Top 10 Tests to Validate Aluminum Foil Detection Performance

- Understanding Detection Challenges with Aluminum Foil Packaging

- Why aluminum foil complicates metal detection

- Principles behind foil-optimized detectors

- Regulatory & standards context

- Top 10 Tests to Verify Aluminum Foil Detection Performance

- 1. Baseline sensitivity test (no packaging)

- 2. Foil-only background mapping

- 3. Packaged product sensitivity (masked test)

- 4. Multi-position scan repeatability

- 5. Velocity and throughput test

- 6. Moisture and temperature stress test

- 7. Noise and electromagnetic interference (EMI) evaluation

- 8. False-reject and false-acceptance rate analysis

- 9. Peak-hold and transient detection test

- 10. Routine calibration and traceability verification

- Designing an Effective Test Protocol

- Choosing test pieces and acceptance criteria

- Sample size and statistical confidence

- Documentation and audit-readiness

- Practical Tips, Troubleshooting, and Performance Comparison

- Common causes of reduced sensitivity and countermeasures

- When to escalate to vendor support

- Performance comparison table

- Validation Records, Traceability, and Standards References

- Recommended documentation structure

- Standards & guidance to cite during audits

- Lab accreditation and traceable calibration

- Frequently Asked Questions (FAQ)

- Q: Can a metal detector reliably detect metal inside aluminum foil packages?

- Q: How often should we perform sensitivity verification?

- Q: Do we need to slow the line to improve detection in foil-packed products?

- Q: What are acceptable false-reject rates?

- Q: Where can I find recognized standards to support our validation?

Ensuring consistent detection of magnetic metal contaminants in aluminum foil-packaged products is a critical part of any food safety program. This guide focuses on robust, repeatable tests that validate aluminum foil detection performance for a metal detector for food industry use — helping operators, quality managers, and auditors demonstrate capability, meet regulatory expectations, and minimize false rejects caused by conductive or packing materials.

Understanding Detection Challenges with Aluminum Foil Packaging

Why aluminum foil complicates metal detection

Aluminum foil is conductive and can create a masking effect or variable background signal that compromises the sensitivity of conventional metal detectors. For food processors using a metal detector for food industry applications, the presence of aluminum packaging (bags, pouches, wrappers) can lead to either missed contaminants or an elevated nuisance-reject rate unless the detection system is optimized and validated specifically for foil-wrapped products.

Principles behind foil-optimized detectors

Specialized units, such as the Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection, include high-sensitivity sensors and filtering algorithms that reduce the foil background while preserving sensitivity to magnetic metal contaminants. Configuration options (e.g., multiple frequency modes, dynamic balancing and product learning) are essential to tuning performance across product types and pack geometries.

Regulatory & standards context

Validation testing should align with recognized food-safety frameworks. Refer to ISO 22000 for food safety management principles (ISO 22000) and FDA guidance under FSMA for preventive controls (FDA — FSMA). For background on metal detectors and their technologies, the Wikipedia overview is useful (Metal detector — Wikipedia).

Top 10 Tests to Verify Aluminum Foil Detection Performance

1. Baseline sensitivity test (no packaging)

Purpose: Establish the instrument's inherent sensitivity to small magnetic metal pieces without any foil influence. Method: Run a series of standard test pieces (e.g., 1.5mm ball, 2mm wire loop) through the aperture on a clean conveyor at production speed. Acceptance: Detector must alarm on each standard piece 100% of the time. This creates the baseline benchmark for later masked tests.

2. Foil-only background mapping

Purpose: Measure the detector response to empty aluminum foil pouches or common packaging formats used in production. Method: Pass empty foil pouches, sealed bags, or sheets through in the orientation used at line speed and record the variability and peak background signal. Acceptance: Background variation should be within the detector's automatic balancing range — if not, adjust balance or use foil-specific modes.

3. Packaged product sensitivity (masked test)

Purpose: Assess real-world sensitivity when the product is in its normal foil packaging. Method: Place calibrated test pieces (see table below) at multiple positions within representative foil-packaged products (center, edge, top, bottom) and pass them through at production speed. Acceptance: Minimum acceptable detection rate typically ≥95% for each test piece position; define stricter criteria per internal policy or customer requirements.

4. Multi-position scan repeatability

Purpose: Verify consistent detection across conveyor width and different product orientations. Method: For each representative product, test detection at the left, center and right of the aperture and with the pack oriented both ways. Run at least 10 passes per position. Acceptance: Standard deviation of alarm rates between positions should be small; investigate positions with reduced sensitivity.

5. Velocity and throughput test

Purpose: Confirm detection performance at maximum expected line speed and throughput. Method: Perform packaged product sensitivity tests while incrementally increasing line speed to the maximum production rate (and slightly above). Acceptance: Detector must maintain acceptable detection rates at declared production speeds. If sensitivity drops, adjust aperture settings, slow line, or change product handling to reduce turbulence or lift.

6. Moisture and temperature stress test

Purpose: Aluminum foil and product moisture can change dielectric and conductive properties. Method: Test with freshly roasted/steaming items, chilled items and at varying ambient temperatures representative of the facility. Include high-humidity conditions if relevant. Acceptance: No systematic loss of detection performance; log any required setting changes for each condition.

7. Noise and electromagnetic interference (EMI) evaluation

Purpose: Identify external EMI sources (motors, frequency drives, RF) that may increase false rejects or mask signals. Method: Operate suspected equipment near the detector and run sensitivity tests. Use the detector's built-in diagnostics to view noise levels. Acceptance: Detector should remain stable; mitigate EMI by rerouting cables, installing shields, or moving equipment if noise is excessive.

8. False-reject and false-acceptance rate analysis

Purpose: Quantify both false rejects (good product alarmed) and false accepts (contaminated product not alarmed) under normal operations. Method: Run a mixed batch of typical packets and a set of seeded contaminated packets at production speed. Acceptance: Define acceptable false reject rate (often 0.5–2% depending on product economics) and minimum detection for seeded faults (e.g., 95–100%).

9. Peak-hold and transient detection test

Purpose: Confirm the detector properly captures transient signals from contaminant signatures that may be brief during passage. Method: Use high-speed camera synchronization or electronics to ensure that short-duration signals from small fragments are captured. Acceptance: Detector should reliably alarm for standard transient signals; verify firmware peak-hold settings and sample rates.

10. Routine calibration and traceability verification

Purpose: Validate that calibration and verification procedures produce repeatable results with traceable standards. Method: Use certified test pieces traceable to recognized labs; run scheduled verification (daily quick-check, weekly full-check, monthly calibration) and document results. Acceptance: Measurements must remain within control limits; out-of-tolerance events require investigation and corrective action per ISO 22000 style food safety management expectations.

Designing an Effective Test Protocol

Choosing test pieces and acceptance criteria

Select test pieces that reflect likely contaminants and the smallest size you intend to detect in production. Magnetic metal spheres, wires, and stamped particles each simulate different real-world fragments. Acceptance criteria should be defined in your documented control plan and validated by risk assessment (HACCP-style), taking customer and regulatory expectations into account (Codex Alimentarius).

Sample size and statistical confidence

Use statistical sampling to define the number of runs per test. For binary outcomes (detect/not detect), 30+ runs per condition provide reasonable confidence to observe systematic issues. If claims of 99% detection are required, larger sample sizes and formal statistical analysis are necessary.

Documentation and audit-readiness

Record each test run, operator, machine settings, environmental conditions, and results. Maintain a calibration log and corrective action records. This supports compliance with customer audits and standards such as ISO 22000 and helps demonstrate due diligence in case of a recall or incident.

Practical Tips, Troubleshooting, and Performance Comparison

Common causes of reduced sensitivity and countermeasures

Typical issues include improper balance/settings for foil materials, dirty or vibrating conveyors, high EMI, and inconsistent pack presentation. Countermeasures: enable foil compensation modes, stabilize product presentation (guides, infeed rails), schedule regular cleaning, and address EMI at the source.

When to escalate to vendor support

If systematic failures persist after basic troubleshooting (reduced sensitivity at all positions, excessive noise that can't be mitigated, or software/firmware anomalies), contact the detector vendor for remote diagnostics, on-site calibration, or firmware updates. The Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection includes adjustable settings and vendor support options to assist with fine-tuning.

Performance comparison table

| Test | Typical Acceptance | Notes |

|---|---|---|

| Baseline sensitivity (no pack) | 100% detection of standard pieces | Establishes instrument capability |

| Packaged (foil) sensitivity | ≥95% detection per position | Positions: center/edge/top/bottom |

| Speed/stress test | Maintain detection at max speed | Adjust throughput or settings if not met |

| False reject rate | Typically 0.5–2% (policy dependent) | Balance economics and safety |

For a practical example, the 2415 Metal Detector for Aluminum Foil offers adjustable settings and a maximum width of 24mm with heights 20–150mm, making it appropriate for testing across many foil-pack formats. Product details:

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Validation Records, Traceability, and Standards References

Recommended documentation structure

Include test plan, SOPs for daily/weekly/monthly checks, logs of test runs, calibration certificates for test pieces (traceable), corrective actions and final sign-off by QA. Keep versions controlled and readily available for audits.

Standards & guidance to cite during audits

Useful references include ISO 22000 (ISO 22000) for food safety systems, FDA FSMA materials on preventive controls (FDA — FSMA), and Codex Alimentarius guidelines for general food safety principles (Codex). For technical background on detection technologies, consult the metal detector overview at Wikipedia.

Lab accreditation and traceable calibration

Where formal claims are made about minimum detectable sizes or % detection, consider independent verification by an accredited laboratory (ISO/IEC 17025) to provide defensible evidence for customers and regulators.

Frequently Asked Questions (FAQ)

Q: Can a metal detector reliably detect metal inside aluminum foil packages?

A: Yes — provided the detector is designed or tuned for aluminum foil applications, validated with the tests in this guide, and operated with stable product presentation and appropriate settings. The 2415 Metal Detector is built with high-sensitivity sensors and foil compensation features to address this challenge.

Q: How often should we perform sensitivity verification?

A: Perform a quick verification daily (start-of-shift) and a full sensitivity check weekly or whenever product, packaging, or line conditions change. Document results and maintain traceability to test pieces.

Q: Do we need to slow the line to improve detection in foil-packed products?

A: Not necessarily. First attempt tuning the detector (frequency modes, sensitivity, balance) and improve pack presentation. If unacceptable detection persists at production speed, evaluate trade-offs between line speed and food safety risk.

Q: What are acceptable false-reject rates?

A: Acceptable rates depend on product value, shelf-life, and customer expectations. Many processors target <2% but set policy based on risk assessment and commercial considerations.

Q: Where can I find recognized standards to support our validation?

A: Start with ISO 22000 for management systems (ISO 22000), FDA FSMA guidance (FDA — FSMA), and Codex Alimentarius (Codex) for global food safety principles.

If you need help implementing a validation program tailored to your line, testing protocol templates, or on-site tuning of a metal detector for food industry use, contact our team or view product specifications for the 2415 Metal Detector for Aluminum Foil.

Contact Sales / View Product: For detailed specifications, site assessment, or to schedule an on-site trial of the Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection, please contact our sales team or request a demo.

Top 10 multihead weigher machine Manufacturers and Supplier Brands

Energy, Maintenance, and Uptime: Procurement Guide to VFFS

What are the application scenarios of vacuum packing machine?

Top 10 Food Grain Packing Machine Features to Look For

About Solution suggestions

How can Kenwei solutions help reduce waste in my production process?

Kenwei solutions improve accuracy in weighing, packaging, and quality control, reducing the chances of overfill or underfill. This leads to less product waste and higher operational efficiency.

What are Kenwei’s primary solutions for industrial weighing and packaging?

Kenwei provides comprehensive solutions for automated weighing and packaging, including multi-head weighers, linear weighers, check weighers, metal detectors, and packing machines. These solutions are tailored to improve speed, accuracy, and efficiency in various industries such as food, pharmaceuticals, and chemicals.

Can Kenwei provide a solution for mixed-product weighing?

Yes, Kenwei’s multi-head weighers are ideal for mixed-product weighing. They can handle a variety of products in different shapes and sizes, ensuring that the correct portions are weighed and packaged quickly.

About After Sales Support

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

About Product choice

Can Kenwei's machines be used in my industry?

Kenwei’s equipment is highly versatile and can be used across a wide range of industries, including:Food,Pharmaceuticals,Chemicals,Plastics and Agriculture.

Plastics If you're unsure whether our products are suitable for your industry, please contact us, and we can provide you with specific solutions tailored to your needs.

Dropped Metal Detector for Powder Granules For Food Industry

Enhance food safety with Kenwei’s Dropped Metal Detector for Powder Granules. This advanced food metal detector ensures precise detection in the food industry, safeguarding products and maintaining high quality standards throughout processing.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

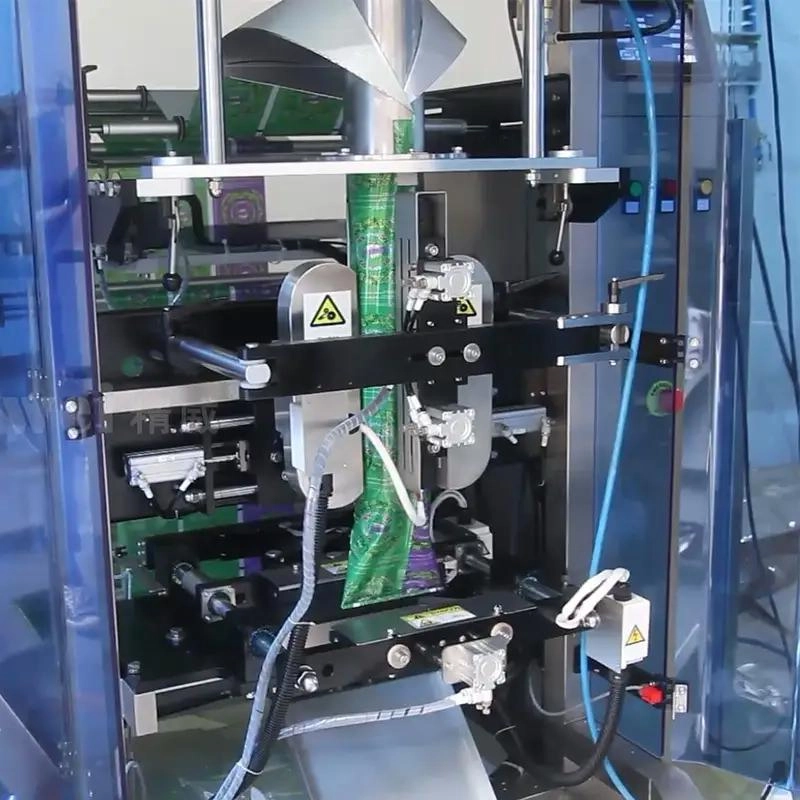

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei