Combination Weigher with Pouches: Packaging Format Guide

- Combination Weigher with Pouches: Packaging Format Guide

- Overview — What a combination weigher does for pouch packaging

- Why choose a combination weigher for pouch packaging

- Pouch types commonly used with combination weighers

- Vertical Form-Fill-Seal (VFFS) integration

- Pre-made pouch machines and retort pouch integration

- How pouch format affects speed and accuracy

- Packaging format comparison — speed, sealing, and suitability

- Product handling: hopper, chute, and anti-clogging design

- Weigher head count and configuration decisions

- Accuracy and legal compliance for net weight

- Sanitation, materials, and ease of maintenance

- Line integration: automation, controls, and Industry 4.0

- ROI and cost considerations for pouch lines

- Case example — practical throughput and savings (illustrative)

- How Kenwei supports pouch packaging projects

- Implementation checklist before buying a combination weigher for pouches

- Final recommendations — choosing the right pouch solution

- FAQ — Frequently Asked Questions

- Can a combination weigher handle sticky or wet products in pouches?

- What pouch format gives the highest speed with a combination weigher?

- How do I ensure accuracy and minimize giveaway?

- Is retrofitting an existing VFFS with a new combination weigher difficult?

- Do combination weighers support multiple SKUs and quick changeovers?

- How do I get a tailored solution from Kenwei?

Combination Weigher with Pouches: Packaging Format Guide

Overview — What a combination weigher does for pouch packaging

A combination weigher (multihead weigher) is an automated weighing machine that combines precise weights from several dosing heads to reach a target weight. When paired with pouch packaging equipment—such as vertical form-fill-seal (VFFS) machines, pre-made pouch machines, or horizontal flow wrappers—the combination weigher becomes the central element of a high-speed, high-accuracy pouch packaging line. This guide explains which pouch formats work best, integration considerations, performance factors, and practical implementation tips for manufacturers seeking efficient pouch solutions.

Why choose a combination weigher for pouch packaging

Combination weighers deliver fast cycle times, consistent accuracy, and flexibility across a wide range of product types (free-flowing snacks, frozen vegetables, nuts, granules, pet food, confectionery, and many non-foods). Their multihead design reduces giveaway and increases throughput compared with single-head or linear weighers. For pouch packaging lines, a combination weigher feeds measured doses reliably to the pouch machine's filling chute, enabling higher speeds and better yield—key commercial benefits for brands aiming to reduce cost per pack and ensure consistent filling.

Pouch types commonly used with combination weighers

Pouch choice impacts machine layout, cycle time, sealing method, and product presentation. Common pouch types used with combination weighers include pillow pouches, stand-up (doypack) pouches, center-seal pouches, quad-seal/flat-bottom pouches, and stick packs/sachets. Each format has different requirements for filling orientation, pouch handling, and downstream sealing, so select a pouch that balances marketing needs and line efficiency.

Vertical Form-Fill-Seal (VFFS) integration

VFFS machines are the most common partners for combination weighers because they form pouches from roll film and are highly adaptable to different pouch heights and seals. Integration points include mechanical mounting (weigher discharge chute over VFFS hopper), communication protocol (trigger signals for cycle synchronization), and pneumatic or servo conveyors for product transfer. A well-integrated combination weigher + VFFS system minimizes product loss, reduces cycle mismatch, and maximizes packs-per-minute.

Pre-made pouch machines and retort pouch integration

Pre-made pouch machines work well when brand presentation or complex sealing is needed. For retortable or high-barrier pouches, the combination weigher must precisely deliver product at a controlled rate to avoid pouch deformation. Additional equipment—such as a timed dosing gate or buffer hopper—often helps synchronize fill rates with slower sealing cycles of specialized pouch machines.

How pouch format affects speed and accuracy

Pouch format, product flow, and target net weight influence achievable speed and accuracy. Smaller packets and free-flowing products typically allow higher speeds; sticky or irregular products reduce throughput. Combination weighers are optimized by head configuration (10, 14, 16, 20, etc.), feeder designs, and vibration tuning. Properly matched systems achieve both high speed and low giveaway, but trade-offs between throughput and weight accuracy are common and must be balanced for each SKU.

Packaging format comparison — speed, sealing, and suitability

Below is a practical comparison of common pouch formats and their typical compatibility with combination weighers. Values are industry-typical ranges to guide selection; actual performance depends on product and equipment models.

| Pouch Format | Typical Speed (packs/min) | Sealing Type | Best for | Notes |

|---|---|---|---|---|

| Pillow pouch | 30–120 | Back seal or fin seal | Snacks, confectionery, granules | Simple, high-speed with VFFS |

| Stand-up (doypack) | 15–60 | Bottom gusset seal; zipper options | High Quality snacks, pet treats, sauces (with spout) | Requires careful pouch handling; slower than pillow |

| Quad-seal / Flat-bottom | 10–50 | Multiple side seals, often complex | Heavier products, High Quality presentation | Better shelf stability; slower format changeover |

| Center-seal | 20–90 | Center back seal | Powders, snacks, frozen goods | Good product support; moderate speed |

| Sachet / stick | 40–200 (stick higher) | Fin-type seals, horizontal or vertical | Single-serve, powders, liquid shots | High speed for small fills but needs precise dosing |

Product handling: hopper, chute, and anti-clogging design

Product characteristics dictate hopper and chute design. Free-flowing items require simple funnels; fragile or sticky items benefit from low-impact, wide chutes and buffer hoppers to prevent bridging. Anti-clogging features—gentle agitators, sloped surfaces, anti-static coatings, or vibratory feeders—maintain continuous flow into the combination weigher. For powders, dust control and proper sealing at transfer points are essential to protect equipment and product hygiene.

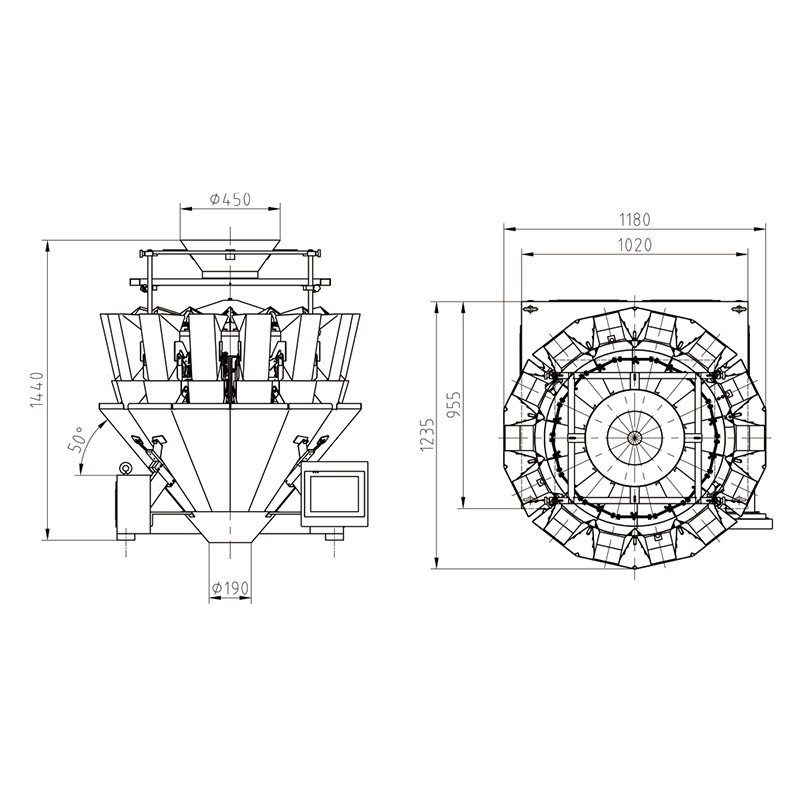

Weigher head count and configuration decisions

The number of heads impacts speed and accuracy. Typical multihead weighers come in 10, 14, 16, 20, 24-head variants and beyond. More heads allow finer combination possibilities and faster cycles for small portion sizes. For larger pouch weights, fewer heads with larger buckets can be more effective. Choosing the right head count depends on target weight range, desired packs per minute, and product particle size.

Accuracy and legal compliance for net weight

Combination weighers help minimize giveaway while meeting net weight regulations. Accuracy depends on calibration, environmental stability, and machine tuning. Regular verification against certified weights and implementing checkweighers downstream (Kenwei supplies such systems) ensures compliance with legal metrology and brand promises. Many manufacturers aim for ±1–2% accuracy for granular products, but targets differ by product and market requirements.

Sanitation, materials, and ease of maintenance

Material contact surfaces should be stainless steel (SUS304 or SUS316 for corrosive products) and designed for quick-change parts, tool-free disassembly, and washdown if required. Food plants often demand IP65 or higher protection for electronics and hygienic designs that minimize traps for residues. Kenwei's machines include hygienic chassis options and quick-release buckets to reduce downtime during cleaning and product changeovers.

Line integration: automation, controls, and Industry 4.0

Modern combination weighers communicate via standard industrial protocols (Ethernet/IP, Modbus TCP, Profinet) to synchronize with pouch machines, vision systems, metal detectors, and checkweighers. Data logging for weight distributions, reject rates, and production counts supports quality control and process improvement. Remote diagnostics and recipe transfer reduce setup time for SKU changes and enable predictive maintenance.

ROI and cost considerations for pouch lines

Investing in a combination weigher with pouch integration is usually justified by reduced product giveaway, higher throughput, and lower labor costs. Typical payback periods for automated weighing and pouching lines range from 12 to 36 months depending on production volume, product value, and labor savings. Consider total cost of ownership: initial equipment cost, spare parts inventory, maintenance, tooling for pouch formats, and utility consumption. A factory planning frequent SKU changes should budget for additional changeover tooling and staff training.

Case example — practical throughput and savings (illustrative)

Consider a snack pack line producing 60g packs where automation reduces average giveaway by 0.5g per pack. For a production run of 1,000,000 packs per year, the saved product equals 500,000g (500 kg) annually. At a product cost of $3.00/kg, annual savings are $1,500—additional savings come from labor reduction and improved uptime. Real-world savings may be higher for higher-value products; manufacturers should run a site-specific ROI with measured giveaway and labor inputs.

How Kenwei supports pouch packaging projects

Kenwei is a powerful manufacturer of multi-head weighers and provides one-stop automated weighing and packaging solutions including multi-head weighers, metal detectors, linear weighers, and checkweighers. Located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province, Kenwei offers customization, installation, commissioning, training, and after-sales service. Our systems are optimized for high speed and high precision, designed to integrate smoothly with VFFS and pre-made pouch machines to deliver efficient pouch packaging lines tailored to specific products and formats.

Implementation checklist before buying a combination weigher for pouches

Before selecting equipment, collect these essential inputs: target pouch formats and sizes, product physical properties (particle size, fragility, moisture), target packs per minute, required net weight tolerances, available floor space and utilities, integration needs (metal detection, checkweighing), and cleanliness/food-grade requirements. Also request references for similar product installations and factory acceptance testing (FAT) options.

Final recommendations — choosing the right pouch solution

Choose a combination weigher configuration that matches your product profile and production targets. For small, high-speed packets prioritize more heads and precise feeders; for larger pouch weights consider larger buckets and robust transfer chutes. Partner with vendors who provide integration, FAT, and local service. Optimizing the full system—weigher, pouch machine, conveyors, metal detector, and checkweigher—delivers the best balance of speed, accuracy, and uptime.

FAQ — Frequently Asked Questions

Can a combination weigher handle sticky or wet products in pouches?

Yes, but handling sticky or wet products requires special design features: non-stick coatings, steeper chutes, gentle agitation, wider discharge openings, and frequent cleaning access. Some systems use troughs or positive transfer belts to avoid sticking in buckets.

What pouch format gives the highest speed with a combination weigher?

Pillow pouches and small sachets/stick packs typically achieve the highest speeds when paired with high-head-count weighers and fast VFFS equipment. Stand-up and quad-seal pouches are usually slower due to handling and sealing complexity.

How do I ensure accuracy and minimize giveaway?

Use the correct head count, tune feeder vibrations, implement regular calibration routines, and install a downstream checkweigher for verification. Recipe management and environmental control (temperature/humidity) also help maintain accuracy.

Is retrofitting an existing VFFS with a new combination weigher difficult?

Retrofitting is common. Challenges include mechanical alignment, communication protocol compatibility, and adjusting discharge geometry. Working with experienced integrators (like Kenwei) reduces risk and accelerates commissioning.

Do combination weighers support multiple SKUs and quick changeovers?

Yes. Modern weighers support digital recipes for quick parameter changes, tool-less parts replacement, and adjustable feeders. Planning for frequent SKU changes requires investing in quick-release components and operator training.

How do I get a tailored solution from Kenwei?

Contact Kenwei through our website (https://www.kenweigroup.com/) with product samples, target pouch formats, and production targets. Kenwei offers consulting, FAT, installation, and local commissioning to ensure your pouch line performs as specified.

Top food pouch packing machine Manufacturers and Suppliers in China

Top 10 Metal Detectors for Aluminum Foil in Food Plants

How Multihead Weighers Improve Packaging Efficiency 2026

Top 10 Inspection Line Configurations for Aluminum Foil

About products customization

Can Kenwei machines be customized for different industries?

Yes,According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on.

How do I request a custom-built Kenwei machine?

To request a customized machine, simply contact our sales or engineering team.

About Cooperation Process

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

About Logistics

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

10-Head Standard No-Spring Multihead Weigher 1.6L for Precise Weighing

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Standard Multihead Weigher with New Springless Actuator for Food Weighing Machine

The Standard Multihead Weigher features a high-speed, spring-free hopper with a new aluminum shell design, ensuring stable and fast weighing performance. The integrative welding of the mouthpiece case and middle seat enhances the overall machine strength. Ideal for weighing granular products like melon seeds, peanuts, nuts, almonds, raisins, candies, and pistachios, this 14-head multihead weigher offers hopper options of 1.6L and 2L. With a maximum weighing speed of 120 packs per minute, it delivers rapid and accurate results for high-volume operations.

14-Head High-Speed Springless Multihead Weigher for Accurate Weighing

The high-speed weigher features a new spring-free aluminum shell design with double chute feeding and dual high-speed hopper alternating feeding, significantly boosting feeding speed. It is ideal for weighing materials such as melon seeds, peanuts, nuts, almonds, raisins, candy, pistachios, and more. The 18-head high-speed weigher is equipped with 2L hoppers, achieving a maximum weighing speed of up to 180 bags per minute.

16-Head Multihead Weigher with 1.6L Three-Layer Hopper for Accurate Weighing

The Kenwei 16-Head Multihead Weigher with a 1.6L Three-Layer Hopper provides precise and efficient weighing with a maximum speed of 240 packs per minute, optimizing your production line. The main vibrating pan supports two types of mixed materials, offering versatility and consistent performance. This advanced multihead packing machine is ideal for a wide range of products, including nuts, raisins, candies, potato chips, and other snack foods, as well as hardware and plastic materials. It ensures reliable performance and high accuracy in various industries.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei