The latest trends for linear weigher packaging machine

- The Latest Trends for Linear Weigher Packaging Machine in 2025

- Rising Demand for Automation in Linear Weigher Packaging Machines

- Smart Technology Integration in Linear Weigher Packaging Machines

- Sustainability Driving Innovations in Linear Weigher Packaging Machines

- Customization and Flexibility in Linear Weigher Packaging Machines

- High-Speed Performance in Linear Weigher Packaging Machines

- Enhanced Precision with Digital Load Cells in Linear Weigher Packaging Machines

- Compact Designs for Space Efficiency in Linear Weigher Packaging Machines

- Cost-Effective Maintenance and Durability of Linear Weigher Packaging Machines

- Growing Applications Across Industries for Linear Weigher Packaging Machines

- Conclusion: Stay Ahead with the Latest Linear Weigher Packaging Machine Trends

The Latest Trends for Linear Weigher Packaging Machine in 2025

Linear weigher packaging machines have become essential tools in industries such as food processing, pharmaceuticals, and manufacturing, where precision and efficiency in weighing and packaging are critical. As we move into 2025, the industry is witnessing transformative trends driven by technological advancements and changing consumer demands. At Kenwei, a trusted name in multi-head weighers and linear weighers, we are at the forefront of these innovations, providing high-speed and high-precision solutions to meet diverse needs. In this blog, we’ll explore the latest trends for linear weigher packaging machines and how they can elevate your operations.

Rising Demand for Automation in Linear Weigher Packaging Machines

Automation is no longer a luxury but a necessity in modern packaging lines. Businesses are increasingly adopting automated linear weigher packaging machines to streamline processes, reduce labor costs, and improve accuracy. According to recent industry reports, the global packaging automation market is expected to grow from USD 80.34 billion in 2024 to USD 182.49 billion by 2035, reflecting a strong compound annual growth rate (CAGR). At Kenwei, our linear weighers are designed to integrate seamlessly into automated systems, ensuring minimal downtime and maximum productivity for your linear weigher packaging machine needs.

Smart Technology Integration in Linear Weigher Packaging Machines

The integration of smart technologies like IoT (Internet of Things) and AI (Artificial Intelligence) is revolutionizing the linear weigher packaging machine landscape. These technologies enable real-time monitoring, predictive maintenance, and data-driven decision-making. For instance, smart linear weighers can detect and adjust for discrepancies in product weight instantly, reducing waste and ensuring consistency. Kenwei’s advanced linear weigher packaging machines come equipped with user-friendly interfaces and digital load cells for precise control, helping businesses stay ahead in a competitive market.

Sustainability Driving Innovations in Linear Weigher Packaging Machines

Sustainability is a key focus for industries worldwide, and the packaging sector is no exception. Companies are seeking eco-friendly solutions to meet regulatory standards and consumer expectations. Linear weigher packaging machines are now being designed to work with biodegradable and recyclable packaging materials. Additionally, energy-efficient designs help reduce the carbon footprint of operations. At Kenwei, we are committed to supporting sustainable practices by offering linear weigher packaging machines that optimize material usage and minimize waste, ensuring your business contributes to a greener future.

Customization and Flexibility in Linear Weigher Packaging Machines

Every industry has unique needs, and the demand for customizable linear weigher packaging machines is on the rise. Whether you’re packaging grains, snacks, or pharmaceutical tablets, flexibility in equipment is crucial. Modern linear weighers, like those from Kenwei, offer adjustable parameters, multi-language touch screens, and the ability to handle various product types in a single discharge. This versatility ensures that your linear weigher packaging machine can adapt to changing production requirements without the need for costly upgrades.

High-Speed Performance in Linear Weigher Packaging Machines

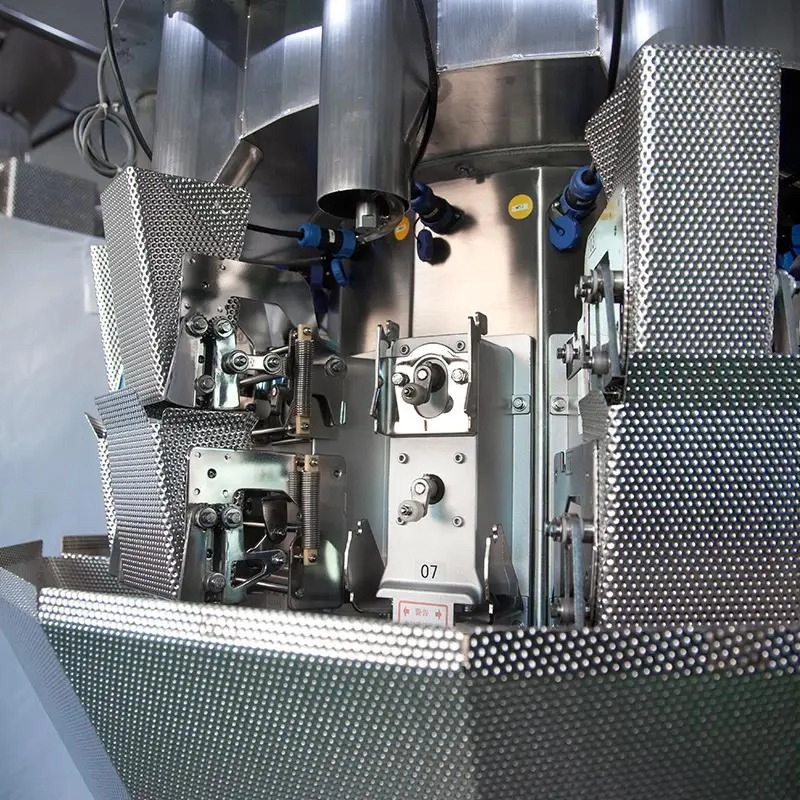

Speed is a game-changer in today’s fast-paced market. High-speed linear weigher packaging machines are becoming the norm as businesses strive to meet tight deadlines and high-volume demands. With innovations in vibratory feeders and motor drive systems, these machines can weigh and dispense products at impressive rates without compromising accuracy. Kenwei’s linear weighers are engineered for high-speed operations, making them the ideal choice for businesses looking to boost output with a reliable linear weigher packaging machine.

Enhanced Precision with Digital Load Cells in Linear Weigher Packaging Machines

Accuracy is the backbone of any weighing system, and recent advancements in digital load cell technology have taken precision to new heights in linear weigher packaging machines. These components ensure consistent measurements, even for uneven or free-flowing materials like seeds, pulses, or snacks. At Kenwei, our linear weighers are equipped with high-precision digital load cells to guarantee accurate portioning, helping you maintain product quality and customer satisfaction with every use of your linear weigher packaging machine.

Compact Designs for Space Efficiency in Linear Weigher Packaging Machines

Space constraints are a common challenge in manufacturing facilities, and the trend toward compact linear weigher packaging machines addresses this issue effectively. Modern designs focus on smaller footprints without sacrificing performance, making them ideal for businesses with limited floor space. Kenwei’s linear weighers are crafted to fit into tight production lines while delivering the same high-speed and precision standards you expect from a top-tier linear weigher packaging machine.

Cost-Effective Maintenance and Durability of Linear Weigher Packaging Machines

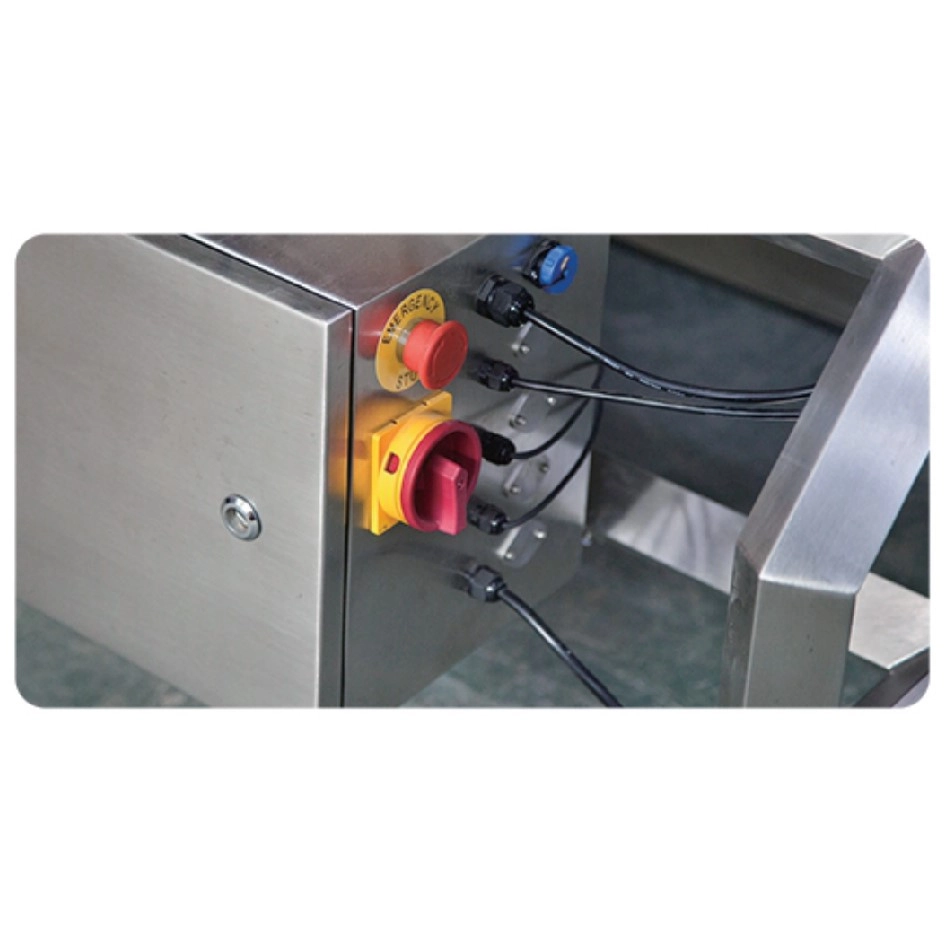

Maintenance costs and machine downtime can significantly impact a company’s bottom line. Thankfully, the latest linear weigher packaging machines are built with durability and ease of maintenance in mind. Features like plug-in motor drive boards simplify repairs, reducing both time and expense. Kenwei’s commitment to quality ensures that our linear weigher packaging machines are built to last, offering long-term reliability and cost savings for your business.

Growing Applications Across Industries for Linear Weigher Packaging Machines

The versatility of linear weigher packaging machines has led to their adoption across a wide range of industries. From food and beverage to pharmaceuticals and agriculture, these machines handle everything from dry fruits and chips to fertilizers and plastic granules. This broad applicability makes them a valuable investment for any business. Kenwei’s linear weighers cater to diverse sectors, providing tailored solutions to meet the unique demands of each industry with our advanced linear weigher packaging machine technology.

Conclusion: Stay Ahead with the Latest Linear Weigher Packaging Machine Trends

The linear weigher packaging machine industry is evolving rapidly, with trends like automation, smart technology, sustainability, and customization shaping the future. As a leader in weighing and packaging solutions, Kenwei is dedicated to helping businesses leverage these innovations to improve efficiency, reduce costs, and meet market demands. Whether you’re looking to upgrade your current setup or invest in a new linear weigher packaging machine, our team at Kenwei is ready to provide high-speed, precise, and customized solutions. Visit our website to explore our range of products and discover how we can support your growth in 2025 and beyond.

Frequently Asked Questions (FAQs) About Linear Weigher Packaging Machines

1. What is a linear weigher packaging machine?

A linear weigher packaging machine is a specialized equipment used to weigh and dispense precise quantities of products like grains, snacks, or pharmaceuticals. It ensures accuracy and efficiency in packaging processes, making it ideal for various industries.

2. How does a linear weigher packaging machine improve productivity?

By automating the weighing and dispensing process, a linear weigher packaging machine reduces manual labor, minimizes errors, and speeds up production. This results in higher output and consistent product quality.

3. Can a linear weigher packaging machine handle different products?

Yes, modern linear weighers are highly versatile and can handle a wide range of products, from dry goods to uneven materials. Kenwei’s machines offer adjustable settings to accommodate diverse needs.

4. What industries use linear weigher packaging machines?

These machines are widely used in food processing, pharmaceuticals, agriculture, and manufacturing. They are perfect for packaging items like nuts, seeds, tablets, and granules with precision.

5. Why choose Kenwei for linear weigher packaging machines?

Kenwei offers high-speed, high-precision linear weighers backed by comprehensive design, manufacturing, and after-sales support. Our solutions are tailored to meet your specific requirements, ensuring long-term value.

Scalability: Future-Proofing Your Vertical Packaging Investment

Integrating backup systems with 14 head multihead weighers

The latest trends for multihead weighing machine

G5020 Food Metal Detector: Ensuring Precision Rejecting Defects

About Solution suggestions

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

About Cooperation Process

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

About Price and payment

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

About products customization

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

Semi Automatic Vacuum Feeding Linear Weigher System for Powder and Small Granules Weighing JW-B19

The Kenwei JW-B19 Semi-Automatic Vacuum Feeding Linear Weigher is ideal for precise weighing of powders and small granules like sugar, salt, rice, coffee, and milk powder. With full automation, high accuracy, and space-saving design, it boosts efficiency while reducing labor and cost. Perfect for industries needing reliable, flexible, and compact weighing solutions.

3 Head Linear Weigher Packaging Machine for Small Granules

High speed single head linear weigher for sugar sesame weighing

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei