Combination Weigher Maintenance Tips to Reduce Downtime

- Combination Weigher Maintenance Tips to Reduce Downtime

- Why proactive maintenance matters for your combination weigher

- Daily maintenance checklist for combination weigher reliability

- Weekly tasks: mechanical and electrical checks

- Monthly and quarterly maintenance: calibration and deeper inspections

- Calibration best practices for combination weigher accuracy

- Preventive vs. reactive maintenance: a practical comparison

- Essential spare parts and inventory strategy for fast recovery

- Software, sensors, and firmware: keep the control system healthy

- Operator training and standardized SOPs to reduce human error

- Troubleshooting common combination weigher issues

- Cleaning and hygiene: balancing thoroughness and uptime

- Condition monitoring and predictive maintenance options

- How Kenwei supports your combination weigher uptime

- Checklist: quick reference for combination weigher maintenance

- FAQ — Combination weigher maintenance questions

- How often should I calibrate my combination weigher?

- What daily tasks can operators do to prevent downtime?

- Which spare parts are most critical to keep in stock?

- Can software updates affect weighing accuracy?

- How does preventive maintenance affect production costs?

- How can Kenwei help with my maintenance program?

Combination Weigher Maintenance Tips to Reduce Downtime

Why proactive maintenance matters for your combination weigher

A well-maintained combination weigher delivers consistent accuracy, higher throughput, and fewer production stops. Preventive maintenance reduces the risk of misweighing, mechanical failures, and contamination — common causes of unplanned downtime on high-speed packing lines. Focusing on routine care for feeders, hoppers, load cells, and control systems keeps your equipment running reliably and protects product quality.

Daily maintenance checklist for combination weigher reliability

Simple daily checks prevent buildup issues and catch small faults early. Typical daily tasks include visual inspection, cleaning of hoppers and feeders, checking for product spill or foreign material, ensuring pneumatic lines are dry and leak-free, and confirming all safety guards are in place. These quick routines help avoid blockages and maintain weigh accuracy on busy production shifts.

Weekly tasks: mechanical and electrical checks

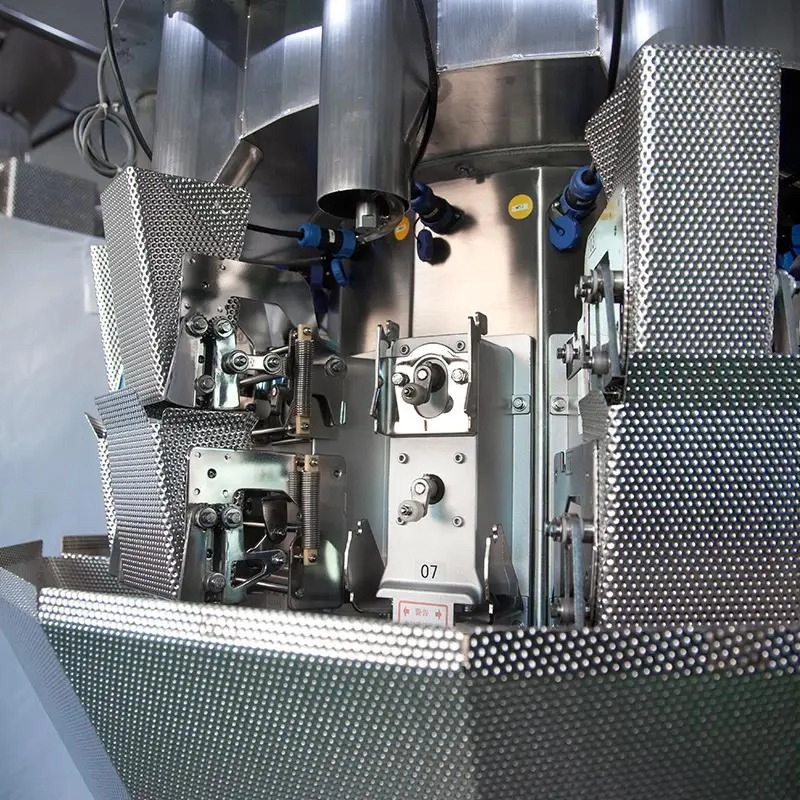

On a weekly cadence, perform more detailed checks: inspect vibration motors and feeder trays for wear, verify belt tension and alignment, examine load cell mounts and wiring for signs of loosening or corrosion, and review alarm logs in the machine HMI. Tighten accessible fasteners to the manufacturer’s torque guidance. Weekly attention prevents progressive failures that can cascade into longer downtime.

Monthly and quarterly maintenance: calibration and deeper inspections

Monthly and quarterly tasks should include load cell and scale calibration checks, motor current and vibration analysis, thorough cleaning of dead zones, lubrication of bearings and moving joints per manufacturer recommendations, and firmware/software backup. Schedule a full-bin simulation and test runs with known sample weights to verify multihead distribution behavior. Regular calibration ensures the combination weigher maintains legal-for-trade or production tolerances.

Calibration best practices for combination weigher accuracy

Calibration is essential to sustain weighing precision. Use certified test weights or traceable calibration kits, follow the combination weigher manufacturer’s procedures, and log every calibration action. For many production environments, quarterly checks are typical; high-volume or regulated lines may require monthly or even weekly checks. Keep calibration records for audits and to track drift trends.

Preventive vs. reactive maintenance: a practical comparison

Comparing preventive and reactive approaches clarifies why scheduled care pays off. The table below highlights key differences and impacts on downtime and cost profiles.

| Aspect | Preventive Maintenance | Reactive Maintenance |

|---|---|---|

| Frequency | Scheduled (daily/weekly/monthly/quarterly) | As failures occur |

| Impact on Downtime | Lower unplanned downtime; predictable stops | Higher unplanned downtime; disruptions to production |

| Cost Profile | Regular, budgeted maintenance costs | Potentially high emergency repair costs |

| Product Quality Risk | Reduced risk of misweighing or contamination | Higher risk of inaccurate weights and rejects |

| Spare Parts Management | Planned spares stocking reduces repair time | Rush orders and longer lead times common |

Essential spare parts and inventory strategy for fast recovery

Stocking the right spare parts is crucial for minimizing downtime after a failure. Typical critical spares for a combination weigher include: a replacement load cell, vibration motors, inverter drives, PLC modules, hopper bowls, belts, and a basic sensor kit (photoelectric/optical sensors). Maintain a small, prioritized inventory of parts based on historical failure modes and lead times to restore operations quickly.

Software, sensors, and firmware: keep the control system healthy

Modern combination weighers rely heavily on electronics and software. Regularly back up HMI recipes and PLC configurations, install vetted firmware updates from the OEM, and verify sensor alignment and cleanliness. Replace or recalibrate sensors showing drift. Software issues can be subtle — logging and trend data help identify anomalies before they cause a shutdown.

Operator training and standardized SOPs to reduce human error

Many stoppages are caused by incorrect machine setup or cleaning procedures. Create clear SOPs for changeovers, cleaning, and start-up/shutdown sequences. Train operators on troubleshooting basics, alarm meanings, safe handling, and escalation steps. A well-trained operator can often resolve minor issues on the line, saving valuable production time.

Troubleshooting common combination weigher issues

Fast, logical troubleshooting reduces repair times. Common issues include inconsistent feed patterns (check feeder amplitude and drive), weight dispersion errors (inspect load cell mounts and distribution timing), electrical noise or intermittent PLC errors (verify grounding and cabling), and product bridging in hoppers (modify flow aids or install agitators). Keep a troubleshooting checklist to standardize response steps and document resolutions.

Cleaning and hygiene: balancing thoroughness and uptime

Food and pharmaceutical lines require diligent cleaning. Design cleaning routines that align with production schedules: quick clean cycles between shifts and deeper cleandowns during planned maintenance windows. Use removable hopper bowls and wash-down rated components where possible. Plan CIP or regular wash procedures to minimize disassembly while ensuring sanitary standards.

Condition monitoring and predictive maintenance options

Implement condition monitoring where feasible: vibration sensors on motors, thermal monitoring on bearings, and load trend analysis can reveal wear before failure. Predictive maintenance relies on data trends rather than fixed calendars — it’s an investment that can significantly reduce unplanned downtime for high-volume operations. Start small with one or two indicators and expand as ROI becomes clear.

How Kenwei supports your combination weigher uptime

Kenwei is a leading manufacturer of multi-head weighers, offering high-speed, high-precision machines built for continuous production. We provide one-stop automated weighing and packaging solutions, plus installation, commissioning, technical training, and after-sales service. For maintenance support, Kenwei can advise on spare parts kits, provide calibrated test weights, and deliver on-site or remote troubleshooting. Learn more at https://www.kenweigroup.com/.

Checklist: quick reference for combination weigher maintenance

Keep this short checklist near the machine to guide shift staff:

- Daily: Clean hoppers/feeder bowls, check sensors, verify no spills.

- Weekly: Inspect drives, belts, wiring, and tighten fasteners.

- Monthly: Calibrate scale, lubricate bearings, backup recipes.

- Quarterly: Full inspection, test run with reference weights, firmware review.

- Annually: Professional service, load cell certification if needed.

FAQ — Combination weigher maintenance questions

How often should I calibrate my combination weigher?

Calibration frequency depends on production volume and regulatory requirements. Many facilities perform calibration checks monthly or quarterly; high-volume or regulated lines may check more often. Keep a log of calibration results to spot drift trends.

What daily tasks can operators do to prevent downtime?

Operators should clean feed paths and hoppers, check for product buildup, confirm sensors are clean and aligned, review the HMI for alarms, and ensure safety guards are in place. These quick steps prevent many common interruptions.

Which spare parts are most critical to keep in stock?

Critical spares typically include a replacement load cell, vibration motor, inverter/drive, PLC module, belts, and commonly failing sensors. Prioritize parts based on your machine’s failure history and supplier lead times.

Can software updates affect weighing accuracy?

Yes. Firmware or control software updates can change control loops or filter settings. Always test updates in a controlled environment, back up configurations, and follow OEM guidance.

How does preventive maintenance affect production costs?

Preventive maintenance smooths production with predictable stops and fewer emergency repairs. While it requires scheduled resources, it typically reduces overall costs by avoiding expensive downtime and product waste.

How can Kenwei help with my maintenance program?

Kenwei offers tailored support including installation, commissioning, operator training, spare parts kits, calibration guidance, and both on-site and remote troubleshooting. Visit https://www.kenweigroup.com/ for service options and contact information.

Integrating backup systems with 14 head multihead weighers

The B2B Buyer’s Guide to metal detectors for food industry

Integrating a Food Packaging Machine into Your Line

Reducing product giveaway with JW-B12 weighing accuracy strategies

About Product choice

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

Can Kenwei's machines be used in my industry?

Kenwei’s equipment is highly versatile and can be used across a wide range of industries, including:Food,Pharmaceuticals,Chemicals,Plastics and Agriculture.

Plastics If you're unsure whether our products are suitable for your industry, please contact us, and we can provide you with specific solutions tailored to your needs.

About Logistics

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

About Solution suggestions

How can Kenwei solutions help reduce waste in my production process?

Kenwei solutions improve accuracy in weighing, packaging, and quality control, reducing the chances of overfill or underfill. This leads to less product waste and higher operational efficiency.

About Cooperation Process

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

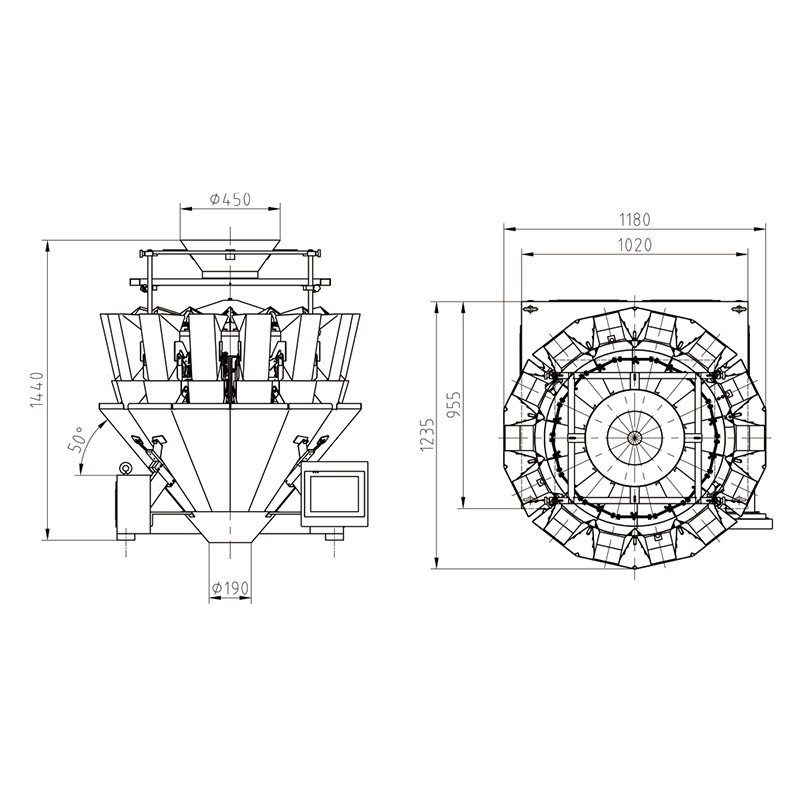

10-Head Standard No-Spring Multihead Weigher 1.6L for Precise Weighing

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Standard Multihead Weigher with New Springless Actuator for Food Weighing Machine

The Standard Multihead Weigher features a high-speed, spring-free hopper with a new aluminum shell design, ensuring stable and fast weighing performance. The integrative welding of the mouthpiece case and middle seat enhances the overall machine strength. Ideal for weighing granular products like melon seeds, peanuts, nuts, almonds, raisins, candies, and pistachios, this 14-head multihead weigher offers hopper options of 1.6L and 2L. With a maximum weighing speed of 120 packs per minute, it delivers rapid and accurate results for high-volume operations.

14-Head High-Speed Springless Multihead Weigher for Accurate Weighing

The high-speed weigher features a new spring-free aluminum shell design with double chute feeding and dual high-speed hopper alternating feeding, significantly boosting feeding speed. It is ideal for weighing materials such as melon seeds, peanuts, nuts, almonds, raisins, candy, pistachios, and more. The 18-head high-speed weigher is equipped with 2L hoppers, achieving a maximum weighing speed of up to 180 bags per minute.

16-Head Multihead Weigher with 1.6L Three-Layer Hopper for Accurate Weighing

The Kenwei 16-Head Multihead Weigher with a 1.6L Three-Layer Hopper provides precise and efficient weighing with a maximum speed of 240 packs per minute, optimizing your production line. The main vibrating pan supports two types of mixed materials, offering versatility and consistent performance. This advanced multihead packing machine is ideal for a wide range of products, including nuts, raisins, candies, potato chips, and other snack foods, as well as hardware and plastic materials. It ensures reliable performance and high accuracy in various industries.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei