Top 10 Food Grain Packing Machine Features to Look For

- Introduction: Understanding for Top 10 Food Grain Packing Machine Features to Look For

- 1. High-Speed Multihead Weighing Performance

- 2. High Precision and Repeatability

- 3. Wide Product & Bag Size Flexibility

- 4. Hygienic Design & Food-Grade Materials

- 5. Intelligent Control Systems & User Interface

- 6. Integrated Metal Detection & Contamination Control

- 7. Modular Design & Easy Maintenance

- 8. Dust Control and Environmental Sealing

- 9. Packaging Compatibility & Sealing Options

- 10. After-sales Support, Customization & Compliance

- Comparing Weigher Types for Food Grain Packing

- How Kenwei Supports Buyers of Food Grain Packing Machines

- Checklist: Quick Decision Guide Before You Buy

- Conclusion: Make an informed purchase for long-term value

- Frequently Asked Questions

Introduction: Understanding for Top 10 Food Grain Packing Machine Features to Look For

When buyers search for Top 10 Food Grain Packing Machine Features to Look For, they typically want clear, actionable criteria to evaluate equipment for packing rice, wheat, corn, pulses, and other grains. This guide provides practical, user-centered advice to help purchasing managers, packaging engineers, and plant owners choose reliable, high-speed packing solutions. It integrates keywords such as buy packing machine, multi-head weigher, packaging automation, and Kenwei to support decision-making and vendor selection.

1. High-Speed Multihead Weighing Performance

Feature overview: Look for packing machines that deliver consistent throughput. For grains, multihead weighers typically achieve 60–180 packs per minute (ppm) depending on model, head count, and bag size — enabling high-volume production lines. If your plant requires faster verification or post-pack weighing, combine with high-speed check weighers that can reach up to 300 ppm for small packages.

2. High Precision and Repeatability

Feature overview: Precision matters for cost control and compliance. Industry-accepted accuracy for multihead weighers handling grains commonly ranges from ±0.1 g to ±1 g for small pack weights and ±0.2%–±1% of target weight for larger packs. High precision reduces giveaway and material waste, lowering long-term costs and improving margin when you buy a packing machine.

3. Wide Product & Bag Size Flexibility

Feature overview: A versatile food grain packing machine should handle varied grain types (free-flowing rice, broken rice, pulses, corn grits) and a broad bag size range (for example, 25 g snack packs up to 25 kg sacks). Look for adjustable infeed, hopper design, and configurable weigher heads to minimize changeover time and support SKU expansion.

4. Hygienic Design & Food-Grade Materials

Feature overview: Choose machines constructed of stainless steel (SS304 or SS316 where needed), with smooth welds, drainable hoppers, and easy-to-clean surfaces. Hygienic design lowers contamination risk and simplifies HACCP and BRC compliance. For buyers prioritizing food safety, specify sanitary seals, rounded edges, and quick-disassembly components.

5. Intelligent Control Systems & User Interface

Feature overview: Modern packing lines rely on PLCs, touchscreen HMIs, recipe management, and remote diagnostics. Commercially minded purchasers should look for machines with touchscreen interfaces, multi-language support, recipe recall for fast changeovers, and industry-standard communications (Ethernet/IP, Modbus) to integrate with MES and SCADA systems.

6. Integrated Metal Detection & Contamination Control

Feature overview: Combining metal detectors with packing machines adds a critical safety layer. Effective contamination control includes infeed sieves, metal detection calibrated for grains, and reject systems that remove contaminated packs without slowing the line. Choose vendors that can integrate metal detection, X-ray (if required), and automatic rejection seamlessly.

7. Modular Design & Easy Maintenance

Feature overview: Modular machines reduce downtime and support scalability. Features to prioritize: tool-less access panels, modular weigh modules, plug-and-play electrical connectors, and standardized spare parts. These reduce mean time to repair (MTTR) and simplify service, which is especially important when buying automated systems for continuous operations.

8. Dust Control and Environmental Sealing

Feature overview: Grain handling generates dust that affects product quality and operator safety. Effective dust control includes enclosed conveyors, dust extraction ports, dust-tight hoppers, and positive-pressure enclosures for sensitive electronics. Good environmental sealing prolongs equipment life and keeps the workplace compliant with local regulations.

9. Packaging Compatibility & Sealing Options

Feature overview: Ensure the packing machine supports the sealing and bag styles Kenwei uses—pillow bags, gusseted bags, center-seal, block-bottom, or stand-up pouches. Look for robust vertical form-fill-seal (VFFS) or pre-made bag feeding, and sealing technologies (heat-seal, impulse seal, ultrasonic sealing) compatible with your packaging film and moisture barrier requirements.

10. After-sales Support, Customization & Compliance

Feature overview: Commercial buyers need dependable service. Evaluate vendors on warranty terms, local technical support, training, spare parts availability, and options for customization (e.g., special infeed for sticky grains). Confirm the machine meets relevant standards (CE, UL, local food safety regulations) and ask for references in grain packing applications.

Comparing Weigher Types for Food Grain Packing

Feature overview: Choosing the right weigher technology affects speed, accuracy, and cost. The table below compares commonly used systems for grain packing.

| Weigher Type | Typical Speed (packs/min) | Typical Accuracy | Best for | Common Grain Applications |

|---|---|---|---|---|

| Multihead weigher | 60–180 ppm | ±0.1 g to ±1 g (or ±0.2%–1%) | High-speed, high-accuracy packing | Rice, pulses, mixed grains, granular snacks |

| Linear (loss-in-weight) weigher | 30–120 ppm | ±0.5–2 g | Simple products, lower throughput | Coarse grains, flakes, large seeds |

| Check weigher (for verification) | Up to 300 ppm | ±0.5–2 g | Quality control, regulatory verification | All packaged grain types |

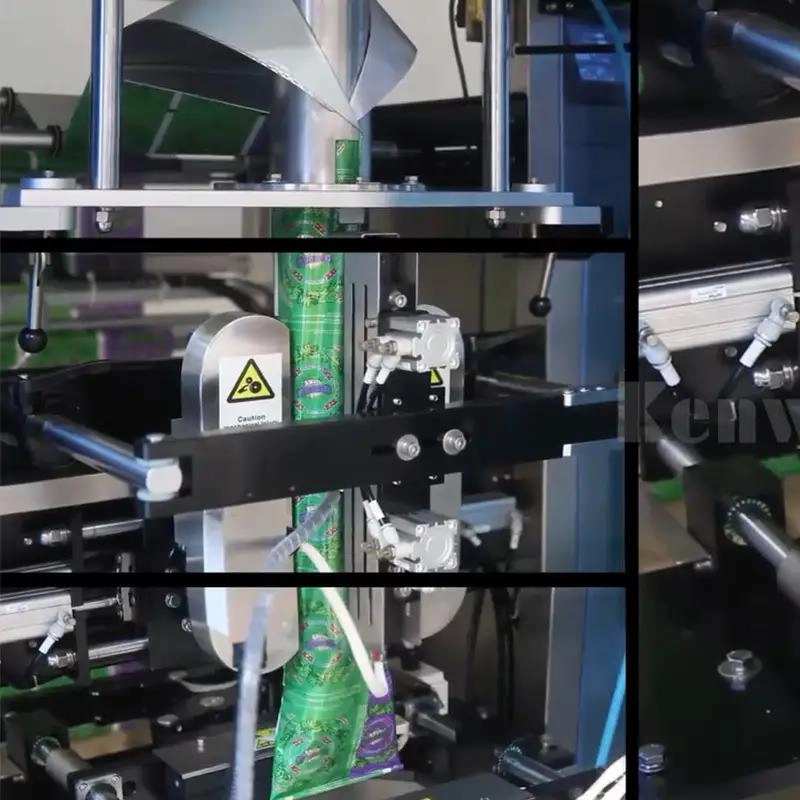

How Kenwei Supports Buyers of Food Grain Packing Machines

Feature overview: As a powerful manufacturer of multi-head weighers, Guangdong Kenwei combines automated weighing systems with metal detectors, linear weighers, and check weighers to supply one-stop packaging solutions. Located in Fusha High-tech Industrial Park, Zhongshan City, Kenwei emphasizes high speed, high precision, customization, installation, and after-sales service—helping you buy a packing machine that fits your production and compliance needs.

Checklist: Quick Decision Guide Before You Buy

Feature overview: Use this quick checklist to evaluate vendors and machines before committing to purchase: desired throughput (ppm), target pack sizes, accuracy requirements, material compatibility, hygiene standards, integration with existing lines, warranty & service terms, and total cost of ownership (TCO) including maintenance and spare parts.

Conclusion: Make an informed purchase for long-term value

Choosing the right food grain packing machine means balancing speed, accuracy, hygiene, maintainability, and vendor support. Prioritize the Top 10 Food Grain Packing Machine Features to Look For—especially precision, hygienic construction, intelligent controls, contamination protection, and strong after-sales service. For manufacturers seeking proven multihead weighers and integrated packing solutions, Kenwei offers configurable systems and global support to optimize yield and reduce operating costs.

Frequently Asked Questions

Q: What is the most important feature when selecting a grain packing machine?A: Accuracy and repeatability are often the top priorities because they directly affect product giveaway and profit margins. Pair high accuracy with adequate speed for your production needs.Q: Can one machine handle multiple grain types and bag sizes?A: Yes. Many modern multihead weighers are designed for flexibility. Check the machine's adjustable settings, head configuration, and available hoppers to ensure compatibility with your SKUs.Q: How do I decide between a multihead and a linear weigher?A: Choose a multihead weigher for higher throughput and better accuracy for small to medium packs. Use linear weighers for coarse, large-sized products or when budget constraints favor simpler systems.Q: How important is dust control in grain packing lines?A: Very important. Dust control improves product quality, reduces health risks, protects electronics, and helps meet local workplace and food safety regulations.Q: What after-sales services should buyers expect from suppliers like Kenwei?A: Expect installation, commissioning, operator training, preventive maintenance plans, spare parts supply, remote diagnostics, and timely technical support tailored to grain packing applications.

How Food Metal Detectors Prevent Contamination in Production

Top combination weigher machine Manufacturers and Suppliers in China

How to Choose a Vertical Packaging Machine for High Throughput

Integrating Combination Weigher into Automated Packaging Lines

About Product choice

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

About Cooperation Process

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

About After Sales Support

How do I claim warranty service?

To claim warranty service, please contact our customer support team with your machine’s product code and a description of the issue. If applicable, we may request photos or videos of the issue to facilitate troubleshooting.

About Price and payment

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

About Solution suggestions

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Combined weighing and packaging machine with screw feeder for powder materials

The Kenwei combined weighing and packaging machine with screw feeder is ideal for powder packaging. This advanced weighing and packaging machine of powder ensures high precision and efficiency, making it your top choice power packaging machine for powder materials.

Semi Automatic Multi-function Single Bucket Conveying Powder granule food Packaging Machine With Linear Weigher JW-B20

The Kenwei JW-B20 Semi-Automatic Multi-Function Packaging Machine with Linear Weigher is ideal for powders and granules like sugar, salt, rice, coffee, and milk powder. It automates feeding, weighing, and output with high accuracy and efficiency. Compact and cost-effective, it suits various bag types not supported by standard machines, making it perfect for flexible, space-saving packaging needs.

Food Metal Detector Manufacturer For Reject Defective Products G5020

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei