The latest trends for combination food weigher

- The Latest Trends for Combination Food Weighers in 2025

- Why Combination Food Weighers Are Essential for Modern Food Packaging

- Trend 1: Integration of IoT and Smart Technology in Combination Food Weighers

- Trend 2: Focus on Sustainability with Energy-Efficient Combination Food Weighers

- Trend 3: Advanced Automation for High-Speed Combination Food Weighers

- Trend 4: Customization and Flexibility in Combination Food Weighers

- Trend 5: Enhanced Accuracy and Reduced Giveaway with Combination Food Weighers

- Trend 6: Improved Hygiene and Food Safety Standards in Combination Food Weighers

- Trend 7: Compact Designs for Space-Constrained Facilities Using Combination Food Weighers

- How Kenwei Stays Ahead with Combination Food Weigher Innovations

- Conclusion: Embrace the Future with Combination Food Weighers

The Latest Trends for Combination Food Weighers in 2025

In the fast-evolving food packaging industry, staying ahead of the curve is essential for businesses aiming to optimize efficiency and meet consumer demands. As a powerful manufacturer of multi-head weighers, Kenwei is at the forefront of innovation in this space. Located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province, Kenwei is committed to developing high-speed, high-precision solutions like metal detectors, multi-head weighers, linear weighers, and check weighers. Our one-stop automated weighing and packaging solutions are tailored to meet customization needs, solidifying our reputation for thoughtful and fast service. In this blog, we dive into the latest trends for combination food weighers in 2025, showcasing how these advancements can transform your operations. Visit us at kenweigroup.com to learn more about our cutting-edge technology.

Why Combination Food Weighers Are Essential for Modern Food Packaging

The demand for speed and accuracy in food packaging has never been higher. A combination food weigher plays a critical role in ensuring precise portioning of products, minimizing waste, and maximizing throughput. At Kenwei, our multi-head weighers are designed to handle a wide range of products, from snacks to frozen goods, with unparalleled precision. As consumer preferences shift towards packaged and ready-to-eat foods, businesses are relying on advanced combination food weighers to maintain consistency and meet stringent quality standards. This trend highlights the growing need for reliable equipment that boosts productivity while reducing operational costs.

Trend 1: Integration of IoT and Smart Technology in Combination Food Weighers

One of the most significant trends for combination food weighers in 2025 is the integration of the Internet of Things (IoT) and smart technology. IoT connectivity allows weighers to communicate with other machines in real-time, enabling seamless data sharing and remote monitoring. This innovation enhances operational efficiency by predicting maintenance needs and reducing downtime. At Kenwei, we are incorporating smart features into our combination food weighers to help businesses optimize their production lines. For instance, real-time analytics can identify bottlenecks, ensuring that your packaging process runs smoothly and efficiently.

Trend 2: Focus on Sustainability with Energy-Efficient Combination Food Weighers

Sustainability is a driving force in the food industry, and equipment manufacturers are responding by designing energy-efficient solutions. In 2025, combination food weighers are being developed with eco-friendly features to reduce energy consumption and support green initiatives. According to recent industry insights, sustainable practices are a top priority for over 60% of food manufacturers globally. Kenwei is committed to this trend by offering combination food weighers that minimize power usage without compromising on speed or accuracy. This not only lowers operational costs but also aligns with the growing demand for environmentally responsible packaging solutions.

Trend 3: Advanced Automation for High-Speed Combination Food Weighers

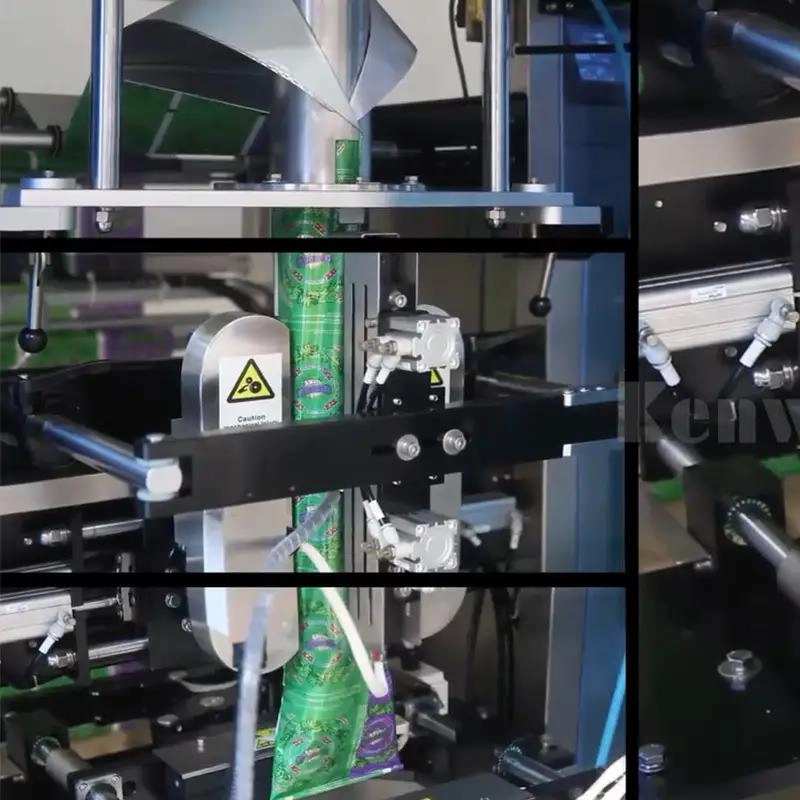

Automation continues to revolutionize the food packaging sector, and combination food weighers are no exception. In 2025, fully automated weighers are becoming the norm, capable of handling complex tasks with minimal human intervention. These systems improve consistency, reduce labor costs, and enhance safety by limiting manual handling. Kenwei’s high-speed combination food weighers are equipped with cutting-edge automation technology, designed to meet the needs of high-volume production lines. Whether you’re packaging snacks, grains, or confectionery, our solutions ensure precision at every step, helping you stay competitive in a fast-paced market.

Trend 4: Customization and Flexibility in Combination Food Weighers

Consumer preferences are diverse, and food manufacturers must adapt quickly to changing demands. This has led to a surge in demand for customizable combination food weighers that can handle a variety of products and packaging formats. In 2025, flexibility is key, and Kenwei is leading the way with tailored solutions that cater to specific industry needs. Our one-stop automated weighing and packaging systems are designed to accommodate different product types, weights, and speeds, ensuring that businesses can scale operations without investing in new equipment. This trend underscores the importance of versatile combination food weighers in meeting unique customer requirements.

Trend 5: Enhanced Accuracy and Reduced Giveaway with Combination Food Weighers

Product giveaway—when more product than necessary is included in a package—can significantly impact profitability. In 2025, advancements in combination food weigher technology are focusing on ultra-high precision to minimize giveaway. Kenwei’s multi-head weighers are engineered to deliver exact measurements, ensuring that every package meets weight specifications. This trend not only boosts cost-efficiency but also enhances customer satisfaction by maintaining consistent portion sizes. With error margins as low as 0.1 grams in some models, our combination food weighers set a new standard for accuracy in the industry.

Trend 6: Improved Hygiene and Food Safety Standards in Combination Food Weighers

Food safety remains a top concern for manufacturers, and combination food weighers are evolving to meet stricter hygiene standards in 2025. Equipment is now designed with easy-to-clean surfaces, stainless steel components, and compliance with international food safety regulations. At Kenwei, we prioritize hygiene in our combination food weighers, incorporating features like IP65 waterproof ratings and removable parts for thorough cleaning. This trend is crucial for industries dealing with sensitive products like meat, dairy, and ready-to-eat meals, ensuring that contamination risks are minimized.

Trend 7: Compact Designs for Space-Constrained Facilities Using Combination Food Weighers

Not all production facilities have ample space for large machinery, which is why compact combination food weighers are gaining traction in 2025. These smaller yet powerful systems are ideal for businesses with limited floor space, offering the same level of precision and speed as larger models. Kenwei has developed compact multi-head weighers that seamlessly integrate into existing production lines without requiring extensive modifications. This trend allows small and medium-sized enterprises to adopt advanced combination food weigher technology without the burden of high infrastructure costs.

How Kenwei Stays Ahead with Combination Food Weigher Innovations

As a leader in the multi-head weigher industry, Kenwei is dedicated to pushing boundaries with innovative combination food weigher solutions. Our comprehensive capabilities in design, manufacturing, marketing, installation, technical training, and after-sales service set us apart. Based in Guangdong, we aim to become the world’s leading weighing and packing machine manufacturer by continuously improving our technology. Whether it’s through IoT integration, sustainability efforts, or customized solutions, Kenwei ensures that our combination food weighers meet the latest industry trends and customer expectations.

Conclusion: Embrace the Future with Combination Food Weighers

The landscape of food packaging is changing rapidly, and staying updated with the latest trends for combination food weighers is vital for success. From IoT-driven smart technology to energy-efficient designs and enhanced accuracy, the innovations of 2025 promise to elevate efficiency and profitability. At Kenwei, we are committed to providing high-speed, high-precision combination food weighers that align with these trends, helping businesses achieve their goals. Ready to transform your packaging line with cutting-edge solutions? Explore our range of products at kenweigroup.com and partner with us to stay ahead in the industry.

Frequently Asked Questions (FAQs) About Combination Food Weighers

1. What is a combination food weigher?

A combination food weigher is a machine used in the food packaging industry to measure and portion products accurately. It combines multiple weighing heads to achieve precise weights, reducing giveaway and improving efficiency. Kenwei’s combination food weighers are known for their high speed and precision.

2. How do combination food weighers improve productivity?

Combination food weighers enhance productivity by automating the weighing process, ensuring consistent portion sizes, and minimizing manual labor. With advanced technology like IoT integration, they also reduce downtime through predictive maintenance, as seen in Kenwei’s innovative solutions.

3. Are combination food weighers suitable for small businesses?

Yes, many combination food weighers in 2025 are designed with compact footprints, making them ideal for small businesses with limited space. Kenwei offers customizable and space-saving options to meet the needs of various business sizes.

4. How do combination food weighers support sustainability?

Modern combination food weighers are built with energy-efficient features to reduce power consumption. At Kenwei, we focus on eco-friendly designs that help businesses lower their carbon footprint while maintaining high performance.

5. Why choose Kenwei for combination food weighers?

Kenwei is a trusted manufacturer with a strong reputation for high-quality, precise, and fast combination food weighers. We provide one-stop solutions, excellent after-sales service, and tailored equipment to meet specific industry demands.

Top 10 food packing machine Manufacturers and Supplier Brands in America

What are the application scenarios of vffs packaging machine?

Integrating Economic VFFS with Multihead Weighers: Best Practices

How to Choose a Vertical Packaging Machine for High Throughput

About Cooperation Process

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

About Solution suggestions

Can Kenwei solutions be adapted for different product packaging types?

Yes, Kenwei solutions can handle a variety of packaging types, including bags, boxes, pouches, and bottles. We can customize machines to suit your packaging format, ensuring compatibility with your packaging equipment.

About Product choice

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

About Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Combined Check Weigher and Metal Detector for Food Industrial Weighing and Sorting

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei