Economic VFFS: ROI and TCO Analysis for Procurement Teams

- Economic VFFS: ROI and TCO Analysis for Procurement Teams

- What is the Economic vertical form fill seal packing machine (VFFS) and why procurement teams care about vertical packaging machine economics

- Key cost components to include in TCO for a vertical packaging machine

- How procurement should structure an ROI calculation for a vertical packaging machine

- Example 5-year TCO comparison: Economic VFFS vs High Quality VFFS

- Sensitivity analysis: which variables most affect TCO for a vertical packaging machine

- Sample sensitivity cases

- Operational KPIs procurement should request when evaluating a vertical packaging machine

- Procurement checklist: what to verify before buying a vertical packaging machine

- Risk factors and mitigation strategies for purchasing a vertical packaging machine

- How the Economic VFFS supports procurement goals: brand advantages and fit

- Practical steps procurement teams should take next

- Frequently Asked Questions (FAQ)

- Q: How long is the typical payback period for an Economic VFFS?

- Q: Does the Economic VFFS support automated integration with multihead weighers and checkweighers?

- Q: What certifications should I expect for a vertical packaging machine used in food production?

- Q: How do I validate vendor uptime claims?

- Q: What is the difference between ROI and TCO when assessing a vertical packaging machine?

- Contact sales / View product

- Authoritative references and further reading

Economic VFFS: ROI and TCO Analysis for Procurement Teams

What is the Economic vertical form fill seal packing machine (VFFS) and why procurement teams care about vertical packaging machine economics

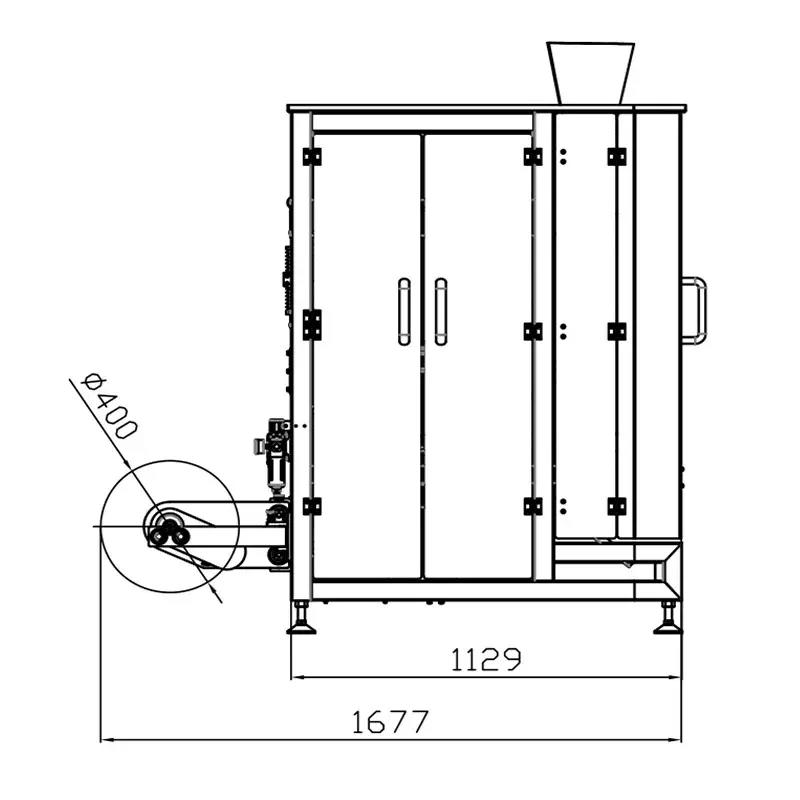

The economical vertical form fill seal (VFFS) packaging machine offers a variety of models designed with a sturdy 304 stainless steel frame. It is equipped with safety door protection and supports multiple bag types, including pillow bags, angle belt bags, printed bags, and triangle bags. This versatile machine is ideal for packaging a wide range of materials, such as snacks, frozen foods, coffee beans, oats, sugar, salt, rice, small hardware components, and more. Affordable and cost-effective, it provides reliable performance and efficiency for diverse packaging needs.

For procurement teams, selecting a vertical packaging machine is not just about purchase price. The Economic vertical form fill seal packing machine (VFFS) positions itself as a low-cost, reliable option—but to make an informed purchase decision you must analyse both ROI (return on investment) and TCO (total cost of ownership). This article breaks down the financial, operational, and strategic considerations procurement teams should use to evaluate an Economic VFFS versus alternative machines. Once return on investment is clear, buyers should assess system compatibility by reviewing integrating economic VFFS with multihead weighers: best practices for complete packaging lines.

Key cost components to include in TCO for a vertical packaging machine

To calculate TCO correctly, include all direct and indirect costs over the expected useful life (commonly 3–7 years). For a vertical packaging machine, these categories typically include:

- Capital expenditure (CAPEX): Purchase price, freight, installation, commissioning.

- Depreciation/tax considerations: Book depreciation or tax benefits.

- Planned maintenance and service contracts: Annual preventive maintenance and planned parts replacement.

- Unplanned maintenance and spare parts: Mean time to repair (MTTR) and parts inventory needs.

- Energy consumption: Electricity to run motors, heaters (for seal bars), and controls.

- Consumables: Film, sealing jaws, belts, printer ribbons, lubricants, and knives.

- Labor: Operators, line support, changeover staff and training costs.

- Downtime and lost production: Lost throughput, expedited freight, and penalties.

- Floor space and utilities: Space cost, compressed air, water (if used) and HVAC load.

- End-of-life costs: Disposal, recycling, or resale value.

How procurement should structure an ROI calculation for a vertical packaging machine

ROI should compare incremental benefits to incremental costs. Typical steps:

- Define the baseline: existing machine or manual pack line performance.

- Estimate incremental revenue or cost savings: higher throughput, lower material waste, reduced labor, or lower energy.

- Calculate incremental costs: purchase price difference, training, integration costs.

- Compute payback period and ROI: payback = net initial cost / annual net benefit. ROI = (total net benefit over period - initial cost) / initial cost.

- Run sensitivity scenarios: change downtime, material cost, labor rates to test robustness.

Example 5-year TCO comparison: Economic VFFS vs High Quality VFFS

Below is a sample scenario to illustrate TCO and per-unit cost. Replace the assumptions with your plant-specific numbers when you calculate your own ROI.

| Item | Economic VFFS (example) | High Quality VFFS (example) |

|---|---|---|

| Purchase price | $30,000 | $65,000 |

| Annual maintenance & service | $1,500 | $3,500 |

| Annual energy | $800 | $1,200 |

| Annual consumables | $2,000 | $1,800 |

| Labor (operators & support) | $30,000 | $24,000 (assumes 0.2 FTE savings) |

| Annual downtime recovery cost (lost production/overtime) | $4,000 (assumes 4% downtime) | $1,500 (assumes 1.5% downtime) |

| Other annual spare parts | $1,000 | $800 |

| Annual recurring total (excl. depreciation) | $39,300 | $32,800 |

| 5-year recurring total | $196,500 | $164,000 |

| 5-year TCO (purchase + recurring) | $226,500 | $229,000 |

Per-unit cost example: assuming 5 million bags per year, over 5 years total volume = 25 million bags.

- Economic VFFS total cost per bag = $226,500 / 25,000,000 = $0.00906

- High Quality VFFS total cost per bag = $229,000 / 25,000,000 = $0.00916

Result: In this scenario the Economic VFFS has a slightly lower 5-year TCO and per-bag cost. The difference is small, so procurement teams must weigh non-financial factors such as reliability, upgrade potential, service network, and brand support.

Sensitivity analysis: which variables most affect TCO for a vertical packaging machine

Run sensitivity checks on these variables because they often change the decision:

- Downtime % — small improvements in reliability can massively reduce lost production costs.

- Labor cost and FTE footprint — automation that reduces headcount can deliver ongoing savings.

- Consumable film cost — film wastage and material efficiency produce direct per-unit savings.

- Service response time and spare parts lead-time — long MTTR increases downtime costs.

- Energy costs — high-volume or energy-intensive lines amplify differences in motor/heater efficiency.

Sample sensitivity cases

If downtime for the Economic VFFS increases from 4% to 7%, the annual downtime recovery cost could jump proportionally (e.g., from $4,000 to $7,000), which would change the 5-year TCO materially. Conversely, if consumable savings from better film handling on the High Quality machine increase, the High Quality may become more attractive.

Operational KPIs procurement should request when evaluating a vertical packaging machine

Ask vendors to provide real-world KPI data for machines under conditions similar to yours. Key metrics:

- OEE (Overall Equipment Effectiveness): availability x performance x quality.

- Throughput (bags per minute) at different bag sizes and film types.

- Changeover time between SKUs and ease of film threading.

- Sealing quality and hermeticity for your product type (critical for frozen or moisture-sensitive goods).

- Average MTTR and recommended spare parts list / critical spares availability.

- Energy consumption per 1,000 bags or per hour.

Procurement checklist: what to verify before buying a vertical packaging machine

Use this checklist to ensure you capture both financial and operational exposures:

- Confirm warranty terms and what is covered (parts, labor, travel).

- Service network and SLA (response time, local service partners).

- Availability and lead time for critical spare parts.

- Certifications (CE, UL, food-contact material compliance) and material specs (304 stainless steel frame).

- Interoperability with upstream/downstream lines (communication protocols, conveyors, checkweighers, multihead weighers).

- Training package for operators and maintenance staff; documentation language and availability.

- Proof-of-performance: references or site visits to similar operations.

- Scalability and upgrade path (e.g., servo upgrades, vision inspection modules).

- Parts kits included with purchase (consumables, spare fuses, belts, knives).

Risk factors and mitigation strategies for purchasing a vertical packaging machine

Common risks and what procurement can do:

- Unexpected downtime — mitigate via extended warranty, local spare parts stocking, and an SLA for on-site support.

- Film compatibility issues — demand factory acceptance test (FAT) with your actual film and product.

- Poor sealing on varied products — request material and sealing trials on your product range.

- Hidden integration costs — include conveyor, checkweigher, and PLC integration costs in the quote.

- Training gaps — negotiate on-site training and competency sign-off as part of purchase.

How the Economic VFFS supports procurement goals: brand advantages and fit

The Economic vertical form fill seal packing machine (VFFS) is designed for procurement teams looking for a balance of affordability and reliability. Key brand and product advantages:

- Cost-effectiveness: competitive purchase price reduces initial CAPEX burden.

- Stainless 304 frame and safety door protection: durable sanitary design reduces contamination risks and supports food safety compliance.

- Versatility: supports multiple bag types (pillow, angle belt, printed, triangle), enabling SKU flexibility without major capital investment.

- Wide material compatibility: suitable for snacks, frozen foods, coffee, rice, small hardware, and more, improving asset utilization across product lines.

- Simple serviceability: designed for straightforward maintenance which helps contain service costs and reduces MTTR.

For procurement teams constrained by budget but requiring a dependable vertical packaging machine, the Economic VFFS offers a compelling baseline TCO while enabling rapid deployment and flexible packaging formats.

Practical steps procurement teams should take next

- Collect your plant-specific inputs (annual volume, labor rates, energy price, target uptime).

- Request a detailed quote including install, training, warranty, spare parts kit, sample FAT with your product and film.

- Perform the TCO calculation with at least three scenarios (best-case, expected, worst-case) changing downtime and consumable prices.

- Ask for customer references and, where possible, an on-site visit to see the machine in production.

- Negotiate service SLAs and consider a multi-year service contract if uptime is business-critical.

Frequently Asked Questions (FAQ)

Q: How long is the typical payback period for an Economic VFFS?

A: Payback varies by application and volume. For many mid-volume operations, payback can occur within 12–36 months when labor savings, reduced waste, and improved throughput are realized. Use your plant-specific figures to calculate exact payback.

Q: Does the Economic VFFS support automated integration with multihead weighers and checkweighers?

A: Yes. Most models support standard communication protocols and mechanical interfaces for multihead weighers, checkweighers, and metal detectors. Verify specific I/O requirements with the vendor.

Q: What certifications should I expect for a vertical packaging machine used in food production?

A: Expect material and machine compliance such as food-grade 304 stainless components, CE marking for European markets, and documentation to support HACCP and local food safety regulations. For specific market requirements (e.g., NSF, UL), request evidence from the vendor.

Q: How do I validate vendor uptime claims?

A: Request historical OEE data, references from similar plants, and perform a factory acceptance test using your products and film to validate throughput and sealing performance.

Q: What is the difference between ROI and TCO when assessing a vertical packaging machine?

A: TCO aggregates all costs across the life of the equipment (purchase + recurring costs + downtime + disposal). ROI focuses on the net benefit (savings or incremental revenue) relative to the investment cost. Both are complementary; TCO helps you understand cost drivers, ROI shows financial return.

Contact sales / View product

If you'd like a personalized ROI/TCO analysis for your facility or to schedule a product demo of the Economic vertical form fill seal packing machine (VFFS), contact our sales team or visit the product page. Our procurement specialists can run scenario-based TCO models using your actual costs and volumes to support your capital approval decision.

Authoritative references and further reading

- Form-fill-seal — Wikipedia: https://en.wikipedia.org/wiki/Form-fill-seal

- PMMI (The Association for Packaging and Processing Technologies): https://www.pmmi.org/

- Packaging Europe (industry articles and trends): https://www.packagingeurope.com/

- ISO — Food safety management (ISO 22000 overview): https://www.iso.org/iso-22000-food-safety-management.

Top 10 Features to Look for in Food Industry Metal Detectors

What are the application scenarios of vffs packaging equipment?

Top 5 automatic grain packing machine Company List and Products Compared

Top 10 Inspection Line Configurations for Aluminum Foil

About Solution suggestions

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

About After Sales Support

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

About Product choice

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

About Logistics

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

About Cooperation Process

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

Automatic Multi-Function Pouch Weighing and Packing Machine – 65 BagsMin for Efficient Packaging

The mini combined weighing and packaging machine integrates a miniature multi-head scale with a vertical packaging machine, all controlled by an advanced PLC program. This fully automatic system handles metering, filling, bag-making, date printing, and packaging output. Ideal for weighing small particles such as Chinese herbal medicine, tea, seeds, monosodium glutamate, chicken essence, coffee beans, chocolate, and more. With its affordable price, low maintenance costs, and high efficiency, the mini combined weighing and packaging machine is an economical choice for small-scale operations.

Mini Combined Weighing and Packing Machine with Multihead Weigher for Tea Powder, Coffee Beans, and More

The mini combined weighing and packaging machine integrates a compact multi-head scale with a vertical packaging machine, all controlled by an advanced PLC program. This fully automated system handles precise metering, filling, bag-making, date printing, and packaging output. Ideal for weighing small particles such as Chinese herbal medicine, tea, seeds, monosodium glutamate, chicken essence, coffee beans, chocolate, and more. The mini combined weighing and packaging machine is cost-effective, economical, and offers low maintenance costs, making it an excellent choice for small-scale packaging operations.

Standard Vertical Weighing And Packaging Machine For Granules Puffy Foods JW-B1

Discover Kenwei’s Standard Vertical Weighing And Packaging Machine For Granules Puffy Foods. This efficient vertical packaging machine accurately weighs and packs a variety of foods, making it the ideal weighing and packaging machine for granules and puffy snacks.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei