Common Kenwei Multihead Weigher Component Issues & Solution

Discover Kenwei's solutions to multihead weigher component problems. Learn about common issues, expert troubleshooting tips, and how Kenwei ensures optimal performance for your multihead weigher systems. Boost reliability and efficiency with Kenwei’s expertise.

At Kenwei, we are committed to helping customers overcome technical challenges related to combination scale components. Below is a comprehensive Q&A guide addressing the most common component-related issues in multihead weighers, ensuring smooth installation, accurate performance, and long-term reliability.

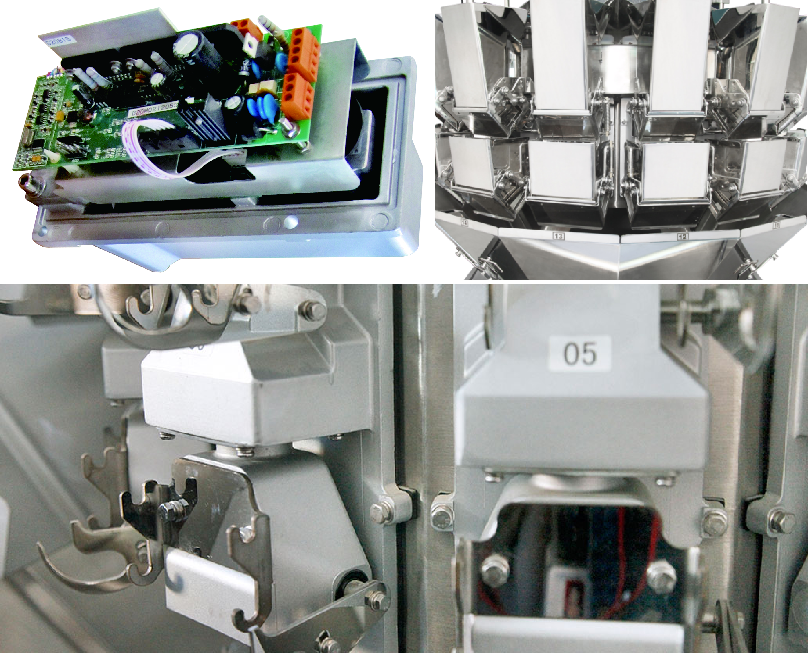

Q1: The motherboard has many plug sockets. Will I make mistakes during installation?

Answer: No. Each socket and plug on our motherboard is coded for precise matching. Only the correct plug can fit into its corresponding socket, making incorrect installation nearly impossible. Additionally, every plug is clearly marked to help you install quickly and accurately.

Q2: Can A/D converter modules be interchanged?

Answer: Yes, but with caution. While the modules look similar, each has a unique identification number. When replacing a module, match the new module with the original number to avoid communication failures. For detailed guidance, refer to the Maintenance Manual.

Q3: Are the sensors universal across all models?

Answer: Sensors of the same specification are interchangeable. For example:

-

1.6L and 2.5L hoppers use 5Kg sensors

-

5L hoppers use 15Kg sensors

-

Material detection systems use 40Kg sensors

Q4: Why is the vibration performance of your linear vibrator so efficient?

Answer: At Kenwei, we prioritize customer satisfaction and precision engineering. Our Vibration Principle Research Group studied top industry designs and combined them with independent innovations to develop the Kenwei-branded linear vibrator, ensuring superior material flow and stability.

Q5: Can 10-head scale hoppers be used with 14-head scales?

Answer: Yes, with limitations. 10-head scale hoppers can be used with 1.6L and 2.5L 14-head scales, thanks to our universal collecting hopper design. However, compatibility may vary by capacity and configuration.

Q6: What innovations have you implemented for material handling?

Answer:

-

Customized vibration plates with adjustable rotation speeds to control material flow.

-

Photoelectric detection systems for precise feeding.

-

Anti-stick and anti-shatter hoppers to handle sticky or fragile materials.

-

Targeted solutions for specific materials, such as:

-

Multi-leg feeders with U-shaped vibrating plates for fine particles (e.g., rice, sugar) to prevent leakage.

-

V-shaped vibrating plates for medium/large uniform particles to improve minimum weight control.

-

Q7: How do you handle weighing and packaging for bulk materials like radix isatidis or oatmeal?

Answer: Large-package materials present unique challenges: poor flow, material overlap, and hopper size limitations. Our solutions include:

-

High-sensitivity material detection with rotating main vibrator for even feeding.

-

Sweeping bars on vibration plates to prevent accumulation and improve flow.

-

Customized linear vibration systems for sticky or uneven materials.

-

Larger 2.5L hoppers to avoid pinching and overflow.

-

'Package counting' software design to ensure precise control for big-bag packaging.

Kenwei’s Commitment to Innovation

From smart modular design to material-specific solutions, Kenwei continues to lead the industry with advanced technology, user-friendly designs, and reliable after-sales support. Our goal is to help customers increase efficiency, reduce downtime, and achieve perfect food weighting and packaging every time.

About Solution suggestions

How can Kenwei solutions help reduce waste in my production process?

Kenwei solutions improve accuracy in weighing, packaging, and quality control, reducing the chances of overfill or underfill. This leads to less product waste and higher operational efficiency.

About Cooperation Process

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

About products customization

Can Kenwei machines support multiple languages?

Yes, we can customize the software interface to support multiple languages, making it easier for operators from different regions to use the machine.

About Product choice

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei