The latest trends for linear weigher manufacturer

- The Latest Trends for Linear Weigher Manufacturer in 2025

- 1. Automation Driving Efficiency for Linear Weigher Manufacturers

- 2. Smart Technology Integration in Linear Weigher Manufacturing

- 3. Sustainability as a Priority for Linear Weigher Manufacturers

- 4. Customization Demands Shaping Linear Weigher Manufacturing

- 5. High-Speed and Precision: Core Focus for Linear Weigher Manufacturers

- 6. Growth in Emerging Markets for Linear Weigher Manufacturers

- 7. Regulatory Compliance and Safety Standards in Linear Weigher Manufacturing

- 8. End-to-End Solutions by Linear Weigher Manufacturers

- 9. Investment in R&D by Linear Weigher Manufacturers

- 10. Enhanced After-Sales Service by Linear Weigher Manufacturers

- Conclusion: Leading the Future as a Linear Weigher Manufacturer

The Latest Trends for Linear Weigher Manufacturer in 2025

As the packaging industry evolves at a rapid pace, staying ahead of trends is crucial for businesses aiming to remain competitive. For a leading linear weigher manufacturer like Kenwei, understanding and adapting to these changes is not just an option but a necessity. At Kenwei, located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province, we are committed to delivering cutting-edge solutions through our high-speed, high-precision linear weighers, multi-head weighers, metal detectors, and check weighers. In this article, we’ll explore the latest trends shaping the linear weigher manufacturing sector in 2025 and how we are pioneering innovation to meet global demands.

1. Automation Driving Efficiency for Linear Weigher Manufacturers

Automation continues to be a game-changer for every linear weigher manufacturer. In 2025, the integration of automated systems in weighing and packaging processes is no longer a luxury but a standard. According to industry insights, the global weighing equipment market is experiencing significant growth due to increased automation, particularly in industries like food, pharmaceuticals, and agriculture. At Kenwei, our linear weighers are designed to seamlessly integrate with automated production lines, reducing labor costs and improving output. This trend ensures faster operations and minimizes human error, helping businesses scale efficiently.

2. Smart Technology Integration in Linear Weigher Manufacturing

Smart technology is transforming the landscape for every linear weigher manufacturer. The rise of IoT (Internet of Things) and AI-powered systems allows machines to communicate, analyze data, and optimize performance in real-time. Recent reports suggest that smart weighing systems are boosting industrial applications by enhancing accuracy and connectivity. At Kenwei, we are embedding intelligent features into our linear weighers to provide predictive maintenance alerts and performance analytics. This not only improves the lifespan of our machines but also ensures consistent precision for our clients’ packaging needs.

3. Sustainability as a Priority for Linear Weigher Manufacturers

Sustainability is no longer a buzzword but a critical focus for any linear weigher manufacturer. With growing consumer and regulatory pressure to reduce environmental impact, manufacturers are adopting eco-friendly practices. In 2025, there’s a noticeable shift towards energy-efficient machines and sustainable packaging materials. Kenwei is committed to this cause by designing linear weighers that consume less power without compromising on speed or accuracy. Additionally, our one-stop automated weighing and packaging solutions help clients minimize material waste, aligning with global sustainability goals.

4. Customization Demands Shaping Linear Weigher Manufacturing

Every industry has unique requirements, and customization is a key trend for a linear weigher manufacturer in 2025. Whether it’s food processing, pharmaceuticals, or agriculture, clients are seeking tailored solutions to meet specific packaging needs. At Kenwei, we pride ourselves on offering personalized linear weigher systems that cater to diverse product types and weights. Our comprehensive capabilities in design and development allow us to create bespoke solutions, ensuring that our clients achieve optimal results with every packaging cycle.

5. High-Speed and Precision: Core Focus for Linear Weigher Manufacturers

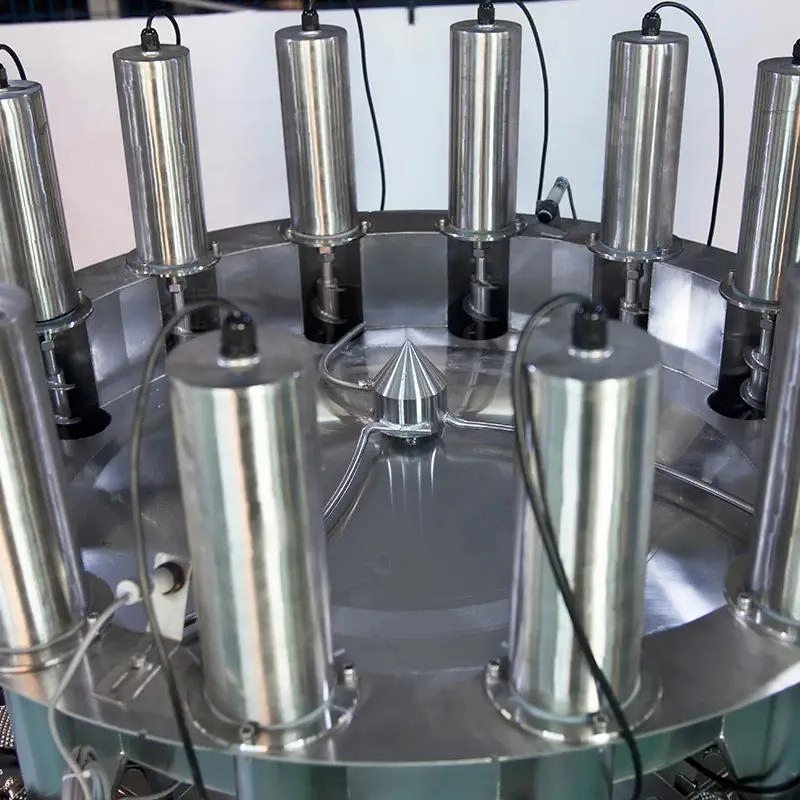

Speed and precision remain at the heart of what defines a top-tier linear weigher manufacturer. With consumer demand for faster production cycles increasing, manufacturers are under pressure to deliver machines that don’t compromise on accuracy. Kenwei’s linear weighers are engineered to handle high-speed operations while maintaining exceptional precision, even for small or granular products. This balance is crucial for industries like snacks and grains, where weight consistency directly impacts customer satisfaction and compliance with regulations.

6. Growth in Emerging Markets for Linear Weigher Manufacturers

Emerging markets are becoming a significant growth driver for every linear weigher manufacturer. As economies in regions like Asia-Pacific, Latin America, and Africa expand, the demand for efficient packaging machinery is skyrocketing. Industry reports indicate that the Asia-Pacific region, in particular, is a key growth area due to its booming food and beverage sector. Kenwei, strategically located in Guangdong Province, is well-positioned to serve these markets with our advanced linear weighers, offering local support and rapid service through our comprehensive after-sales network.

7. Regulatory Compliance and Safety Standards in Linear Weigher Manufacturing

Compliance with international safety and quality standards is a non-negotiable aspect for any linear weigher manufacturer. In 2025, stricter regulations in industries like food and pharmaceuticals are pushing manufacturers to ensure their equipment meets stringent guidelines. At Kenwei, safety and quality are embedded into every stage of our production process. Our linear weighers are designed to comply with global standards, ensuring that our clients can confidently use our machines without worrying about regulatory issues.

8. End-to-End Solutions by Linear Weigher Manufacturers

The demand for integrated, end-to-end solutions is a defining trend for a linear weigher manufacturer. Businesses are looking for partners who can provide complete systems, from weighing to packaging. Kenwei stands out by offering one-stop automated solutions that combine linear weighers with other equipment like check weighers and metal detectors. This approach streamlines operations for our clients, reduces downtime, and ensures compatibility across the production line, making us a trusted partner in the packaging machinery industry.

9. Investment in R&D by Linear Weigher Manufacturers

Innovation is the backbone of success for any linear weigher manufacturer. Continuous investment in research and development (R&D) is essential to keep pace with technological advancements and market needs. At Kenwei, we allocate significant resources to R&D to enhance the functionality and efficiency of our linear weighers. This commitment ensures that we remain at the forefront of the industry, delivering state-of-the-art solutions that help our clients stay competitive in a fast-evolving market.

10. Enhanced After-Sales Service by Linear Weigher Manufacturers

After-sales service is becoming a key differentiator for every linear weigher manufacturer. Clients expect not just high-quality machines but also reliable support post-purchase. Kenwei has built a strong reputation for thoughtful and fast service, offering installation, commissioning, technical training, and ongoing maintenance. Our goal is to ensure that every client experiences minimal downtime and maximum productivity, solidifying our position as a customer-centric linear weigher manufacturer.

Conclusion: Leading the Future as a Linear Weigher Manufacturer

The landscape for a linear weigher manufacturer in 2025 is dynamic and full of opportunities. From embracing automation and smart technology to prioritizing sustainability and customization, the industry is undergoing a significant transformation. At Kenwei, we are dedicated to staying ahead of these trends by delivering high-speed, high-precision linear weighers and comprehensive packaging solutions. With our vision to become the world’s leading weighing and packing machine manufacturer, we continue to innovate and provide unmatched value to our clients across the globe. For more information on how our linear weighers can elevate your business, visit us at https://www.kenweigroup.com/.

Frequently Asked Questions (FAQs)

What is a linear weigher, and how does it benefit businesses?

A linear weigher is a machine used to measure and dispense precise quantities of products, such as granules or powders, into packaging. It benefits businesses by ensuring accuracy, reducing waste, and speeding up the packaging process, which is vital for industries like food and agriculture.

Why choose Kenwei as your linear weigher manufacturer?

Kenwei stands out as a trusted linear weigher manufacturer due to our focus on high-speed, high-precision machines. We offer customized solutions, end-to-end automation, and exceptional after-sales service to ensure client satisfaction.

How are linear weigher manufacturers adapting to sustainability?

Many linear weigher manufacturers, including Kenwei, are designing energy-efficient machines and supporting sustainable packaging practices to reduce environmental impact, aligning with global eco-friendly trends.

Can linear weighers be customized for specific industries?

Yes, at Kenwei, we specialize in creating tailored linear weighers to meet the unique needs of industries like food, pharmaceuticals, and more, ensuring optimal performance for various product types.

What role does automation play in linear weigher manufacturing?

Automation is crucial for a linear weigher manufacturer as it enhances efficiency, reduces labor costs, and minimizes errors. Kenwei integrates automation into our systems to help clients achieve seamless production.

Combination Weigher Trends 2026: What Manufacturers Need to Know

ROI Analysis: Semi Automatic Powder Packing Machines for SMEs

Optimize speed and accuracy on 14 head multihead weighers for pickles

Energy-efficient rotary packing machine practices for factories

About Logistics

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

About products customization

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

About Solution suggestions

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

About After Sales Support

How about the after-sales service?

Warranty :2 years

About Cooperation Process

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Combined Check Weigher and Metal Detector for Food Industrial Weighing and Sorting

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei