

- Revolutionizing Packaging: The Versatility of VFFS Packaging Machines

- Understanding the VFFS Packaging Machine: Form, Fill, and Seal in One Go

- Key Advantages of Implementing VFFS Packaging Solutions

- High Speed and Efficiency for Maximized Throughput

- Precision and Accuracy for Consistent Packaging

- Versatility and Adaptability to Diverse Products

- Cost-Effectiveness Through Material Savings

- Space-Saving Footprint in Production Facilities

- Diverse Application Scenarios of VFFS Packaging Machines

- Snack Foods & Confectionery Packaging

- Grains, Pulses & Cereals Packaging

- Powdered Products Packaging

- Frozen Foods Packaging

- Pet Food & Animal Feeds Packaging

- Non-Food Items & Industrial Components Packaging

- Other Niche Applications

- The Indispensable Role of Multihead Weighers in VFFS Systems

- Choosing the Right VFFS & Weighing Solution with Kenwei

- Future Trends in VFFS Technology and Automated Packaging

- Conclusion: The Enduring Value of VFFS Packaging Machines

- Frequently Asked Questions About VFFS Packaging Machines

Revolutionizing Packaging: The Versatility of VFFS Packaging Machines

In today's fast-paced manufacturing world, efficient and reliable packaging is not just a convenience—it's a necessity. Businesses across various sectors are constantly seeking innovative solutions to boost productivity, ensure product integrity, and reduce operational costs. Among the many packaging technologies available, the VFFS packaging machine, or Vertical Form Fill Seal machine, stands out as a true workhorse. Its incredible versatility and efficiency have made it an indispensable asset in modern production lines worldwide. At Kenwei, a powerful manufacturer of multi-head weighers, we understand the critical role these machines play in delivering high-speed, high-precision automated weighing and packaging solutions.

But what exactly makes the VFFS packaging machine so popular, and where do its capabilities truly shine? This article delves deep into the diverse application scenarios of VFFS systems, exploring how they cater to a myriad of products, from delicate snack foods to robust industrial components. We will uncover why businesses rely on this technology to meet their demanding packaging needs and how integrated solutions, like those provided by Kenwei, elevate packaging efficiency to new heights.

Understanding the VFFS Packaging Machine: Form, Fill, and Seal in One Go

Before exploring its applications, it’s essential to grasp the fundamental operation of a VFFS packaging machine. As its name suggests, a Vertical Form Fill Seal machine performs three key functions sequentially in a vertical orientation: forming the bag, filling it with product, and then sealing it. This all-in-one process ensures a streamlined and highly efficient packaging operation.

The process typically begins with a large roll of film, which is fed over a forming tube. As the film travels downwards, it wraps around the tube, creating the 'form' of the bag. Heat seals then create the vertical and bottom seals of the bag. Once the bag is formed, the product is dispensed into it from above – often using precise weighing equipment like Kenwei's multi-head weighers. Finally, the top of the filled bag is heat-sealed, and the completed package is cut off. This continuous, automated cycle allows for rapid production speeds and consistent package quality, making it an ideal choice for high-volume manufacturing.

Key Advantages of Implementing VFFS Packaging Solutions

The widespread adoption of VFFS packaging machine technology isn't just about its ability to form, fill, and seal. It's about the comprehensive benefits it brings to packaging operations. These advantages directly contribute to improved productivity, cost savings, and enhanced product presentation, making VFFS systems a smart investment for many businesses.

High Speed and Efficiency for Maximized Throughput

One of the most compelling advantages of VFFS machines is their unparalleled speed. Designed for continuous operation, these machines can produce hundreds of bags per minute, significantly boosting production throughput. This high efficiency is crucial for industries with tight deadlines and large production volumes, allowing companies to meet market demand effectively. Kenwei’s integration of high-speed multi-head weighers further optimizes this process, ensuring that the filling stage keeps pace with the machine’s rapid sealing capabilities.

Precision and Accuracy for Consistent Packaging

Accuracy in packaging is paramount, especially for products sold by weight or count. VFFS machines, particularly when paired with advanced weighing systems like Kenwei's high-precision multi-head weighers or linear weighers, ensure precise filling. This minimizes product giveaway, reduces material waste, and guarantees that consumers receive the exact quantity advertised, building trust and maintaining brand reputation. Our check weighers also ensure that every package meets strict weight standards.

Versatility and Adaptability to Diverse Products

The adaptability of VFFS machines is truly remarkable. They can handle a vast array of product types, from granules and powders to liquids and irregular shapes. Furthermore, they can accommodate various bag styles, including pillow bags, gusseted bags, stand-up pouches, and quad seal bags, by simply changing the forming tube and adjusting settings. This versatility makes the VFFS packaging machine a flexible solution for companies with diverse product lines or evolving packaging needs.

Cost-Effectiveness Through Material Savings

VFFS machines utilize film rolls, which are typically more cost-effective than pre-formed bags. By forming the bag in-line, these machines reduce material waste and labor costs associated with manual packaging. The ability to optimize film usage and minimize errors contributes significantly to overall cost savings in packaging operations, enhancing the bottom line for manufacturers.

Space-Saving Footprint in Production Facilities

In many manufacturing facilities, floor space is a High Quality. VFFS machines, with their vertical design, offer a relatively compact footprint compared to horizontal packaging systems. This efficient use of space allows businesses to optimize their layout, accommodate more equipment, or free up valuable area for other operational needs.

Diverse Application Scenarios of VFFS Packaging Machines

The versatility of the VFFS packaging machine truly shines when we examine the myriad of industries and product types it serves. Its ability to handle different product characteristics and bag styles makes it a go-to solution for packaging everything from delicate snacks to robust industrial items.

Snack Foods & Confectionery Packaging

Perhaps one of the most common sights for a VFFS machine is in the snack food industry. Think of your favorite bag of potato chips, pretzels, or even candy bars – chances are, they were packaged on a VFFS machine. These machines excel at handling fragile, irregularly shaped products like crisps, ensuring they are filled gently to prevent breakage. For confectionery, they accurately dispense candies, chocolates, and gummy bears into various bag formats, maintaining product integrity and attractive presentation. The high-speed capability is crucial for meeting the massive demand in this sector.

Grains, Pulses & Cereals Packaging

From staples like rice, beans, and lentils to breakfast cereals and pasta, the VFFS packaging machine is ideally suited for packaging free-flowing granular products. Its precision weighing capabilities, often augmented by multi-head weighers, ensure accurate portioning, which is vital for consumer trust and inventory management. The machines can create large, robust bags for bulk grains or smaller, consumer-ready pouches for quick oats or pasta portions.

Powdered Products Packaging

Packaging powders presents unique challenges, such as dust control and ensuring consistent fill levels. VFFS machines, equipped with specialized auger fillers or vibratory feeders, effectively handle products like flour, sugar, coffee, spices, protein powder, and even powdered detergents. They create tightly sealed bags that prevent leakage and maintain product freshness and hygiene, crucial for both food and non-food powdered goods. Kenwei's integrated solutions ensure precise dosing even for fine powders.

Frozen Foods Packaging

The frozen food sector demands packaging solutions that can withstand low temperatures and maintain product quality. VFFS machines are excellent for packaging frozen vegetables, fruits, seafood, and prepared meals. They can use specialized film materials that remain flexible in cold conditions and provide strong, moisture-resistant seals. The high speed of VFFS ensures quick packaging, minimizing product exposure to ambient temperatures and preserving freshness.

Pet Food & Animal Feeds Packaging

The pet food market is booming, and VFFS machines are central to packaging dry kibble, treats, and even birdseed. They handle various particle sizes and densities with ease, providing accurate weighing and robust packaging that can withstand transportation and storage. The ability to produce larger bags for bulk pet food makes VFFS an economical and efficient choice for manufacturers in this industry.

Non-Food Items & Industrial Components Packaging

Beyond food products, the versatility of the VFFS packaging machine extends to various non-food applications. This includes packaging small hardware components like screws, nuts, bolts, washers, and even electrical components. It's also used for garden seeds, small plastic toys, and granular chemicals. The machine's ability to count or weigh small, distinct items accurately and place them into durable bags makes it invaluable for these industrial and consumer goods sectors.

Other Niche Applications

The adaptability of VFFS technology allows it to serve even more specialized markets. This might include packaging agricultural products like fertilizers, certain types of medical disposables (non-sterile), or even promotional items. As manufacturing processes evolve, the VFFS machine continues to adapt, offering tailor-made packaging solutions for unique product requirements.

The Indispensable Role of Multihead Weighers in VFFS Systems

While the VFFS packaging machine forms and seals the bag, the accuracy and speed of filling are critically dependent on the weighing system it's paired with. This is where Kenwei's expertise truly shines. As a powerful manufacturer of multi-head weighers, we understand that precise weighing is the cornerstone of efficient and profitable packaging. Our multi-head weighers are designed to integrate seamlessly with VFFS machines, creating a complete, high-performance automated weighing and packaging system.

Kenwei multi-head weighers are renowned for their high speed and high precision. They work by combining multiple weigh buckets, each containing a small amount of product, to achieve the target weight with extreme accuracy and speed. This innovative approach drastically reduces product giveaway, saving manufacturers significant costs over time, and ensures every bag contains the exact specified amount. Whether it's our multi-head weighers, linear weighers, or robust check weighers, Kenwei provides the vital link in the VFFS packaging chain, ensuring optimal performance.

We are committed to providing customers with one-stop automated weighing and packaging solutions. This means that from design and development to manufacturing, installation, commissioning, and after-sales service, Kenwei offers comprehensive support. Our ability to meet customer customization requirements ensures that the integrated VFFS and weighing solution is perfectly tailored to specific product needs and production line demands. This holistic approach has helped us establish a good brand image and a reputation for thoughtful and fast service in the packaging machinery industry.

Choosing the Right VFFS & Weighing Solution with Kenwei

Selecting the appropriate VFFS packaging machine and its accompanying weighing system is a critical decision for any business. It requires careful consideration of product characteristics, desired output, bag style, and budget. At Kenwei, located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province, we pride ourselves on our comprehensive capabilities and our commitment to becoming the world's leading weighing packing machine manufacturer.

When you partner with Kenwei, you gain access to our extensive experience in developing and manufacturing not just multi-head weighers, but also metal detectors and check weighers, all designed to integrate flawlessly into your automated packaging line. We offer bespoke solutions, leveraging our R&D strengths to adapt our high-speed, high-precision equipment to your unique challenges. Our dedicated team provides technical training and robust after-sales service, ensuring your investment continues to deliver peak performance for years to come. We believe in providing solutions that are not only efficient but also reliable and tailored to your specific operational needs.

Future Trends in VFFS Technology and Automated Packaging

The packaging industry is dynamic, constantly evolving with technological advancements and changing consumer demands. The VFFS packaging machine is no exception. We foresee several key trends shaping its future, all geared towards even greater efficiency, sustainability, and connectivity.

Firstly, there will be an increased emphasis on smart packaging and Industry 4.0 integration. VFFS machines will become more connected, offering real-time data analytics, predictive maintenance, and remote diagnostics. This will allow for greater operational control and minimize downtime. Secondly, sustainability will continue to drive innovation. Manufacturers will seek VFFS machines capable of handling a wider range of eco-friendly and recyclable film materials, reducing environmental impact. Lastly, customization and flexibility will remain paramount. As consumer preferences shift, VFFS systems will need to adapt quickly to new bag styles, sizes, and product formulations, reinforcing the need for partners like Kenwei who offer adaptable and customized automated weighing and packaging solutions.

Conclusion: The Enduring Value of VFFS Packaging Machines

The VFFS packaging machine is far more than just a piece of equipment; it's a cornerstone of modern manufacturing efficiency. Its diverse application scenarios, spanning snack foods, grains, powders, frozen items, pet food, and various non-food products, underscore its incredible versatility and indispensable role across numerous industries. The ability to deliver high-speed, high-precision packaging in a compact footprint makes it a superior choice for businesses aiming to optimize their production lines.

At Kenwei, we are proud to be at the forefront of this evolution. Our commitment to developing and manufacturing state-of-the-art multi-head weighers, linear weighers, and check weighers ensures that the filling component of your VFFS system operates with unparalleled accuracy and speed. By providing comprehensive, one-stop automated weighing and packaging solutions tailored to your unique customization requirements, we empower businesses to achieve higher throughput, reduce waste, and build a stronger brand reputation. As the packaging industry continues to advance, the VFFS machine, especially when integrated with Kenwei's cutting-edge weighing technology, will remain a vital component in delivering the quality and efficiency that today's market demands. Our vision to become the world's leading weighing packing machine manufacturer drives our continuous innovation and dedication to customer success.

Frequently Asked Questions About VFFS Packaging Machines

1. What does VFFS stand for in packaging?

VFFS stands for Vertical Form Fill Seal. It refers to a type of automated packaging machine that forms a bag from a roll of film, fills it with a product, and then seals the bag, all in a vertical orientation.

2. What types of products can a VFFS machine package?

VFFS machines are highly versatile and can package a wide range of products, including granular products (rice, coffee beans), powders (flour, spices, detergents), frozen foods (vegetables, fruits), snack foods (chips, pretzels), confectionery (candies), pet food (kibble), and various non-food items like small hardware parts or seeds.

3. How does a multihead weigher integrate with a VFFS machine?

A multihead weigher is typically positioned above the VFFS machine. It precisely weighs the product by combining small quantities from multiple hoppers to achieve the target weight. Once the correct weight is achieved, the product is quickly discharged into the formed bag within the VFFS machine, ensuring accurate and high-speed filling.

4. What are the main benefits of using a VFFS packaging machine?

Key benefits include high production speed and efficiency, precise and accurate product weighing (especially with integrated multihead weighers), versatility in handling various products and bag styles, cost-effectiveness through optimized film usage, and a compact, space-saving footprint in production facilities.

5. Can VFFS machines handle different bag sizes and styles?

Yes, VFFS machines are highly adaptable. By changing the forming tube and making appropriate adjustments, they can produce various bag sizes and styles, including pillow bags, gusseted bags, stand-up pouches, and quad seal bags, catering to diverse packaging requirements.

6. Is VFFS packaging suitable for fragile products?

Yes, VFFS machines can be configured with gentle handling systems, such as specialized feeders and discharge chutes, to carefully package fragile products like potato chips or delicate confectionery, minimizing breakage and maintaining product integrity.

7. How does Kenwei support businesses with VFFS packaging solutions?

Kenwei provides one-stop automated weighing and packaging solutions. We manufacture high-speed, high-precision multi-head weighers, linear weighers, and check weighers that seamlessly integrate with VFFS systems. Our services include design, manufacturing, marketing, installation, commissioning, technical training, and comprehensive after-sales support, tailored to meet specific customization requirements.

best multihead weigher choices for confectionery lines 2026

Best Combination Weigher Models 2026 for Snack Packaging

The B2B Buyer’s Guide to commercial food packaging machine

Combination Weigher Trends 2026: What Manufacturers Need to Know

About Cooperation Process

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

Can Kenwei customize equipment to meet my specific needs?

Yes! We offer customized solutions for all of our machines. Our team will work closely with you to understand your specific requirements and create a solution that meets your needs in terms of size, functionality, speed, and other factors.

How to operate it?

Many languages are available for global markets. There are not only detailed instructions, but also machine video for reference learning.

About Solution suggestions

Can Kenwei solutions be adapted for different product packaging types?

Yes, Kenwei solutions can handle a variety of packaging types, including bags, boxes, pouches, and bottles. We can customize machines to suit your packaging format, ensuring compatibility with your packaging equipment.

Double Filling VFFS Packaging Machine for Efficient Dual Product Packaging

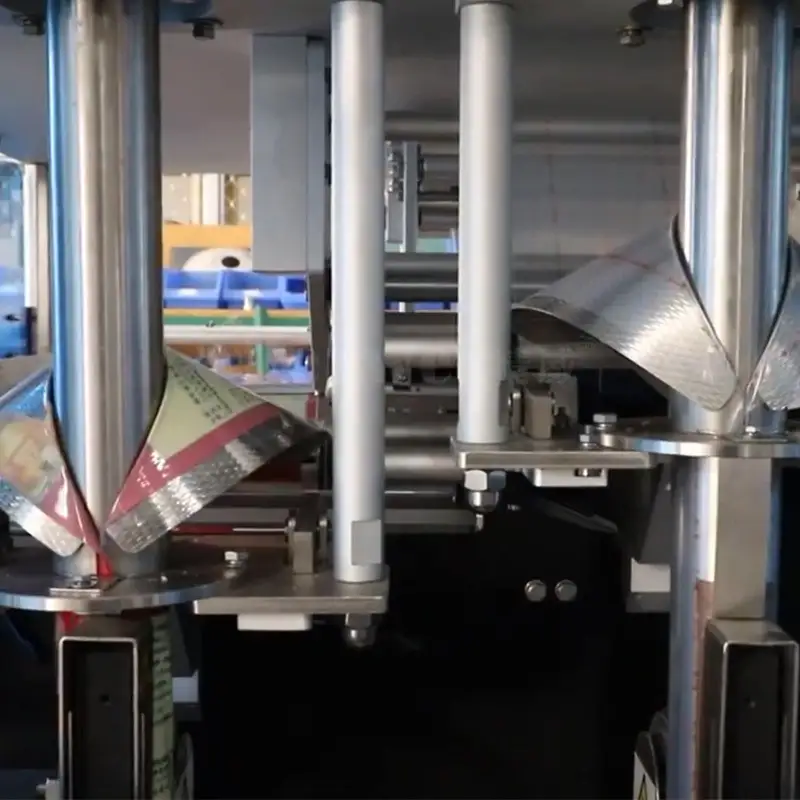

The Fully Automatic High-Speed Vertical Double Filling Form-Fill-Seal (VFFS) machine features a compact design and a complete range of packaging machines and auxiliary equipment, making it adaptable to various materials and space-efficient. It can handle a wide variety of laminated films, single-layer PE films, film thicknesses ranging from 0.04mm to 0.09mm, and paper membrane packaging. This VFFS machine is widely used in food, pharmaceutical, and chemical industries for packaging snacks, powders, liquids, and granular products. The machine forms bags from flat film rolls, fills them with products, and seals them vertically, improving packaging efficiency and ensuring consistent, high-quality production.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei