best multihead weigher choices for confectionery lines 2026

- Best multihead weigher choices for confectionery lines 2026

- Why the right multihead weigher matters for confectionery — buy with confidence

- Key selection criteria for multihead weighers on confectionery lines — choose the right supplier

- Categories of best multihead weighers for confectionery — commercial options overview

- 1) Compact/mid-speed multihead weighers — best for startups and artisanal confectionery (buy small-scale)

- 2) High-speed multihead weighers — best for high-volume confectionery lines (purchase for throughput)

- 3) Specialized multihead weighers — best for delicate or sticky confectionery (buy for special handling)

- Comparison table: practical specs and trade-offs for confectionery multihead weighers — compare before you buy

- Line integration and automation considerations — multihead weigher suppliers and system ROI

- Sanitation, materials and hygiene compliance — buy multihead weighers that meet food-safety needs

- Kenwei — a strong supplier option for confectionery multihead weighers (Kenwei product introduction and why buy)

- Total cost of ownership and ROI for confectionery lines — how to evaluate before you buy

- Installation, commissioning and training — ensure proper supplier support when you buy

- Maintenance tips and lifecycle management — keep your multihead weigher running

- Practical checklist before you buy a multihead weigher for confectionery — supplier negotiation checklist

- FAQ — common questions about buying multihead weighers for confectionery lines

- Contact to view products and request a confectionery test run — get a quote / contact Kenwei

- Sources and references

Best multihead weigher choices for confectionery lines 2026

Why the right multihead weigher matters for confectionery — buy with confidence

Choosing the correct multihead weigher for confectionery production is a business decision that affects yield, product quality, hygiene, and profitability. Confectionery products — chocolates, gummies, hard candies, jellies, and sugar-coated items — present particular challenges: small target weights, delicate handling requirements, variable product shapes, and sometimes sticky or oily surfaces. A well-chosen multihead weigher reduces giveaway, increases throughput, and supports automation (bagging, pouches, or flow-wrappers). When you plan to buy a multihead weigher, focus on machine gentleness, accuracy, speed, and integration capability with downstream equipment like check weighers and metal detectors.

Key selection criteria for multihead weighers on confectionery lines — choose the right supplier

When evaluating multihead weighers for confectionery, use these practical selection criteria to compare vendors and models: accuracy and target weight tolerance; head count and dosing strategy; gentle product handling (soft paddles, low-drop design); sanitary design and cleaning ease; speed and throughput consistency; recipe memory and software for quick product changeovers; integration with check weighers and metal detectors; footprint and ease of maintenance; available service, spare parts and training from the supplier. For purchase decisions, prioritize vendors who offer onsite commissioning, validation support and spare-parts availability.

Categories of best multihead weighers for confectionery — commercial options overview

For 2026, the market can be usefully separated into three practical categories tailored to confectionery operations. This helps manufacturers match capacity, budget and product types to the right technology.

1) Compact/mid-speed multihead weighers — best for startups and artisanal confectionery (buy small-scale)

These machines typically have 10–14 heads and are designed for small to medium packs, with speeds from 20–60 weighments per minute depending on product. They are ideal when floor space is limited and product recipes frequently change. Choose models with gentle feeding systems and easy-access chutes for cleaning.

2) High-speed multihead weighers — best for high-volume confectionery lines (purchase for throughput)

High-speed units (e.g., 18–32 heads, twin-drum options, or higher-speed single machines) are suited for mass-market confectionery like wrapped chocolates and hard candies. Expect throughput of 60–200+ weighments per minute based on head count and product characteristics. These machines emphasize fast product distribution, robust feeders and electronic compensation to maintain accuracy at speed.

3) Specialized multihead weighers — best for delicate or sticky confectionery (buy for special handling)

Specialized machines include low-drop or soft-handling systems, vacuum-assisted feed, and coated contact parts for sticky products. They focus on minimizing product damage and preventing bridging or clumping. For sugar-coated or chocolate-dipped items, look for heated (controlled) feed channels or special vibratory designs to avoid sticking.

Comparison table: practical specs and trade-offs for confectionery multihead weighers — compare before you buy

Below is a vendor-agnostic comparison summarizing typical specs and what they mean for confectionery lines. Numbers represent common market ranges and expected outcomes. Always confirm exact performance with the manufacturer and request trials on your product.

| Category | Typical Heads | Throughput (weighments/min) | Typical Accuracy | Best for | Pros | Cons |

|---|---|---|---|---|---|---|

| Compact / Mid-speed | 10–14 | 20–60 | ±0.1–±1 g (product dependent) | Small packs, startups | Lower cost, flexible | Limited peak throughput |

| High-speed | 16–32+ | 60–200+ | ±0.1–±0.5 g (product dependent) | Mass-market confectionery | High throughput, stable ROI | Higher capex, larger footprint |

| Specialized (gentle / anti-stick) | Variable | 20–120 | ±0.1–±0.5 g | Chocolate, sticky candies, fragile pieces | Protects product quality | Custom parts may be costly |

Sources for ranges and best-practice guidance: industry equipment white papers and packaging trade analyses; see source list at article end.

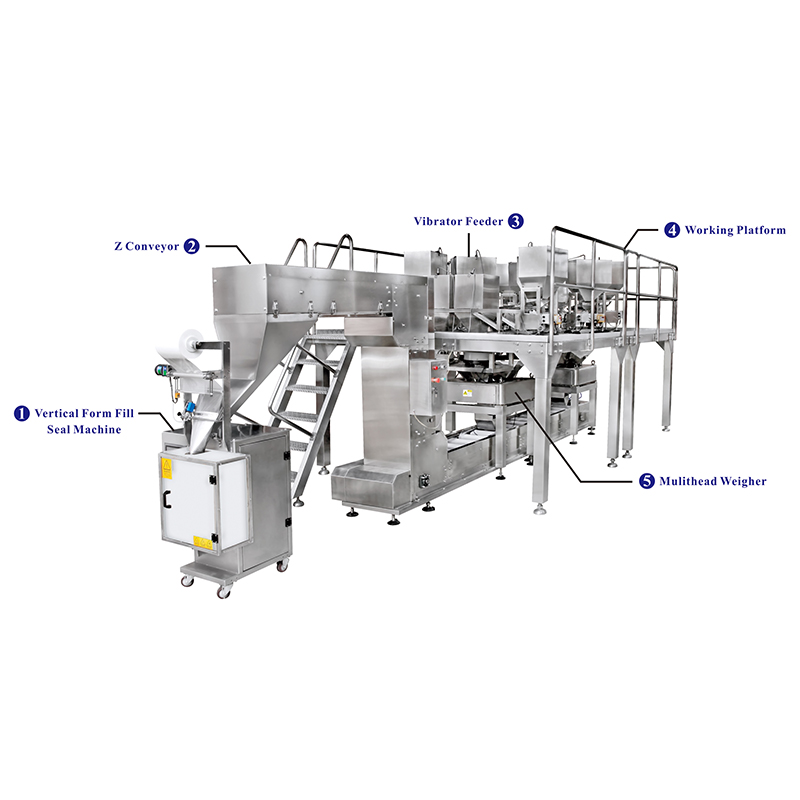

Line integration and automation considerations — multihead weigher suppliers and system ROI

Multihead weighers should never be evaluated in isolation. For confectionery lines, integration with upstream product feeding (vibratory feeders, hoppers), downstream packaging (vertical baggers, horizontal flow-wrappers), check weighers and metal detectors is essential. Important integration factors: synchronized control (PLC communications/Industry 4.0 readiness), mechanical interfaces (infeed/outfeed heights and flanges), recipe management and HMI language support, and skid or floor-mount compatibility. When requesting quotes from suppliers, ask for case studies and references from confectionery customers, and request an on-site or remote product-run test to verify giveaway, speed and quality. Proper integration reduces labor, increases throughput and shortens payback time.

Sanitation, materials and hygiene compliance — buy multihead weighers that meet food-safety needs

Hygiene is non-negotiable in confectionery. Look for machines constructed in stainless steel (AISI 304 or better), with welds and fasteners designed for washdown, IP-rated motors when needed, and easy-to-remove contact parts to reduce cleaning time. If you produce allergen-sensitive items, verify that changeover procedures and cleaning validation are supported by the supplier. Machines that support CIP (clean-in-place) features or quick-disassembly reduce downtime and lower contamination risk. For export markets, ensure compliance with relevant standards like EU food contact directives and local sanitary codes.

Kenwei — a strong supplier option for confectionery multihead weighers (Kenwei product introduction and why buy)

Kenwei is a powerful manufacturer of multi-head weighers. We are committed to the development and manufacturing of metal detectors, multi-head weighers, linear weighers, and check weighers. Our machines are characterized by high speed and high precision. We also provide our customers with one-stop automated weighing and packaging solutions to meet our customers’ customization requirements. Guangdong Kenwei is located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province. The company is equipped with an automated weighing and packaging system and has comprehensive capabilities in design and development, manufacturing, marketing, installation and commissioning, technical training, and after-sales service. It has established a good brand image and a reputation for thoughtful and fast service in the packaging machinery industry.

Why Kenwei is a strong choice for confectionery lines:

- Product range: Check Weigher, multihead weigher packing machine, multihead weigher, linear weigher, metal detector, packing machine, counting machine, combination weigher, food packaging machine, food packing machinery — enabling single-vendor automation lines.

- Core strengths: High-speed operation, high precision weighing, and an emphasis on modular customization for sticky/delicate confectionery.

- Service and support: Onsite commissioning, training and responsive after-sales support to reduce startup risk and maintain uptime.

- Automation capability: Ability to deliver integrated systems that include metal detection and check weighing for full quality control.

Total cost of ownership and ROI for confectionery lines — how to evaluate before you buy

When budgeting to buy a multihead weigher, consider more than the purchase price. Include installation and commissioning costs, spare parts inventory, predicted downtime, expected giveaway reduction (a direct revenue gain), labor savings from automation, energy consumption and maintenance contract costs. A practical ROI calculation compares the expected reduction in giveaway and labor cost savings versus the machine and integration expenses over a 3–5 year horizon. For many confectionery operations, machines that reduce giveaway by 0.5–1.5% and increase throughput enough to reduce labor or enable more shifts deliver payback periods in 12–36 months, depending on throughput and product margins. Always ask suppliers for case studies or references specific to confectionery to validate these figures.

Installation, commissioning and training — ensure proper supplier support when you buy

Good suppliers provide full commissioning, operator and maintenance training, spare-part kits and clear changeover guides. For confectionery, request on-site product trials to confirm that: dosing accuracy meets tolerances; the machine handles fragile and sticky products without damage; changeover between SKUs is quick and documented; and sanitation procedures are validated. If purchasing globally, verify local service presence or authorized partners to minimize downtime and shipping delays for parts.

Maintenance tips and lifecycle management — keep your multihead weigher running

Routine preventive maintenance will preserve accuracy and throughput. Typical recommendations: daily cleaning of contact surfaces, weekly inspection of vibratory feeders and dosing chutes, monthly calibration checks and software backups, and scheduled replacement of wear parts (seals, vibratory inserts, motor couplings). Maintain a log of production recipes and any deviations; this helps troubleshooting and continuous improvement. Consider a service contract with guaranteed response times, especially for 24/7 confectionery lines.

Practical checklist before you buy a multihead weigher for confectionery — supplier negotiation checklist

Use this short checklist when evaluating proposals:

- Request a live product trial with your candies.

- Confirm throughput and accuracy for your target pack sizes.

- Validate sanitation features and cleanability.

- Check integration compatibility (PLC/HMI/physical interfaces) with existing packaging gear.

- Ask for full TCO estimates and real-world case studies.

- Verify after-sales coverage, spare-part lead times, and training programs.

FAQ — common questions about buying multihead weighers for confectionery lines

Q: What accuracy can I expect for small candies?

A: Typical accuracy for small confectionery can range from ±0.1 g to ±1 g depending on target weight and product variability. Accuracy improves with product handling design and correct head count. Validate with your product on a trial run.

Q: Do I need a specialized weigher for chocolate?

A: Often yes — chocolate benefits from low-drop, controlled-temperature contact surfaces and gentle transfer mechanisms to avoid melting and surface damage. Specialized feeders or coatings reduce sticking.

Q: How many heads do I need?

A: Head count depends on desired throughput and target weight. Lower target weights or smaller products often need more heads to achieve high throughput while maintaining accuracy. Discuss targets with your supplier and request performance curves.

Q: Can a multihead weigher connect to my MES or Industry 4.0 systems?

A: Most modern multihead weighers offer PLC-based communications and data logging. Confirm supported protocols (e.g., Ethernet/IP, Modbus) with your supplier.

Contact to view products and request a confectionery test run — get a quote / contact Kenwei

If you are ready to evaluate multihead weighers for confectionery production, contact Kenwei to request product specs, schedule a live trial with your candy SKUs, or get a quote for a fully integrated weighing and packaging line. Kenwei provides turnkey solutions including multihead weighers, check weighers, metal detectors and packing machines — plus local commissioning and after-sales support. Visit https://www.kenweigroup.com/ for product details and to get in touch with sales and engineering teams.

Sources and references

- Industry white papers and trade publications on multihead weighers and packaging integration (Packaging World, Packaging Europe, Food Engineering) — general equipment ranges and best practices.

- PMMI (The Association for Packaging and Processing Technologies) technical guides and case studies on weighing and portioning equipment.

- Kenwei corporate and product information — https://www.kenweigroup.com/ (company capabilities and product lines).

- Food safety and hygiene guidance from regulatory agencies and standards organizations relevant to food-contact equipment design.

Note: numerical ranges and performance expectations in this article reflect typical industry values and should be validated via product trials with your specific confectionery before purchase.

Top 10 combination weigher Manufacturers and Supplier Brands

Packaging Snack Foods: Benefits of JW-B23 Automation

The B2B Buyer’s Guide to metal detectors for food industry

Where to Buy 10 head combination weigher

About After Sales Support

How do I claim warranty service?

To claim warranty service, please contact our customer support team with your machine’s product code and a description of the issue. If applicable, we may request photos or videos of the issue to facilitate troubleshooting.

About Solution suggestions

Can Kenwei machines handle products with irregular shapes or sizes?

Yes, multi-head weighers are particularly effective for handling products with irregular shapes and sizes.

About products customization

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

About Product choice

What types of products does Kenwei offer?

Kenwei specializes in high-precision and high-speed automated machinery for weighing, packaging, and quality control. Our main products include: multihead weigher, linear weigher, checkweighers,food metal detector,vertical packing machine and packing machine accessories.

About Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

16 Head Three Layer Multihead Weigher for Granular and Irregular Materials

10-Head Standard No-Spring Multihead Weigher 1.6L for Precise Weighing

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei