The B2B Buyer’s Guide to packing machinery for snack food

- The B2B Buyer’s Guide to Packing Machinery for Snack Food

- Navigating the Snack Food Packaging Landscape

- Why the Right Packing Machinery Matters for Snack Food Success

- Understanding the Unique Challenges of Snack Food Packaging

- Fragility and Product Integrity

- High-Speed Production Requirements

- Maintaining Freshness and Shelf Life

- Navigating the Diverse World of Snack Products

- Essential Components of Modern Snack Food Packing Machinery

- Precision Weighing Systems: The Heart of Efficiency

- Form-Fill-Seal (FFS) Machines: Versatility in Action

- The Role of Ancillary Equipment in Integrated Snack Packaging Lines

- Critical Factors for Choosing Your Ideal Packing Machinery for Snack Food

- Evaluating Product Characteristics and Compatibility

- Assessing Production Capacity and Speed

- Prioritizing Accuracy and Minimizing Giveaways

- Hygiene, Cleanability, and Food Safety Standards

- Levels of Automation and System Integration

- Flexibility, Adaptability, and Future-Proofing

- Considering Footprint and Operational Space

- Budgeting and Calculating Return on Investment (ROI)

- The Kenwei Advantage: Your Partner in Advanced Snack Packaging Solutions

- Pioneering High-Speed, High-Precision Weighing

- Comprehensive One-Stop Automated Packaging Solutions

- Unrivalled Expertise and Customer-Centric Service

- Emerging Trends Shaping the Future of Snack Food Packaging

- Sustainable Packaging Materials and Practices

- Smart Packaging and Industry 4.0 Integration

- Automation and Robotics in Snack Packaging

- Conclusion: Securing Your Future with Smart Snack Food Packing Machinery Choices

- Frequently Asked Questions about Snack Food Packing Machinery

The B2B Buyer’s Guide to Packing Machinery for Snack Food

Navigating the Snack Food Packaging Landscape

The snack food industry is a dynamic and highly competitive market, characterized by rapid innovation, evolving consumer tastes, and a constant demand for freshness, quality, and convenience. As a B2B buyer in this sector, you understand that selecting the right packing machinery for snack food is not merely an operational decision; it's a strategic investment that directly impacts your product quality, operational efficiency, profitability, and ly, Kenwei's reputation. From delicate potato chips to crunchy nuts and chewy candies, each snack type presents its own unique packaging challenges, requiring specialized equipment that can handle high volumes with utmost precision and speed.

Why the Right Packing Machinery Matters for Snack Food Success

In an industry where margins can be tight and consumer expectations are high, efficient and reliable snack food packaging solutions are paramount. The ideal machinery helps minimize product giveaway, extend shelf life, maintain product integrity, and ensure consistent package quality. Furthermore, the ability to rapidly adapt to new product formats and packaging designs gives manufacturers a crucial competitive edge. This guide is designed to equip you with the knowledge needed to make informed decisions when investing in packing machinery for snack food, ensuring your operations are future-proof and highly efficient.

Understanding the Unique Challenges of Snack Food Packaging

Snack foods, by their very nature, pose distinct challenges for packaging processes that demand specialized machinery. Addressing these challenges effectively is key to optimizing your production line.

Fragility and Product Integrity

Many snack items, such as potato chips, puffed snacks, and certain biscuits, are incredibly fragile. They are susceptible to breakage and damage during handling, weighing, and packaging. The right packing machinery for snack food must employ gentle handling mechanisms to preserve product integrity, ensuring that consumers receive an intact, appealing product. This often involves specific designs for hoppers, chutes, and vibratory feeders to minimize drops and impacts.

High-Speed Production Requirements

The global savory snacks market alone is projected to reach an impressive US$273.6 billion in 2024, with continuous annual growth anticipated. This massive demand necessitates exceptionally high-speed production lines. Snack manufacturers require high-speed snack packaging equipment capable of processing hundreds of bags or pouches per minute without compromising accuracy or quality. Downtime can be incredibly costly, making machine reliability and quick changeover times critical factors.

Maintaining Freshness and Shelf Life

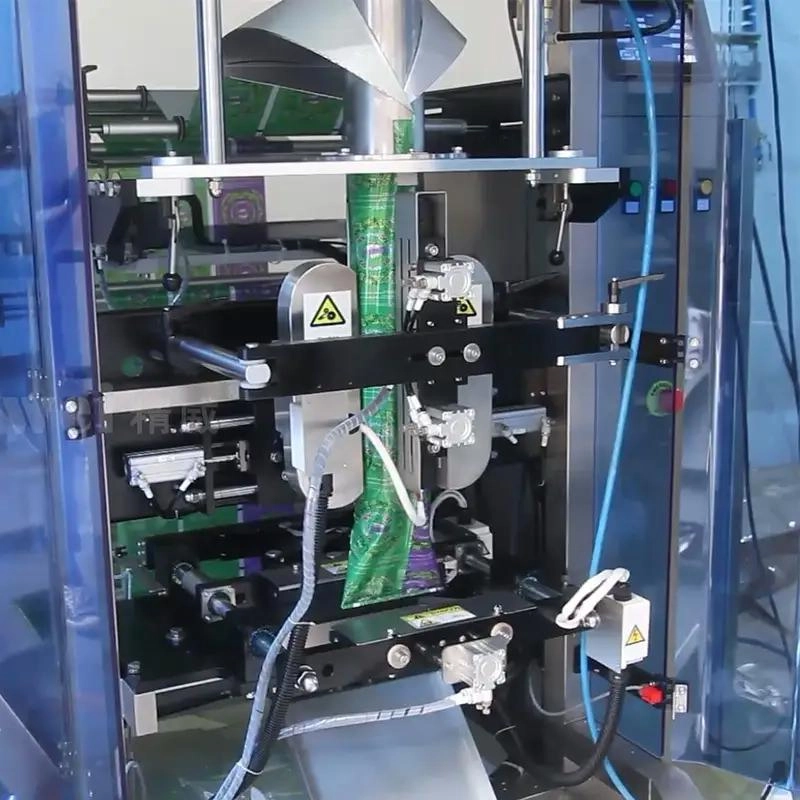

Freshness is non-negotiable for snack foods. Exposure to oxygen and moisture can quickly lead to staleness and spoilage, shortening shelf life. Effective packing machinery for snack food must create strong, airtight seals to protect the product from environmental factors. Features like gas flushing (e.g., nitrogen) are often integrated into vertical form-fill-seal (VFFS) machines to displace oxygen, further extending the product's freshness and preserving its taste and texture.

Navigating the Diverse World of Snack Products

From a single production line, a snack manufacturer might need to pack a wide variety of items: granular products like nuts, irregularly shaped items like pretzels, fine powders like seasoning mixes, and delicate items like crackers. Each type has different flow characteristics and requires specific handling. Therefore, the chosen packing machinery for snack food must offer versatility and flexibility, allowing for quick and easy adjustments between different product types and bag formats without extensive retooling.

Essential Components of Modern Snack Food Packing Machinery

An efficient snack food packaging line comprises several integrated machines, each playing a vital role in the overall process. Understanding these components is crucial for B2B buyers seeking comprehensive automated snack packaging systems.

Precision Weighing Systems: The Heart of Efficiency

At the core of any profitable snack packaging operation is an accurate weighing system. Multihead weighers for snacks, like those manufactured by Kenwei, are the industry standard for their unparalleled speed and precision. They work by distributing product into multiple weigh buckets, combining the weights to achieve the target weight with minimal product giveaway. This accuracy is paramount, as even a small fraction of a gram overfill per bag can lead to substantial financial losses over millions of units. For products requiring less precision or with more uniform piece weights, linear weighers offer a cost-effective alternative. Kenwei specializes in both high-speed and high-precision weighing solutions, ensuring optimal yield and efficiency for various snack types.

Form-Fill-Seal (FFS) Machines: Versatility in Action

FFS machines are central to creating the final package. Vertical Form-Fill-Seal (VFFS) machines are most commonly used for snacks, forming bags from a roll of film, filling them from the top (often directly from a multihead weigher), and then sealing them. They can produce various bag styles, including pillow bags, gusseted bags, and stand-up pouches, suitable for chips, candies, nuts, and more. Horizontal Form-Fill-Seal (HFFS) machines are better suited for products that require horizontal loading or are more delicate, such as cookies or chocolate bars, where precise product placement is essential before sealing.

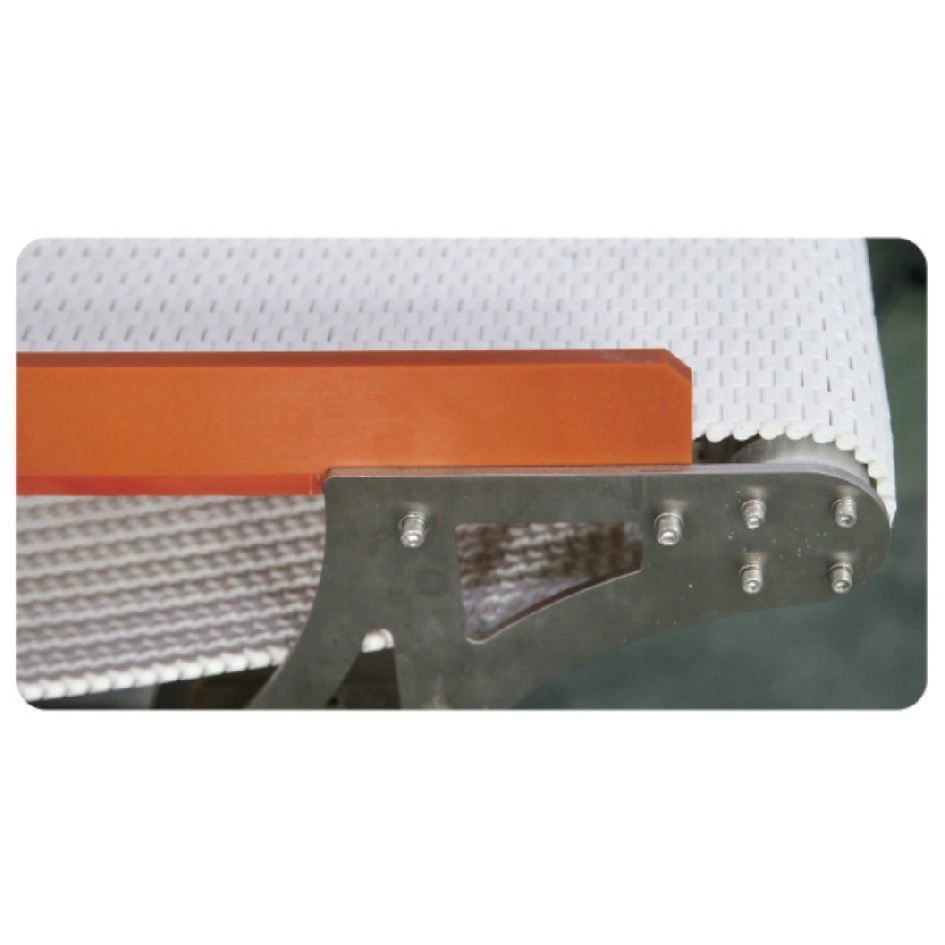

The Role of Ancillary Equipment in Integrated Snack Packaging Lines

Beyond the primary weighing and FFS machines, a complete snack food packaging line integrates several ancillary components for a seamless operation. Conveyor systems transport products efficiently. Metal detectors, a crucial component offered by Kenwei, ensure product safety by identifying and rejecting any metallic contaminants. Check weighers, another Kenwei specialty, verify the final package weight, ensuring compliance with regulations and preventing underfills or excessive overfills. Additionally, coding systems apply batch codes and expiry dates, while carton erectors and case packers prepare the finished bags for shipment, automating the entire process from product intake to palletization. These integrated solutions are vital for achieving maximum throughput and reliability.

Critical Factors for Choosing Your Ideal Packing Machinery for Snack Food

Making the right investment in B2B snack packaging equipment requires careful consideration of several key factors that align with your operational needs and business goals.

Evaluating Product Characteristics and Compatibility

The physical properties of your snack products are the primary determinants. Consider their size, shape, fragility, density, and flow characteristics. For instance, sticky confectionery requires specific non-stick coatings and handling mechanisms, while highly fragile chips need ultra-gentle sloped paths. Ensuring the machine's design and material contact parts are compatible with your specific snack type is fundamental to efficient and damage-free packaging.

Assessing Production Capacity and Speed

Quantify your required output in terms of bags per minute (BPM) or kilograms per hour. Don't just consider current needs; project future growth. High-speed multihead weighers and VFFS machines can achieve speeds exceeding 100 BPM for certain snack types. Over-specifying can lead to unnecessary costs, but under-specifying will result in production bottlenecks. A detailed analysis of your sales forecasts and operational hours will guide this decision.

Prioritizing Accuracy and Minimizing Giveaways

Accuracy is directly tied to profitability. A highly accurate weighing system, such as a precision multihead weigher for snacks, minimizes product giveaway – the amount of product given away beyond the stated package weight. Even a fraction of a gram saved per package accumulates into significant cost savings over time. For example, reducing giveaway by just 0.5 grams per 100-gram bag can save tens of thousands of dollars annually for high-volume producers. Look for machines with proven accuracy records and advanced control systems.

Hygiene, Cleanability, and Food Safety Standards

Food safety is paramount. Food packaging machine manufacturers must adhere to stringent hygiene standards. Look for machines constructed from food-grade stainless steel (e.g., SUS304 or SUS316 for contact parts), with smooth, crevice-free surfaces that are easy to clean and sanitize. Quick-release components and wash-down capabilities are highly desirable for reducing cleaning time and preventing cross-contamination, especially when handling different snack variants.

Levels of Automation and System Integration

Decide on the degree of automation your operation requires. From semi-automatic systems for smaller-scale operations to fully integrated, automated lines that handle everything from weighing to case packing, the level of automation impacts labor costs, efficiency, and consistency. Integrated packaging lines offer seamless communication between machines, minimizing manual intervention and maximizing throughput.

Flexibility, Adaptability, and Future-Proofing

Can the machine handle different bag sizes, film types, or even different snack products? Investing in versatile equipment that can be easily reconfigured for various SKUs or future product launches provides significant long-term value. Look for quick changeover features, intuitive controls, and modular designs that allow for upgrades or additions later.

Considering Footprint and Operational Space

Physical space constraints are often a practical consideration. Evaluate the machine's footprint and ensure it fits comfortably within your existing facility layout, allowing for adequate access for operation, maintenance, and cleaning. Vertical solutions like VFFS machines paired with multihead weighers generally have a smaller footprint compared to horizontal lines for similar throughput.

Budgeting and Calculating Return on Investment (ROI)

While initial cost is a factor, focus on the total cost of ownership (TCO) and return on investment (ROI). Consider energy consumption, maintenance requirements, spare parts availability, and potential labor savings. A higher initial investment in precise, reliable packing machinery for snack food can lead to significant long-term savings through reduced product giveaway, increased efficiency, and minimized downtime.

The Kenwei Advantage: Your Partner in Advanced Snack Packaging Solutions

At Kenwei, we pride ourselves on being a powerful manufacturer committed to delivering top-tier automated weighing and packaging solutions. With extensive experience and a dedication to innovation, we are uniquely positioned to meet the demanding requirements of the snack food industry.

Pioneering High-Speed, High-Precision Weighing

Our core expertise lies in the development and manufacturing of high-speed, high-precision multi-head weighers. Engineered to handle delicate and varied snack products with unparalleled accuracy, Kenwei multi-head weighers significantly reduce product giveaway, optimizing your yield and boosting profitability. We also offer linear weighers for specific applications, ensuring we have the right weighing solution for every snack type.

Comprehensive One-Stop Automated Packaging Solutions

Kenwei goes beyond just weighing. We provide complete, one-stop automated weighing and packaging solutions tailored to your specific needs. Our product range includes not only multi-head weighers and linear weighers but also essential ancillary equipment such as metal detectors and check weighers, vital for quality control and food safety. This comprehensive offering allows for seamless integration and optimized workflow from a single, reliable supplier, meeting your customization requirements with ease.

Unrivalled Expertise and Customer-Centric Service

Located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province, Kenwei boasts comprehensive capabilities in design and development, manufacturing, marketing, installation and commissioning, technical training, and after-sales service. Our commitment to thoughtful and fast service has established a strong brand image and reputation in the packaging machinery industry. Our vision is to become the world's leading weighing packing machine manufacturer, driven by our dedication to quality, innovation, and customer satisfaction. When you partner with Kenwei, you gain access to high-speed, high-precision equipment backed by expert support throughout your machine's lifecycle.

Emerging Trends Shaping the Future of Snack Food Packaging

Staying ahead in the snack food market means being aware of the evolving trends in packaging technology and consumer preferences.

Sustainable Packaging Materials and Practices

With growing environmental concerns, the demand for sustainable packaging is accelerating. B2B buyers are increasingly seeking packing machinery for snack food that can handle eco-friendly materials such as biodegradable films, compostable pouches, and recycled content plastics. Manufacturers are investing in technologies that can work efficiently with these new materials, often requiring precise temperature control and sealing mechanisms. This trend is expected to continue shaping machine design and material compatibility.

Smart Packaging and Industry 4.0 Integration

The integration of IoT (Internet of Things) and AI (Artificial Intelligence) is transforming packaging lines. Smart sensors can monitor machine performance, predict maintenance needs, and optimize operational parameters in real-time. This predictive maintenance reduces downtime and increases overall equipment effectiveness (OEE). Data analytics from smart packaging lines can provide invaluable insights into production efficiency, quality control, and even supply chain logistics, driving smarter business decisions.

Automation and Robotics in Snack Packaging

The drive for increased efficiency and reduced labor costs continues to push the adoption of advanced automation and robotics. Collaborative robots (cobots) are being used for tasks like case packing and palletizing, working safely alongside human operators. Fully automated end-of-line solutions are becoming more prevalent, creating seamless transitions from bagging to ready-to-ship pallets, further enhancing the speed and consistency of snack food packaging solutions.

Conclusion: Securing Your Future with Smart Snack Food Packing Machinery Choices

Choosing the right packing machinery for snack food is a complex but critical decision that can define your operational success and market position. By thoroughly evaluating your product characteristics, production needs, and considering factors like speed, accuracy, hygiene, and flexibility, you can make an investment that pays dividends for years to come. Partnering with a reputable and experienced manufacturer like Kenwei, who offers high-speed, high-precision multi-head weighers and comprehensive automated weighing and packaging solutions, ensures you receive not only cutting-edge equipment but also unparalleled support and expertise. Embrace the future of snack food packaging with intelligent choices that propel your business forward.

Frequently Asked Questions about Snack Food Packing Machinery

What types of snack foods can Kenwei’s machines pack?Kenwei’s multi-head weighers and integrated packaging solutions are versatile and designed to handle a wide range of snack foods, including but not limited to potato chips, puffed snacks, nuts, seeds, candies, biscuits, cookies, dried fruits, granola, pretzels, and various granular or irregularly shaped snack items. Our machines are engineered for precision and gentle handling, suitable for both fragile and robust products.

How does a multi-head weigher improve profitability for snack food producers?A multi-head weigher significantly improves profitability by minimizing product giveaway. Its high precision ensures that each package contains the exact target weight with minimal overfill. Over millions of packages, even a small reduction in giveaway (e.g., 0.5 grams per bag) translates into substantial cost savings on raw materials, directly boosting your bottom line and increasing yield.

What is the typical speed of snack food packing machinery?The speed of snack food packing machinery varies depending on the product, bag size, and specific machine model. Kenwei’s high-speed multi-head weighers, when integrated with suitable VFFS machines, can achieve speeds exceeding 100 bags per minute (BPM) for certain snack types, ensuring high throughput to meet market demands. We can customize solutions to match your required production capacity.

Why are metal detectors and check weighers important for snack food packaging lines?Metal detectors and check weighers are crucial for product safety and quality assurance. Metal detectors, like those offered by Kenwei, identify and reject any metallic contaminants that might accidentally enter the product during processing, protecting consumer health and Kenwei's reputation. Check weighers verify the final package weight, ensuring consistency, preventing underfills or excessive overfills, and ensuring compliance with packaging regulations.

Can Kenwei provide customized packing machinery solutions?Yes, Kenwei specializes in providing one-stop automated weighing and packaging solutions tailored to our customers’ customization requirements. We have comprehensive capabilities in design and development. Whether you need specific machine configurations, integration with existing lines, or solutions for unique product characteristics, our team works closely with you to develop an optimal system that fits your exact operational needs.

What kind of after-sales service does Kenwei offer?Kenwei is committed to providing comprehensive after-sales service. This includes professional installation and commissioning of the machinery, technical training for your operators to ensure efficient use, and ongoing support for maintenance and troubleshooting. We aim to establish a good brand image and a reputation for thoughtful and fast service, ensuring your packaging line operates smoothly and reliably over its lifespan.

Combination Weigher Maintenance Tips to Reduce Downtime

ROI of Investing in Good Metal Detectors for Food Safety

Energy, Maintenance, and Uptime: Procurement Guide to VFFS

What is single head weigher ?

About After Sales Support

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

About Cooperation Process

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

About Solution suggestions

Can Kenwei solutions be adapted for different product packaging types?

Yes, Kenwei solutions can handle a variety of packaging types, including bags, boxes, pouches, and bottles. We can customize machines to suit your packaging format, ensuring compatibility with your packaging equipment.

About Price and payment

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

About Product choice

What types of products does Kenwei offer?

Kenwei specializes in high-precision and high-speed automated machinery for weighing, packaging, and quality control. Our main products include: multihead weigher, linear weigher, checkweighers,food metal detector,vertical packing machine and packing machine accessories.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Combined Check Weigher and Metal Detector for Food Industrial Weighing and Sorting

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei