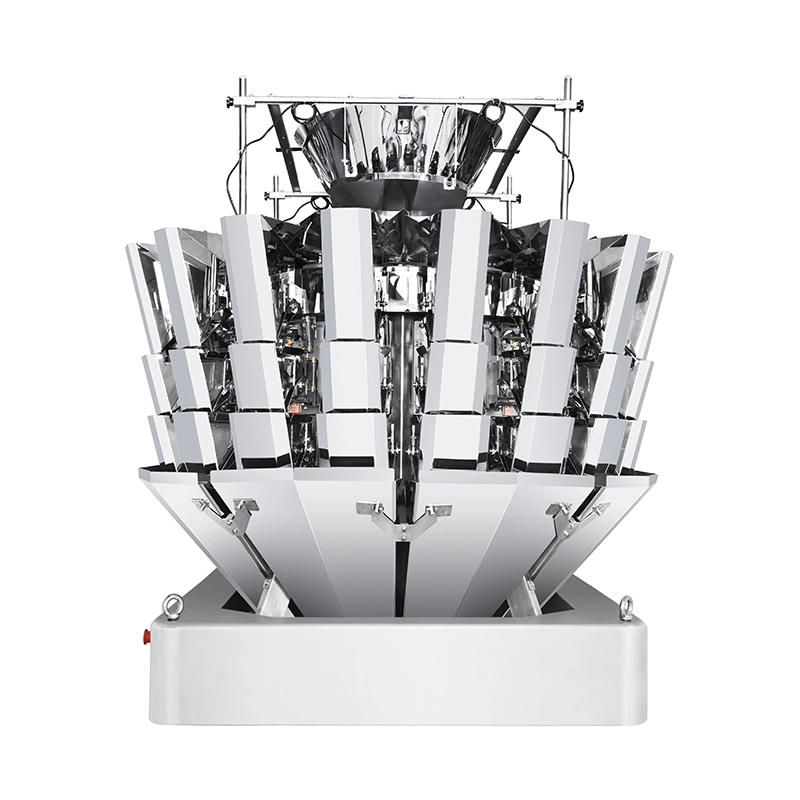

Kenwei 14-Head Multihead Weigher — Accurate, Fast Packaging

Kenwei 14-Head Multihead Weigher — Precision Meets Productivity

The Kenwei 14-head multihead weigher is designed to bring fast, accurate, and reliable weighing to your production line. Built for businesses that need consistent portioning with minimal waste, this weigher balances speed and precision to improve efficiency and product quality.

Key Features

- High speed and accuracy: 14 weighing heads ensure rapid, stable feeding and precise portion control to reduce giveaway and errors.

- Flexible materials handling: ideal for snacks, nuts, frozen foods, granules, confectionery, pet food, and small hardware parts.

- Simple operation: intuitive controls and clear interface make setup and changeovers fast, lowering training time.

- Sturdy, hygienic design: stainless steel construction and easy-to-clean surfaces support food safety standards.

- Customizable options: Kenwei offers tailored modules, special feeders, and integration with metal detectors, checkweighers, and packaging lines.

Why Choose Kenwei

Kenwei is a leading manufacturer of weighing and packing machinery with full capabilities in design, production, installation, and after-sales service. Located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong, we provide one-stop automated weighing and packaging solutions that meet custom requirements. Our focus on fast delivery, thoughtful service, and technical support helps you keep lines running smoothly.

Practical Benefits for Your Business

Installing the 14-head multihead weigher helps lower material waste, increase throughput, and improve packaging consistency. The modular design makes maintenance straightforward, while integration options allow seamless connection to fillers, baggers, and metal detectors. Whether expanding capacity or upgrading existing lines, Kenwei supports the full project lifecycle from consultation to commissioning.

Get Started

To learn more about specifications, customization, and pricing, visit https://www.kenweigroup.com/ or contact our sales team. Choose Kenwei to boost accuracy, speed, and reliability on your production line.

Product Image

Qualification Certificate

Duckbill Hopper-Utility Model Patent Certificate

Executive Director Unit of China Food and Packaging Machinery

Turntable Follow Filling Equipment-Utility Model Patent Certificate

Question you may concern

Can Kenwei solutions be used for both manual and automated packing lines?

Yes, Kenwei machines can be used in both manual and automated packing lines. We can provide integrated systems that work alongside manual labor or fully automated systems depending on your production requirements.

How does Kenwei ensure the quality of its machines?

Kenwei has a stringent quality control system in place. Each machine is rigorously tested for precision, speed, and reliability before it is shipped.

Does Kenwei offer installation and training?

Yes, Kenwei provides installation services and comprehensive training to ensure that your team can operate the machinery efficiently. Our engineers can travel to your facility for on-site installation, and we also offer remote training options if needed.

Do I need to prepare my facility for the delivery of large machines?

Yes, large machines often require special preparations for delivery, including ensuring adequate space for unloading and installation.

If you have any other questions, please write email to us or call us , we will reply you as soon as possible.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

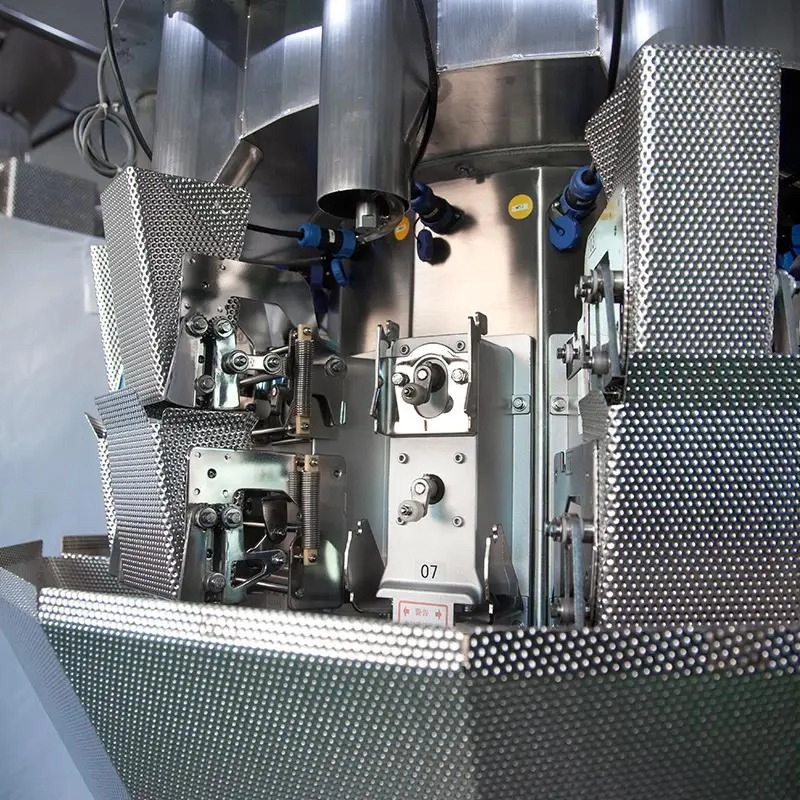

14 Head Multihead Weigher Packaging Machine for Weighing and Packaging Dumplings Wontons

The weighing sensor has high-precision, high-standard professional performance and adopts intelligent multi-sampling stable mode to significantly improve weighing accuracy. It also has an intelligent fault alarm function, making maintenance more efficient and convenient. The equipment supports high-speed wrong material unloading, effectively avoiding material blockage. The overall structure adopts a highly integrated modular design, integrates CAN bus technology, and applies Modbus industrial standard communication protocol to achieve seamless integration of the combined weighing system and the packaging machine.

High Precision 3-Layer 18-Head Standard Weigher for Accurate and Efficient Weighing

The High-Precision 3-Layer 18-Head Standard Weigher is designed for accurate weighing of a wide range of materials, including granular, flake, round, irregular, and puffed items like nuts, seeds, candies, and snacks. It features a separate vibration plate for mixed material applications, a Ling-shaped hopper for faster and more concentrated discharge, a memory bucket for improved accuracy, and an integrated chassis for enhanced stability. Ideal for high-precision, efficient weighing.

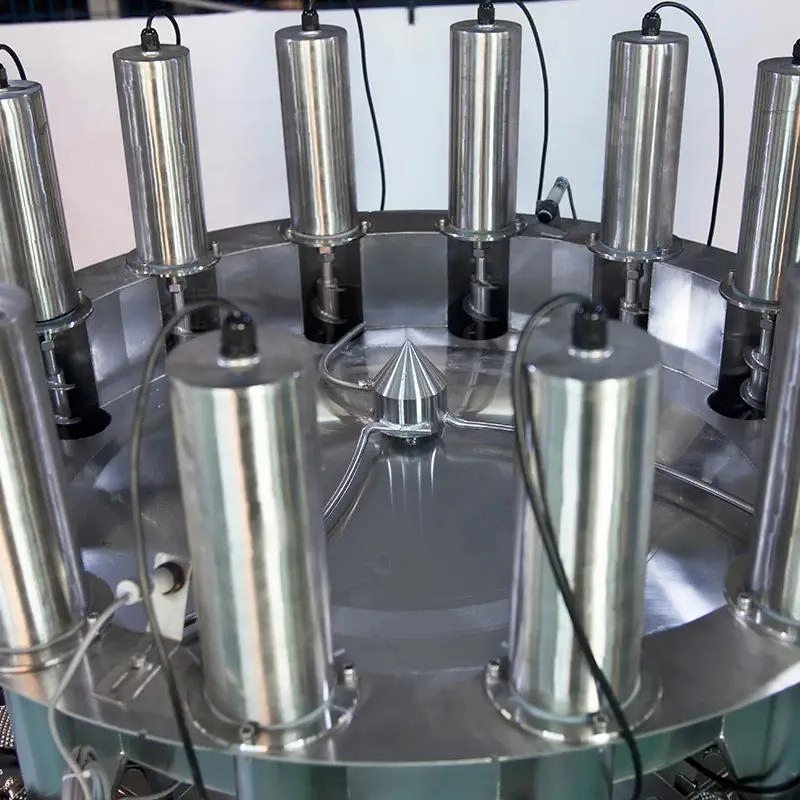

Precision Leak-Proof Multihead Weigher with 3L Hopper for Accurate Small Particle Weighing

The Precision Leak-Proof Multihead Weigher with a 3L hopper is designed for accurate quantitative weighing of small particles like salt, sugar, millet, seeds, and coffee beans. Featuring a leak-proof 3.0L hopper, multi-angle dividing hopper for even material distribution, and a deep U-shaped vibrating plate to prevent leakage. The cast aluminum middle seat enhances strength and reduces weighing stabilization time, making it ideal for fine material applications with high accuracy requirements.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei