Kenwei VFFS Packaging Equipment: High-Speed Automated Packaging

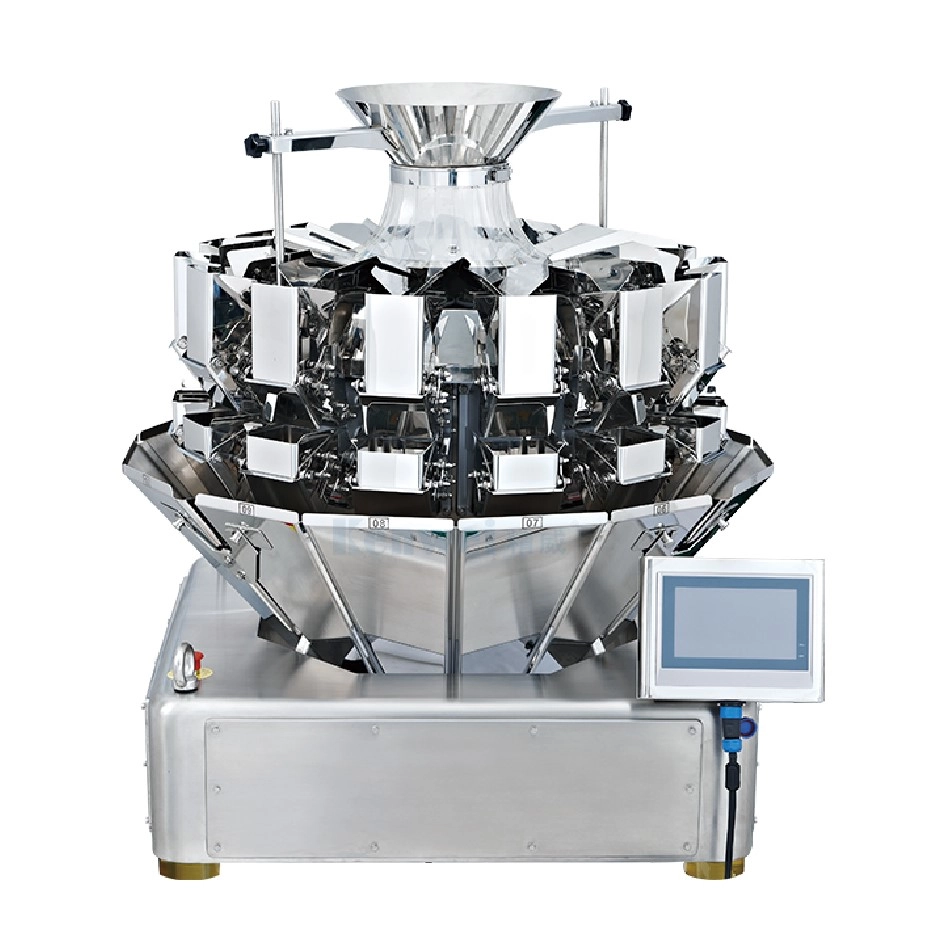

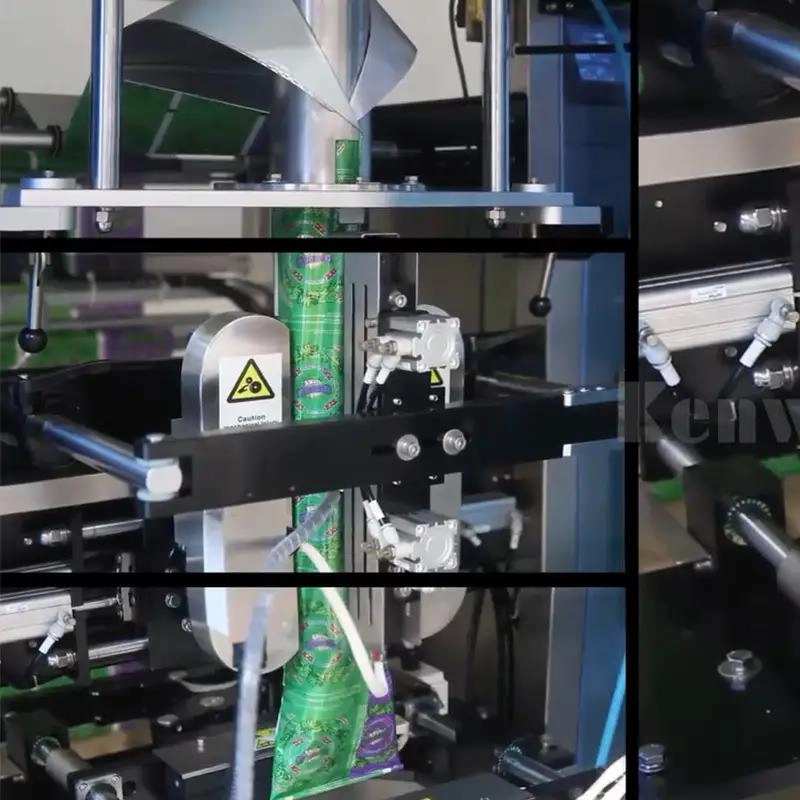

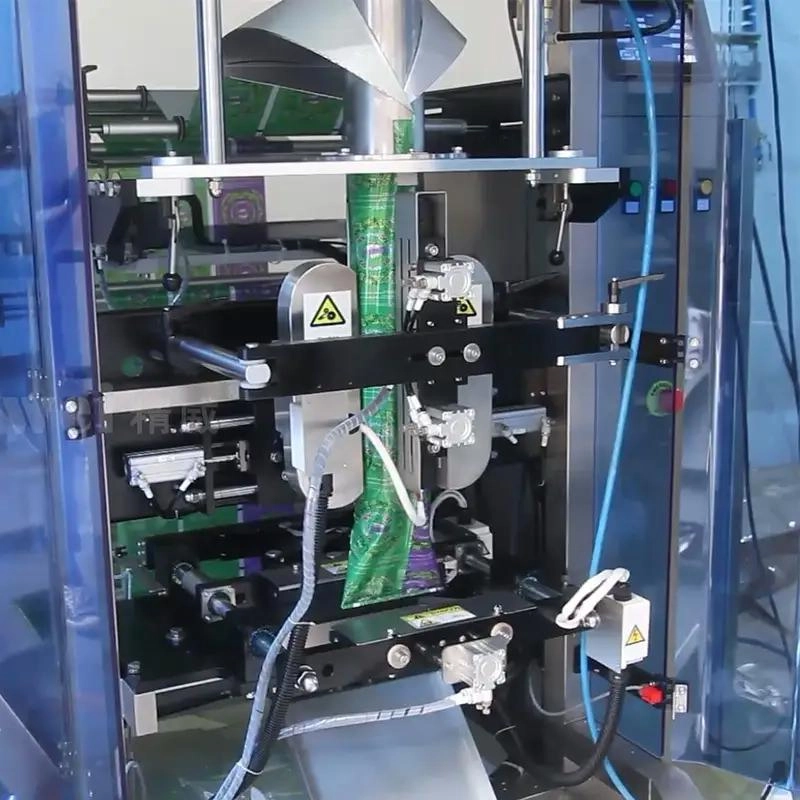

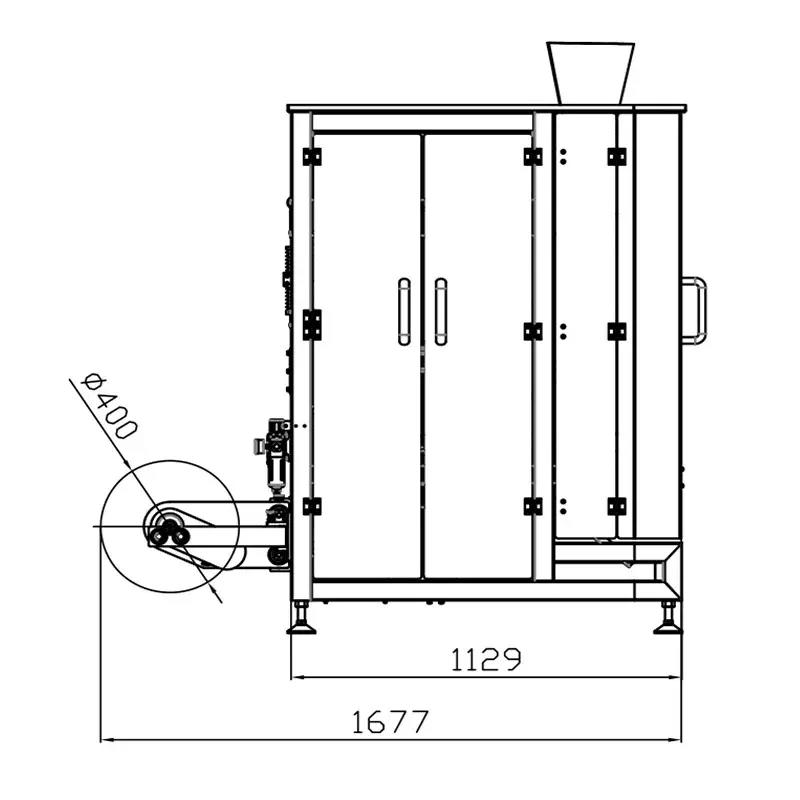

The economical vertical form fill seal (VFFS) packaging machine offers a variety of models designed with a sturdy 304 stainless steel frame. It is equipped with safety door protection and supports multiple bag types, including pillow bags, angle belt bags, printed bags, and triangle bags. This versatile machine is ideal for packaging a wide range of materials, such as snacks, frozen foods, coffee beans, oats, sugar, salt, rice, small hardware components, and more. Affordable and cost-effective, it provides reliable performance and efficiency for diverse packaging needs.

Kenwei VFFS Packaging Equipment: Precision Meets Efficiency

Discover unmatched innovation with Kenwei's VFFS packaging equipment, engineered to elevate your packaging operations to a whole new level. As a leading manufacturer of multi-head weighers, Kenwei integrates advanced technology and automation in every vertical form fill seal (VFFS) system. Whether you’re packaging snacks, granules, powders, or non-food items, our VFFS packaging equipment ensures consistent high-speed performance and remarkable accuracy.

Kenwei’s VFFS packaging equipment stands out for its robust construction, intuitive interface, and adaptability to meet diverse customization requirements. Each machine is equipped with state-of-the-art weighing mechanisms – including metal detectors, multi-head weighers, and check weighers – delivering seamless integration and enhanced efficiency.

Located in the Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province, Kenwei backs every product with comprehensive support: from design and installation to technical training and responsive after-sales service. We’re committed to providing customers with one-stop automated weighing and packaging solutions, tailored to your unique needs.

Choose Kenwei to experience superior precision, speed, and reliability, all supported by a brand with a solid reputation for innovation and service excellence. Enhance your productivity and ensure consistent packaging quality with Kenwei VFFS packaging equipment — the trusted choice for businesses aiming to lead in their markets.

Learn more about how Kenwei can optimize your packaging operations at (https://www.kenweigroup.com/).

Detailed display

Qualification Certificate

Member of China Weighing Instrument Association

Scale hopper-Utility Model Patent Certificate

ICR Polska/VC/LU201107 Check Weigher

FAQ

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

How can Kenwei solutions help reduce waste in my production process?

Kenwei solutions improve accuracy in weighing, packaging, and quality control, reducing the chances of overfill or underfill. This leads to less product waste and higher operational efficiency.

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

If you have another questions, please feel free to contact us.

10-Head Standard No-Spring Multihead Weigher 1.6L for Precise Weighing

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

32 Heads Multihead Weigher for Mixing 4 Products for Coffee and Small Granule Foods

The 32-head mixing weigher is a high-precision combination weighing scale designed for accurate weighing. It is ideal for granular materials with good fluidity and can handle a variety of mixing formulas, including two-in-one, three-in-one, and four-in-one configurations. The maximum weighing speed for mixtures can reach up to 60 bags per minute.

24-Head Multihead Weigher with Memory Bucket for Accurate Weighing

The three-layer, 24-head multihead weigher features an innovative memory bucket for temporary storage of weighing materials. This increases the combination probability and significantly improves the accuracy of the weighing process. The machine, with a separate main vibration disc, supports up to six different mixture formulas, achieving a maximum weighing speed of 240 bags per minute. This high-performance design enhances efficiency and boosts economic benefits.

Super High Precision Mini Multihead Weigher for Accurate Small Granule Weighing

The Mini Multihead Weigher is a high-precision weighing device designed for accurate measurement of small particles. Featuring an ultra-small 0.5L hopper and a low-vibration design, it operates smoothly and efficiently. Ideal for precise quantitative weighing of products such as Chinese medicine tablets, tea, seeds, monosodium glutamate, and other small granules. With a 2-year warranty, it offers the longest quality assurance period in the industry.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei