What are the application scenarios of vffs packaging machine?

- Understanding VFFS Packaging Machines and Their Importance

- Key Features of VFFS Packaging Machines

- Food Industry Applications

- Snacks and Confectionery

- Frozen and Fresh Food

- Powders and Granules

- Pharmaceutical and Healthcare Industry Applications

- Medical Device Packaging

- Tablet and Capsule Packaging

- Chemical and Industrial Applications

- Granular Chemicals and Fertilizers

- Powdered Materials

- Other Notable Application Scenarios

- Pet Food Packaging

- Seed Packaging

- Non-Food Products

- Advantages of Using VFFS Packaging Machines

- Conclusion

- Frequently Asked Questions

Understanding VFFS Packaging Machines and Their Importance

VFFS packaging machines, or Vertical Form Fill Seal machines, are widely employed in modern packaging processes for their efficiency, flexibility, and precision. These machines automatically form packaging film into bags, fill them with the designated product, and seal them vertically. This technology has transformed packaging operations across multiple industries by enabling high-speed, accurate, and hygienic packaging solutions.

Key Features of VFFS Packaging Machines

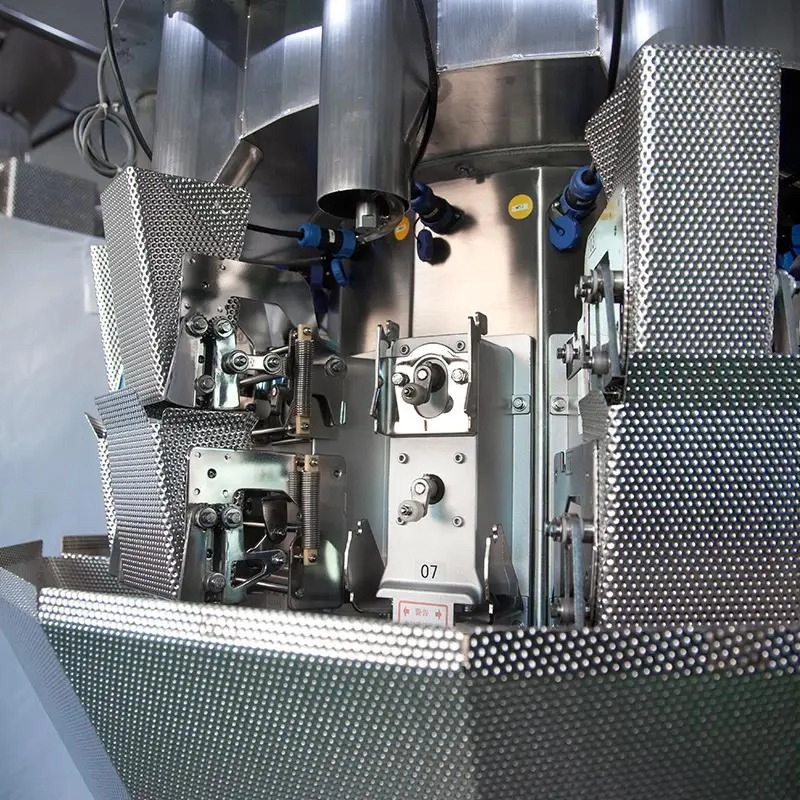

VFFS machines are known for high-speed operation, compact design, and adaptability to different product types, such as powders, granules, liquids, and solids. They offer customizable packaging sizes and shapes, which make them suitable for small businesses and large-scale manufacturers alike. When paired with multi-head weighers like those produced by Kenwei, VFFS machines provide precise filling accuracy and faster packaging cycles.

Food Industry Applications

The food industry is one of the most prominent users of VFFS packaging machines. Their ability to handle a variety of food products, from snacks and candies to frozen vegetables and grains, makes them essential in food packaging lines.

Snacks and Confectionery

VFFS packaging machines efficiently package chips, nuts, candies, and cookies into sealed pouches, preserving freshness and extending shelf life. The machines' speed and precise filling reduce product waste and packaging errors.

Frozen and Fresh Food

Frozen vegetables, fruits, and even fresh produce benefit from VFFS packaging, as the machine ensures hygienic sealing and maintains product quality. Flexible film compatibility allows packaging to withstand freezing conditions without damage.

Powders and Granules

Products such as coffee, protein powders, sugar, and spices are packaged with ease and accuracy using VFFS machines integrated with multi-head weighers. The system guarantees precise portion control critical for retail and foodservice packaging.

Pharmaceutical and Healthcare Industry Applications

In the pharmaceutical and healthcare sector, packaging precision and hygiene standards are vital. VFFS packaging machines offer contamination-free packaging, making them ideal for medical devices, tablets, capsules, and powders.

Medical Device Packaging

VFFS machines create sterile, tamper-evident packaging for medical instruments and accessories. Their customizable sealing options protect products from moisture and environmental damage.

Tablet and Capsule Packaging

By interfacing with high-precision weighers, VFFS machines ensure the exact dose is packaged, a critical requirement for pharmaceuticals. Automated operations reduce human error significantly.

Chemical and Industrial Applications

Beyond food and healthcare, VFFS packaging machines are widely used in packaging chemicals, detergents, fertilizers, and other industrial products.

Granular Chemicals and Fertilizers

Products like granular fertilizers, salts, and detergents are packaged in reliable, moisture-resistant bags. VFFS machines provide consistent bag sizes suitable for distribution and retail purposes.

Powdered Materials

Industrial powders, including cement additives and powdered coatings, require robust packaging solutions that VFFS machines offer through strong seals and durable packaging films.

Other Notable Application Scenarios

VFFS packaging machines are versatile and applicable in areas such as pet food packaging, agricultural seeds packaging, and non-food consumer products packaging.

Pet Food Packaging

From kibble to treats, pet food packaging demands freshness and portion control. VFFS machines enable packaging customization and durability for various product shapes and sizes.

Seed Packaging

Seeds need to be protected from moisture and contamination. VFFS machines provide airtight bags that preserve seed quality and simplify handling.

Non-Food Products

These machines also package items such as hardware parts, small electronic components, and stationery, emphasizing their versatility outside the food sector.

Advantages of Using VFFS Packaging Machines

Implementing VFFS packaging machines brings several benefits:

- High speed and efficiency: Automated packaging significantly increases production capacity.

- Precision and accuracy: Integrating with multi-head weighers guarantees consistent product amounts per package.

- Cost savings: Reduced labor requirements and minimized product waste lead to overall cost reduction.

- Customization options: Wide adaptability for different packaging materials, sizes, and formats.

- Improved hygiene: Contactless packaging enhances food safety and compliance with industry standards.

Conclusion

VFFS packaging machines have become indispensable in many industries due to their flexibility, speed, and accuracy. From food and pharmaceuticals to chemicals and pet products, their broad application scenarios underscore their importance in modern automated packaging lines. When combined with advanced weighing systems like multi-head weighers from Kenwei, businesses can achieve superior packaging solutions tailored to their unique needs, boosting productivity and product quality. Choosing the right VFFS packaging machine allows manufacturers to stay competitive in a fast-evolving marketplace.

Frequently Asked Questions

What types of products can a VFFS packaging machine handle?

VFFS machines are versatile and can handle powders, granules, liquids, solids, and even delicate items like sweets and medical devices.

How does the VFFS machine integrate with multi-head weighers?

Multi-head weighers provide precise weight measurement during the filling process, ensuring each package contains an accurate amount of product, enhancing consistency and reducing waste.

What industries benefit most from using VFFS packaging machines?

Key industries include food and beverage, pharmaceuticals, chemicals, pet food, agricultural seeds, and some non-food consumer goods.

Can VFFS machines handle customized packaging sizes?

Yes, VFFS machines are highly flexible and allow easy adjustments for different bag sizes, shapes, and packaging materials.

What maintenance is required for VFFS packaging machines?

Regular cleaning, lubrication, and routine inspection of moving parts are essential to maintain high performance and extend machine lifespan.

Everything You Need to Know About automatic check weigher

Top Maintenance Tips for Combination Weighers 2026

Everything You Need to Know About single head weigher

Top features to evaluate in a 14 head multihead weigher buying guide

About Product choice

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

Can Kenwei's machines be used in my industry?

Kenwei’s equipment is highly versatile and can be used across a wide range of industries, including:Food,Pharmaceuticals,Chemicals,Plastics and Agriculture.

Plastics If you're unsure whether our products are suitable for your industry, please contact us, and we can provide you with specific solutions tailored to your needs.

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

About After Sales Support

Can I get remote troubleshooting assistance?

Yes, Kenwei offers remote troubleshooting for certain issues. Our technical team can guide you through diagnostics and help resolve issues via phone, video call, or online messaging.

How do I claim warranty service?

To claim warranty service, please contact our customer support team with your machine’s product code and a description of the issue. If applicable, we may request photos or videos of the issue to facilitate troubleshooting.

Double Filling VFFS Packaging Machine for Efficient Dual Product Packaging

The Fully Automatic High-Speed Vertical Double Filling Form-Fill-Seal (VFFS) machine features a compact design and a complete range of packaging machines and auxiliary equipment, making it adaptable to various materials and space-efficient. It can handle a wide variety of laminated films, single-layer PE films, film thicknesses ranging from 0.04mm to 0.09mm, and paper membrane packaging. This VFFS machine is widely used in food, pharmaceutical, and chemical industries for packaging snacks, powders, liquids, and granular products. The machine forms bags from flat film rolls, fills them with products, and seals them vertically, improving packaging efficiency and ensuring consistent, high-quality production.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei