Linear Weigher vs Multihead Weigher: Key Differences and Buying Guide

- Linear Weigher vs Multihead Weigher: Key Differences

- Introduction — Why this comparison matters for purchasing decisions

- How buyers shapes this guide

- What is a Linear Weigher?

- Definition and core working principle

- Typical strengths and business-intent keywords

- What is a Multihead Weigher?

- Definition and core working principle

- Typical strengths and commercial keywords

- Head-to-head comparison — Linear Weigher vs Multihead Weigher

- At-a-glance comparison table

- Detailed factors to consider

- 1. Throughput and production targets

- 2. Portion size and accuracy requirements

- 3. Product characteristics and handling

- 4. Cost of ownership and ROI

- 5. Floor space and integration

- 6. Maintenance, hygiene and regulatory needs

- Case-based recommendations

- When to choose a Linear Weigher

- When to choose a Multihead Weigher

- How Kenwei supports your choice

- Kenwei's capabilities and one-stop solutions

- Practical steps to choose the right machine

- 1. Conduct product testing

- 2. Compare total cost of ownership

- 3. Plan for future scalability

- 4. Verify hygiene and compliance

- Conclusion — Matching machine choice to business goals

- Summary and final recommendation

- Frequently Asked Questions

Linear Weigher vs Multihead Weigher: Key Differences

Introduction — Why this comparison matters for purchasing decisions

Choosing between a linear weigher and a multihead weigher is a common decision for food, hardware, chemical and consumer-goods manufacturers evaluating automated weighing and packaging lines. The right choice affects throughput, yield, product quality, floor space, and total cost of ownership. This article objectively compares Linear Weigher vs Multihead Weigher: Key Differences so procurement teams and production managers can make informed decisions aligned with their business goals.

How buyers shapes this guide

Users searching Linear Weigher vs Multihead Weigher: Key Differences typically want to know: which machine fits their product type, desired speed, accuracy needs, budget, and integration complexity. This guide addresses those commercial concerns and provides practical recommendations for vendors such as Kenwei, a manufacturer of multihead weighers and end-to-end automated weighing systems.

What is a Linear Weigher?

Definition and core working principle

A linear weigher (also called a linear combination weigher or linear scale feeder) uses multiple independent linear weight channels or load-cell conveyors arranged in a line. Each channel fills with product, reports weight, and pre-combinations are calculated to reach target portion weight. Filled channels discharge in sequence into a packaging machine or hopper.

Typical strengths and business-intent keywords

Linear weighers are valued for simplicity, reliability, and lower upfront cost. Keywords business buyers look for include linear weigher cost-effective, large portion weighing, and simple maintenance linear weigher.

What is a Multihead Weigher?

Definition and core working principle

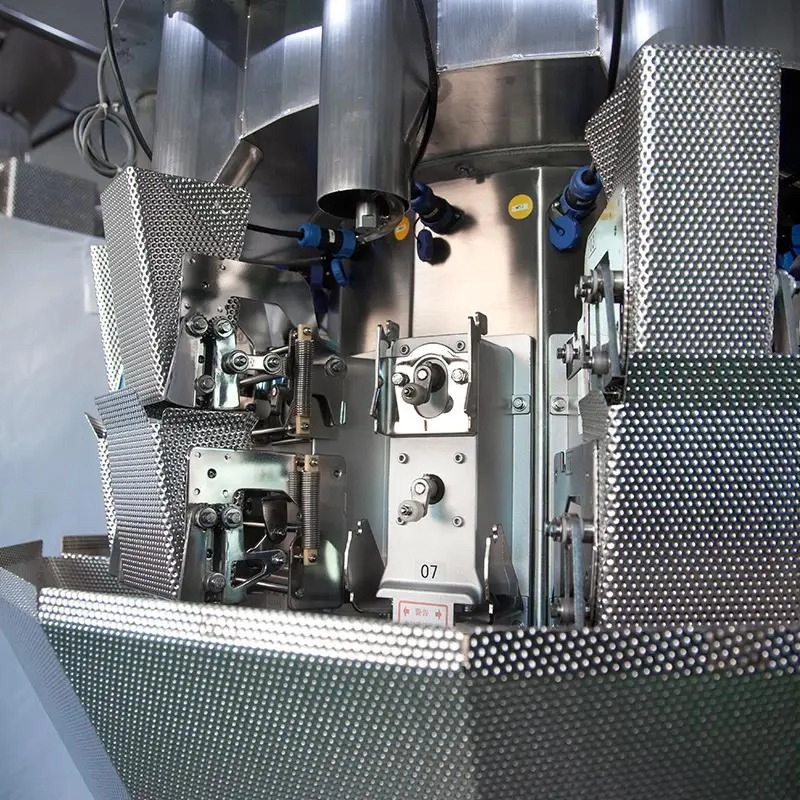

A multihead weigher (also called a combination weigher or multi-head combination scale) uses many (commonly 10–14, but can be 6 to 20+) radial heads arranged around a central collection hopper. Product is dosed into individual weigh heads, each head measures weight on a load cell, and a fast combinatorial algorithm selects a subset of heads whose summed weight matches the target. The selected heads discharge simultaneously to form a final portion.

Typical strengths and commercial keywords

Multihead weighers are known for high throughput and high accuracy for small and mixed products. Buyers search using terms like high speed multihead weigher, accurate portion weighing, and automated packing multihead.

Head-to-head comparison — Linear Weigher vs Multihead Weigher

At-a-glance comparison table

The following table summarizes practical differences. Actual performance always depends on specific models, product characteristics, and portion sizes.

| Characteristic | Linear Weigher | Multihead Weigher |

|---|---|---|

| Typical throughput | Low–medium (e.g., 10–60 portions/min depending on channels and portion size) | Medium–high (e.g., 30–200 portions/min depending on head count and portion size) |

| Typical accuracy | Good for large portions; accuracy often ±0.5–5 g depending on portion size | High for small portions; accuracy often ±0.1–1 g depending on product and portion size |

| Best for product types | Large particles, fragile items, sticky or bulky products, single-feed lines | Free-flowing solids, mixed components (snacks, nuts, confectionery), small to medium portions |

| Initial cost | Lower | Higher |

| Space / footprint | Compact to medium | Often larger footprint due to radial arrangement and vibration feeders |

| Maintenance complexity | Lower — fewer moving parts | Higher — more heads and more components to service |

| Flexibility | Good for product-specific lines | Better for multi-SKU, high-speed lines and mixed product blends |

Detailed factors to consider

1. Throughput and production targets

If your target is high-speed packaging (e.g., >60–80 packs/min for snack-size portions), a multihead weigher is usually the better option. For lower-speed lines or large, single-piece portions, a linear weigher may be sufficient and more cost-effective.

2. Portion size and accuracy requirements

Multihead weighers excel at delivering tight accuracy on small portion sizes (e.g., <50–100 g). Linear weighers handle larger portions with acceptable accuracy and are more forgiving for bulky items that don’t settle well in multihead feeders.

3. Product characteristics and handling

Sticky, wet, or highly irregular products (e.g., wet meat, chews, large frozen pieces) often perform better on linear systems or specialized feeders because they don’t flow consistently between multiple heads. Free-flowing dry products, mixes and small components perform exceptionally well on multihead weighers.

4. Cost of ownership and ROI

Initial purchase price for multihead weighers is typically higher, but higher throughput and improved yield (less giveaway) can deliver faster ROI in high-volume operations. Linear weighers have lower upfront costs and can be ideal when CAPEX is constrained and volumes are moderate.

5. Floor space and integration

Consider how each machine integrates with existing conveyors, vertical form-fill-seal (VFFS) machines or tray fillers. Multihead machines require radial feed hoppers and more clearance; linear weighers can be integrated in tighter lines.

6. Maintenance, hygiene and regulatory needs

Multihead weighers have more mechanical components and may require more frequent calibration and upkeep. However, modern designs from reputable manufacturers (like Kenwei) include hygienic, stainless-steel construction and easy-clean features to meet food safety standards. Linear weighers are often simpler to service and clean.

Case-based recommendations

When to choose a Linear Weigher

- Your product is large, sticky, or fragile (e.g., large nuts, whole fruits, bakery items). - You run moderate volumes and want lower initial investment. - You have limited floor space and need a compact solution. - You prioritize simplicity and lower maintenance complexity.

When to choose a Multihead Weigher

- You need high throughput and high accuracy for small to medium portions (e.g., snacks, confectionery, frozen vegetables). - You run multiple SKUs and require fast changeovers and precise portion control to reduce giveaway. - You want a scalable solution (add heads or integrate more lines for higher capacity). - Your business emphasis is on automated, high-speed packing and minimal human intervention.

How Kenwei supports your choice

Kenwei's capabilities and one-stop solutions

Kenwei is a manufacturer specializing in multihead weighers and automated weighing-packaging systems. Headquartered in Guangdong, Kenwei offers machines designed for high speed and precision and provides end-to-end services: design, manufacturing, integration, installation, training and after-sales support. If you are evaluating Linear Weigher vs Multihead Weigher: Key Differences for your production line, Kenwei can help by offering tailored solutions that match product characteristics, throughput goals and budget constraints. More at https://www.kenweigroup.com/.

Practical steps to choose the right machine

1. Conduct product testing

Request on-site trials or lab tests from suppliers. Real-world testing with your product and target packaging is the most reliable way to assess accuracy, speed and yield.

2. Compare total cost of ownership

Look beyond purchase price: include installation, spare parts, downtime risk, energy consumption, and expected yield loss (giveaway). A higher-capacity multihead may produce better lifetime economics.

3. Plan for future scalability

Consider expected volume growth and SKU changes. If you anticipate rapid expansion or frequent product mixes, a flexible multihead solution may avoid costly upgrades later.

4. Verify hygiene and compliance

Ensure the machine meets relevant food safety standards (e.g., stainless-steel contact surfaces, easy-to-clean design). Ask suppliers for certifications and cleaning protocols.

Conclusion — Matching machine choice to business goals

Summary and final recommendation

Linear weighers and multihead weighers each have clear strengths. Choose a linear weigher when handling large, irregular, or sticky products on moderate-speed lines with constrained budgets. Choose a multihead weigher when you need high throughput, excellent small-portion accuracy, and flexibility for mixed or multi-SKU production. Use product testing and a total-cost analysis to validate the decision. For manufacturers seeking high-speed, high-precision solutions, Kenwei provides proven multihead weighers and integrated systems with global support.

Frequently Asked Questions

What is the main difference between a linear weigher and a multihead weigher?The main difference is architecture and dosing method: linear weighers use a line of independent linear channels that combine sequentially, while multihead weighers use multiple radial heads and combinatorial selection to create portions quickly and often more accurately for small sizes.

Can a linear weigher handle mixed-product blends as well as a multihead weigher?Mixed blends are usually better handled by multihead weighers because multiple heads can combine components and achieve target weight with minimal segregation. Linear systems can handle blends but with more limitations and potential segregation issues.

Which machine gives better accuracy for small portion sizes?Multihead weighers usually offer superior accuracy for small portions (e.g., snack-size portions) due to fast combination algorithms and many small-capacity heads.

How should I assess ROI when choosing between the two?Compare not only purchase price but also throughput, reduction in giveaway, energy use, maintenance, downtime, and expected life. High-throughput lines often justify the higher initial cost of multihead weighers through faster ROI.

Are multihead weighers harder to maintain?They can be more complex because of the larger number of moving parts and heads, but modern designs focus on easy access, modular head replacement, and hygienic features to simplify maintenance.

Where can I test my product on real equipment?Contact reputable manufacturers (e.g., Kenwei at https://www.kenweigroup.com/) to request product trials or on-site demonstrations. Real product testing is essential to confirm speed, accuracy, and handling characteristics.

Troubleshooting Common Combination Weigher Problems

Troubleshooting common issues with a 14 head multihead weigher

Future Trends in Food Packing Machine Technology

Where to Buy 10 head combination weigher

About Cooperation Process

Can Kenwei customize equipment to meet my specific needs?

Yes! We offer customized solutions for all of our machines. Our team will work closely with you to understand your specific requirements and create a solution that meets your needs in terms of size, functionality, speed, and other factors.

About products customization

Can Kenwei machines support multiple languages?

Yes, we can customize the software interface to support multiple languages, making it easier for operators from different regions to use the machine.

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

About Product choice

Can Kenwei's machines be used in my industry?

Kenwei’s equipment is highly versatile and can be used across a wide range of industries, including:Food,Pharmaceuticals,Chemicals,Plastics and Agriculture.

Plastics If you're unsure whether our products are suitable for your industry, please contact us, and we can provide you with specific solutions tailored to your needs.

About Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Food Metal Detector Manufacturer For Reject Defective Products G5020

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei