Where to Buy vffs packaging

- Where to Buy VFFS Packaging: A Comprehensive Guide

- Understanding VFFS Packaging and Its Importance

- Where to Buy VFFS Packaging Machines and Materials

- Why Choosing Kenwei for Your VFFS Packaging Needs Makes Sense

- Factors to Consider When Purchasing VFFS Packaging Machines

- Steps to Ensure Successful Purchase and Installation

- Future Trends in VFFS Packaging

- Conclusion

- Common Questions About Buying VFFS Packaging Equipment

Where to Buy VFFS Packaging: A Comprehensive Guide

Vertical Form Fill Seal (VFFS) packaging has become a leading choice in the packaging industry due to its efficiency and versatility. Whether you are packaging snacks, powders, or frozen foods, VFFS machines offer an automated and reliable solution. However, a common question arises for many manufacturers and businesses: Where to buy VFFS packaging? we will explore the best sources for VFFS packaging equipment and materials, highlight key factors to consider when purchasing, and explain how partnering with a reputable supplier like Kenwei can elevate your packaging operations.

Understanding VFFS Packaging and Its Importance

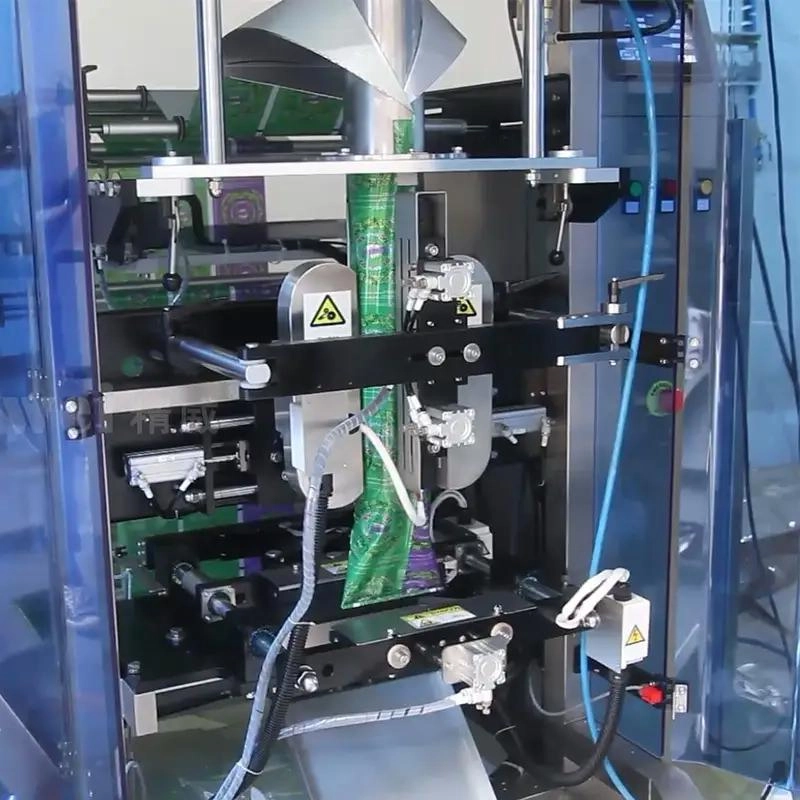

First, it’s important to understand what VFFS packaging is. VFFS machines create bags from a flat roll of film, fill them with product, then seal them vertically, producing efficient, sealed packets quickly. This method is widely used due to its speed, adaptability, and capability to package a vast range of products, from granular food items to liquids.

Choosing the right VFFS packaging equipment directly impacts your production efficiency, product safety, and overall cost. High-quality packaging machines minimize material waste and machine downtime, while ensuring packaging integrity and an appealing package presentation.

Where to Buy VFFS Packaging Machines and Materials

When looking to buy VFFS packaging solutions, consider these key channels:

- Direct Manufacturers: Buying directly from manufacturers like Kenwei offers the best combination of price, customization options, and after-sales support. Manufacturers provide a comprehensive suite including multi-head weighers, metal detectors, and VFFS machines, allowing for integrated automated weighing and packaging systems.

- Industry Distributors and Dealers: Authorized distributors often provide access to multiple brands but may charge a High Quality and offer limited customization compared to direct manufacturers.

- Online Marketplaces and B2B Platforms: While platforms like Alibaba and Made-in-China supply numerous options for VFFS packaging equipment, buyer caution is advised. Assess product specifications carefully and verify supplier credibility before purchase.

Why Choosing Kenwei for Your VFFS Packaging Needs Makes Sense

Located in Guangdong Province’s Fusha High-tech Industrial Park, Kenwei specializes in high-speed, precision multi-head weighers and automated packaging machines. Their integrated solutions combine weighing and VFFS packaging into one streamlined system designed to meet custom product requirements and production volumes.

Kenwei’s advantages include:

- Customization: Tailored solutions adapt to various products, from powders to granules to powders, enhancing packaging accuracy and reducing waste.

- Comprehensive Service: Kenwei offers full support, including design, installation, commissioning, training, and after-sales service.

- Advanced Technology: Their machines feature precise weight control and rapid packaging speeds, boosting productivity and minimizing product giveaway.

Factors to Consider When Purchasing VFFS Packaging Machines

To ensure you select the best VFFS packaging machines, keep the following factors in mind:

- Packaging Material Compatibility: The machine must handle your specific film materials, be it polyethylene, laminated films, or biodegradable options.

- Production Capacity: Consider the machine’s speed and volume capabilities to match your output goals.

- Machine Integration: Evaluate if it can integrate with existing weighing machines, metal detectors, or check weighers for a seamless production line.

- After-Sales Support: Reliable technical support and spare parts availability can save downtime and ensure longevity.

- Industry Compliance: Ensure the equipment meets regulatory standards regarding hygiene and safety.

Steps to Ensure Successful Purchase and Installation

Purchasing a VFFS packaging machine involves more than just the initial buy. Follow these steps for a successful investment:

- Define Your Requirements: Detail your product types, packaging sizes, and production rates.

- Research Suppliers: Compare manufacturers based on reputation, equipment specs, and service options.

- Request Demonstrations: Viewing machines in operation helps assess suitability.

- Discuss Customization: Make sure the manufacturer can tailor features according to your needs.

- Plan Installation and Training: Opt for suppliers who provide comprehensive installation and user training.

Future Trends in VFFS Packaging

The packaging industry is evolving with a focus on sustainability and automation. VFFS packaging machines are increasingly supporting eco-friendly films and intelligent controls that optimize material use and reduce waste. Investing in advanced technology now positions your business to stay competitive in a market that values speed, precision, and environmental responsibility.

Conclusion

Knowing where to buy VFFS packaging begins with understanding your specific needs and selecting a trusted partner. Manufacturers like Kenwei provide cutting-edge, customizable VFFS packaging and weighing systems tailored to diverse industries. Their comprehensive services and high-performance equipment ensure a smooth transition to automated packing with improved efficiency and product quality. When investing in VFFS packaging machines, prioritize customization, after-sales service, and technological advancement to secure long-term success.

Common Questions About Buying VFFS Packaging Equipment

What is the average cost of a VFFS packaging machine?

The cost varies widely depending on machine size, speed, features, and customization, typically ranging from $10,000 to over $100,000.

How do I choose the right VFFS packaging material?

Consider product compatibility, sealing properties, barrier requirements, and sustainability goals when selecting films or bags.

Can VFFS machines handle multi-head weighers?

Yes, many modern VFFS machines, including those from Kenwei, integrate seamlessly with multi-head weighers for accurate filling and increased efficiency.

Do manufacturers provide training for operating VFFS machines?

Reputable manufacturers typically offer installation support and operator training to ensure efficient use and maintenance.

How important is after-sales service?

It is vital for minimizing downtime and extending machine lifespan; always choose suppliers with strong technical support.

Energy, Maintenance, and Uptime: Procurement Guide to VFFS

Linear Weigher Accuracy: Tips to Reduce Weight Variance for Reliable Production

Everything You Need to Know About food packing machine

How Sensitivity Affects Food Metal Detector Performance

About Logistics

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

About Product choice

Can Kenwei's machines be used in my industry?

Kenwei’s equipment is highly versatile and can be used across a wide range of industries, including:Food,Pharmaceuticals,Chemicals,Plastics and Agriculture.

Plastics If you're unsure whether our products are suitable for your industry, please contact us, and we can provide you with specific solutions tailored to your needs.

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

About Price and payment

How is the price of Kenwei machines determined?

The price of Kenwei machines depends on several factors, including the type of machine, customization requirements, production volume, and any additional features or integrations. We provide tailored quotes based on your specific needs and requirements.

About Solution suggestions

How can Kenwei solutions help reduce waste in my production process?

Kenwei solutions improve accuracy in weighing, packaging, and quality control, reducing the chances of overfill or underfill. This leads to less product waste and higher operational efficiency.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Combined Check Weigher and Metal Detector for Food Industrial Weighing and Sorting

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei