How Multihead Weighers Improve Packaging Efficiency 2026

- How Multihead Weighers Improve Packaging Efficiency 2026

- Why manufacturers choose a multihead weigher for modern packaging lines

- Speed and throughput: where multihead weighers win

- Accuracy and reduction of giveaway: improving yield and margins

- Integration and automation: Industry 4.0 capabilities

- Product versatility: from delicate snacks to irregular solids

- Hygiene, maintenance and uptime: design matters

- Selection criteria: choosing the right multihead weigher in 2026

- Comparison: multihead weigher vs linear weigher vs check weigher

- Quantifying ROI: typical benefits and payback drivers

- Kenwei: a one-stop provider of multihead weighers and packaging solutions

- Kenwei product range and core advantages

- How Kenwei supports deployment and long-term efficiency

- FAQ — Frequently Asked Questions about multihead weighers

- Contact Kenwei / See our products

- Sources and references

How Multihead Weighers Improve Packaging Efficiency 2026

Why manufacturers choose a multihead weigher for modern packaging lines

Packaging operations in 2026 face continuous pressure to increase throughput, reduce costs, maintain product quality, and meet stricter food safety and traceability requirements. A multihead weigher is a precision automated weighing device that simultaneously weighs portions using multiple weigh buckets and combinatorial algorithms. The result is faster cycle times, higher accuracy, and more stable production than many alternative systems. For manufacturers looking to buy a multihead weigher, understanding how it delivers measurable benefits across speed, accuracy, integration, and hygiene is critical to justify capital investments.

Speed and throughput: where multihead weighers win

One of the most direct ways a multihead weigher improves packaging efficiency is by increasing throughput. By operating multiple heads (buckets) in parallel and using high-speed combinational calculations, a multihead weigher can produce many accurate portions per minute while keeping the individual portion weight close to target. This is especially valuable for snack foods, frozen items, granules, and other high-volume products.

Compared to a single-head or basic linear weighing system, a multihead weigher typically delivers higher maximum feed rates while maintaining portion accuracy. That allows upstream and downstream equipment—feeders, baggers, or vertical form-fill-seal machines—to run at higher speeds without causing bottlenecks.

Accuracy and reduction of giveaway: improving yield and margins

Accuracy is one of the strongest ROI drivers for multihead weighers. Every package that contains slightly more product than required represents giveaway. Multihead weighers use many small-weight combinations to closely meet target weights with minimal overfill. Over time, reduced giveaway translates directly into cost savings.

Beyond reduced giveaway, improved accuracy lowers variability and customer complaints related to underfill/overfill. For food manufacturers operating on thin margins, cutting even a small percentage of giveaway can pay back equipment costs quickly.

Integration and automation: Industry 4.0 capabilities

Modern multihead weighers are built with digital controls, recipe management, and communication ports that enable integration into plant-wide automation systems. Benefits include:

- Remote monitoring of performance metrics (OEE, head faults, throughput)

- Automatic product changeovers using saved recipes, reducing downtime

- Direct integration with check weighers, metal detectors, and packaging machines for closed-loop process control

These features reduce human error, speed line adjustments, and provide traceability data required by regulatory agencies and retailers.

Product versatility: from delicate snacks to irregular solids

A well-specified multihead weigher handles a wide range of products: chips, nuts, frozen vegetables, dried fruit, confectionery, granules, and even irregular or sticky items. The correct combination of head count, bucket volume, and feeding system allows one machine to serve multiple SKUs—reducing the need to buy separate equipment for each product.

Manufacturers benefit from fewer changeovers and lower capital expense when a single multihead weigher covers several SKUs. Proper feeder design, vibration control, and selectable bucket speeds are key to preserving product integrity while maintaining high speeds.

Hygiene, maintenance and uptime: design matters

Sanitary design is an essential factor for food packaging efficiency. Multihead weighers with easy-clean frames, stainless-steel construction, open-access components, and sealed motors minimize downtime for cleaning and reduce contamination risk. Quick-release buckets and tool-free access further speed washdown and maintenance.

Design choices that reduce cleaning time and simplify maintenance directly increase the effective available production time (uptime). Predictive maintenance enabled by onboard diagnostics and remote monitoring also helps schedule service without sudden stoppages.

Selection criteria: choosing the right multihead weigher in 2026

When purchasing a multihead weigher, consider these practical selection factors to ensure you improve packaging efficiency:

- Throughput requirement: Match machine speed to the highest expected line speed, not just current output.

- Product characteristics: Bulk density, particle size, fragility, stickiness, and moisture affect head/bucket choice.

- Head count and bucket volume: More heads often give better combination accuracy; bucket size affects minimum/maximum weight ranges.

- Sanitary standards: Choose IP/food-grade finishes and CIP-compatible designs for wet or hygroscopic products.

- Integration and controls: Ensure PLC/HMI compatibility, Ethernet/IP or OPC-UA connectivity for Industry 4.0 requirements.

- After-sales support: Fast spare parts, commissioning, and local technical support reduce downtime.

Evaluating vendors against these criteria prevents common mistakes like under-sizing a machine for future line expansion.

Comparison: multihead weigher vs linear weigher vs check weigher

Below is a concise comparison of the three common weighing technologies used on packaging lines. Values are typical industry ranges and should be validated with specific manufacturer datasheets for precise planning.

| Characteristic | Multihead Weigher | Linear Weigher | Check Weigher |

|---|---|---|---|

| Primary function | Portion weighing for packaging | Continuous weighing for granular powders or solids | Post-pack verification and reject of under/overweight packs |

| Typical speed | Up to hundreds of packs/min depending on heads and product | Moderate speeds; better for powders/granules | High-speed verification; matches upstream line speed |

| Accuracy | High (minimal giveaway with combinatorial calculation) | Good for continuous dosing, less precise with variable sizes | Verification only—no portioning |

| Best for | Snacks, frozen, nuts, confectionery, mixed products | Powders, free-flowing granules | All packaged products requiring weight compliance |

| Integration | Direct into filling/bagging line; often combined with metal detectors | Often upstream of fillers or hoppers | Downstream to reject non-compliant packs |

Quantifying ROI: typical benefits and payback drivers

Calculating ROI for a multihead weigher relies on several measurable benefits:

- Reduced giveaway (material savings)

- Increased throughput (production capacity)

- Lower labor costs due to automation

- Fewer customer complaints/returns (quality savings)

As an example (illustrative): if improved accuracy reduces giveaway by 1% on a product costing $2.50/kg and annual throughput is 500,000 kg, the annual saving from reduced giveaway would be about $12,500. Adding labor savings and higher throughput often shortens payback to 12–36 months depending on machine cost and utilization. Always run a site-specific calculation with your finance and operations teams before purchase.

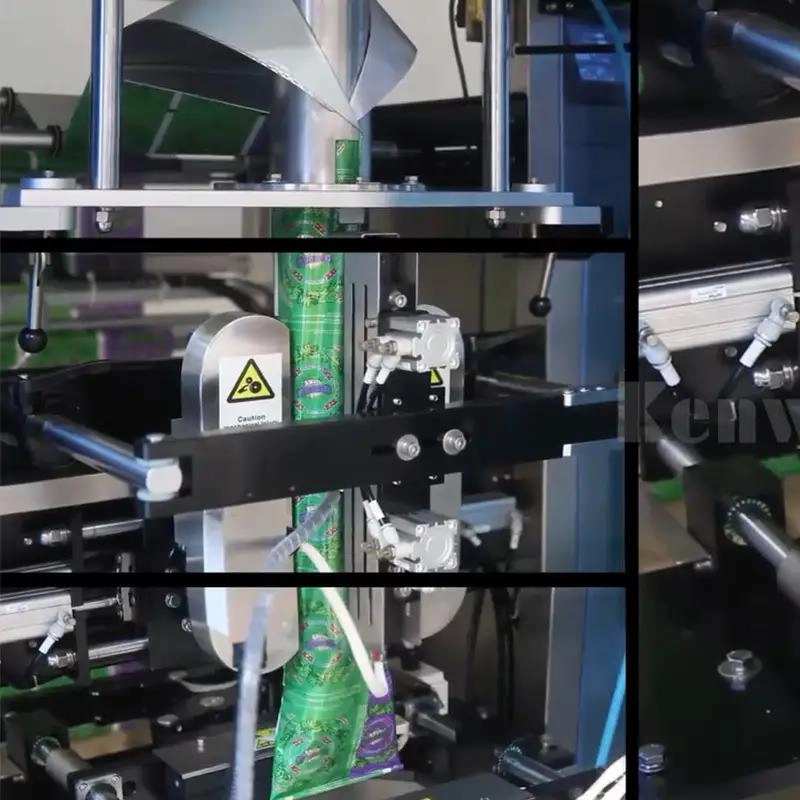

Kenwei: a one-stop provider of multihead weighers and packaging solutions

Kenwei is a powerful manufacturer of multi-head weighers. We are committed to the development and manufacturing of metal detectors, multi-head weighers, linear weighers, and check weighers. Our machines are characterized by high speed and high precision. We also provide our customers with one-stop automated weighing and packaging solutions to meet our customers’ customization requirements. Guangdong Kenwei is located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province. The company is equipped with an automated weighing and packaging system and has comprehensive capabilities in design and development, manufacturing, marketing, installation and commissioning, technical training, and after-sales service. It has established a good brand image and a reputation for thoughtful and fast service in the packaging machinery industry. Our vision is to become the world's leading weighing packing machine manufacturer. Our website is https://www.kenweigroup.com/

Kenwei product range and core advantages

Kenwei’s product lineup supports the full weighing and packaging chain: Check Weigher, multihead weigher packing machine, multihead weigher, linear weigher, metal detector, packing machine, counting machine, combination weigher, food packaging machine, and food packing machinery. Core competitive strengths include:

- High-speed, high-precision mechanical and control design that improves line throughput

- Customization capability for special products or packaging formats

- Integrated solutions—Kenwei supplies coordinated systems (weigher + metal detector + packaging) to minimize integration risk

- Local support and fast after-sales service, shortening downtime

- Focus on sanitary, easy-clean designs for food safety compliance

Choosing a manufacturer that offers both the equipment and engineering resources helps accelerate commissioning and achieve the efficiency gains described above.

How Kenwei supports deployment and long-term efficiency

Beyond selling equipment, Kenwei provides full lifecycle services: design and development, on-site installation and commissioning, operator and maintenance training, spare parts provisioning, and responsive after-sales service. For manufacturers seeking to automate or upgrade packaging lines in 2026, working with a partner who supports fast deployment and continuous improvement is essential to capture the promised efficiency benefits.

FAQ — Frequently Asked Questions about multihead weighers

Q: What is a multihead weigher used for?

A: A multihead weigher accurately portions product into pre-determined weights for packaging. It's widely used for snacks, confectionery, frozen foods, nuts, dried fruit, and similar products.

Q: How much production speed improvement can I expect?

A: Speed gains depend on product, head count, and integration. Multihead weighers typically allow higher throughput than single-head or basic linear systems for piece or irregular products. Validate expected speeds with manufacturer datasheets and on-site trials.

Q: How does a multihead weigher reduce giveaway?

A: By using many small-weight combinations and an optimized algorithm, multihead weighers achieve target weights with minimal overfill compared with less precise dosing methods.

Q: Are multihead weighers sanitary and easy to clean?

A: Modern designs prioritize stainless steel construction, open frames, quick-release buckets, and CIP-compatible features. Choose machines with food-grade finishes and easy-access parts for fast washdown.

Q: Can one multihead weigher handle multiple SKUs?

A: Yes—if you select appropriate bucket sizes, heads, and feeders. Manufacturers provide recipe storage for rapid changeovers between SKUs.

Q: What level of automation should I expect?

A: Expect PLC/HMI controls, recipe management, remote monitoring, and communication protocols (Ethernet/IP, OPC-UA) for Industry 4.0 integration. Confirm compatibility with your plant systems.

Q: How to decide on head count and bucket size?

A: This depends on target weight ranges, product characteristics, and throughput needs. Manufacturers will provide selection guidance—request a sizing study or on-site test if possible.

Contact Kenwei / See our products

If you are evaluating multihead weighers to improve packaging efficiency in 2026, contact Kenwei for consultations, site assessments, or product demonstrations. Our team can recommend the right multihead weigher packing machine, combination weigher, check weigher, or complete automated solution to meet your throughput, accuracy, and sanitary requirements. Visit our website to view product lines and request a quote: https://www.kenweigroup.com/

Sources and references

- Industry manufacturer datasheets and brochures (Ishida, Mettler Toledo, typical multihead weigher manufacturers) for performance characteristics and sanitary features.

- Packaging industry reports and trade associations (PMMI and industry whitepapers) on automation and Industry 4.0 trends.

- Market research summaries (e.g., Grand View Research and similar market analysis firms) on packaging machinery market growth and automation adoption.

- Packaging trade publications and case studies on giveaway reduction and ROI from multihead weighers (Packaging World, Food Engineering).

How to Choose a Vertical Packaging Machine for High Throughput

The B2B Buyer’s Guide to vffs bagging machine

Top combination mulithead weigher Manufacturers and Suppliers in China

Calibration Tips for Accurate Metal Detection in Food Lines

About Product choice

What types of products does Kenwei offer?

Kenwei specializes in high-precision and high-speed automated machinery for weighing, packaging, and quality control. Our main products include: multihead weigher, linear weigher, checkweighers,food metal detector,vertical packing machine and packing machine accessories.

About Solution suggestions

How can Kenwei solutions help reduce waste in my production process?

Kenwei solutions improve accuracy in weighing, packaging, and quality control, reducing the chances of overfill or underfill. This leads to less product waste and higher operational efficiency.

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

About After Sales Support

How about the after-sales service?

Warranty :2 years

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

16 Head Three Layer Multihead Weigher for Granular and Irregular Materials

10-Head Standard No-Spring Multihead Weigher 1.6L for Precise Weighing

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei