Calibration Tips for Accurate Metal Detection in Food Lines

- Calibration Tips for Accurate Metal Detection in Food Lines

- Why precise calibration matters for a metal detector for food industry

- Understand your detector: features that affect calibration

- Pre-calibration checklist: environmental and production factors

- Step-by-step calibration procedure for a metal detector for food industry

- Key calibration principle: calibrate to the worst-case scenario

- Selecting and using test pieces (reference standards)

- Calibration checkpoints and recommended frequency

- Common calibration challenges and practical solutions

- Validation, documentation, and regulatory alignment

- Example validation acceptance criteria

- How Food Metal Detector Manufacturer For Reject Defective Products G5020 helps with calibration

- Practical tips to reduce downtime during calibration

- FAQ — Calibration and use of a metal detector for food industry

- Q: How often should I fully calibrate my metal detector?

- Q: What size test piece should I use?

- Q: Can metal detectors find stainless steel?

- Q: What is product effect and how do I compensate for it?

- Q: When should I use X-ray instead of a metal detector?

- Contact and view product

- Authoritative references

Calibration Tips for Accurate Metal Detection in Food Lines

Why precise calibration matters for a metal detector for food industry

Accurate calibration of metal detectors in food processing lines is essential to protect consumers, prevent costly recalls, and maintain production efficiency. Poor calibration leads to false accepts (contaminants passing through), false rejects (good product wasted), regulatory non-compliance, and brand reputation damage. This article provides actionable calibration tips tailored to food manufacturers, packaging lines, and quality teams using a metal detector for food industry operations. Practical steps here apply to a wide range of detectors, including multi-frequency systems such as the Food Metal Detector Manufacturer For Reject Defective Products G5020. Accurate calibration also plays a key role in meeting regulatory requirements. To stay compliant, food manufacturers should follow HACCP and metal detector compliance guidelines that ensure food safety audits are passed with confidence.

Understand your detector: features that affect calibration

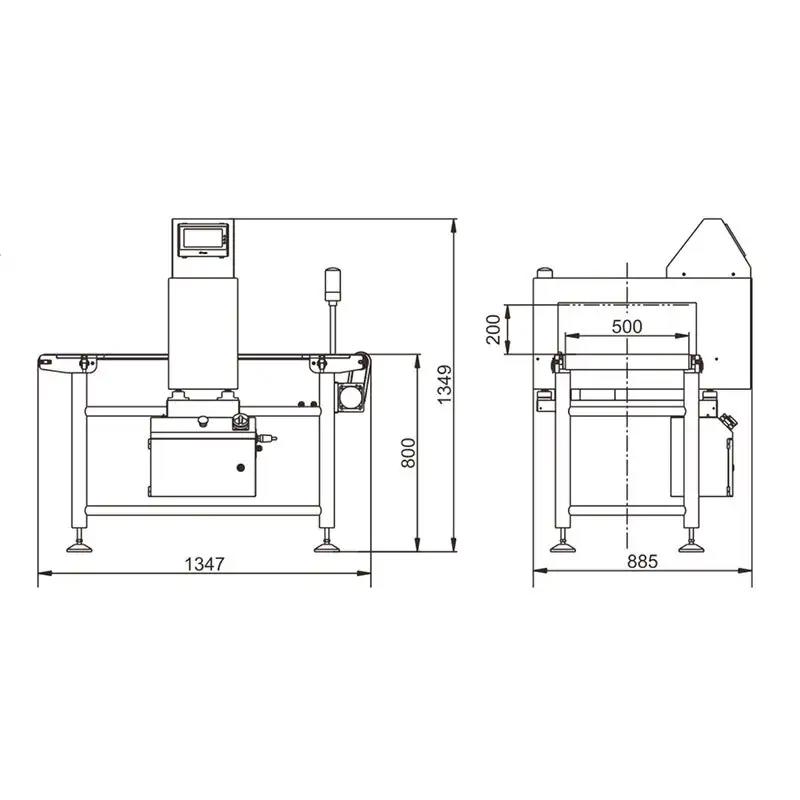

Before you begin calibration, understand the specific capabilities and limitations of your metal detector. Modern systems vary by detection technology (single-frequency, multi-frequency, head sizes), conveyor design, and software features like product-compensation (real-time metal effect suppression). Multi-frequency detectors typically offer better performance across product types and packaging materials, but they require thoughtful configuration. The Food Metal Detector Manufacturer For Reject Defective Products G5020 is a multi-frequency metal detector designed to reduce contamination risks with a specialized conveyor belt and to maintain high detection sensitivity. It is easy to disassemble for maintenance and is suitable for food, pharmaceuticals, spices, plastics, electronics, textiles, toys, and handicrafts.

The G5020 product summary:

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Pre-calibration checklist: environmental and production factors

Calibration must account for the environment and the product stream. Use this checklist before adjusting sensitivity:

- Stabilize environmental conditions: Allow the detector to warm up (typically 15–30 minutes) and reach stable temperature.

- Minimize electrical noise: Verify nearby equipment, variable-frequency drives (VFDs), and wireless devices are not generating interference.

- Set normal running speed: Calibrate at the conveyor speed used in production; speed affects sensitivity.

- Maintain consistent product presentation: Use representative samples including typical variations (moisture, fat content, size, and packaging).

- Clean and align the conveyor: Remove debris, confirm belt tracking, and ensure metal-free conveyor supports if applicable.

- Document baseline: Record current settings, firmware version, and last calibration date before changes.

Step-by-step calibration procedure for a metal detector for food industry

Follow a structured procedure for reproducible results. The steps below are industry-proven and vendor-agnostic; adapt them to G5020 or your model's interface.

- Warm-up and self-test: Power on, run built-in diagnostics, and allow the unit to stabilize.

- Set operating mode: Choose multi-frequency or specific frequency modes based on product characteristics.

- Establish product effect compensation: Run product effect tests to let the detector learn the normal signature of the product while it's moving.

- Choose test pieces: Use calibrated reference test pieces (spheres and rods) starting from the smallest sizes relevant to your risk profile.

- Position test pieces correctly: Test at the worst-case position across the aperture (e.g., far edge, center, and low/high on the belt) and on multiple orientations for elongated pieces.

- Adjust sensitivity incrementally: Increase sensitivity until the smallest acceptable test piece is detected reliably in repeated trials (typically 3 of 3 or 10 of 10 depending on SOP).

- Set reject logic: Configure the rejection device timing and verification (e.g., double-check chute) and ensure it does not introduce false positives.

- Verify detection on packaged products: Repeat tests with common packaging formats and combinations (metalized film, trays, cans).

- Document and lock settings: Save the calibrated profile, generate a calibration record, and apply appropriate access controls to settings.

Key calibration principle: calibrate to the worst-case scenario

Always calibrate based on the worst-case product presentation: the product and packaging combination that most reduces detection sensitivity. For many baked, frozen, or metalized-packaged products this is crucial. Calibrating to an average product can leave vulnerabilities.

Selecting and using test pieces (reference standards)

Choosing correct test pieces is one of the most important elements for meaningful calibration. Reference pieces typically come in spheres and rods, made of iron, stainless steel, and aluminum to represent a range of likely contaminants.

- Start with smallest sizes required by your internal risk assessment or regulatory guidance.

- Use multiple metal types: ferrous (iron), non-ferrous (aluminum), and stainless (304/316) since stainless is harder to detect.

- Test orientations: For rods or flat pieces, test in several orientations (long axis parallel and perpendicular to the conveyor).

- Keep traceable calibration records for test pieces: Replace or recalibrate them if they are damaged or corroded.

Calibration checkpoints and recommended frequency

Below is a practical table showing typical calibration and verification intervals. Adjust frequencies to match your HACCP plan, production risk, and regulatory requirements.

| Checkpoint | Recommended Frequency | Acceptable Tolerance / Action | Tools Required |

|---|---|---|---|

| Daily verification (sensitivity check) | Start of shift | Detects 1–2 representative test pieces (or SOP-defined piece); investigate if fails | Reference test pieces, log sheet |

| Full calibration | Monthly or when product changes | Detects smallest defined piece across worst-case positions | Full set of test pieces, documentation |

| After maintenance or belt change | Immediately | Full verification required | Tools for mechanical checks, test pieces |

| After electrical/line changes | Immediately | Verify no added noise; re-calibrate if performance degraded | Oscilloscope (optional), test pieces |

| Annual audit calibration | Yearly | Independent validation or calibration certificate | Certified lab or third-party inspector |

Common calibration challenges and practical solutions

Food lines pose specific challenges. Below are common problems and how to resolve them.

- High product effect (wet, salty, fatty products): Use multi-frequency detectors and increase product compensation; run validation with real product samples.

- Metalized packaging or printing: Consider X-ray inspection for metalized films or use combined inspection strategies; adjust detector settings and validate against packages.

- Electromagnetic interference (EMI): Physically separate noisy equipment, ground the detector, and use ferrite filters on cables. If EMI persists, schedule calibration during low-noise windows.

- Conveyor mechanical issues: Ensure belt tracking and no metal fragments from wear. Replace or repair worn parts that introduce false signals.

- Variability in product presentation: Standardize product loading orientation and use in-line dividers to reduce variability.

Validation, documentation, and regulatory alignment

Calibration is only one part of a compliant metal detection program. Validate that calibrated settings meet your HACCP/food safety plan requirements and industry standards (ISO 22000, BRCGS) and keep traceable records. A robust program includes:

- Calibration records with dates, operator names, test-piece ID, and detection results.

- Change control for any setting modifications.

- Audit-ready SOPs describing daily checks, full calibration, and corrective action criteria.

- Periodic third-party verification or laboratory certification for critical lines.

Example validation acceptance criteria

Your acceptance criteria should be risk-based. Example: a production line may require 10 consecutive detections of the smallest defined stainless-steel test piece in the worst-case position before accepting a new calibration profile.

How Food Metal Detector Manufacturer For Reject Defective Products G5020 helps with calibration

The G5020's multi-frequency architecture reduces product effect sensitivity and provides more stable readings across diverse products — a significant advantage when calibrating lines with variable recipes or packaging. The specialized conveyor minimizes metal contamination from mechanical parts and simplifies worst-case positioning tests through easy disassembly. Key benefits relevant to calibration and ongoing verification:

- Multi-frequency detection reduces the need for repeated re-tuning across different products.

- Easy-to-disassemble conveyor enables faster cleaning and repeatable test-piece placement for reliable calibrations.

- High detection sensitivity and digital logging options allow clearer evidence during audits.

- Robust mechanical design reduces false alarms from worn metal parts.

Practical tips to reduce downtime during calibration

Calibration doesn't have to halt production for long. Apply these tips to minimize downtime:

- Use a trained operator or calibration team and maintain a concise checklist.

- Keep pre-labeled test kits and spares on-site for quick use.

- Schedule full calibrations during product changeovers or planned maintenance windows.

- Use saved detector profiles for popular products to restore settings quickly after checks.

FAQ — Calibration and use of a metal detector for food industry

Q: How often should I fully calibrate my metal detector?

A: Full calibration is commonly performed monthly or whenever the product, packaging, conveyor, or electrical environment changes. Daily verification checks should be performed at the start of each shift.

Q: What size test piece should I use?

A: Choose the smallest test piece your risk assessment requires to detect. Typical programs use 2–5 mm ferrous, 3–6 mm non-ferrous, and slightly larger stainless specimens depending on consumer risk and product effect.

Q: Can metal detectors find stainless steel?

A: Yes, but stainless (especially austenitic 304/316) is less magnetic and harder to detect. Use specific stainless test pieces and consider multi-frequency detectors such as the G5020 to improve detection.

Q: What is product effect and how do I compensate for it?

A: Product effect is the influence of the product’s conductivity and dielectric properties on detector signals. Compensate via product learning/configuration on the detector, use test pieces on product samples, and select appropriate frequency modes.

Q: When should I use X-ray instead of a metal detector?

A: X-ray is preferable when products have metalized packaging, high product effect, or you need to detect non-metallic contaminants (glass, stone). Many factories use both technologies in complementary roles.

Contact and view product

For hands-on support, calibration services, or to evaluate the Food Metal Detector Manufacturer For Reject Defective Products G5020 on your line, contact our sales and technical team. We offer factory acceptance testing, on-site commissioning, and training to ensure your metal detector for food industry operations meet your safety and productivity goals. View product details and request a quote to schedule a demonstration.

Authoritative references

For further guidance and regulatory context, consult these authoritative resources:

- U.S. Food and Drug Administration (FDA) — Food Safety Modernization Act (FSMA): https://www.fda.gov/food/food-safety-modernization-act-fsma

- Codex Alimentarius Commission (FAO/WHO): http://www.fao.org/fao-who-codexalimentarius/en/

- ISO 22000 — Food safety management systems: https://www.iso.org/standard/65464.

- BRCGS — Global Standard for Food Safety: https://www.brcgs.com/

- AOAC International — analytical and testing methods: https://www.aoac.org/

- Metal detector (general background) — Wikipedia: https://en.wikipedia.org/wiki/Metal_detector

Maintaining accurate calibration on a metal detector for food industry lines protects consumers, reduces waste, and supports regulatory compliance. Use structured procedures, representative test pieces, and a documented verification program. When paired with devices like the Food Metal Detector Manufacturer For Reject Defective Products G5020, manufacturers gain greater sensitivity and easier maintenance to keep detection performance reliable.

The B2B Buyer’s Guide to combination weigher packing line

Optimizing Snack Packaging with Multihead Weigher Machines

Top 10 linear weigher Manufacturers and Supplier Brands

Best 10 head multihead weigher manufacturers and supplier brands

About After Sales Support

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

About Price and payment

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

About Product choice

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

About products customization

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

Dropped Metal Detector for Powder Granules For Food Industry

Enhance food safety with Kenwei’s Dropped Metal Detector for Powder Granules. This advanced food metal detector ensures precise detection in the food industry, safeguarding products and maintaining high quality standards throughout processing.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei