Troubleshooting False Alarms on Food Metal Detectors

- Troubleshooting False Alarms on Food Metal Detectors

- Why addressing false alarms matters for a metal detector for food industry

- Common causes of false alarms in metal detector for food industry

- Product effect and how to recognize it on a metal detector for food industry

- Environmental interference affecting metal detector for food industry performance

- Mechanical and conveyor issues that trigger false alarms on metal detector for food industry

- Electronic interference and EMI—diagnosing issues for metal detector for food industry

- Calibration, sensitivity and configuration: core settings for any metal detector for food industry

- When to use multi-frequency detectors like the Food Metal Detector Manufacturer For Reject Defective Products G5020

- Step-by-step troubleshooting checklist for metal detector for food industry

- Comparison table: typical causes of false alarms and recommended fixes for metal detector for food industry

- Testing, verification, and record-keeping for metal detector for food industry

- Maintenance best practices to reduce false alarms on metal detector for food industry

- When to contact technical support or consider replacement for your metal detector for food industry

- Brand advantages: why choose Food Metal Detector Manufacturer For Reject Defective Products G5020 for metal detector for food industry

- Practical case example: reducing false alarms on a spice packing line

- Frequently Asked Questions (FAQ) about metal detector for food industry and false alarms

- Q1: What is the most common cause of false alarms?

- Q2: How often should I calibrate or test my metal detector for food industry?

- Q3: Will a multi-frequency detector eliminate all false alarms?

- Q4: Can environmental EMI be permanently fixed?

- Q5: What data should I collect when troubleshooting persistent false alarms?

- Contact us / View product

- Authoritative references and further reading

Troubleshooting False Alarms on Food Metal Detectors

Why addressing false alarms matters for a metal detector for food industry

False alarms on metal detectors used in food production are more than an inconvenience — they interrupt production lines, increase downtime, inflate inspection costs, and can lead to unnecessary product loss and customer complaints. For facilities that must meet strict safety standards (HACCP, GFSI, ISO 22000), reliably distinguishing true positives from nuisance alarms is critical. This guide focuses on practical troubleshooting steps to reduce false positives and keep your metal detector for food industry operating efficiently. Reducing false alarms allows operators to focus on true contamination risks. Learn how advanced systems handle precision detection in detecting small ferrous and non-ferrous particles with G5020 technology.

Common causes of false alarms in metal detector for food industry

Understanding why metal detectors signal falsely is the first step to reducing them. Causes generally fall into five categories: product effect, environmental interference, mechanical issues, electronic/electromagnetic interference (EMI), and setup/calibration problems. Below we explain each category, typical symptoms, and corrective actions.

Product effect and how to recognize it on a metal detector for food industry

Product effect occurs when the composition, density, geometry, or temperature of the product itself produces a signal that mimics metal. High-mineral content products (spices, certain cheeses), products with varying moisture levels, or items with an irregular profile can trigger detectors configured incorrectly.

- Symptoms: Alarms occur consistently when certain SKUs, batches, or packaging speeds pass the head.

- Quick fixes: Use product-matched sensitivity settings, run product effect compensation (if available), and test with product samples during setup.

- Prevention: Use multi-frequency detectors or dynamic product compensation to reduce susceptibility to product effect.

Environmental interference affecting metal detector for food industry performance

Environmental factors surrounding the detector can produce false alarms. Nearby metal structures, vibrating machinery, conveyors with metal parts, or fluctuating power supplies are common culprits.

Remediation steps:

- Re-locate or re-orient the detector head if possible, increasing distance from heavy metal structures.

- Check and improve grounding and earthing connections; poor grounding amplifies EMI.

- Stabilize power supply—use line filters or dedicated circuits to reduce electrical noise.

Mechanical and conveyor issues that trigger false alarms on metal detector for food industry

Mechanical issues such as misaligned conveyor belts, metal fragments or wear on conveyor components, and inconsistent product travel can all trigger nuisance alarms.

- Inspect conveyor for sagging or off-center belt and correct alignment.

- Replace or shield any exposed metal near the detection head (fasteners, supports).

- Ensure consistent product spacing and orientation—irregular product flow can confuse the detector.

Electronic interference and EMI—diagnosing issues for metal detector for food industry

EMI can come from motors, variable frequency drives (VFDs), radio equipment, or nearby fluorescent/LED lighting. EMI typically produces intermittent, unpredictable alarms.

Diagnosis and fixes:

- Temporarily power down nearby equipment one at a time to isolate the source.

- Install ferrite chokes and shielded cables on signal and power lines.

- Consider relocating VFDs or adding EMI suppression devices.

Calibration, sensitivity and configuration: core settings for any metal detector for food industry

Incorrect calibration or overly aggressive sensitivity settings are frequent causes of false alarms. Follow a structured calibration process tied to actual product samples.

- Use representative samples (including the packaging) during setup and testing.

- Start with lower sensitivity and increase only until detection goals are met with acceptable false alarm rate.

- Use frequency scanning or multi-frequency modes where available to select the best operating frequency for your product mix.

When to use multi-frequency detectors like the Food Metal Detector Manufacturer For Reject Defective Products G5020

Multi-frequency detectors are designed to handle challenging product effects and mixed production lines. The Food Metal Detector Manufacturer For Reject Defective Products G5020 uses multi-frequency technology to improve discrimination between product effect and true metal contamination. It is particularly effective for products with high moisture or mineral content and for facilities running multiple SKUs.

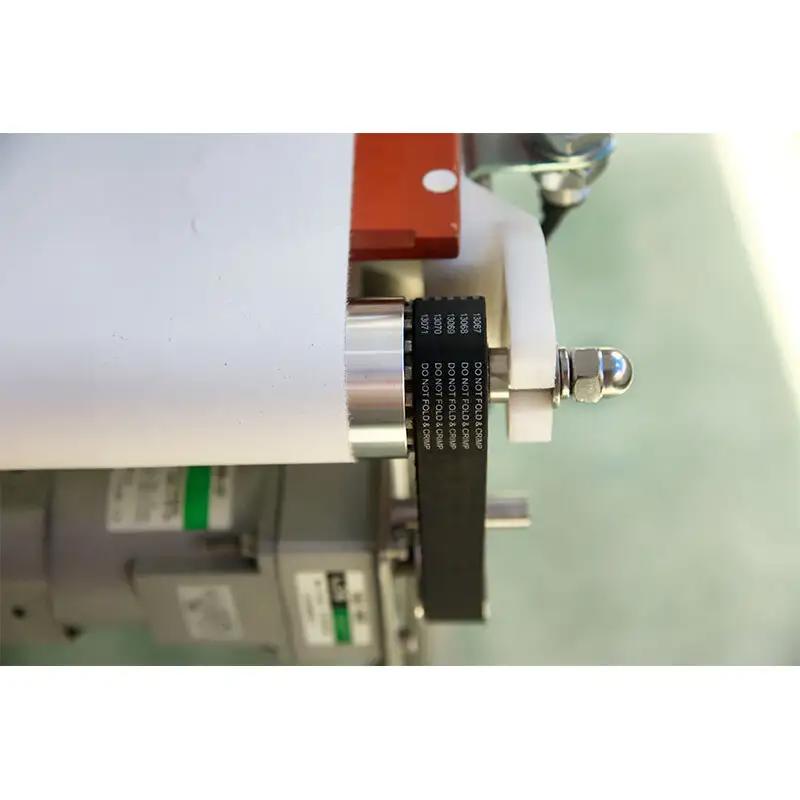

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Step-by-step troubleshooting checklist for metal detector for food industry

Use the following checklist to diagnose and resolve false alarms systematically.

- Confirm frequency and sensitivity settings match product specifications.

- Run a product effect scan or use multi-frequency mode.

- Temporarily remove nearby equipment to identify potential EMI sources.

- Inspect conveyor and support structure for loose metal and alignment issues.

- Verify grounding and power quality; install filters as needed.

- Perform a controlled challenge test with known metal standards and record results.

- Document alarms with timestamps, product batch numbers, and photos where feasible.

Comparison table: typical causes of false alarms and recommended fixes for metal detector for food industry

| Cause | Symptoms | Likely Root Cause | Immediate Fix | Preventive Action |

|---|---|---|---|---|

| Product effect | Alarms with specific SKU or batch | High moisture/minerals or irregular profile | Adjust sensitivity, use product compensation | Use multi-frequency detectors; calibrate per SKU |

| Environmental EMI | Random, intermittent alarms | Nearby motors, VFDs, lighting | Isolate or power-down equipment to test | Install filters, move detector, shield sources |

| Mechanical issues | Alarms increase after maintenance | Misaligned belts, loose studs | Inspect & repair conveyor hardware | Scheduled mechanical inspections |

| Calibration error | Alarms after sensitivity change | Incorrect setup procedure | Re-run calibration with product samples | Operator training, documented SOPs |

Testing, verification, and record-keeping for metal detector for food industry

Regulatory and customer expectations demand documented verification. Implement daily or per-shift challenge testing with certified test pieces. Keep logs of alarm events, test results, and corrective actions. A good record helps identify patterns (e.g., alarms associated with a specific shift or SKU) and supports HACCP audits.

Maintenance best practices to reduce false alarms on metal detector for food industry

Routine maintenance prevents many false alarm sources. Key items include:

- Daily visual inspection of the head and conveyor for debris.

- Weekly cleaning schedules that follow manufacturer guidance to avoid damaging sensors.

- Periodic recalibration following any mechanical repair or process change.

- Firmware and software updates from the manufacturer to improve filtering algorithms.

When to contact technical support or consider replacement for your metal detector for food industry

If nuisance alarms persist after performing the checklist, contact the manufacturer's technical support. Provide detailed logs, sample images, and results of challenge tests. Consider upgrading to a detector with multi-frequency capability (like the G5020) or improved rejection logic if your product range is particularly challenging.

Brand advantages: why choose Food Metal Detector Manufacturer For Reject Defective Products G5020 for metal detector for food industry

The G5020 is optimized for demanding food industry applications. Key advantages include:

- Multi-frequency detection improves discrimination against product effect across varied SKUs.

- Specialized conveyor belt reduces contamination risks and is easy to disassemble for cleaning and maintenance.

- High sensitivity while maintaining stability in electrically noisy environments when properly installed.

- Designed for quick integration into production lines and straightforward operator interfaces to minimize human errors during calibration.

Practical case example: reducing false alarms on a spice packing line

A mid-size packer of dried spices saw frequent false alarms due to high mineral content and variable moisture. After switching to a multi-frequency setup, optimizing conveyor grounding, and introducing SKU-specific calibration profiles, false alarms dropped by more than 70% and line throughput increased. This demonstrates the combined value of correct equipment selection (metal detector for food industry), disciplined setup, and maintenance.

Frequently Asked Questions (FAQ) about metal detector for food industry and false alarms

Q1: What is the most common cause of false alarms?

A1: Product effect—when the product's physical properties mimic metal—accounts for a large share, especially for moist or mineral-rich foods.

Q2: How often should I calibrate or test my metal detector for food industry?

A2: Perform challenge tests at least daily or per shift, and recalibrate whenever the product, packaging, speed, or line mechanics change.

Q3: Will a multi-frequency detector eliminate all false alarms?

A3: No detector completely eliminates nuisance alarms, but multi-frequency systems like the G5020 significantly reduce them for difficult products by allowing better discrimination and per-SKU optimization.

Q4: Can environmental EMI be permanently fixed?

A4: Often yes — through grounding improvements, EMI filters, relocating sources, or shielding. A site survey by a qualified engineer can identify the most effective actions.

Q5: What data should I collect when troubleshooting persistent false alarms?

A5: Record timestamps, product SKU and batch, conveyor speed, ambient conditions, operator on duty, and photos/video of the event. Also keep challenge test records and maintenance logs.

Contact us / View product

If you would like help diagnosing persistent false alarms, scheduling an on-site audit, or evaluating the Food Metal Detector Manufacturer For Reject Defective Products G5020 for your line, contact our sales team to request a demo or quotation. Email: sales@yourcompany.com or request a demo via our website contact form. For quick reference, search our site for product model G5020 to review technical specs and ordering options.

Authoritative references and further reading

- FDA (U.S. Food and Drug Administration) – Food Safety and Inspection Guidance: https://www.fda.gov

- ISO 22000 — Food safety management systems: https://www.iso.org/iso-22000-food-safety-management.

- BRCGS – Global Standards for food safety: https://www.brcgs.com

- AOAC International — Official methods and guidance: https://www.aoac.org

- Wikipedia — Metal detector (for general technical background): https://en.wikipedia.org/wiki/Metal_detector

- USDA — Food Safety and Inspection Service: https://www.fsis.usda.gov

Following the procedures above will reduce nuisance alarms, improve line efficiency, and strengthen your food safety program. For tailored assistance, reach out to our experienced engineers—early diagnosis and the right technology (such as the G5020) often pay for themselves through reduced downtime and fewer product rejections.

Tips for buy packing machine for food products

JW-B20 Semi-Auto Powder Packing: Key Specs Buyers Need

Top 10 checkweigher machine Manufacturers and Supplier Brands in America

What are the application scenarios of dry food packaging machine?

About After Sales Support

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

About Solution suggestions

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

About Cooperation Process

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

Dropped Metal Detector for Powder Granules For Food Industry

Enhance food safety with Kenwei’s Dropped Metal Detector for Powder Granules. This advanced food metal detector ensures precise detection in the food industry, safeguarding products and maintaining high quality standards throughout processing.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei