Detecting Small Ferrous and Non-Ferrous Particles with G5020

- Detecting Small Ferrous and Non-Ferrous Particles with G5020

- Why a reliable metal detector for food industry is essential

- How the Food Metal Detector Manufacturer For Reject Defective Products G5020 works

- Detecting ferrous versus non-ferrous particles: physics and practical sensitivity

- Installation and integration with multihead weighers and packaging lines

- Best practices to maximize detection and minimize false rejects with a metal detector for food industry

- Validation, testing, and regulatory compliance

- Maintenance and hygienic design: keeping sensitivity high

- Return on investment (ROI) and cost considerations for metal detector deployment

- Food Metal Detector Manufacturer For Reject Defective Products G5020 — product brief

- Brand advantages: why choose our G5020 for your food production line

- Frequently Asked Questions (FAQ)

- Q: Can the G5020 detect very small aluminum flakes in a wet sauce? (metal detector for food industry)

- Q: How often should sensitivity tests be run on the metal detector for food industry lines?

- Q: Does the G5020 integrate with existing multihead weighers and reject systems?

- Q: Are there products for which a metal detector is insufficient?

- Q: What documentation is provided for audits and compliance?

- Contact and product viewing CTA

- References and authoritative sources

Detecting Small Ferrous and Non-Ferrous Particles with G5020

Why a reliable metal detector for food industry is essential

Contamination by metal fragments is one of the most common foreign-body risks in food manufacturing. Even tiny ferrous or non-ferrous particles can cause product recalls, damage consumer trust, and create regulatory headaches. Food processors need robust metal detection systems that deliver consistently high sensitivity, low false-reject rates, and integration-friendly design. A metal detector for food industry applications must be tuned for real-world production conditions — wet products, varying packaging, and high-speed lines — while meeting industry standards such as HACCP and local food safety regulations. High sensitivity must be protected in harsh production environments. Our article on sanitation and IP rating for food metal detectors explains how proper enclosure design keeps equipment safe during washdowns.

How the Food Metal Detector Manufacturer For Reject Defective Products G5020 works

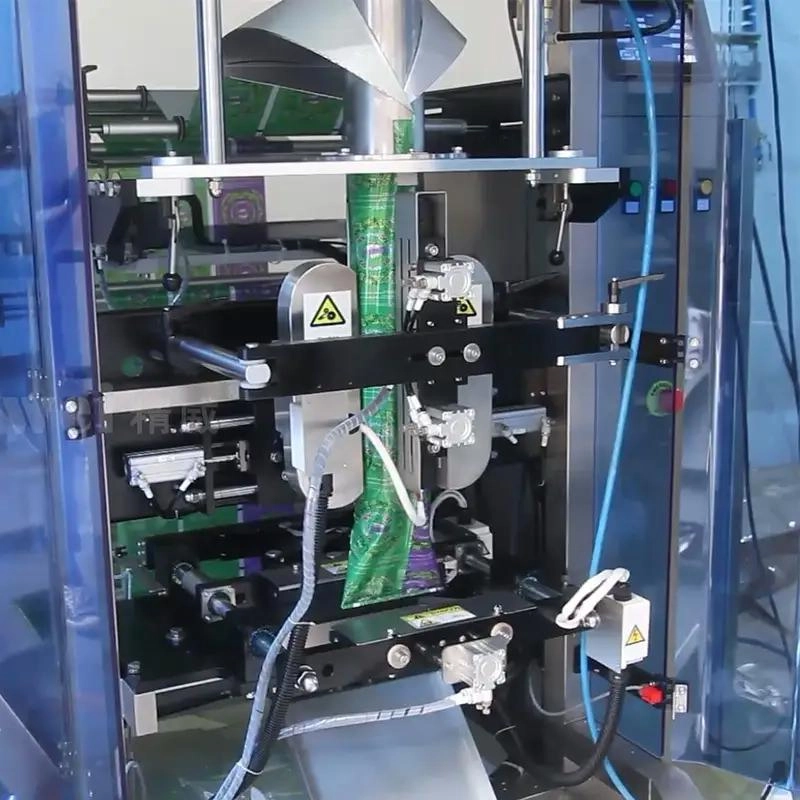

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The G5020 uses multi-frequency detection technology to separate the signal signatures of ferrous, non-ferrous (like aluminum), and stainless-steel particles. Multi-frequency operation reduces masking effects from variable product conductivity and moisture, maintaining sensitivity across many product types. The system continuously monitors its own health and offers digital signal processing to reduce electrical noise and false alarms. A rapid reject mechanism removes defective products from the stream with minimal product loss and helps maintain line throughput.

Detecting ferrous versus non-ferrous particles: physics and practical sensitivity

Ferrous metals (iron, low-carbon steels) and non-ferrous metals (aluminum, copper) interact differently with the detector's electromagnetic field. Ferrous particles are magnetic and produce a strong, distinct response. Non-ferrous metals rely on eddy-current effects and often present smaller signatures, especially when thin or fragmented.

Key practical points for sensitivity:

- Ferrous particles: typically detected at smaller sizes relative to non-ferrous, but shape and orientation matter.

- Non-ferrous particles: require higher sensitivity settings and often benefit from optimized conveyor aperture and frequency selection.

- Stainless steel: detection depends on alloy and heat treatment — some grades are nearly non-magnetic and can be challenging; multi-frequency detectors like the G5020 improve detection for difficult grades.

To achieve reliable detection of sub-millimeter particles, the detector must be placed close to the product, maintain stable grounding, and run appropriate test pieces as part of routine verification.

Installation and integration with multihead weighers and packaging lines

Integrating a metal detector for food industry production lines, especially those that include multihead weighers, requires careful planning. The G5020 is designed with a compact conveyor layout and hygienic construction to fit after multihead weighers and before final packaging. Typical integration steps include:

- Placing the detector after the multihead weigher and any metal-tolerant equipment to minimize masking effects.

- Synchronizing line speed and reject timing so the reject actuator removes only the contaminated package and does not disrupt upstream dosing.

- Providing stable power, earth grounding, and EMI shielding to reduce electrical interference from motors and other equipment.

- Ensuring mechanical alignment and conveyor leveling to avoid product bounce and maintain detection consistency.

Good integration reduces false rejects, safeguards product weights and fill accuracy, and maintains production efficiency.

Best practices to maximize detection and minimize false rejects with a metal detector for food industry

To get the most from the G5020 and similar metal detectors, follow practical operational practices:

- Use representative test pieces (ferrous, non-ferrous, stainless) and validate sensitivity daily or per shift.

- Set up product profiling to let the detector learn the product signal and automatically compensate for acceptable variability.

- Apply appropriate frequency selections and sensitivity levels for each product family. Multi-frequency detectors allow frequency mixing to reduce masking from very conductive or wet products.

- Manage line environment: reduce nearby power noise, maintain consistent product positioning, and avoid metallic fixtures in the detection zone.

- Implement a rejection strategy that uses minimal contact (air blast or pusher) to avoid reseeding contaminants or damaging packaging.

These steps lower both the risk of passing contaminated product and the volume of good product falsely rejected.

Validation, testing, and regulatory compliance

Regulatory frameworks and major retailers expect documented metal detection systems as part of a company’s hazard control plan (HACCP) and Good Manufacturing Practice (GMP). The following actions are recommended for compliance:

- Create written procedures for verification tests, frequency of tests, and acceptance criteria.

- Maintain test logs (including test pieces used, detection results, and operator name).

- Perform annual calibration and firmware validation where applicable.

- Keep records to demonstrate due diligence during audits and customer inquiries.

Below is a comparative table showing approximate detectable particle sizes under controlled conditions — values will vary by product, packaging, and detector tuning.

| Metal Type | Typical Detectable Size (mm) | Notes |

|---|---|---|

| Ferrous | 0.8 - 1.5 | Best detection; orientation less critical |

| Non-ferrous (Aluminum) | 1.5 - 3.0 | Requires higher sensitivity; thin shards harder |

| Stainless Steel (varies) | 2.0 - 4.0+ | Depends on grade and heat treatment; use multi-frequency |

Maintenance and hygienic design: keeping sensitivity high

Maintaining a metal detector for food industry use requires a schedule that includes cleaning, mechanical inspection, and electronic verification. The G5020's conveyor and modular design make disassembly and cleaning straightforward — critical in food environments where sanitation is frequent. Maintenance best practices include:

- Daily visual checks for belt integrity, guiding rails, and debris in the aperture.

- Regular cleaning following your HACCP cleaning schedule; ensure power is isolated during cleaning.

- Monthly sensitivity checks using certified test pieces and logging results.

- Periodic firmware updates and electronics checks by qualified service personnel.

Routine maintenance preserves detection performance and extends equipment life.

Return on investment (ROI) and cost considerations for metal detector deployment

Investment in a high-performance metal detector such as the G5020 reduces the risk of recalls, product rework, and customer complaints. When evaluating ROI, consider:

- Cost of a single recall (direct losses, distribution, penalties, reputational damage).

- Reduction in customer claims and warranty costs.

- Lower insurance High Qualitys and improved buyer confidence.

- Increased line uptime when false-reject rates are minimized.

Often the cost of a reliable detector is recovered quickly through avoided incidents and through improved operational efficiency.

Food Metal Detector Manufacturer For Reject Defective Products G5020 — product brief

The Food Metal Detector Manufacturer For Reject Defective Products G5020 is engineered for demanding production environments where detecting small ferrous and non-ferrous particles is critical. The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Key features at a glance:

- Multi-frequency detection for improved sensitivity across product types

- Hygienic, quick-release conveyor components for easy cleaning

- Adjustable sensitivity profiles and product memory

- Robust reject options (pusher, air blast, drop) to match packaging and speed

- Self-diagnostic monitoring and event logging for audit trails

Brand advantages: why choose our G5020 for your food production line

Our brand combines deep experience in food industry inspection equipment with practical engineering focused on production realities:

- Industry expertise: experience integrating with multihead weighers, packaging machines, and downstream equipment.

- After-sales support: local service, training, and preventative maintenance plans to keep sensitivity and uptime high.

- Customization: flexible conveyor widths, reject methods, and software interfaces to meet customer-specific needs.

- Compliance-ready: validation documentation and testing protocols that align to HACCP and major retailer requirements.

These advantages make the G5020 a practical, low-risk choice for manufacturers who need dependable metal detection performance and measurable business benefits.

Frequently Asked Questions (FAQ)

Q: Can the G5020 detect very small aluminum flakes in a wet sauce? (metal detector for food industry)

A: Detection of very small aluminum in wet, conductive products is difficult for any detector. The G5020's multi-frequency operation improves performance in such conditions, but detection limits will still be larger than for dry products. We recommend representative in-line validation tests and possibly a secondary inspection step (e.g., x-ray) for critical products.

Q: How often should sensitivity tests be run on the metal detector for food industry lines?

A: Best practice is daily verification tests with certified test pieces for each product line or shift. Additionally, run a complete validation whenever product formulation or packaging changes.

Q: Does the G5020 integrate with existing multihead weighers and reject systems?

A: Yes. The G5020 is designed for easy integration. Typical setups place the detector after the multihead weigher and before primary packaging sealing to ensure accurate reject timing. We offer interface support and on-site commissioning to optimize integration.

Q: Are there products for which a metal detector is insufficient?

A: Very low-density metal fragments or extremely small non-ferrous shards in certain high-conductivity products can be challenging. In these cases, complementary technologies such as x-ray inspection may be recommended to meet safety requirements.

Q: What documentation is provided for audits and compliance?

A: The G5020 comes with test procedures, calibration records, and a validation protocol. We also provide template logs and can train staff on HACCP-compliant record keeping.

Contact and product viewing CTA

If you want to reduce the risk of metal contamination on your production line and learn how the G5020 can be configured for your products, contact our sales team for a consultation, live demo, or on-site trial. View the product spec sheet, request sensitivity trials with your own product, or schedule a commissioning visit. Get in touch today to protect Kenwei and improve line efficiency.

References and authoritative sources

Industry references consulted for best practices and regulatory context:

- HACCP principles and application: Codex Alimentarius - https://www.fao.org/fao-who-codexalimentarius

- Food safety and inspection guidance: U.S. FDA Food Safety - https://www.fda.gov/food

- Metal detector technology overview: Wikipedia - Metal detector - https://en.wikipedia.org/wiki/Metal_detector

- Guidance on foreign object control and mitigation: Food Safety Magazine / industry best practices (example resources) - https://www.foodsafetymagazine.com

For tailored recommendations, sensitivity validation, and system quotations, reach out to our technical sales team and arrange product trials with your real production batches.

Energy, Maintenance, and Uptime: Procurement Guide to VFFS

Top 10 Linear Weigher Features to Look For

Top 10 Tests to Validate Aluminum Foil Detection Performance

Top food pouch packing machine Manufacturers and Suppliers in China

About Product choice

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

Are Kenwei’s products suitable for small-scale or large-scale operations?

Yes! We offer machines that are scalable to meet the needs of both small and large-scale operations.

About products customization

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

About After Sales Support

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

Dropped Metal Detector for Powder Granules For Food Industry

Enhance food safety with Kenwei’s Dropped Metal Detector for Powder Granules. This advanced food metal detector ensures precise detection in the food industry, safeguarding products and maintaining high quality standards throughout processing.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei