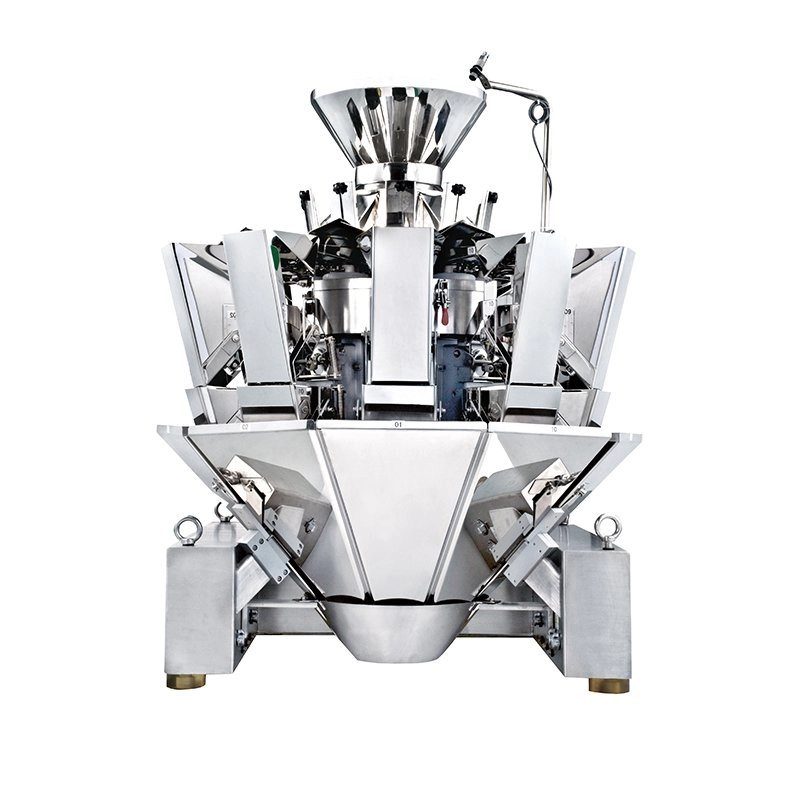

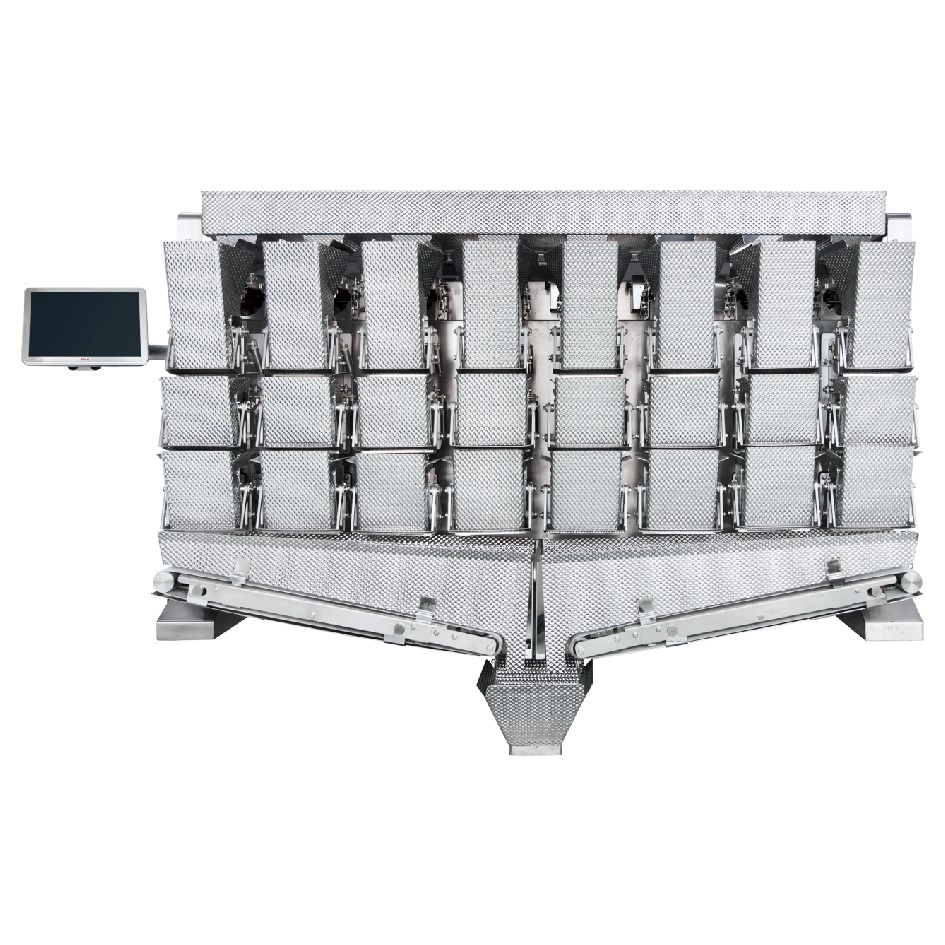

14 Head Multihead Weigher Packaging Machine for Weighing and Packaging Dumplings Wontons

The weighing sensor has high-precision, high-standard professional performance and adopts intelligent multi-sampling stable mode to significantly improve weighing accuracy. It also has an intelligent fault alarm function, making maintenance more efficient and convenient. The equipment supports high-speed wrong material unloading, effectively avoiding material blockage. The overall structure adopts a highly integrated modular design, integrates CAN bus technology, and applies Modbus industrial standard communication protocol to achieve seamless integration of the combined weighing system and the packaging machine.

| Material | 304 stainless steel | Certification | CE, OIML, SGS |

| Availability | OEM/ODM | Delivery Time | 7-30days |

| Start Port | Zhongshan port | Supply Ability | 5000 sets/year |

Feature

-

● Features a high-precision, high-standard special load cell for enhanced accuracy.

-

● Utilizes intelligent multi-sampling stable mode for improved weighing precision.

-

● Equipped with an intelligent fault alarm system for easy maintenance and troubleshooting.

-

● High-speed staggered discharge function effectively prevents material blockages.

-

● Incorporates a highly integrated modular design and CAN bus technology for greater efficiency.

-

● Supports the Modbus industry-standard communication protocol, enabling seamless integration with combination weighing and packaging machine interfaces.

Technical Specification

Technical Specification

| Model | JW-A14 |

| Identify Code | A14-2-11 |

| Weighing Range | 10-1500g |

| Accuracy*1 | X(0.5) |

| Max Speed*2 | 70P/M |

| Hopper Volume | 1.6L |

| Control Panel | 7"Touch Screen |

| Options | Dimple Plate/Timing Hopper/Printer/Reject Device |

| Driving System | Step Motor |

| Power Requirement | 220V/1000W/50/60Hz/10A |

| Packing Dimension(mm) | 1930(L)X1460(W)X1040(H)/1820(L)X1100(W)X290(H) |

| Gross Weight | 530kg |

| *1: Can refer to the national standard GB/T27738-2011 or the international Legal Organization No.61 International Recommendation OIML R61 2004(E) | |

| *2: Depends on product shape, product density, target weight, etc. | |

Application

It is ideal for breakage-proof, precise quantitative weighing of materials with low free-fall combinations, such as Yuntun, dumplings, egg rolls, and similar delicate products.

Frequently Asked Questions

We've Got Answers

Browse some answers to our most common questions, or you can drop us a line to ask something else.

About Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

About Cooperation Process

How can I start a cooperation with Kenwei?

To begin a cooperation, simply contact our sales or customer service team via email or phone. You can also fill out the inquiry form on our website. Once we receive your request, a representative will get in touch with you to discuss your specific needs and provide you with a tailored solution.

About products customization

Can Kenwei machines support multiple languages?

Yes, we can customize the software interface to support multiple languages, making it easier for operators from different regions to use the machine.

About Price and payment

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

About After Sales Support

Can I get remote troubleshooting assistance?

Yes, Kenwei offers remote troubleshooting for certain issues. Our technical team can guide you through diagnostics and help resolve issues via phone, video call, or online messaging.

Leak Proof Multi Head Combination Weigher for Small Particle&Powder

Belt Feeding Multihead Weigher with 3-Layer Hopper for Accurate Weighing Precision

32 Heads Multihead Weigher for Mixing 4 Products for Coffee and Small Granule Foods

Automatic Multihead Weigher for Stick and Bar-Shaped Materials

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei