What are the application scenarios of vffs packaging machine?

- What are the Application Scenarios of VFFS Packaging Machine?

- Food Industry: The Dominant Sector for VFFS Packaging Machines

- Non-Food Industries Benefiting from VFFS Technology

- Emerging Segments Using VFFS Packaging Machines

- Technological Advantages: Why Choose VFFS for Your Packaging Needs

- Application Scenarios: Real-World Industry Examples

- Frequently Asked Questions (FAQs)

- Conclusion

- Ready to streamline your packaging process or explore tailored automation solutions? Contact Kenwei for expert consultation and discover why we’re trusted worldwide for high-performance VFFS packaging machines.

What are the Application Scenarios of VFFS Packaging Machine?

VFFS packaging machines, or vertical form fill seal machines, have revolutionized the packaging industry with their versatility, efficiency, and reliability. At Kenwei, we pride ourselves on developing high-speed, high-precision multi-head weighers and automated weighing and packaging solutions, including VFFS packaging machines that meet diverse industry needs. we delve into the various application scenarios of VFFS packaging machines, demonstrating their adaptability and key role in modern production lines.

Introduction to VFFS Packaging Machines

VFFS packaging machines are automated equipment designed to form packaging material into a bag shape, fill it with product, and then seal it—all in a vertical format. Renowned for their speed and accuracy, especially when paired with multi-head weighers, VFFS machines have become the backbone of numerous industries. Their ability to handle various product types and packaging materials with minimal manual intervention makes them a top choice for manufacturers seeking efficiency and consistency.

Food Industry: The Dominant Sector for VFFS Packaging Machines

Snack Foods, Cereals, and Confectionery

The most prominent use of VFFS packaging machines is in the food industry, where quick and hygienic packaging is paramount. Snack foods, cereals, nuts, dried fruits, and confectioneries are packaged efficiently using VFFS packaging machines, often integrated with Kenwei’s multi-head weighers for precise portioning. The machines ensure product freshness through reliable sealing, comply with food safety regulations, and scale up productivity for mass production.

Frozen Foods and Ready-to-Eat Meals

VFFS packaging machines are ideal for frozen foods, vegetables, and ready-to-eat meals, where maintaining the integrity of the product is crucial. These machines can be tailored for various pouch types—pillow, gusseted, block-bottom bags—meeting different freezer storage and consumer requirements.

Powders and Granular Food Products

Flour, coffee, spices, sugar, salt, and granular food items like rice or grains are efficiently processed on VFFS packaging equipment. Kenwei’s solutions manage dust control and precise dosage, ensuring each bag contains the exact weight, minimizing wastage, and maintaining quality.

Non-Food Industries Benefiting from VFFS Technology

Pharmaceutical and Nutraceutical Applications

In pharmaceutical and nutraceutical production, product safety and compliance are non-negotiable. VFFS packaging machines deliver hermetically sealed packages for pills, tablets, powders, and medical devices, ensuring product protection from contaminants and prolonging shelf-life. Batch numbers and expiry dates are easily printed for traceability.

Chemical and Industrial Products

Chemical powders, cleaning agents, fertilizers, and industrial granules require robust packaging to ensure safe transportation and storage. Kenwei VFFS machines are customized with anti-corrosive materials and enhanced sealing technology to withstand harsh environments.

Pet Food and Animal Feed

The pet food industry thrives on the VFFS packaging machine’s speed and accuracy. Bulk products—from kibble to seeds and grains—are processed efficiently, providing packaging solutions that range from small sachets to large-format bags, all while maintaining product freshness and safety.

Emerging Segments Using VFFS Packaging Machines

Hardware and Spare Parts Packaging

With rising e-commerce demands, VFFS packaging machines have found their way into hardware and spare parts packaging. Screws, bolts, accessories, and small components are rapidly counted, weighed, and sealed in neat pouches, streamlining logistics and inventory processes.

Cosmetics and Personal Care Items

Single-use sachets, sample-sized products, and refill packaging in the cosmetics industry increasingly rely on VFFS technology. The machine’s gentle handling capabilities protect fragile creams and powders, while precise filling maintains brand consistency and user satisfaction.

Technological Advantages: Why Choose VFFS for Your Packaging Needs

High Speed and Automation

Kenwei’s VFFS packaging machines work seamlessly with multi-head weighers, delivering rapid bags-per-minute rates that far exceed manual alternatives. Automation minimizes human error, cuts labor costs, and helps businesses scale quickly.

Versatility of Bag Types and Sizes

Whether your product requires a small sachet, gusseted bag, quad-seal, or block bottom pack, VFFS packaging machines are designed for fast changeovers, accommodating various bag types and sizes with minimal downtime.

Integration with Quality Control Devices

Kenwei integrates advanced metal detectors, check weighers, and rejection systems into automated packaging lines. This ensures each package meets stringent quality standards, as well as enabling complete traceability and compliance with industry regulations.

Customization for Unique Packaging Needs

Every business is unique. Kenwei’s VFFS packaging machines are fully customizable to handle unique products, specific packaging materials, and special sealing requirements. From food-grade stainless steel for edible goods to anti-static features for electronics, our systems adapt seamlessly.

Application Scenarios: Real-World Industry Examples

Dairy Industry

Powdered milk, cheese cubes, and yogurt toppings are efficiently processed with VFFS packaging machines. Moisture-sensitive products benefit from airtight packaging, extending shelf life and maintaining flavor.

Agricultural Sector

Seeds, fertilizers, and pesticides can be safely and accurately packed using VFFS machines. The flexible packaging format allows for efficient export and minimizes product damage during transportation.

Retail and Supermarkets

Single-serve and bulk retail products leverage VFFS packaging for attractive shelf presentation, ease of use, and efficient inventory control. Flashy, customized designs are supported by advanced printing modules.

Logistics and Fulfillment

Automated VFFS packaging machines streamline the handling and packing of promotional materials, documents, and small e-commerce packages, reducing manual labor and ensuring consistency.

Frequently Asked Questions (FAQs)

What is a VFFS packaging machine?

A VFFS packaging machine (Vertical Form Fill Seal) is a device that creates pouches from roll stock film, fills them with product, and seals them vertically in an automated process.

Which industries commonly use VFFS packaging machines?

VFFS packaging machines are widely used in the food, pharmaceutical, chemical, pet food, agricultural, cosmetics, and hardware sectors due to their versatility and efficiency.

Can VFFS machines handle both solid and liquid products?

Most VFFS packaging machines, particularly those manufactured by Kenwei, can be configured to package solids, granules, powders, and certain liquids with high precision.

How does a VFFS packaging machine improve efficiency?

By automating the form, fill, and seal process, VFFS packaging machines increase packaging speed, consistency, and accuracy while reducing labor costs and minimizing product wastage.

Can Kenwei customize VFFS machines for my specific application?

Yes, Kenwei specializes in providing tailor-made weighing and packaging solutions, adjusting our VFFS machines to match your product, bag type, and production requirements.

Are VFFS packaging machines hygienic for food products?

Kenwei ensures all food-grade VFFS machines are constructed with stainless steel and adhere to rigorous hygiene and safety standards suitable for food applications.

What are the most common bag types produced by VFFS packaging machines?

Typical bag formats include pillow bags, gusseted bags, block-bottom bags, quad-seal pouches, and sachets.

How does Kenwei support after-sales and technical training?

We offer comprehensive after-sales support, technical training, installation, and commissioning services to ensure your VFFS packaging machines run smoothly.

Where is Kenwei located and how can I get support?

Kenwei operates from Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province, and provides fast, thoughtful service globally. Visit (https://www.kenweigroup.com/) for contact information.

Conclusion

The VFFS packaging machine is a cornerstone of automated packaging lines across multiple sectors, enabling speed, precision, and adaptability. From food to pharmaceuticals and beyond, Kenwei’s advanced VFFS solutions meet a broad spectrum of requirements, empowering companies with reliable, customizable, and efficient packaging processes. As a leader in the global weighing and packaging machinery industry, Kenwei is dedicated to innovation and customer satisfaction, making us your ideal partner for automation success. For expert guidance and the latest in VFFS packaging machine technology, connect with Kenwei today.

Ready to streamline your packaging process or explore tailored automation solutions? Contact Kenwei for expert consultation and discover why we’re trusted worldwide for high-performance VFFS packaging machines.

Combination Weigher with Pouches: Packaging Format Guide

Top 10 combination weigher Manufacturers and Supplier Brands

Energy Efficiency Tips for Combination Weigher Operations

Best 10 head multihead weigher manufacturers and supplier brands

About Solution suggestions

Can Kenwei machines handle products with irregular shapes or sizes?

Yes, multi-head weighers are particularly effective for handling products with irregular shapes and sizes.

About products customization

Can Kenwei machines support multiple languages?

Yes, we can customize the software interface to support multiple languages, making it easier for operators from different regions to use the machine.

Can Kenwei machines be customized for different industries?

Yes,According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on.

About Cooperation Process

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

About Product choice

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

Double Filling VFFS Packaging Machine for Efficient Dual Product Packaging

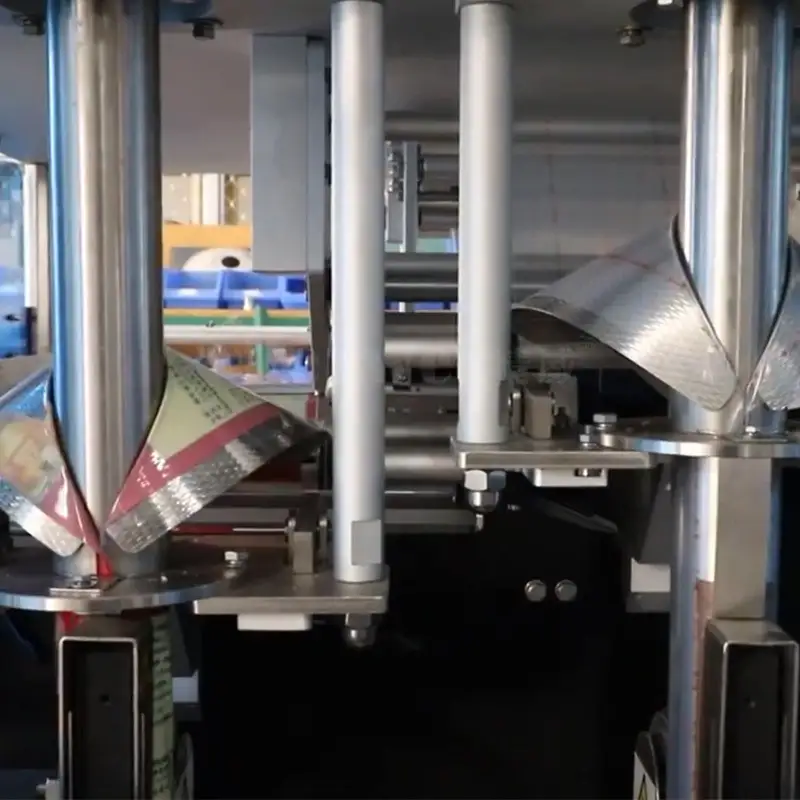

The Fully Automatic High-Speed Vertical Double Filling Form-Fill-Seal (VFFS) machine features a compact design and a complete range of packaging machines and auxiliary equipment, making it adaptable to various materials and space-efficient. It can handle a wide variety of laminated films, single-layer PE films, film thicknesses ranging from 0.04mm to 0.09mm, and paper membrane packaging. This VFFS machine is widely used in food, pharmaceutical, and chemical industries for packaging snacks, powders, liquids, and granular products. The machine forms bags from flat film rolls, fills them with products, and seals them vertically, improving packaging efficiency and ensuring consistent, high-quality production.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei