Kenwei Showcases Innovative Weighing and Packaging Solutions at ProPak China 2019

Kenwei was interviewed by ProPak China 2019, showcasing our innovative solutions and industry expertise. Discover insights from the exclusive interview and how Kenwei leads in packaging technology. Stay updated with Kenwei’s latest news and achievements.

Guangdong Kenwei Intellectualized Machinery Co., Ltd. is at the forefront of developing and manufacturing high-speed, stable, and accurate multi-head combination weighing scales, multi-head linear scales, weight check weighers, metal detectors, material transport systems, and more. The company specializes in providing customized automatic quantitative weighing and packaging systems designed to meet a variety of customer needs across industries.

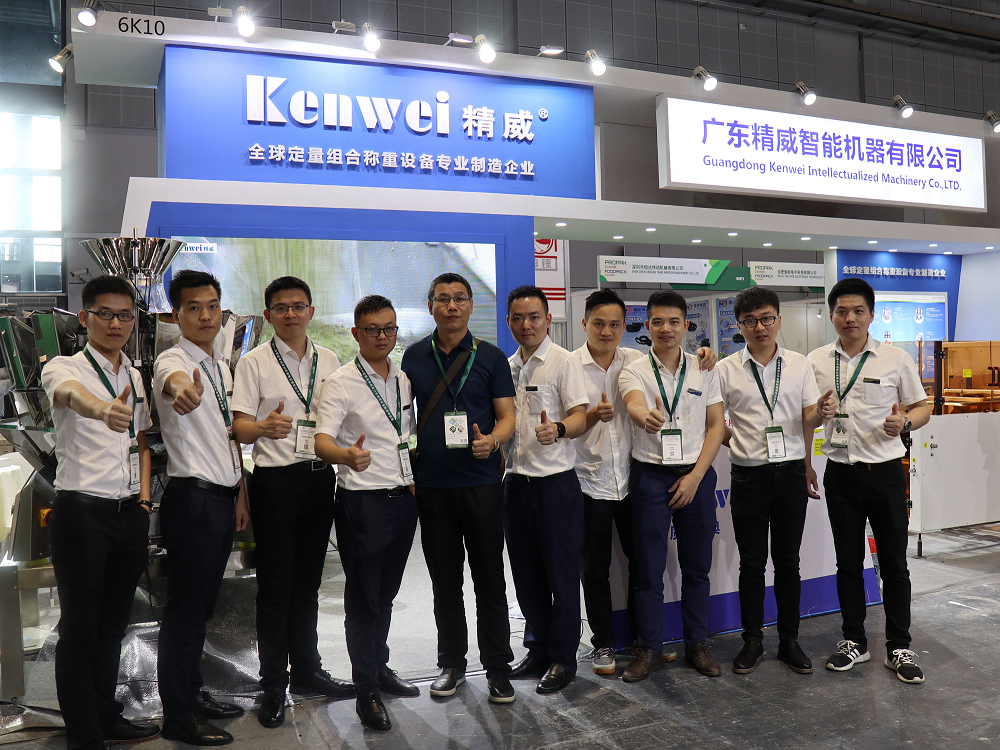

Kenwei’s Participation in ProPak China 2019

During an exclusive interview at the ProPak China 2019 exhibition, Yin Yunbing, General Manager of Kenwei, expressed the company’s excitement about the event, saying, "ProPak China 2019 is a premier event in the processing and packaging technology industry. At this grand exhibition, we are proud to showcase our comprehensive range of products and demonstrate the technological strength and innovation behind our solutions."

Kenwei’s exhibit includes the following advanced packaging systems and individual products:

-

Automatic filling systems

-

Automatic opening, packing, and sealing systems

-

14-head economic combination weighers

-

14-head double-screw pickle weighers

-

14-head 7.5L salad weighers

-

12-head belt-type manual weighers

-

Aluminum foil metal detectors

These products underscore Kenwei's leadership in the industry, focusing on innovation, precision, and efficiency in every solution.

Kenwei’s Vision for the Future of Packaging Technology

In the face of rapidly changing market dynamics and fierce competition, Yin Yunbing emphasized, "China’s food packaging industry is aligning with Industry 4.0, advancing toward intelligent manufacturing. We envision a future where high-speed networked combination scales, robots, visual processing applications, and intelligent, flexible production lines will become increasingly integrated into packaging operations."

Looking ahead, Yin Yunbing shared his commitment to customer-centric innovation: "We will focus on understanding customer needs more deeply, improving product quality, refining our pricing strategy, enhancing service speed, and responding to user feedback. By doing so, we can continue to improve customer satisfaction and build long-term, mutually beneficial partnerships based on trust."

A Commitment to Long-Term Partnerships

Kenwei aims to build lasting relationships with customers, becoming a trusted strategic partner in the packaging industry. "We look forward to working closely with a wide range of users, ensuring that our collaboration is rooted in trust, mutual benefit, and a shared commitment to excellence," said Yin Yunbing.

Kenwei’s dedication to innovation and customer satisfaction makes it a trusted leader in intelligent weighing and packaging solutions. Visit Kenwei at future exhibitions to discover how the company can help you achieve efficiency and precision in your packaging operations.

About products customization

Can Kenwei machines support multiple languages?

Yes, we can customize the software interface to support multiple languages, making it easier for operators from different regions to use the machine.

Can Kenwei machines be customized for different industries?

Yes,According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on.

Can I customize Kenwei machines to suit my specific needs?

Yes, Kenwei offers a wide range of customization options to ensure that our machines meet your production requirements.

About Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

About Solution suggestions

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

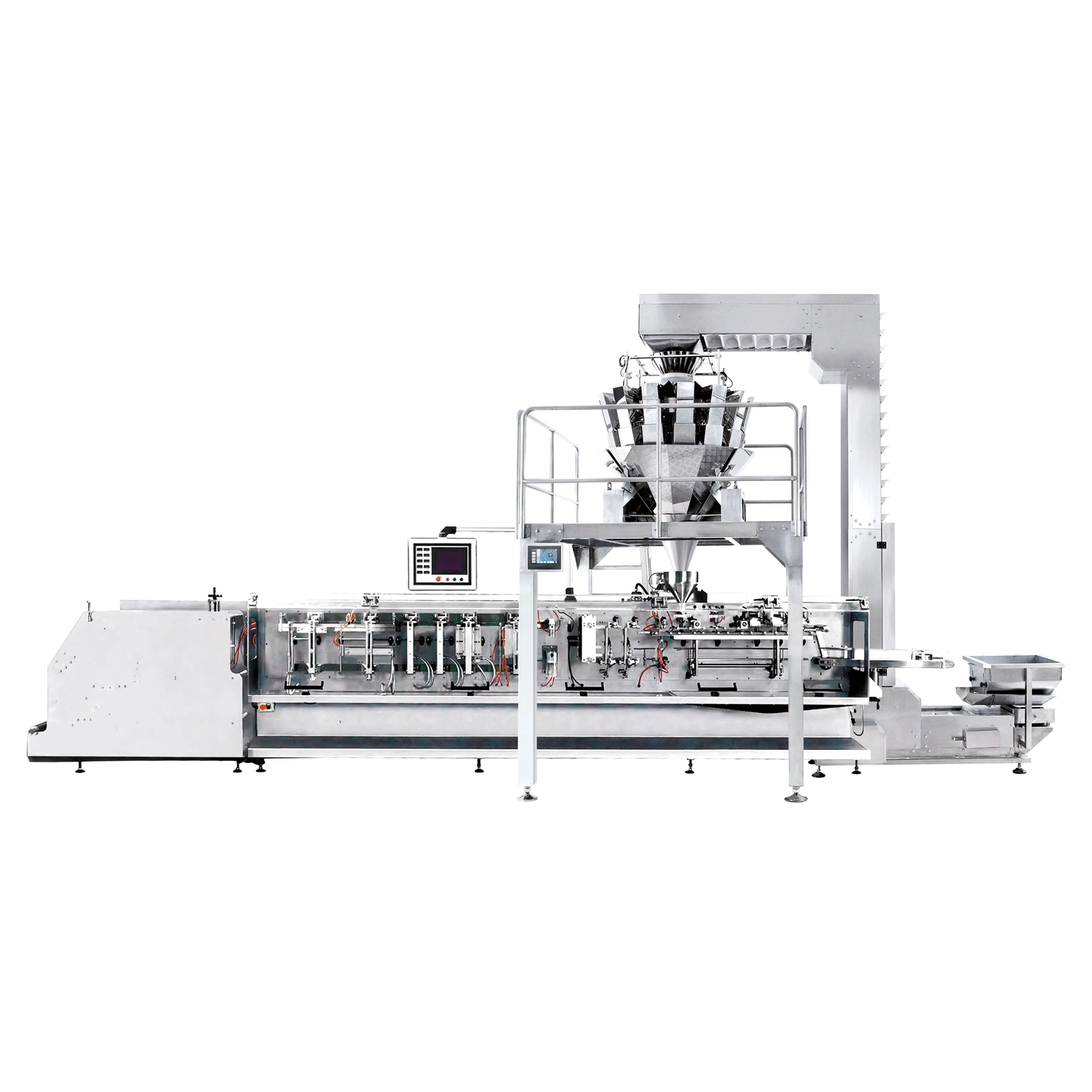

The JW-B13 Standard Pre-Made Bag Packing Machine is an advanced weighing and packing system ideal for granules, slices, and irregular products like snacks, nuts, pet food, and hardware. This fully automated line includes a vibrator feeder, Z conveyor, working platform, multihead weigher, and horizontal packing machine. It ensures high weighing accuracy, fast packing speed, and premium bagging quality—perfect for efficient, stable, and precise packaging.

The Kenwei JW-B22 Precision Food Packaging Machine with Single Head Bulk Linear Weigher is designed for heavy-duty weighing up to 50kg. It automates feeding, weighing, bag sewing, and output for maximum efficiency. Ideal for grains like corn, rice, soybeans, barley, and wheat, it ensures high accuracy and reliability for the food, chemical, and light industries, making it the top choice for bulk grain packaging.

The Kenwei JW-B16 Two Outlet Semi-Auto Sugar Weighing and Packaging Machine delivers high-precision, automated weighing for granules, slices, and irregular products like candy, coffee beans, and pet food. With a compact, cost-effective design and excellent price-performance ratio, it supports unique bag types and boosts efficiency. Optional add-ons like check weighers, metal detectors, and conveyors ensure quality control and seamless integration. Ideal for food and hardware industries.

The Kenwei JW-B26 Single Multihead Weigher Mixing and Packaging System offers fully automated operation, completing feeding, weighing, filling, date printing, and product output with high accuracy and speed. Ideal for granules, slices, irregular shapes, and mixed products like candy, nuts, snacks, pet food, and even small hardware. Its versatility and precision make it a perfect solution for diverse packaging needs.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei