Packaging Secrets of Pre-made Hot Pot Soup Packets

Efficient and standardized production of food cooking bags is of course inseparable from professional and safe measuring and packaging equipment. In particular, the ingredients in the hot pot cooking package belong to a variety of mixed ingredients, including solid base ingredients, high-viscosity oils, seasoning soups, etc.? In the face of complex mixed ingredients, how do customize suitable and safe high-standard quantitative filling and packaging equipment? Let's learn how these hot pot pre-made soup dumplings are packaged.

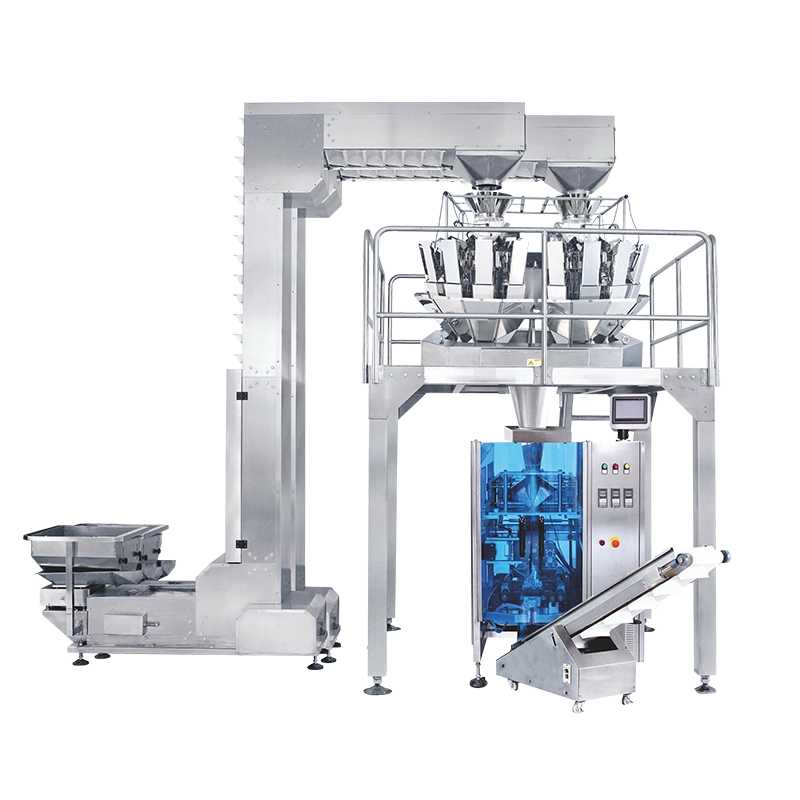

The system is equipped with Guangdong Kenwei's new 14 head two layers screw feeding multihead weigher. It adopts an IP65 waterproof case, and the contact parts are food-grade 304 stainless steel plates with small patterns and smooth and efficient operation.This combination weigher is widely applicable to the weighing requirements of more viscous pickled shredded vegetables such as mustard, pickled radish strips, etc. At the same time, it is matched with bag packaging machines and metering soup filling equipment, which is suitable for use in various specific production environments and supports a variety of Customized packaging requirements, comprehensive and cost-effective.

-

⦁ Double-layer screw feeding scheme, material control is more precise and has wider application.

-

⦁ The scraper-type double-door hopper can effectively solve the sticking phenomenon of super-viscous materials.

-

⦁ Two-point material detection function, accurate control of feeding time, and material thickness.

-

⦁ Accuracy range X (0.5); metering speed up to 50 packs/min.

Customer's request-

⦁ The actual single material measurement is 76 grams.

-

⦁ Set the precision to upper deviation 4 and lower deviation 3.

-

⦁ Equipped with a quantitative liquid injection device and a rotary bag-feeding packaging machine for sealing.

- Guangdong Kenwei has been focusing on the r&d and production of small measurement and high-precision quantitative weighing equipment for 16 years and continues to provide the food industry with high quality, efficient, and cost-effective multi-head combined weighing equipment, closely following the current market trend, and continuously enriching more competitive "weapons" for merchants.

-

About products customization

Can I customize the size of Kenwei machines?

Yes, we can tailor the dimensions of our machines to fit your available space and production layout. Whether you need compact machines or larger equipment, we can accommodate your size requirements.

About Solution suggestions

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

About After Sales Support

How about the after-sales service?

Warranty :2 years

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

About Cooperation Process

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

Single Multihead Weigher Mixing And Weighing Packaging System For Weighing Packaging Mixing Materials JW-B26

The Kenwei JW-B26 Single Multihead Weigher Mixing and Packaging System offers fully automated operation, completing feeding, weighing, filling, date printing, and product output with high accuracy and speed. Ideal for granules, slices, irregular shapes, and mixed products like candy, nuts, snacks, pet food, and even small hardware. Its versatility and precision make it a perfect solution for diverse packaging needs.

Combined weighing and powder packing machine with vacuum feeder JW-B6

The system includes a vacuum feeder, multihead weigher, and vertical packaging machine.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Food Metal Detector Manufacturer For Reject Defective Products G5020

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei