The Role of Premade Pouch Packing Machines in Modern Manufacturing

- Introduction

- What is a Premade Pouch Packing Machine?

- Key Components of Premade Pouch Packing Machines

- How Premade Pouch Machines Improve Production Efficiency

- Cost-Effectiveness and ROI

- Applications Across Industries

- Advanced Features Driving Innovation

- Challenges in Adoption

- Future Trends in Premade Pouch Packaging

- Conclusion

In today’s fast-paced manufacturing environment, efficiency and sustainability are top priorities. Premade pouch packing machines are revolutionizing packaging by automating filling and sealing processes. From food and beverages to pharmaceuticals, they ensure precision, reduce waste, and boost ROI.

Introduction

In a business landscape where efficiency and sustainability are critical, the demand for advanced packaging solutions has grown dramatically. Among these innovations, the premade pouch packing machine has emerged as a game-changer. These machines simplify production, enhance consistency, and minimize material waste, making them essential across industries including food, personal care, pharmaceuticals, and pet care.

What is a Premade Pouch Packing Machine?

A premade pouch packing machine is an automated packaging system designed to fill and seal pre-formed pouches. Unlike traditional methods that create bags during the process, these machines use ready-made pouches, eliminating unnecessary steps and improving efficiency.

Industries such as food processing, cosmetics, and pharmaceuticals leverage this technology for its reliability, speed, and precision. Compared to manual or semi-automated solutions, these machines reduce errors and ensure consistent product quality.

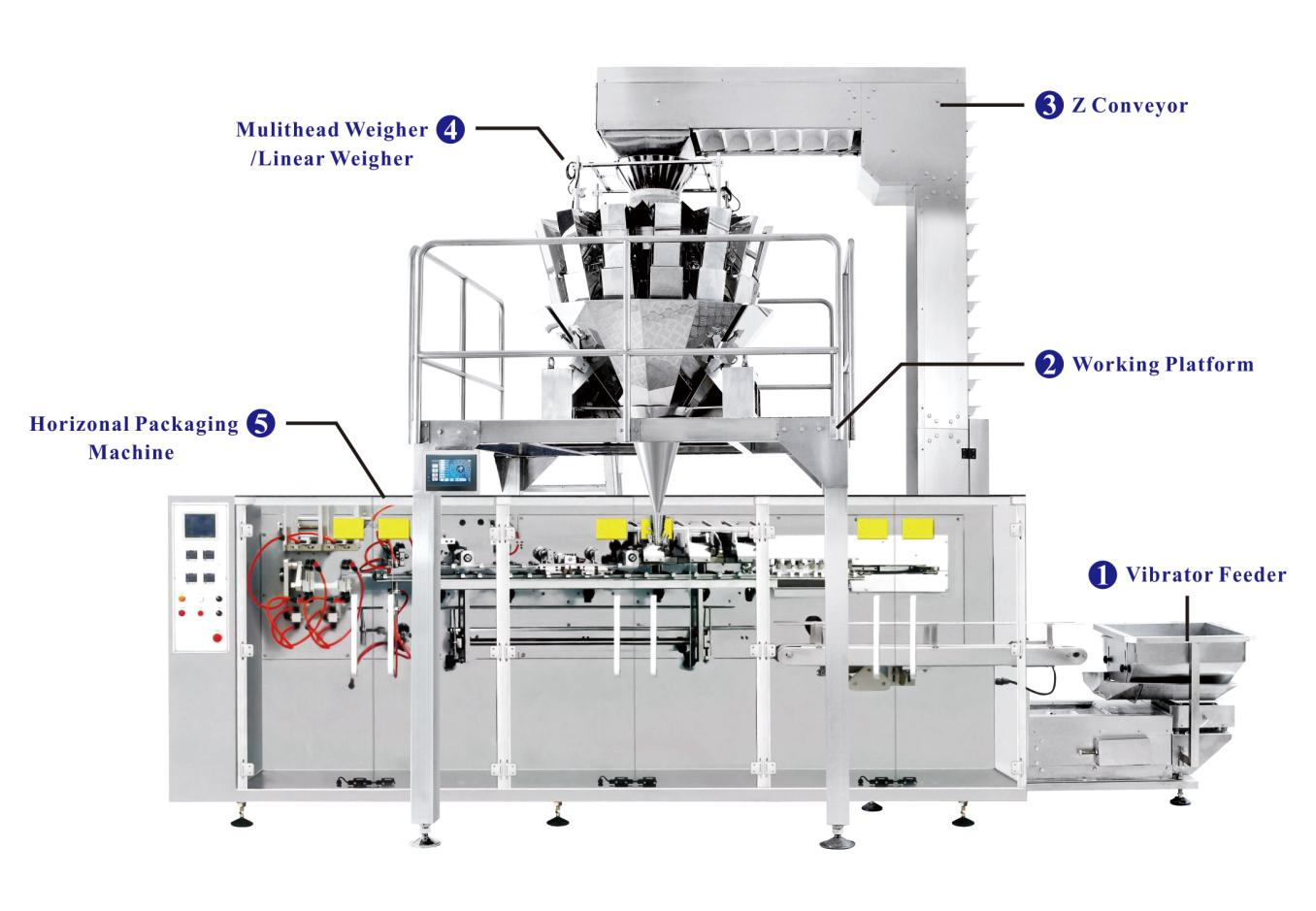

Key Components of Premade Pouch Packing Machines

-

Pouch Feeding System – Automatically loads pre-formed pouches of various shapes (stand-up, gusseted, or flat).

-

Filling System – Precisely dispenses powders, granules, or solids, often using multihead weighers for high accuracy.

-

Sealing System – Ensures airtight, durable seals with options like resealable zippers, spouts, or tear notches.

-

Control Panel – Provides user-friendly monitoring with real-time adjustments to speed, filling, and sealing.

-

Discharge Mechanism – Smoothly transfers sealed pouches to conveyors or collection points to maintain workflow efficiency.

How Premade Pouch Machines Improve Production Efficiency

-

Speed and Throughput – Capable of handling thousands of pouches per hour, ideal for large-scale operations.

-

Precision and Consistency – Eliminates human errors, ensuring uniform filling and sealing.

-

Reduced Material Waste – Optimizes resource use with clean sealing and accurate filling, supporting sustainability goals.

-

Versatility – Adapts easily to multiple pouch types and product categories without complex changeovers.

Cost-Effectiveness and ROI

While the initial investment in a premade pouch packing machine may seem high, the long-term savings are substantial. Automation reduces labor costs, increases efficiency, and minimizes product waste. These advantages translate to faster scalability and improved competitiveness for businesses of all sizes.

Applications Across Industries

-

Food & Beverage – Perfect for snacks, sauces, coffee, and ready-to-eat meals.

-

Personal Care – Ideal for shampoos, lotions, creams, and liquid-based products.

-

Pharmaceuticals – Ensures safe and accurate packaging of powders, tablets, and supplements under strict compliance.

-

Pet Care – Efficiently packages kibbles, treats, and wet food, maintaining freshness and shelf appeal.

Advanced Features Driving Innovation

Modern premade pouch packing machines integrate cutting-edge technologies:

-

Smart Sensors – Real-time fault detection reduces downtime.

-

IoT Integration – Enables remote monitoring and predictive maintenance.

-

Energy Efficiency – Eco-friendly designs reduce power consumption.

-

Automated Changeovers – Allows quick adjustments between different pouch types and product lines.

Challenges in Adoption

-

High Initial Costs – May be a barrier for small businesses.

-

Workforce Training – Requires skilled operators for setup and maintenance.

-

Customization Needs – Specialized packaging may demand tailored machine configurations.

Future Trends in Premade Pouch Packaging

-

Eco-Friendly Materials – Growth in recyclable and biodegradable pouch options.

-

Robotics Integration – Advanced robotic arms for higher speed and precision.

-

Blockchain Technology – Enhances supply chain transparency and product traceability.

Conclusion

The premade pouch packing machine has revolutionized modern packaging with its efficiency, accuracy, and adaptability. By reducing waste, cutting costs, and supporting sustainability, it is now indispensable across industries. Businesses that embrace this automated solution position themselves for long-term success in an increasingly competitive marketplace.

About Solution suggestions

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

About products customization

Can Kenwei machines be customized for different industries?

Yes,According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on.

About After Sales Support

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

About Price and payment

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

About Cooperation Process

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei