Calculating ROI: Increasing Throughput with Packing Machines

- Boosting Throughput with Food Packing Machines: A Data-Driven ROI Approach

- Why throughput and ROI matter for food packing machine investments

- Key metrics to use when evaluating a food packing machine ROI

- Practical ROI formula for food packing machine upgrades

- Example calculation: multihead weigher for snack food line (with table)

- When to choose a multihead weigher versus other food packing machine types

- Integration considerations: how to maximize throughput gains from your food packing machine

- Total cost of ownership (TCO) and hidden costs for food packing machine projects

- Kenwei: multihead weigher and food packing machine capabilities (manufacturer spotlight)

- Checklist: questions to ask suppliers when calculating ROI for a food packing machine

- FAQ — Frequently Asked Questions

- Contact & next steps

- References

Boosting Throughput with Food Packing Machines: A Data-Driven ROI Approach

Why throughput and ROI matter for food packing machine investments

For food manufacturers, throughput directly affects unit cost, service levels, and the ability to meet demand peaks. Investing in a food packing machine—whether a multihead weigher, linear weigher, or automated packing line—must be justified by measurable gains: higher output, lower giveaway, reduced labor, and better uptime. Calculating a robust return on investment (ROI) ensures purchase decisions deliver profitable capacity and not just upgraded equipment.

Key metrics to use when evaluating a food packing machine ROI

Before calculating ROI, gather reliable baseline metrics. Commonly used metrics include:

- Throughput (units/hour or kg/hour)

- Yield and giveaway (%)

- Labor cost per shift (including benefits)

- Machine uptime and mean time between failures (MTBF)

- Changeover time for SKUs

- Capital cost, installation, and training cost

Each metric should be recorded over a representative period (typically 1–3 months) to smooth out daily variability. Ensuring accuracy here makes the ROI calculation defensible and actionable.

Practical ROI formula for food packing machine upgrades

Use a straightforward payback / ROI approach combining annual net savings and total installed cost:

Annual Savings = (Increased throughput value) + (Labor savings) + (Reduced giveaway value) + (Quality/recall avoidance) - (Additional operating costs)

Then:

ROI (%) = (Annual Savings / Total Installed Cost) × 100

Or compute simple payback period:

Payback (years) = Total Installed Cost / Annual Savings

This approach is flexible: “increased throughput value” can be monetized as incremental revenue or avoided overtime/outsourcing costs.

Example calculation: multihead weigher for snack food line (with table)

Below is a conservative, realistic example using industry-typical numbers to show how a multihead food packing machine can pay back. All figures are illustrative and sourced in the references.

| Item | Baseline | After Upgrade | Annual Impact (12 months) |

|---|---|---|---|

| Throughput (bags/hour) | 1,200 | 1,800 | Increase 600 bags/hr × 16 hrs/day × 250 days = 2,400,000 additional bags |

| Average bag price (revenue per bag) | $0.60 | ||

| Increased throughput revenue | 2,400,000 × $0.60 = $1,440,000 | ||

| Giveaway reduction (per bag) | 8g | 3g | Saving 5g × 3,000,000 produced bags = 15,000 kg × $2.50/kg = $37,500 |

| Labor savings | Reduce 3 FTEs (operators) × $45,000/year fully loaded = $135,000 | ||

| Quality & downtime savings | Improved uptime & fewer rejects = $60,000 | ||

| Total Annual Savings | $1,440,000 + $37,500 + $135,000 + $60,000 = $1,672,500 | ||

| Total Installed Cost (machine + installation + training) | $450,000 | ||

| Payback | $450,000 / $1,672,500 = 0.27 years (~3.3 months) | ||

| ROI | ($1,672,500 / $450,000) ×100 = 371.7% (annual) | ||

Notes: this example assumes the packing machine is the bottleneck—so throughput increases translate directly to sellable units. If another process (fryer, cooker, or upstream packer) is the bottleneck, throughput gains will be constrained and the financial benefit proportionally reduced.

When to choose a multihead weigher versus other food packing machine types

Selecting the right food packing machine depends on product, speed, accuracy, and budget:

- Multihead weigher: Best for high-speed bagging of free-flowing solids (snacks, nuts, frozen vegetables). Advantages: speed, low giveaway, high accuracy. Consider when throughput targets exceed 600–900 bags/hr per line.

- Linear weigher: Better for lower-speed applications, sticky or fragile products, or where cost sensitivity is high. Easier maintenance but lower top speed.

- Check weigher & metal detector: Critical for compliance and quality control. These machines do not replace weighers but protect brand and reduce recall risks.

Table: Typical throughput ranges (illustrative)

| Machine Type | Typical Throughput (bags/hr) | Primary Strength |

|---|---|---|

| Multihead weigher | 600–3,000+ | High speed, high accuracy, low giveaway |

| Linear weigher | 200–900 | Simple products, lower cost, gentle handling |

| Check weigher | N/A (quality control) | Ensure correct weight and detect under/overfill |

| Metal detector | N/A (safety) | Foreign object detection before packing |

Integration considerations: how to maximize throughput gains from your food packing machine

Buying a high-speed food packing machine is necessary but not sufficient. Integration and process design determine the realized ROI. Focus on:

- Line balancing—ensure upstream and downstream processes match the new machine’s speed.

- Automation of feeding and conveying to reduce manual intervention.

- Quick-change tooling and recipe management to cut changeover time.

- Real-time monitoring (OEE dashboards) to track throughput, uptime, and quality.

- Operator training and preventative maintenance programs to sustain MTBF.

Example KPI targets post-implementation: uptime > 92%, giveaway reduction ≥ 30%, and changeover ≤ 10 minutes for planned SKUs.

Total cost of ownership (TCO) and hidden costs for food packing machine projects

Beyond purchase price, include:

- Installation and mechanical integration costs

- Electrical, PLC programming, and HMI customization

- Spare parts and service agreements

- Training and documentation

- Floor space and possible civil works

Calculate a 3–5 year TCO to compare machines. In many cases, a slightly higher capital cost for a higher-precision food packing machine is offset within 12–24 months by giveaway reduction and increased throughput.

Kenwei: multihead weigher and food packing machine capabilities (manufacturer spotlight)

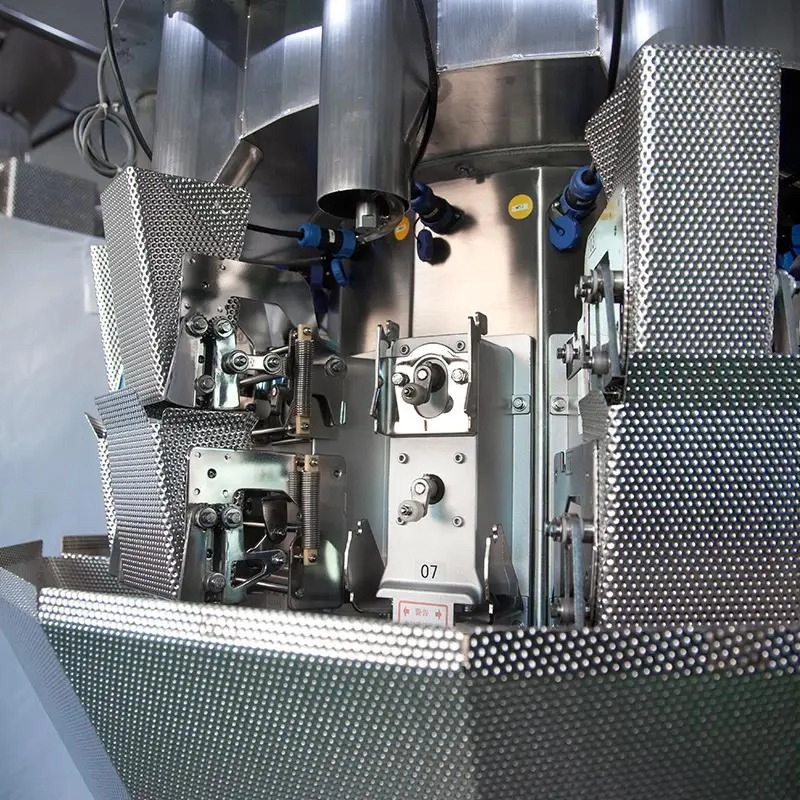

Kenwei is a powerful manufacturer of multi-head weighers. We are committed to the development and manufacturing of metal detectors, multi-head weighers, linear weighers, and check weighers. Our machines are characterized by high speed and high precision. We also provide our customers with one-stop automated weighing and packaging solutions to meet our customers’ customization requirements. Guangdong Kenwei is located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province. The company is equipped with an automated weighing and packaging system and has comprehensive capabilities in design and development, manufacturing, marketing, installation and commissioning, technical training, and after-sales service. It has established a good brand image and a reputation for thoughtful and fast service in the packaging machinery industry.

Our vision is to become the world's leading weighing packing machine manufacturer. See Kenwei product strengths and main products: Check Weigher, multihead weigher packing machine, multihead weigher, linear weigher, metal detector, packing machine, counting machine, combination weigher, food packaging machine, food packing machinery. Kenwei emphasizes customization, rapid installation, high precision weighing algorithms, and integrated solutions combining weighing, metal detection, and checkweighing to secure both productivity and compliance. Website: https://www.kenweigroup.com/

Checklist: questions to ask suppliers when calculating ROI for a food packing machine

- What are guaranteed throughput and accuracy figures for my product? (ask for factory acceptance test data)

- What is the expected MTBF and recommended preventive maintenance schedule?

- What are real-world examples (case studies) showing ROI on similar products?

- Which spare parts are critical and what are their lead times?

- What is included in installation, commissioning, and training?

- Can the machine integrate with my MES or OEE monitoring platform?

FAQ — Frequently Asked Questions

Q1: How quickly can I expect a food packing machine to pay for itself?

A: Payback depends on bottleneck position, product value, and baseline metrics. Typical payback ranges from 3 months (when capacity is the main constraint) to 24 months. Use the ROI formula and real baseline data to estimate accurately.

Q2: Will a multihead weigher reduce my product giveaway?

A: Yes. Multihead weighers use combination algorithms to select near-target fills, typically reducing giveaway by 20–50% compared to less accurate volumetric or manual methods. Real results depend on product behavior and setup.

Q3: What hidden costs should I budget for besides machine price?

A: Include installation, electrical work, conveyors/feeding systems, spare parts, service contracts, operator training, and potential civil modifications. Plan for 10–30% of machine cost in integration expenses.

Q4: How do I know if the packing machine will actually increase plant throughput?

A: Conduct a line audit to identify the current bottleneck. If the packing step is the bottleneck, a higher-capacity food packing machine should increase throughput. If not, upstream or downstream upgrades may be required.

Q5: Can a food packing machine handle multiple SKUs and quick changeovers?

A: Modern machines support recipe management, tool-less change parts, and programmatic settings to enable fast changeovers. Verify changeover times in supplier tests and include them in your ROI timeline.

Q6: Do I need a metal detector and check weigher if I have a multihead weigher?

A: Yes. A multihead weigher controls fill weight but does not detect metal contamination or ensure final pack compliance. Metal detectors and check weighers are essential complementary systems for safety and regulatory compliance.

Contact & next steps

Ready to quantify the ROI for your plant? Start with a 2–4 week baseline study to capture throughput, giveaway, uptime, and labor costs. For tailored solutions, Kenwei offers integrated project support from design to after-sales. Visit Kenwei: https://www.kenweigroup.com/. Contact your supplier to request factory acceptance test data and a detailed TCO proposal before purchase.

References

- PMMI – The Association for Packaging and Processing Technologies: Packaging Machinery Overview. https://www.pmmi.org/ (accessed June 2024)

- Packaging World: Technical articles on multihead weighers and combination weighers. https://www.packworld.com/ (accessed June 2024)

- Statista: Global food packaging market insights. https://www.statista.com/ (accessed June 2024)

- U.S. Bureau of Labor Statistics: Employer costs for employee compensation (used for benchmarking labor costs). https://www.bls.gov/ (accessed June 2024)

- Kenwei Group official website: Company and product information. https://www.kenweigroup.com/ (accessed June 2024)

For a customized ROI model built on your exact production data, reach out through Kenwei’s site or your local representative. The right food packing machine will not only increase throughput but can transform cost structure, quality, and competitiveness.

What are the application scenarios of vffs packaging machine?

Reducing Waste with a Food Grain Packing Machine: Practical Guide for Processors

Energy-Efficient Food Grain Packing Machine Technologies: Practical Solutions for Lower Costs and Higher Throughput

Top features to evaluate in a 14 head multihead weigher buying guide

About Solution suggestions

Can Kenwei provide solutions for high-volume production?

Yes, Kenwei specializes in high-speed, high-throughput machines designed for large-scale operations. Our multi-head weighers, packing machines, and check weighers.

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

About Cooperation Process

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

About Price and payment

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

Semi Automatic Multi-function Single Bucket Conveying Powder granule food Packaging Machine With Linear Weigher JW-B20

The Kenwei JW-B20 Semi-Automatic Multi-Function Packaging Machine with Linear Weigher is ideal for powders and granules like sugar, salt, rice, coffee, and milk powder. It automates feeding, weighing, and output with high accuracy and efficiency. Compact and cost-effective, it suits various bag types not supported by standard machines, making it perfect for flexible, space-saving packaging needs.

Rotary Packaging and Weighing System with Multihead Weigher for Peanuts Melon Seeds JW-B8

Kenwei Rotary Packaging and Weighing System with Multihead Weigher is an efficient food packing machine designed for peanuts and melon seeds. This rotary packaging machine ensures high-speed, precise weighing and sealing, making your production smarter and faster.

Automatic Weighing and Canning Filling System for Efficient Packaging Solutions JW-B24

The Kenwei Automatic Canning and Weighing Filling System offers a fully integrated solution for efficient food packaging. Featuring a multihead weigher, Z-type conveyor, vibrator feeder, and capping machine, it automates feeding, weighing, filling, and labeling with high accuracy. Perfect for snacks, puffed foods, fruits, hardware, and granular materials in cans. Ideal for modern production lines.

Single Head Belt Linear Weigher for Vegetable Product Weighing

The Single Head Belt Linear Weigher is constructed from food-grade stainless steel, making it ideal for materials with slight stickiness, such as brown sugar, black sugar, and industrial salt, which have low fluidity. This linear scale features a single hopper with a 15-liter capacity, designed for weighing larger materials efficiently.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei