What are the application scenarios of automated packaging systems?

- Understanding Automated Packaging Systems and Their Growing Significance

- Food Industry: Enhancing Efficiency and Ensuring Food Safety

- Pharmaceutical Sector: Precision and Compliance in Packaging

- Chemical Industry: Handling Hazardous and Diverse Materials Safely

- Pet Food and Animal Feed Packaging: Meeting Growing Demands with Reliability

- Hardware and Fasteners: Packaging Small Components Efficiently

- Snack and Confectionery Industry: Combining Speed with Precision

- Frozen Food Packaging: Preserving Quality through Automation

- Cosmetics and Personal Care Packaging: Customized Solutions for Delicate Products

- Logistics and E-commerce: Streamlining Packaging for Diverse Product Lines

- Kenwei’s One-Stop Automated Weighing and Packaging Solutions

- Conclusion: The Broad Impact of Automated Packaging Systems Across Industries

- Frequently Asked Questions

Understanding Automated Packaging Systems and Their Growing Significance

Automated packaging systems have revolutionized the way industries handle the packing process. These systems integrate machinery such as multi-head weighers, metal detectors, linear weighers, and check weighers to streamline product packaging with high speed and precision. As a leader in the industry, Guangdong Kenwei specializes in providing advanced automated weighing and packaging solutions designed to meet a wide range of customization demands. This article explores the major application scenarios of automated packaging systems and how Kenwei’s high-performance equipment plays a vital role across various sectors.

Food Industry: Enhancing Efficiency and Ensuring Food Safety

The food processing industry relies heavily on automated packaging systems for fast, accurate, and hygienic packing solutions. Multi-head weighers and check weighers precisely measure bulk and granular food products like snacks, nuts, frozen foods, confectionery, and coffee, significantly reducing product giveaway and improving yield. Incorporating metal detectors ensures compliance with food safety standards by eliminating contaminants. Kenwei’s high-speed multi-head weighers are ideal in this environment, maintaining output while preserving product integrity.

Pharmaceutical Sector: Precision and Compliance in Packaging

The pharmaceutical industry requires rigorous accuracy, traceability, and regulatory compliance. Automated packaging systems aid in the precise weighing and packaging of tablets, capsules, powders, and liquids. Kenwei’s equipment offers meticulous control, ensuring each package meets dosage requirements and quality standards, minimizing human error, and enhancing production throughput. Plus, the systems' integration capability facilitates automated data capture crucial for pharma quality assurance.

Chemical Industry: Handling Hazardous and Diverse Materials Safely

Automated packaging facilitates the controlled handling of chemicals such as powders, granules, and liquids, which can be hazardous or require contamination-free environments. By automating the packing process, manufacturers reduce manual handling risks and improve operational efficiency. Kenwei’s linear weighers and multi-head weighers support accurate batching and portioning, while customized packaging solutions ensure compliance with industry safety protocols.

Pet Food and Animal Feed Packaging: Meeting Growing Demands with Reliability

The pet food market is flourishing globally, driving the need for automated packaging solutions that can handle various product types, from dry kibble to mixed feed blends. Kenwei’s automated weighing and packaging systems enable high-speed, precise portion control, facilitating consistent package weights and reducing product loss. The system customization allows accommodation of different bag sizes and packaging materials, addressing varied consumer expectations.

Hardware and Fasteners: Packaging Small Components Efficiently

In the hardware manufacturing sector, products like screws, nuts, bolts, and fasteners require rapid and accurate packaging for inventory and distribution. Kenwei’s multi-head weighers and check weighers provide high-accuracy measurements, ensuring efficient batch packaging that enhances warehouse and supply chain management. The automation reduces manual labor, boosts speed, and lowers packaging costs.

Snack and Confectionery Industry: Combining Speed with Precision

Snacks and confectionery items demand automated packaging systems capable of handling delicate products without damage while maintaining high throughput. Kenwei's multi-head weighing technology ensures uniform distribution of candies, chocolates, and snack mixes into packaging, minimizing product giveaways and maximizing shelf appeal. The integration with metal detectors and check weighers secures food safety and quality consistency.

Frozen Food Packaging: Preserving Quality through Automation

Frozen food products require quick and precise packaging to maintain freshness and prevent spoilage. Automated systems from Kenwei deliver high-speed weighing and packaging that minimizes exposure time to ambient conditions. The equipment’s robustness ensures stable performance even under low-temperature production environments, thus maintaining consistent product quality and reducing waste.

Cosmetics and Personal Care Packaging: Customized Solutions for Delicate Products

The cosmetics sector benefits from automated packaging systems tailored to handle a variety of product forms, including powders, creams, and small containers. Kenwei’s precise weighing technology and automated packaging lines enhance packaging accuracy, allowing manufacturers to meet strict product labeling and weight regulations. This automation also improves production efficiency and packaging aesthetics.

Logistics and E-commerce: Streamlining Packaging for Diverse Product Lines

The rapid growth of e-commerce and logistics has increased demand for automated packaging systems capable of handling diverse product sizes and weights. Kenwei’s flexible and customizable weighing and packaging solutions enable quick adjustments for different SKUs, ensuring operational agility and reducing packaging errors. This adaptability improves fulfillment speed and customer satisfaction.

Kenwei’s One-Stop Automated Weighing and Packaging Solutions

Guangdong Kenwei’s comprehensive range of multi-head weighers, metal detectors, linear weighers, and check weighers form the backbone of its automated packaging systems. Located in Fusha High-tech Industrial Park, Zhongshan City, Kenwei integrates design, manufacturing, marketing, installation, and after-sales service to deliver tailored solutions globally. With an emphasis on high speed and high accuracy, Kenwei supports clients in achieving optimized packaging performance, reduced labor costs, and enhanced product safety across numerous industries.

Conclusion: The Broad Impact of Automated Packaging Systems Across Industries

Automated packaging systems are essential in today’s manufacturing landscape to meet increasing demands for speed, accuracy, and safety. They find application across a diverse array of industries—from food and pharmaceuticals to hardware and e-commerce—each benefiting from the reduced manual workload, improved quality control, and maximized operational efficiency. Kenwei, with its advanced weighing and packaging technology, continues to drive innovation and support industry growth through customized, high-performance automated solutions.

Frequently Asked Questions

What industries benefit most from automated packaging systems?

Automated packaging systems are highly beneficial in food processing, pharmaceuticals, chemicals, pet food, hardware, snacks, frozen foods, cosmetics, and logistics sectors.

How do multi-head weighers improve packaging accuracy?

Multi-head weighers combine multiple weighing heads to quickly and precisely measure product portions, reducing product giveaway and ensuring consistent package weights.

What customization options does Kenwei offer for automated packaging systems?

Kenwei provides tailoring in weighing technology, packaging formats, integration with detection devices, and software solutions to meet specific product requirements and production workflows.

Does Kenwei provide after-sales service and technical training?

Yes, Kenwei offers comprehensive after-sales support including installation, commissioning, technical training, and maintenance to ensure smooth system operation.

Can automated packaging systems handle both granular and liquid products?

Yes, systems such as linear weighers and multi-head weighers can be adapted to process various product types, including granular solids and liquids, with appropriate customization.

Top 10 metal detector machine Manufacturers and Supplier Brands in America

The latest trends for food manufacturing metal detector

Reliability Metrics Buyers Need for Multihead Weigher Purchases

Best Combination Weigher Models for Small Food Plants 2025

About Product choice

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

About Cooperation Process

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

How to operate it?

Many languages are available for global markets. There are not only detailed instructions, but also machine video for reference learning.

About Solution suggestions

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

About After Sales Support

How about the after-sales service?

Warranty :2 years

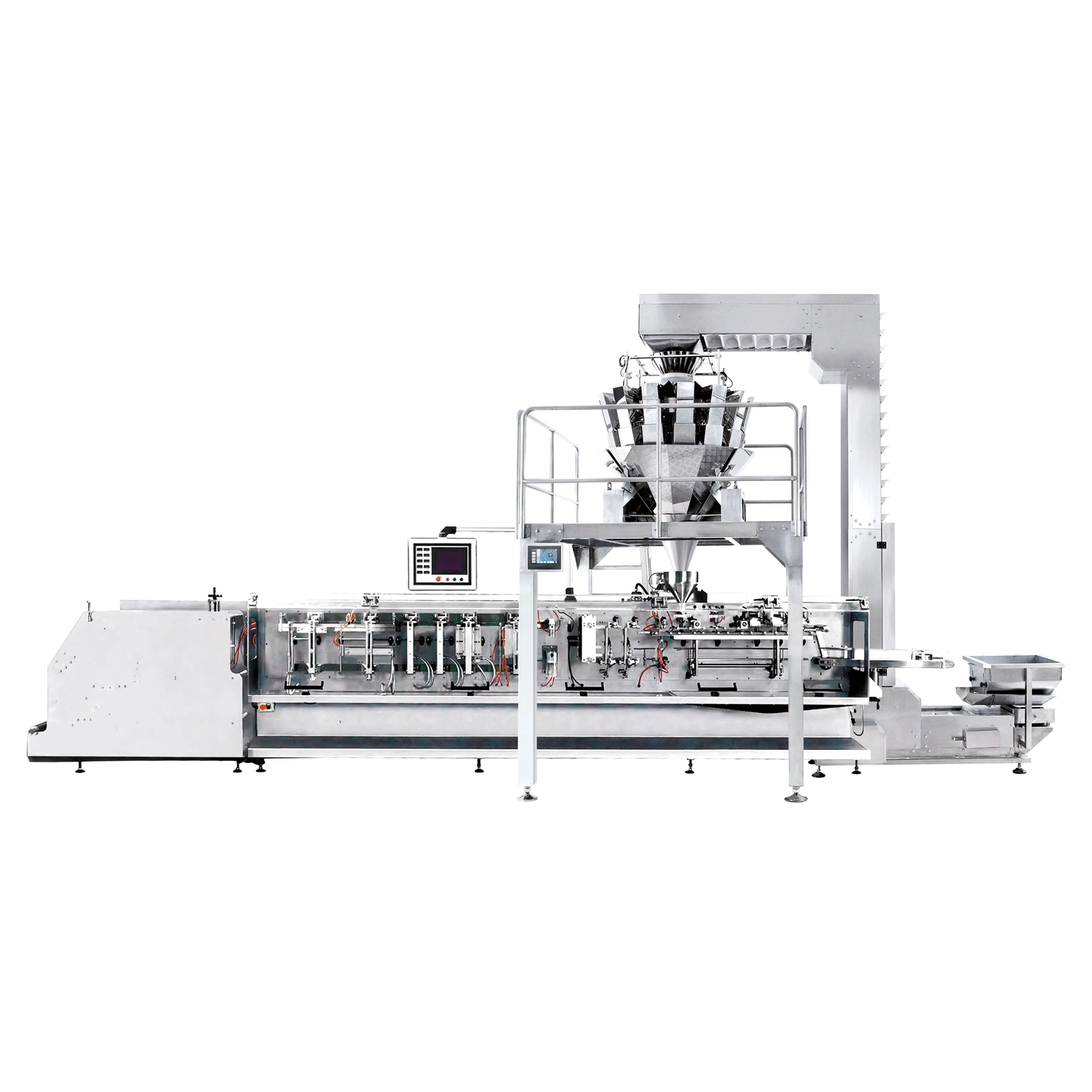

Automatic Premade Pouch Weighing and Filling Machine for Snacks Pet Food JW-B13

The JW-B13 Standard Pre-Made Bag Packing Machine is an advanced weighing and packing system ideal for granules, slices, and irregular products like snacks, nuts, pet food, and hardware. This fully automated line includes a vibrator feeder, Z conveyor, working platform, multihead weigher, and horizontal packing machine. It ensures high weighing accuracy, fast packing speed, and premium bagging quality—perfect for efficient, stable, and precise packaging.

Two Outlet Semi Auto Sugar Weighing and Packaging Machine JW-B16

The Kenwei JW-B16 Two Outlet Semi-Auto Sugar Weighing and Packaging Machine delivers high-precision, automated weighing for granules, slices, and irregular products like candy, coffee beans, and pet food. With a compact, cost-effective design and excellent price-performance ratio, it supports unique bag types and boosts efficiency. Optional add-ons like check weighers, metal detectors, and conveyors ensure quality control and seamless integration. Ideal for food and hardware industries.

Economic vertical form fill seal packing machine(VFFS)

The economical vertical form fill seal (VFFS) packaging machine offers a variety of models designed with a sturdy 304 stainless steel frame. It is equipped with safety door protection and supports multiple bag types, including pillow bags, angle belt bags, printed bags, and triangle bags. This versatile machine is ideal for packaging a wide range of materials, such as snacks, frozen foods, coffee beans, oats, sugar, salt, rice, small hardware components, and more. Affordable and cost-effective, it provides reliable performance and efficiency for diverse packaging needs.

Parallel Robot Pick and Place System for Automated Packaging and Production Lines

The parallel manipulator features a 4-axis linkage structure and a high-precision servo control system, ensuring accurate and reliable operation. It can be integrated with a vision system or onboard conveyor, supporting customized conveying solutions with flexible configuration options. This system is ideal for automated handling of various materials across industries such as food, pharmaceuticals, condiments, plastics, handicrafts, electronics, and more.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei