The B2B Buyer’s Guide to meat packaging machine

- Navigating the Complexities of Meat Packaging Machine Procurement

- Understanding Your Specific Meat Product & Packaging Needs

- Types of Meat Products (Fresh, Frozen, Processed)

- Desired Packaging Formats (Vacuum, MAP, Thermoforming, Bagging)

- Production Scale & Speed Requirements

- Crucial Regulatory Compliance & Hygiene Standards

- Essential Components of a Modern Meat Packaging Line

- High-Precision Weighing Systems (Kenwei Multi-head Weighers)

- Efficient Filling and Sealing Equipment

- Critical Metal Detection Systems (Kenwei Metal Detectors)

- Accurate Check Weighing Solutions (Kenwei Check Weighers)

- Integrated Conveyance and Automation

- Key Factors When Selecting Your Meat Packaging Machine Partner

- Machine Technology and Material Robustness

- Achieving Optimal Speed, Accuracy, and Overall Efficiency

- The Power of Integrated & Automated Solutions (Kenwei One-Stop Solutions)

- Customization Capabilities for Unique Operations (Kenwei Customization)

- Evaluating Total Cost of Ownership (TCO) for Long-Term Value

- Why Kenwei Excels in Automated Meat Packaging Solutions

- Pioneering High-Speed, High-Precision Weighing Technology

- Comprehensive Weighing and Packaging Equipment Range

- Tailored One-Stop Solutions for Diverse Meat Operations

- Unwavering Commitment to Quality, Service, and Global Leadership

- A Strategic Approach to the Meat Packaging Machine Procurement Process

- Defining Your Requirements Clearly

- Thorough Vendor Research and Due Diligence

- Engaging with Suppliers and Reviewing Proposals

- Rigorous Testing and Seamless Integration

- Prioritizing After-Sales Support and Training

- Future Innovations Shaping the Meat Packaging Industry

- Advancements in Automation and Artificial Intelligence

- The Growing Imperative of Sustainable Packaging Solutions

- Enhanced Traceability and Smart Packaging Technologies

In the dynamic and highly regulated meat processing industry, efficient and reliable packaging is not just a necessity; it's a cornerstone of product quality, safety, and market competitiveness. For B2B buyers, investing in the right meat packaging machine is a strategic decision that impacts everything from operational efficiency and cost-effectiveness to brand reputation and compliance with stringent food safety standards. This comprehensive guide aims to demystify the complex world of industrial meat packaging, providing a roadmap for making informed purchasing decisions. From understanding your specific production needs to evaluating critical machine features and future-proofing your investment, we'll equip you with the knowledge to select a solution that truly elevates your meat processing and packaging capabilities.

Navigating the Complexities of Meat Packaging Machine Procurement

Acquiring a state-of-the-art meat packaging machine is a significant investment for any business involved in meat processing, be it large-scale industrial plants or specialized butcheries. The choice of equipment profoundly influences operational efficiency, product shelf life, food safety, and ly, profitability. This section delves into the foundational considerations that pave the way for a successful investment in high-quality meat packaging solutions.

Understanding Your Specific Meat Product & Packaging Needs

The first and most critical step in procuring a meat packaging machine is to conduct a thorough analysis of your specific products and operational requirements. Meat products vary widely in their physical properties, shelf-life requirements, and intended market, each dictating distinct packaging approaches.

Types of Meat Products (Fresh, Frozen, Processed)

Consider the form factor and characteristics of the meat you're packaging. Are you handling fresh cuts (e.g., steaks, chops, ground meat), frozen products (e.g., poultry, seafood, frozen patties), or processed meats (e.g., sausages, deli slices, cured meats)? Fresh meat often requires packaging that extends shelf life while maintaining visual appeal, often through Modified Atmosphere Packaging (MAP) or vacuum sealing. Frozen products need robust packaging that can withstand extreme temperatures and prevent freezer burn. Processed meats, with their diverse forms, demand versatile systems capable of handling various textures and shapes with precision.

Desired Packaging Formats (Vacuum, MAP, Thermoforming, Bagging)

The desired final packaging format is another crucial determinant. Common formats include:

- Vacuum Packaging: Removes air to prevent spoilage, ideal for fresh meat, extending shelf life significantly.

- Modified Atmosphere Packaging (MAP): Replaces air with a specific gas mixture to slow spoilage and maintain color, often used for fresh cuts in trays.

- Thermoforming Packaging: Creates custom-shaped trays or pouches from roll stock, suitable for various meat types and offering high visual appeal.

- Bagging Solutions: Utilizes pre-made bags or form-fill-seal (FFS) technology for various cuts, ground meat, or portioned products.

- Tray Sealing: Seals film onto pre-formed trays, common for retail-ready fresh meat.

Your choice will depend on shelf-life goals, market presentation, and logistics. High-speed meat packaging machinery can accommodate many of these formats.

Production Scale & Speed Requirements

The volume of meat you process daily or hourly directly dictates the required speed and capacity of your packaging line. Small-scale operations might manage with semi-automatic machines, but medium to large-scale meat processors will require high-speed, fully automated meat packaging solutions to meet demand and maximize throughput. Over-specifying can lead to unnecessary costs, while under-specifying can create bottlenecks. Accurate forecasting of your production volume is essential for determining the right machine capacity.

Crucial Regulatory Compliance & Hygiene Standards

The meat industry is one of the most heavily regulated sectors globally. Compliance with food safety standards is non-negotiable. Key regulations and certifications include USDA (United States Department of Agriculture), FDA (Food and Drug Administration), HACCP (Hazard Analysis and Critical Control Points), GMP (Good Manufacturing Practices), and CE marking (for European markets). Your meat packaging machine must be designed and constructed to meet these rigorous standards, typically featuring stainless steel construction, easy-to-clean surfaces, and washdown capabilities to prevent bacterial contamination and ensure product safety. Kenwei’s commitment to high hygiene standards ensures compliance with such regulations, providing peace of mind for meat processing businesses.

Essential Components of a Modern Meat Packaging Line

A comprehensive meat packaging line is typically an integrated system of specialized machines working in unison. Understanding each component's role is vital for building an efficient and reliable automated meat packaging solution.

High-Precision Weighing Systems (Kenwei Multi-head Weighers)

At the heart of many meat packaging operations lies the weighing system. For products like ground meat, poultry pieces, sausages, or portioned cuts, accurate weighing is paramount for cost control and consumer satisfaction. Multi-head weighers, such as those manufactured by Kenwei, are specifically designed for high-speed and high-precision weighing. They utilize multiple weigh buckets to combine portions, achieving target weights with minimal product giveaway, thereby maximizing profitability. Kenwei's multi-head weighers are engineered to handle various meat textures and consistencies, ensuring consistent and precise product delivery to the packaging machine.

Efficient Filling and Sealing Equipment

Once weighed, the meat product needs to be filled into its container and securely sealed. This involves various machines depending on the packaging format:

- Form-Fill-Seal (FFS) Machines: Create bags from roll stock, fill them with product, and seal them, ideal for high-volume bagging operations.

- Tray Sealers: Automatically fill and seal pre-formed trays with film, commonly used for retail-ready fresh meat.

- Thermoforming Machines: Form trays or pouches from plastic film, fill them, and then seal them, offering great flexibility in packaging design.

- Vacuum Packaging Machines: Remove air from packages and hermetically seal them, crucial for extending shelf life.

The efficiency and reliability of these machines directly impact throughput and product integrity.

Critical Metal Detection Systems (Kenwei Metal Detectors)

Food safety is non-negotiable. Metal detectors are indispensable in any meat packaging line, positioned after the filling or sealing stage to ensure no foreign metallic contaminants (e.g., from machinery wear) make it into the final product. Kenwei manufactures advanced metal detectors that can identify even minute metal particles, automatically rejecting contaminated products, thereby safeguarding consumer health and brand reputation. Their integration into an automated line is seamless, contributing to a robust quality control process.

Accurate Check Weighing Solutions (Kenwei Check Weighers)

Following packaging, check weighers provide a final quality control check, verifying that each packaged product meets its specified weight. This is critical for compliance with legal weight requirements and preventing both under-filled (customer dissatisfaction) and over-filled (product giveaway) packages. Kenwei's check weighers are designed for high accuracy and speed, capable of identifying and rejecting non-conforming packages on the fly. This ensures consistency and optimizes product yield, making them an essential part of any efficient meat packaging solution.

Integrated Conveyance and Automation

Beyond the core machinery, a modern meat packaging line relies on a sophisticated system of conveyors, robotics, and automation software to ensure smooth product flow. Automated systems minimize manual handling, reduce labor costs, and improve overall line efficiency. Kenwei specializes in providing one-stop automated weighing and packaging solutions, integrating all these components seamlessly to create a cohesive and highly efficient production line, from product intake to final packaging.

Key Factors When Selecting Your Meat Packaging Machine Partner

Choosing the right meat packaging machine is more than just selecting a piece of equipment; it's about partnering with a manufacturer who understands your unique challenges and can deliver a solution that meets your operational and financial goals. Several factors must be carefully evaluated beyond the basic functions of the machine.

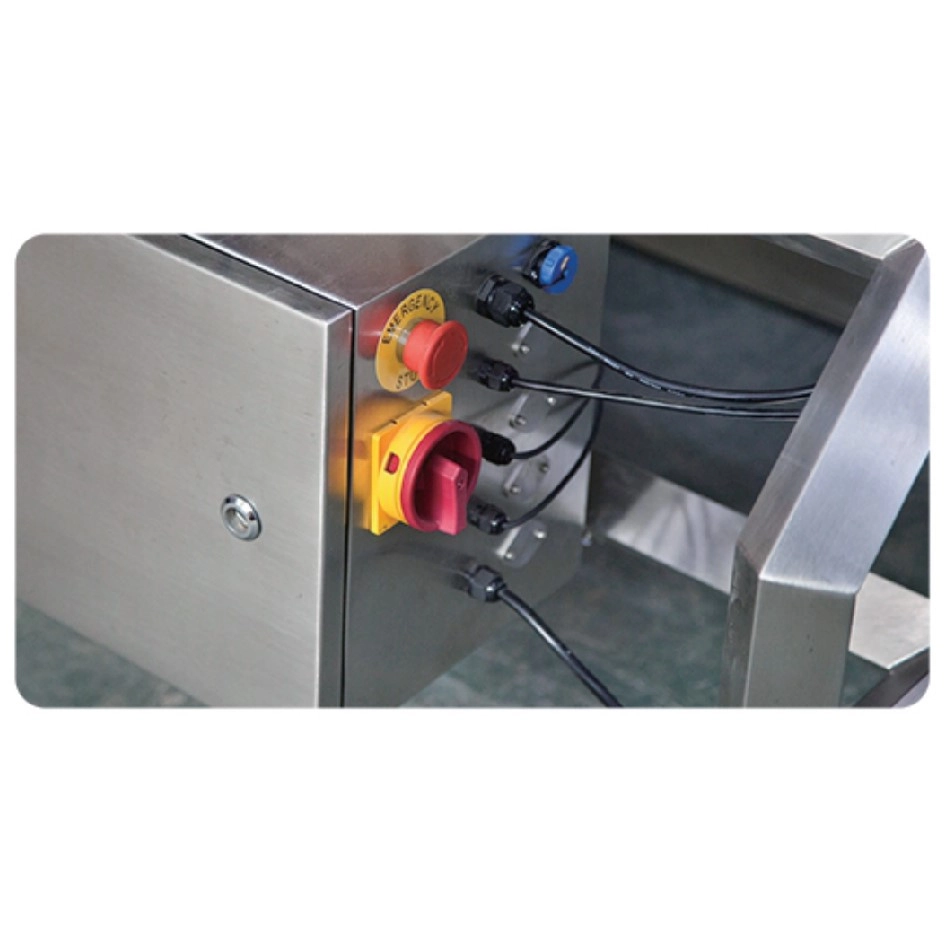

Machine Technology and Material Robustness

The technology embedded in the machine dictates its performance, longevity, and ease of use. Look for machines with advanced control systems (PLCs, touchscreens) that offer precision, flexibility, and diagnostic capabilities. Material robustness is paramount in the harsh meat processing environment. Machines should be constructed from high-grade, food-contact-approved stainless steel (e.g., SUS304 or SUS316) that resists corrosion, is easy to clean, and withstands aggressive washdown procedures. Kenwei’s commitment to durable materials ensures the longevity and reliability of their industrial meat packaging equipment.

Achieving Optimal Speed, Accuracy, and Overall Efficiency

These three metrics are crucial for profitability. Speed relates to how many packages can be processed per minute, directly impacting throughput. Accuracy, especially in weighing, minimizes costly product giveaway and ensures legal compliance. Efficiency encompasses uptime, changeover times, and energy consumption. A high-speed meat packaging machine must maintain precision, and a high-precision machine must be able to operate at your required speeds. Kenwei prides itself on manufacturing machines characterized by both high speed and high precision, striking an optimal balance for peak operational performance.

The Power of Integrated & Automated Solutions (Kenwei One-Stop Solutions)

Many B2B buyers now seek comprehensive, integrated solutions rather than individual machines. An automated meat packaging line, featuring seamless integration of weighers, fillers, sealers, metal detectors, and check weighers, significantly reduces labor requirements, minimizes human error, and optimizes overall production flow. Kenwei excels in providing one-stop automated weighing and packaging solutions. This means they can design, develop, manufacture, install, and commission an entire system tailored to your specific needs, providing a cohesive and efficient production environment.

Customization Capabilities for Unique Operations (Kenwei Customization)

Every meat processing facility has unique layouts, product variations, and production demands. A 'one-size-fits-all' approach rarely works. Look for manufacturers who offer strong customization capabilities. This includes adapting machine dimensions, conveyor configurations, software integration with existing systems, and specialized tooling for specific product types or packaging formats. Kenwei understands the need for tailored solutions and is adept at meeting customers’ customization requirements, ensuring the final system perfectly integrates with existing operations and addresses specific challenges.

Evaluating Total Cost of Ownership (TCO) for Long-Term Value

The initial purchase price is just one component of the total cost. TCO includes factors like energy consumption, maintenance costs, spare parts availability, operational labor, and potential downtime. A seemingly cheaper machine might incur higher operational costs over its lifespan due to inefficiency, frequent breakdowns, or expensive parts. Conversely, a higher initial investment in a robust, high-efficiency machine from a reputable manufacturer like Kenwei often translates to lower TCO and greater long-term value, thanks to its reliability, precision, and lower operational expenditures.

Why Kenwei Excels in Automated Meat Packaging Solutions

In the competitive landscape of packaging machinery, Kenwei has established itself as a formidable force, particularly in automated weighing and packaging solutions. Our expertise and commitment make us an ideal partner for businesses seeking to optimize their meat packaging operations.

Pioneering High-Speed, High-Precision Weighing Technology

At the core of Kenwei's offerings are our multi-head weighers, renowned for their unparalleled high speed and high precision. This critical combination ensures that meat products are weighed accurately and efficiently, minimizing product giveaway and maximizing throughput. Whether dealing with fresh ground beef, IQF poultry pieces, or portioned deli meats, our weighers deliver consistent performance, which is vital for cost control and compliance in the meat industry. This dedication to precision is a cornerstone of our reliable meat packaging equipment.

Comprehensive Weighing and Packaging Equipment Range

Beyond multi-head weighers, Kenwei's product portfolio extends to metal detectors, linear weighers, and check weighers. This comprehensive range allows us to address various stages of the meat packaging process. Our metal detectors provide essential safety assurance by detecting foreign metallic objects, while check weighers ensure every package meets its target weight specification. This integrated approach ensures a robust and compliant packaging line, positioning us as a leading provider of automated meat packaging solutions.

Tailored One-Stop Solutions for Diverse Meat Operations

Understanding that every meat processing facility has unique needs, Kenwei specializes in providing one-stop automated weighing and packaging solutions. From initial design and development to manufacturing, marketing, installation, commissioning, technical training, and diligent after-sales service, we cover the entire project lifecycle. This holistic approach ensures seamless integration, optimal performance, and personalized support, meeting even the most stringent customization requirements of our clients. Our aim is to simplify your procurement process for an industrial meat packaging machine.

Unwavering Commitment to Quality, Service, and Global Leadership

Located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province, Kenwei has built a strong brand image and a reputation for thoughtful and fast service within the packaging machinery industry. Our vision is clear: to become the world's leading weighing packing machine manufacturer. This ambition is underpinned by our dedication to continuous innovation, stringent quality control, and an unyielding focus on customer satisfaction, making us a trusted partner for B2B buyers seeking advanced meat packaging equipment.

A Strategic Approach to the Meat Packaging Machine Procurement Process

The procurement of a meat packaging machine is a significant capital expenditure requiring a structured, strategic approach to ensure a successful outcome and maximum return on investment. Following a well-defined process minimizes risks and optimizes the selection of your automated meat packaging solutions.

Defining Your Requirements Clearly

Before engaging with vendors, thoroughly document your operational needs. This includes specific product characteristics (e.g., temperature, viscosity, fragility), desired packaging formats, target throughput, space constraints in your facility, regulatory compliance requirements (USDA, FDA, HACCP), and budget range. Include future growth projections to ensure scalability. A detailed specification document will serve as a foundational tool for evaluating potential suppliers of meat processing equipment.

Thorough Vendor Research and Due Diligence

Identify potential suppliers with a proven track record in the meat packaging sector. Research their reputation, technological capabilities, customer testimonials, and financial stability. Look for manufacturers, like Kenwei, who specialize in automated weighing and packaging solutions and have experience with meat products. Verify their certifications and commitment to industry standards. Visiting their manufacturing facilities, if possible, can provide valuable insights into their quality control and production processes.

Engaging with Suppliers and Reviewing Proposals

Issue your detailed Request for Proposal (RFP) to a shortlist of qualified vendors. Review proposals meticulously, comparing not just pricing but also technical specifications, machine features, customization options, estimated delivery times, and warranty terms. Pay close attention to proposed service level agreements (SLAs), including response times for support and spare parts availability. Don't hesitate to ask for demonstrations or references, especially for specialized meat packaging machinery.

Rigorous Testing and Seamless Integration

Once a vendor is selected, factory acceptance testing (FAT) is crucial. This involves testing the machine at the manufacturer's facility using your actual products or similar ones to ensure it meets all specified performance criteria (speed, accuracy, and hygiene). After delivery, site acceptance testing (SAT) confirms the machine functions correctly within your facility. Ensure that the chosen solution can be seamlessly integrated with your existing production lines and IT systems. Kenwei's comprehensive capabilities, from design to installation and commissioning, ensure a smooth integration process.

Prioritizing After-Sales Support and Training

The relationship with your supplier extends far beyond the point of sale. Excellent after-sales support, including technical assistance, spare parts availability, and preventative maintenance services, is vital for minimizing downtime and maximizing the lifespan of your industrial meat packaging machine. Comprehensive training for your operators and maintenance staff is equally important to ensure efficient operation and troubleshooting. Kenwei's reputation for thoughtful and fast service in the packaging machinery industry underscores our commitment to long-term customer satisfaction and operational continuity.

Future Innovations Shaping the Meat Packaging Industry

The meat packaging sector is constantly evolving, driven by technological advancements, changing consumer demands, and increasing environmental concerns. Staying abreast of these trends is crucial for B2B buyers looking to make future-proof investments in meat packaging equipment.

Advancements in Automation and Artificial Intelligence

Automation continues to be a dominant trend. Robotics and AI are increasingly integrated into meat packaging lines to handle delicate products, improve sorting precision, and enhance efficiency. AI-powered vision systems can detect product defects or inconsistencies at high speeds, reducing waste and improving quality control. The demand for automated meat packaging solutions is projected to grow, driven by labor shortages and the need for higher throughput. Kenwei's focus on automated weighing and packaging solutions positions us at the forefront of this evolution, offering sophisticated systems that meet these growing needs.

The Growing Imperative of Sustainable Packaging Solutions

Environmental concerns are pushing the industry towards more sustainable packaging materials and practices. This includes the use of biodegradable films, compostable trays, and recyclable plastic alternatives. Companies are also exploring ways to reduce packaging material usage through innovative designs and lighter materials. Buyers should look for machinery capable of handling these new sustainable materials without compromising on efficiency or product protection. The global sustainable packaging market is growing significantly, reflecting a major industry shift.

Enhanced Traceability and Smart Packaging Technologies

Consumers and regulators alike demand greater transparency and traceability in the food supply chain. Smart packaging, incorporating QR codes, RFID tags, or NFC chips, enables end-to-end traceability, providing information on product origin, processing dates, and even nutritional facts. This technology enhances food safety, aids in recall management, and builds consumer trust. Furthermore, sensor-equipped packaging can monitor product freshness and integrity during transit and storage, signaling spoilage. Integrating these technologies into meat packaging lines will become increasingly important for compliance and competitive advantage.

The meat packaging industry is undergoing a significant transformation, with a strong emphasis on smart, efficient, and sustainable practices. Investing in machinery that is adaptable to these emerging trends will ensure your operations remain competitive and resilient in the years to come.

Selecting the optimal meat packaging machine is a pivotal decision that directly impacts the efficiency, safety, and profitability of your meat processing operations. By thoroughly understanding your specific product needs, meticulously evaluating key machine components—including high-precision multi-head weighers, metal detectors, and check weighers—and choosing a partner with strong capabilities in automated solutions and customization, you can make a truly informed investment. Kenwei, with its commitment to high speed, high precision, comprehensive one-stop solutions, and dedicated after-sales support, stands ready to be your trusted partner in navigating this complex landscape. Our vision to be the world's leading weighing packing machine manufacturer underscores our dedication to innovation and customer success. By embracing advanced technologies and prioritizing long-term value, you can ensure your meat packaging operations are not only compliant and efficient today but also poised for future growth and market leadership. Partner with Kenwei to elevate your meat packaging capabilities and secure a competitive edge in the market.

*

Frequently Asked Questions About Meat Packaging Machines

Q: What types of meat packaging machines does Kenwei offer?

A: Kenwei offers a comprehensive range of automated weighing and packaging solutions, including high-speed and high-precision multi-head weighers, metal detectors, linear weighers, and check weighers, all suitable for various meat packaging applications. We also provide integrated one-stop solutions tailored to specific customer requirements.

Q: How important is hygiene in meat packaging machinery?

A: Hygiene is paramount. Meat packaging machines must be designed with food-grade materials (like stainless steel), feature easy-to-clean surfaces, and often include washdown capabilities to meet stringent food safety regulations such as USDA, FDA, and HACCP. Kenwei machines are built to meet these rigorous standards.

Q: Can Kenwei machines handle different types of meat products?

A: Yes, Kenwei machines are highly versatile. Our multi-head weighers and integrated systems can be customized to handle a wide range of meat products, including fresh cuts, ground meat, frozen poultry, sausages, and deli products, accommodating various textures and forms with high precision.

Q: What is a multi-head weigher, and why is it crucial for meat packaging?

A: A multi-head weigher uses multiple weigh buckets to accurately and quickly combine portions of product to achieve a target weight. It’s crucial for meat packaging because it significantly reduces product giveaway, ensures consistent package weights, and operates at high speeds, directly impacting profitability and compliance.

Q: Does Kenwei provide customization for specific packaging needs?

A: Absolutely. Kenwei is committed to meeting our customers’ customization requirements. We provide tailored solutions to integrate seamlessly with your existing production lines, accommodate unique product sizes, and adapt to specific packaging formats, ensuring your automated meat packaging system is perfectly suited to your operation.

Q: What kind of after-sales support does Kenwei offer?

A: Kenwei provides comprehensive after-sales support, encompassing installation, commissioning, technical training for your staff, and responsive technical assistance. We are dedicated to ensuring the long-term reliability and optimal performance of your meat packaging machine, maintaining a reputation for thoughtful and fast service.

Q: What are the benefits of an automated meat packaging solution?

A: Automated meat packaging solutions offer numerous benefits, including increased production speed and efficiency, enhanced weighing accuracy (reducing product giveaway), improved food safety through reduced human contact, lower labor costs, and consistent product quality. Kenwei specializes in providing these one-stop automated solutions.

Increase Packaging Speed: Optimize Your Multihead Weigher Settings

The latest trends for multihead weighing machine

What are the application scenarios of vffs packaging machine?

Selecting Good Metal Detectors for High-Speed Production Lines

About Solution suggestions

How can Kenwei solutions help reduce waste in my production process?

Kenwei solutions improve accuracy in weighing, packaging, and quality control, reducing the chances of overfill or underfill. This leads to less product waste and higher operational efficiency.

What industries benefit the most from Kenwei solutions?

Kenwei solutions are ideal for a wide range of industries, including:

1)Food Packaging snacks, grains, and powdered beverages.

2)Pharmaceuticals: Precise weighing of tablets, and capsules.

3)Chemicals: Weighing and packaging granular and powdered chemicals.

4)Agriculture: Packaging seeds, grains, and fertilizers.

What are Kenwei’s primary solutions for industrial weighing and packaging?

Kenwei provides comprehensive solutions for automated weighing and packaging, including multi-head weighers, linear weighers, check weighers, metal detectors, and packing machines. These solutions are tailored to improve speed, accuracy, and efficiency in various industries such as food, pharmaceuticals, and chemicals.

About Cooperation Process

Can Kenwei customize equipment to meet my specific needs?

Yes! We offer customized solutions for all of our machines. Our team will work closely with you to understand your specific requirements and create a solution that meets your needs in terms of size, functionality, speed, and other factors.

About After Sales Support

Can I get remote troubleshooting assistance?

Yes, Kenwei offers remote troubleshooting for certain issues. Our technical team can guide you through diagnostics and help resolve issues via phone, video call, or online messaging.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Combined Check Weigher and Metal Detector for Food Industrial Weighing and Sorting

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei