How G5020 Reject Systems Reduce Product Recalls

- How G5020 Reject Systems Reduce Product Recalls

- Introduction: Why metal detection matters for food safety and recalls

- What the G5020 is: Key features of this metal detector for food industry use

- How multi-frequency detection increases sensitivity in the metal detector for food industry

- Hygienic conveyor design reduces secondary contamination risks

- Smart rejection logic: balancing safety and yield

- Ease of maintenance and quick disassembly reduce downtime and inspection gaps

- Validation and traceability: documenting performance to prevent recalls

- Integration with HACCP and preventive control plans

- Reducing false rejects: how optimized sensitivity avoids unnecessary waste

- Technical comparison: G5020 versus typical single-frequency detectors

- Operational best practices to maximize recall prevention

- Regulatory and standards alignment for metal detection systems

- How the G5020 reduces the scale and cost of recalls in practice

- Brand advantages: Why choose Food Metal Detector Manufacturer For Reject Defective Products G5020

- Real-world scenarios: typical contamination incidents prevented

- Implementation checklist for buyers of a metal detector for food industry use

- Cost-benefit overview: investment versus recall reduction

- Frequently Asked Questions (FAQ)

- 1. What types of metal can the G5020 detect?

- 2. How often should the G5020 be tested and calibrated?

- 3. Will the G5020 increase my false rejects?

- 4. Is the G5020 suitable for wet or chilled production lines?

- 5. Can the G5020 integrate with my existing production control systems?

- Contact us / View product

- Authoritative references and further reading

How G5020 Reject Systems Reduce Product Recalls

Introduction: Why metal detection matters for food safety and recalls

Product recalls due to metal contaminants are costly, damage brand reputation, and risk consumer health. A robust metal detection and rejection system is a cornerstone of preventive controls for food producers. The Food Metal Detector Manufacturer For Reject Defective Products G5020 is designed to address these challenges by combining multi-frequency detection, hygienic design, and intelligent rejection strategies tailored to reduce the incidence and impact of contaminated shipments.

What the G5020 is: Key features of this metal detector for food industry use

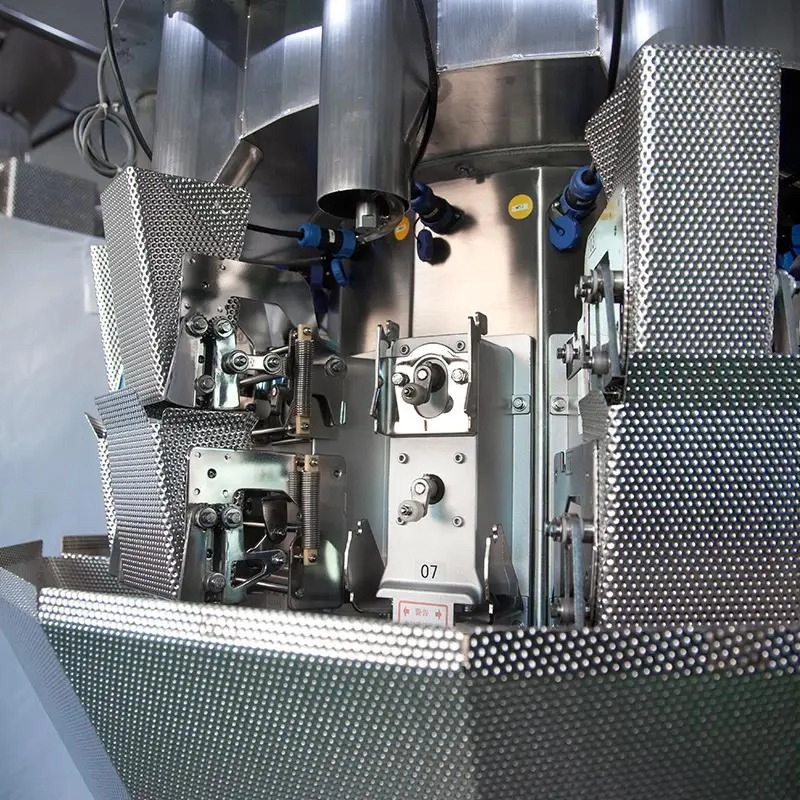

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

How multi-frequency detection increases sensitivity in the metal detector for food industry

Multi-frequency metal detectors like the G5020 sweep multiple frequencies simultaneously to detect a broader range of metal types and sizes. Single-frequency detectors can miss small stainless-steel fragments or aluminum pieces in complex product matrices. By using multi-frequency technology, the G5020 reduces both false negatives (missed contaminants) and false positives caused by product effect, increasing the likelihood that true metal contaminants are identified and rejected before packaging and distribution.

Hygienic conveyor design reduces secondary contamination risks

Conveyor design in a metal detector for food industry applications must minimize crevices, product traps, and areas that promote bacterial growth or retention of foreign material. The G5020's specialized conveyor belt is engineered to lower contamination risk by using materials and geometry that are easy to clean and resist wear. Smooth transfer points and tool-less disassembly allow for frequent sanitation without long line stoppages, directly lowering the probability that a retained contaminant later causes a recall.

Smart rejection logic: balancing safety and yield

Reject systems influence recall prevention by ensuring contaminated items are removed reliably while minimizing unnecessary product loss. The G5020 integrates configurable rejection strategies—diverter arms, pusher actuators, and stop-and-reject logic—tuned to product speed, size, and packaging type. By adopting adjustable delay lines, synchronised rejection timing, and validated rejection verification, the system helps ensure that only confirmed contaminant events trigger a reject. This reduces wasted product while maintaining protective recall prevention measures.

Ease of maintenance and quick disassembly reduce downtime and inspection gaps

Regular calibration and inspection are essential to maintain the performance of any metal detector for food industry environments. The G5020's easy-to-disassemble construction enables rapid cleaning, inspection, and access for service technicians. Shorter maintenance cycles decrease the window when detection performance could drift, reducing the risk that contaminated product is produced and shipped when detection capability is compromised.

Validation and traceability: documenting performance to prevent recalls

Regulatory bodies and auditors expect documented validation of metal detection systems. The G5020 supports validation programs by providing diagnostic readouts, event logs, and performance test capabilities (such as on-board test routines and test piece verification). System logs that record detection events, rejection counts, and operator actions create traceability that helps quickly identify root causes and provide evidence during investigations—often limiting the scope and cost of a recall.

Integration with HACCP and preventive control plans

Effective food safety systems incorporate metal detection into Hazard Analysis and Critical Control Points (HACCP) or modern Preventive Controls. As a metal detector for food industry operations, the G5020 is intended to serve as a critical control point (CCP). Its configurable alarm thresholds, event logging, and compatibility with supervisory control systems allow it to be integrated into plant automation and quality workflows, ensuring deviations are immediately acted upon and documented.

Reducing false rejects: how optimized sensitivity avoids unnecessary waste

False rejects can cause production interruptions and unnecessary costs, but overly conservative sensitivity risks missing contaminants. The G5020 reduces false rejects through product effect compensation, multi-frequency tuning, and tailored rejection logic. Optimized sensitivity settings based on product testing keep the detector responsive to true metal hazards while limiting spurious stops that can disrupt operations and create secondary safety risks.

Technical comparison: G5020 versus typical single-frequency detectors

Below is a concise comparison table showing key performance metrics where the G5020 outperforms typical single-frequency detectors commonly used in the food industry.

| Metric | G5020 (Multi-frequency) | Typical Single-frequency Detector |

|---|---|---|

| Detection sensitivity (small metal fragments) | High — better detection of stainless steel and aluminum | Moderate — may miss low conductivity metals |

| Product effect compensation | Advanced multi-frequency compensation | Basic or single-band compensation |

| Hygienic design and cleanability | Specialized conveyor; tool-less disassembly | Variable; often more crevices |

| False reject rate | Lower when properly validated | Higher risk under complex product matrices |

| Integration with logs and validation | Comprehensive event logging and test support | Basic logging; limited validation tools |

Operational best practices to maximize recall prevention

To make the most of a metal detector for food industry settings, manufacturers should combine the right equipment with disciplined operational practices: regular calibration and test-piece verification, documented operator training, scheduled preventative maintenance, validated rejection strategies, and integrated event logging. The G5020 is built to support these practices through ease of maintenance, validation features, and configurable settings aligned with industry guidance.

Regulatory and standards alignment for metal detection systems

Metal detectors used in food processing are part of the preventive controls recognized by regulatory authorities. The G5020 is designed to help manufacturers meet expectations set by authorities such as the U.S. Food and Drug Administration (FDA), EU food safety regulations, and industry standards from organizations like ISO and AOAC. Proper validation and documentation are critical to demonstrate due diligence during audits or in the event of a contamination incident.

How the G5020 reduces the scale and cost of recalls in practice

When a contamination event is detected early in production by a reliable metal detector for food industry use like the G5020, manufacturers can isolate affected batches, perform targeted investigations, and avoid broad market withdrawals. Rapid rejection and logging restrict the volume of contaminated product that reaches packaging or distribution, reduce the time to root cause analysis, and lower recall scope. Efficient rejection systems and clear traceability often translate into smaller recall notices, fewer affected customers, and lower remediation costs.

Brand advantages: Why choose Food Metal Detector Manufacturer For Reject Defective Products G5020

Choosing the G5020 offers several competitive advantages: proven multi-frequency detection to tackle challenging products, hygienic conveyor engineering that supports sanitary operations, easy-to-disassemble components for fast cleaning, configurable rejection options for different line layouts, and comprehensive logging for validation and audits. Together, these features help food producers lower recall risk, maintain product quality, and protect brand reputation.

Real-world scenarios: typical contamination incidents prevented

Examples where the G5020 can prevent costly recalls include: detection of small stainless steel shaving from manufacturing equipment in spice blends; aluminum foil fragments in processed meats; and wire or solder pieces in confectionery lines. In each case, early detection and automated rejection prevent contaminated batches from being packed and shipped, reducing consumer risk and potential liability.

Implementation checklist for buyers of a metal detector for food industry use

Before integrating the G5020, follow this checklist to maximize effectiveness:

- Perform product-specific sensitivity testing with representative test pieces.

- Define rejection strategies aligned to packaging style and line speed.

- Establish validation and re-validation schedules and document them.

- Train operators on test-piece procedures, alarm response, and maintenance.

- Integrate system logging with site quality and SCADA systems for traceability.

Cost-benefit overview: investment versus recall reduction

While capital cost for a robust metal detector for food industry operations is a consideration, the avoided costs of a single large recall—direct product losses, logistics, legal exposure, and brand damage—often justify the investment. The G5020's design aims to lower both detection failures (which can lead to recalls) and false rejects (which add operational cost), balancing protection and yield.

Frequently Asked Questions (FAQ)

1. What types of metal can the G5020 detect?

The G5020's multi-frequency technology improves detection of a wide range of metals, including ferrous, non-ferrous (aluminum), and low-conductivity stainless steel fragments that are often challenging for single-frequency detectors.

2. How often should the G5020 be tested and calibrated?

Daily test-piece checks are recommended for critical control points, with full calibration and validation performed on a schedule defined in your HACCP or preventive control plan. The G5020 supports frequent on-line verification to keep records for audits.

3. Will the G5020 increase my false rejects?

Properly configured and validated, the G5020 is designed to reduce false rejects through multi-frequency compensation and product-specific tuning. Field validation and operator training are key to minimizing false positives.

4. Is the G5020 suitable for wet or chilled production lines?

Yes. The G5020's hygienic conveyor materials and IP ratings for electronics are selected to suit common wet and chilled line conditions—confirm specific environmental ratings with technical documentation for your scenario.

5. Can the G5020 integrate with my existing production control systems?

Yes. The G5020 offers event logging and communication interfaces for integration with SCADA, MES, or plant quality systems to support traceability and automated responses.

Contact us / View product

To learn more about how the Food Metal Detector Manufacturer For Reject Defective Products G5020 can reduce product recalls on your lines, contact our sales team or request a product demo. We offer on-site testing, validation support, and lifecycle service plans to keep your detection systems performing optimally. Even the best reject systems rely on accurate detection performance. That’s why proper setup matters—our article on calibration tips for accurate metal detection in food lines explains how to maintain consistent sensitivity and reliability.

Authoritative references and further reading

For regulatory guidance and industry best practices referenced see the following authoritative sources:

- U.S. Food & Drug Administration (FDA) Food Safety: https://www.fda.gov/food

- European Food Safety Authority (EFSA): https://www.efsa.europa.eu

- AOAC International (methods and validation guidance): https://www.aoac.org

- ISO — International Organization for Standardization (food safety management): https://www.iso.org

- Food Safety Modernization Act (FSMA) Preventive Controls: https://www.fda.gov/food/food-safety-modernization-act-fsma

Troubleshooting False Alarms on Food Metal Detectors

Integrating backup systems with 14 head multihead weighers

The latest trends for multihead weighing machine

What are the application scenarios of automated packaging systems?

About Cooperation Process

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

About After Sales Support

How about the after-sales service?

Warranty :2 years

About Solution suggestions

What are Kenwei’s primary solutions for industrial weighing and packaging?

Kenwei provides comprehensive solutions for automated weighing and packaging, including multi-head weighers, linear weighers, check weighers, metal detectors, and packing machines. These solutions are tailored to improve speed, accuracy, and efficiency in various industries such as food, pharmaceuticals, and chemicals.

About Product choice

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

Dropped Metal Detector for Powder Granules For Food Industry

Enhance food safety with Kenwei’s Dropped Metal Detector for Powder Granules. This advanced food metal detector ensures precise detection in the food industry, safeguarding products and maintaining high quality standards throughout processing.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei