Sanitation and IP Rating: Protecting Metal Detectors in Plants

- Sanitation and IP Rating: Protecting Metal Detectors in Food Plants

- Why sanitation matters for a metal detector for food industry use

- About the product: Food Metal Detector Manufacturer For Reject Defective Products G5020

- Understanding IP ratings and their relevance to metal detector for food industry

- IP rating breakdown and recommended use cases

- Hygienic design principles for metal detector for food industry

- Sanitation procedures and best practices for metal detectors in plants

- Impact of sanitation on detection sensitivity and performance

- Multi-frequency advantage: why choose the G5020 in sanitized environments

- Installation, placement and mechanical protection strategies

- Maintenance, validation and regulatory compliance

- Materials compatibility and chemical resistance

- Comparative table: Choosing the right IP-rated metal detector for your cleaning regime

- Operational tips to minimize sanitation-related detection issues

- Brand strengths: Why choose the G5020 from Food Metal Detector Manufacturer For Reject Defective Products

- FAQ — Frequently Asked Questions about sanitation and IP ratings for metal detectors

- Q1: What IP rating do I need for my metal detector for food industry washdown?

- Q2: How often should I validate the G5020 metal detector for food industry use?

- Q3: Can sanitation chemicals damage my metal detector?

- Q4: Will frequent cleaning affect detection sensitivity?

- Q5: How does multi-frequency detection help in sanitized environments?

- Contact and next steps — see the G5020 in your plant

- References and authoritative sources

Sanitation and IP Rating: Protecting Metal Detectors in Food Plants

Why sanitation matters for a metal detector for food industry use

In food production environments, sanitation is not optional — it is central to product safety, regulatory compliance, and brand reputation. A well-maintained metal detector for food industry operations prevents contaminated product from reaching consumers, reduces costly recalls, and supports HACCP, FSMA and GFSI-aligned programs. Poor sanitation increases microbial risk and can accelerate equipment degradation, short-circuiting sophisticated electronics and causing false rejects or missed contaminants.

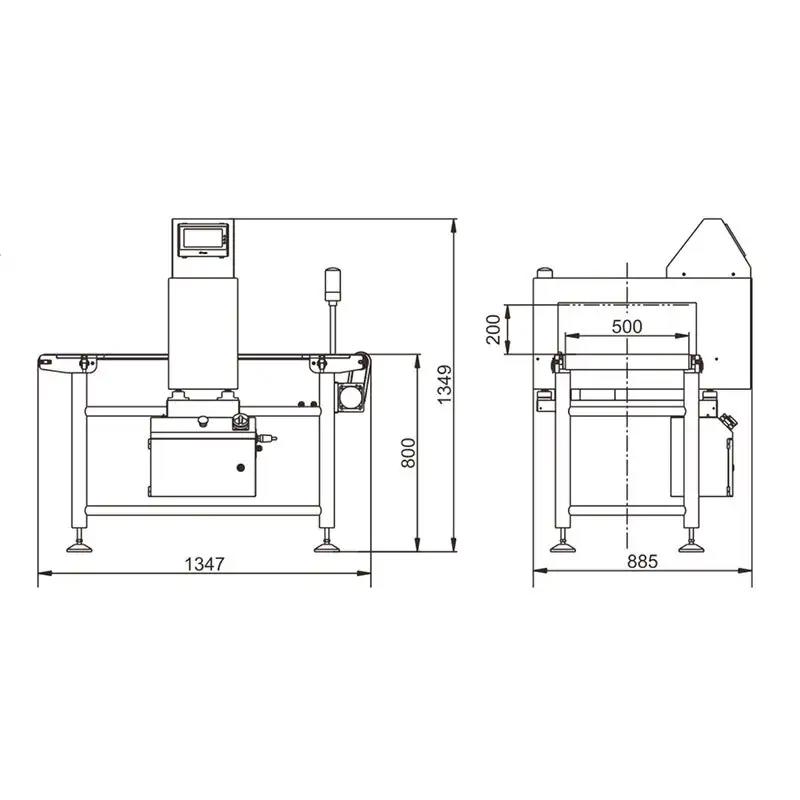

About the product: Food Metal Detector Manufacturer For Reject Defective Products G5020

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Understanding IP ratings and their relevance to metal detector for food industry

IP (Ingress Protection) ratings define how well equipment is protected against solids and liquids. For metal detector for food industry applications, choosing the correct IP rating is a balance between hygiene needs and the environment of use (wet/dry, washdown frequency, presence of high-pressure/temperature cleaning). Typical ratings encountered in food processing are IP54, IP65, IP66 and IP69K. Higher IP ratings reduce the risk of moisture ingress that can corrode sensors or electronics and compromise detection sensitivity.

IP rating breakdown and recommended use cases

| IP Rating | Protection | Common Food Plant Use |

|---|---|---|

| IP54 | Protection against dust and splashing water | Dry-process areas, light splashing, protected locations |

| IP65 | Dust tight; protection from low-pressure jets of water | General washdown areas, conveyors near wash zones |

| IP66 | Dust tight; protection from high-pressure water jets | Frequent washdown lines, heavy cleaning operations |

| IP69K | Dust tight; protection from high-temperature, high-pressure washdowns | Areas requiring hygienic high-pressure/steam cleaning (CIP/SIP adjacent lines) |

Choosing an IP-rated metal detector for food industry environments reduces the likelihood of contamination or equipment failure caused by water ingress and makes daily sanitation procedures safer and more effective.

Hygienic design principles for metal detector for food industry

Hygienic design minimizes places where food residue and moisture can accumulate. Key principles include:

- Use of smooth, crevice-free surfaces and FDA/food-grade materials (e.g., 304/316 stainless steel).

- Rounded corners, sloped surfaces for drainage, and sealed joints to prevent residue buildup.

- Quick-release, tool-free components for fast disassembly and cleaning.

- Belt materials that resist bacterial growth and are easy to sanitize.

- Electrical enclosures rated appropriately (IP65–IP69K) and designed to prevent condensation.

The G5020 exemplifies these design features with a specialized conveyor belt and easy-to-disassemble structure intended to reduce contamination risk while maintaining high detection sensitivity.

Sanitation procedures and best practices for metal detectors in plants

Consistent, validated cleaning protocols are required to maintain performance and comply with food safety standards. Recommended steps:

- Develop written SOPs that specify cleaning agents, concentrations, contact times, and rinse procedures suitable for the detector materials and IP rating.

- Perform dry cleaning (brushing, vacuuming) before wet cleaning to remove large debris.

- Use low-abrasion sanitizers and avoid harsh chemicals that can damage seals, belts, and sensor coatings.

- Ensure electrical power is isolated per lock-out/tag-out before opening enclosures for deep cleaning or maintenance.

- Document each cleaning session and use checklists for verification.

These practices protect the metal detector for food industry environments from contamination and electrical damage, preserving detection sensitivity and prolonging equipment life.

Impact of sanitation on detection sensitivity and performance

Sanitation influences metal detector performance in multiple ways:

- Residue buildup on conveyor belts or in detector apertures can mask or shield contaminants, reducing sensitivity.

- Moisture ingress into electronics causes corrosion or shorting that degrades detection circuits.

- Incorrect cleaning chemicals can alter belt dielectric properties, affecting calibration.

Regular performance checks with certified test pieces, plus routine calibration and documentation, ensure that the metal detector for food industry use remains accurate after cleaning cycles.

Multi-frequency advantage: why choose the G5020 in sanitized environments

Multi-frequency metal detectors like the Food Metal Detector Manufacturer For Reject Defective Products G5020 offer robust detection across a variety of product types, including wet, conductive, and dry products common in food lines. Benefits include:

- Improved sensitivity for both ferrous and non-ferrous metals in products with high ‘product effect’.

- Reduced false rejects by adapting frequency to product conductivity and moisture content.

- Better immunity to environmental electrical noise which is common in plants with heavy washdown equipment.

Combined with the G5020's hygienic conveyor and easy-disassembly design, multi-frequency detection helps maintain accurate inspection even in challenging sanitary conditions.

Installation, placement and mechanical protection strategies

Proper installation minimizes sanitation-related issues and maximizes detection reliability:

- Install metal detectors after primary processing and before packaging or secondary seals where detection is most effective.

- Ensure adequate sealing between detector frames and conveyors to avoid pockets where debris can collect.

- Provide physical covers or splash guards where necessary, but ensure they do not trap moisture.

- Design reject systems (pusher, diverter, flapper) that are hygienically compatible and do not cause product pooling or jams.

Consider the plant’s cleaning procedures when selecting mounting hardware and reject mechanisms to ensure they withstand the chosen washdown routines.

Maintenance, validation and regulatory compliance

Maintaining compliance means combining preventive maintenance with documented validation:

- Establish a preventive maintenance schedule for seals, belts, and electrical enclosures.

- Perform periodic validation using certified test pieces and log results to prove ongoing sensitivity.

- Keep records of cleaning agents, batch numbers, and sanitation schedules for audit readiness.

- Ensure equipment meets relevant standards (e.g., BRCGS, FDA FSMA expectations, EHEDG guidance on hygienic design).

Documentation demonstrates due diligence and supports recalls tracing and root cause analyses if contamination occurs.

Materials compatibility and chemical resistance

Choose materials that resist the chosen sanitation chemistries and temperatures. Stainless steel 316 is preferred where high chloride or acidic cleaning agents are used. Belting materials should be food-grade, with proven resistance to common sanitisers (quaternary ammonium compounds, peracetic acid, chlorine-based agents) to avoid degradation that can create contamination risks or alter detector response.

Comparative table: Choosing the right IP-rated metal detector for your cleaning regime

| Cleaning Regime | Typical IP Requirement | Notes |

|---|---|---|

| Dry cleaning; occasional light spray | IP54 | Cost-effective for dry lines; avoid frequent washdown |

| Regular washdown (low pressure) | IP65 | General food processing lines with daily cleaning |

| High-pressure washdown | IP66 | Requires robust seals and hose-proof enclosures |

| High-pressure, high-temperature (e.g., CIP/SIP adjacent) | IP69K | Best for lines needing aggressive steam/jet cleaning |

Operational tips to minimize sanitation-related detection issues

Day-to-day operations can reduce risks and extend equipment life:

- Train operators on correct cleaning sequences and the importance of pre-clean removal of bulk debris.

- Use protective covers during cleaning where appropriate, then remove covers to dry fully.

- Monitor belt condition and replace at first sign of wear to avoid product trapping and microbial growth.

- Schedule deep-clean downtime during low-production periods to allow full disassembly and inspection.

Brand strengths: Why choose the G5020 from Food Metal Detector Manufacturer For Reject Defective Products

The G5020 is designed specifically for food plant demands: hygienic conveyor design reduces contamination risk, multi-frequency detection offers high sensitivity across product types, and tool-free disassembly simplifies sanitation and maintenance. Combined IP-rated protection and food-grade materials make the G5020 a practical solution that supports regulatory compliance, reduces downtime, and improves product safety outcomes.

FAQ — Frequently Asked Questions about sanitation and IP ratings for metal detectors

Q1: What IP rating do I need for my metal detector for food industry washdown?

A1: For light washdown choose IP65. For frequent high-pressure cleaning select IP66. For high-pressure and high-temperature cleaning (e.g., near CIP lines), IP69K is recommended.

Q2: How often should I validate the G5020 metal detector for food industry use?

A2: Validate sensitivity daily or per shift with test pieces for critical control points; perform full calibration and documented validation monthly or per your HACCP and regulatory requirements.

Q3: Can sanitation chemicals damage my metal detector?

A3: Yes—some aggressive sanitizers can degrade seals, electronics, and belts. Use recommended concentrations and consult manufacturer compatibility charts. Prefer equipment with stainless steel 316 and food-grade components for chemical resistance.

Q4: Will frequent cleaning affect detection sensitivity?

A4: If cleaning is done correctly and validated, sensitivity should remain stable. However, residue buildup or damaged belts/seals can reduce sensitivity. Regular inspection and test-piece validation mitigate this risk.

Q5: How does multi-frequency detection help in sanitized environments?

A5: Multi-frequency detection adapts to product effect caused by moisture and conductivity, improving sensitivity to small metal contaminants while reducing false positives often triggered by environmental noise in wet processing areas.

Contact and next steps — see the G5020 in your plant

If you are evaluating a metal detector for food industry use, request a demo or a hygiene-focused specification sheet for the Food Metal Detector Manufacturer For Reject Defective Products G5020. Our technical team can advise on IP selection, cleaning protocols and installation to match your plant’s sanitation regime.

Contact us: Reach out to our sales team to schedule a trial, request validation documentation, or obtain a custom cleaning and maintenance plan for your line.

References and authoritative sources

- IEC/Wikipedia — IP Code (Ingress Protection): https://en.wikipedia.org/wiki/IP_Code

- EHEDG — European Hygienic Engineering & Design Group: https://www.ehedg.org/en/

- US FDA — Food Safety (FSMA overview): https://www.fda.gov/food/food-safety-modernization-act-fsma

- Codex Alimentarius — Food safety principles: http://www.fao.org/fao-who-codexalimentarius/en/

- BRCGS — Global food safety standards: https://www.brcgs.com/

Where to Buy food combination weigher

Calculating ROI: Increasing Throughput with Packing Machines

Packaging Frozen Foods: Food Packing Machine Best Practices

The B2B Buyer’s Guide to checkweigher metal detector combination

About Cooperation Process

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

About Price and payment

Can I get a detailed quote before making a purchase?

Absolutely! We provide detailed quotes that break down the costs for the machines, customization, shipping, and any additional services. Please contact our sales team with your requirements to receive a customized quote.

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

About products customization

Can Kenwei machines support multiple languages?

Yes, we can customize the software interface to support multiple languages, making it easier for operators from different regions to use the machine.

Dropped Metal Detector for Powder Granules For Food Industry

Enhance food safety with Kenwei’s Dropped Metal Detector for Powder Granules. This advanced food metal detector ensures precise detection in the food industry, safeguarding products and maintaining high quality standards throughout processing.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

High Sensitivity Horizontal Metal Detector for Food and Pharmaceutical Industries

The Horizontal Metal Detector Series is ideal for detecting both ferrous and non-ferrous metals in food, pharmaceutical, chemical, textile, and rubber products. Equipped with a 7" industrial touch screen and supporting 32 languages, it features high sensitivity, digital signal processing, and intelligent algorithms for stable, precise detection. With stainless steel waterproof construction and multiple rejection options, it's perfect for HACCP and GMP compliance.

Automatic 8-Track Electronic Counting and Filling Packaging Machine

This counting machine offers a two-channel, eight-track electronic system with adjustable height, supporting bottle heights from 20 to 100mm. It requires no reset during fast line changes, making it perfect for counting products of various shapes. With a maximum speed of 4,000 particles per minute, it is ideal for pharmaceutical, food, chemical, plastic, healthcare, and other industries, delivering efficient and precise counting.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei