Tips for buy multihead weigher machine

- Introduction: Why choosing the right multihead weigher machine matters

- Understand your production needs: throughput, accuracy and product profile

- Throughput vs. accuracy trade-offs

- Product characteristics and handling needs

- Compare technical specifications of multihead weigher machine models

- Number of heads and weighing combinations

- Controller, software and connectivity

- Build quality, materials and hygiene standards

- Sanitation and cleanability features

- Integration and automation: fitting the multihead weigher into your line

- Line balancing and buffers

- Factory testing, FAT and site acceptance

- Product testing and sample runs

- After-sales service, training and spare parts strategy

- Local support and spare-part availability

- Customization, flexibility and future-proofing

- Software updates and recipe portability

- Calculating total cost of ownership (TCO) and ROI

- Hidden costs and energy consumption

- Safety, compliance and certifications

- Allergen control and GMP alignment

- How to evaluate suppliers and choose the right partner

- Decision checklist before purchase

- Conclusion: Buying a multihead weigher machine with confidence

Introduction: Why choosing the right multihead weigher machine matters

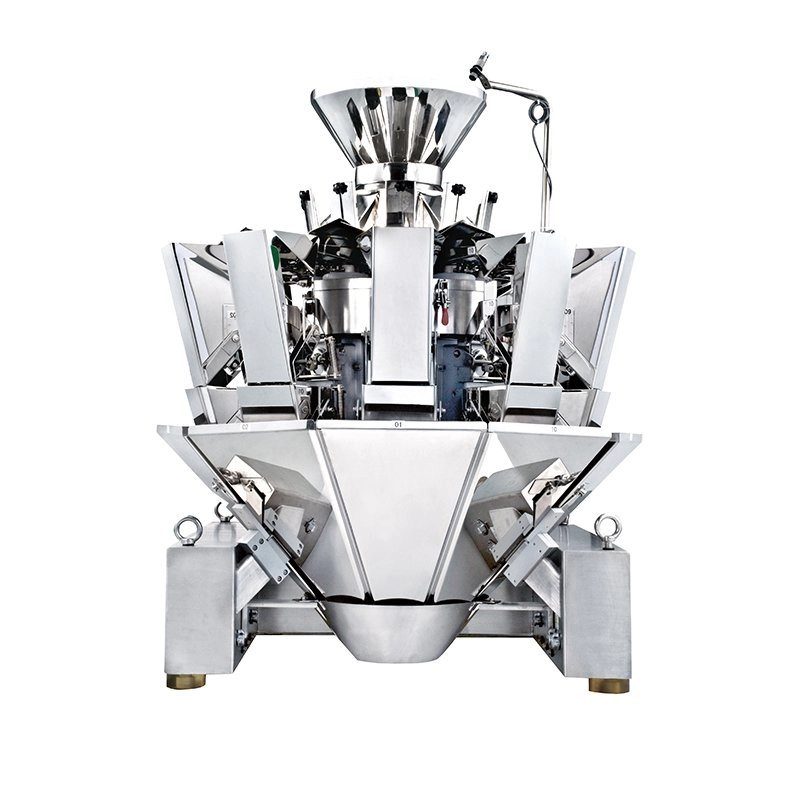

Buying a multihead weigher machine is a strategic decision for any food, snack, confectionery, frozen, fresh produce, or hardware packing line because it directly impacts yield, product quality, and operating costs. This guide explains the practical steps and commercial criteria buyers use when selecting a multi-head weigher, helping you compare vendors, avoid common pitfalls, and speed up ROI. Kenwei is a manufacturer with experience in multi-head weighers, metal detectors, linear weighers and complete automated weighing and packaging systems; our goal is to help you buy a solution that fits both current needs and future growth.

Understand your production needs: throughput, accuracy and product profile

Start by documenting the most important metrics for your line: required packs per minute (throughput), acceptable weight tolerance or giveaway tolerances, typical pack weights, and variety of product shapes and sizes. For example, snack producers may prioritize throughput and range of pack weights, while delicate confectionery makers emphasize gentle handling to avoid breakage. Having clear production targets lets you shortlist multihead weigher machine models that meet both speed and accuracy requirements.

Throughput vs. accuracy trade-offs

Every multihead weigher machine balances speed and precision: higher throughput often requires faster feeder and discharge systems plus more heads to maintain accuracy. Define minimum acceptable accuracy and target packs/minute; suppliers can then propose configurations (number of heads, bowl size, combination algorithms) that meet those targets without overpaying for unnecessary capacity.

Product characteristics and handling needs

List product characteristics—free-flowing powder, fragile chips, irregular nuts, sticky candies, or wet frozen goods—because the feeder type, vibratory settings, feed chute geometry, and discharge system all depend on the product. Some products require gentle transport, temperature control in hoppers, or special coatings; make sure the multihead weigher machine you consider supports those options or offers product testing at the factory.

Compare technical specifications of multihead weigher machine models

Once you know throughput and product type, compare technical specs across candidates: number of heads, net weight range, smallest increment (resolution), trough/bin size, PLC/controller, recipe capacity, communication protocols, and physical footprint. These specs determine how well a multihead weigher machine integrates into your line and whether it can handle the full product mix or only a subset.

Number of heads and weighing combinations

More heads generally allow higher throughput and finer combination possibilities to reach target weights with lower giveaway, but that comes with higher cost and maintenance. Typical configurations range from 10 to 24 heads for many applications; select a head-count that matches your throughput and product variability while keeping ease of servicing in mind.

Controller, software and connectivity

Modern multihead weigher machine controllers support recipe management, statistical process control (SPC) data, and remote diagnostics. Ensure the controller offers Ethernet/Profinet/Modbus connectivity to your MES/PLC, supports multiple recipes, and can export performance logs for traceability and OEE monitoring.

Build quality, materials and hygiene standards

Inspect construction materials (food-grade stainless steel such as 304/316 where needed), weld quality, surface finishes, and ease of access for cleaning. Hygienic design reduces downtime for cleaning and prevents contamination; ask about IP ratings for washdown capability and available finishes suitable for high-moisture or corrosive environments.

Sanitation and cleanability features

Look for easy-to-open tool-less panels, sloped surfaces that drain, and minimal crevices where product can accumulate. For wet or allergen-sensitive production, ask for CIP-compatible options and details on how the multihead weigher machine supports fast sanitation without special tools.

Integration and automation: fitting the multihead weigher into your line

Consider how the multihead weigher machine will integrate with upstream and downstream equipment—feeders, vibratory bowls, conveyors, pouchers or vertical form-fill-seal machines, metal detectors and checkweighers. Confirm electrical, pneumatic and data interfaces, required footprint, and safety guarding. Good supplier collaboration at this stage reduces installation surprises and helps maintain planned line RPM.

Line balancing and buffers

Ask about buffering solutions and surge hoppers to smooth differences between upstream filling and multihead weigh cycles. Proper line balancing minimizes starved or blocked conditions and keeps your packaging machine running at target speed.

Factory testing, FAT and site acceptance

Require a Factory Acceptance Test (FAT) with your product samples before shipment. FAT should demonstrate target throughput, accuracy, rejection rates, and connectivity to PLC/MES. After installation, a Site Acceptance Test (SAT) validates performance under real line conditions. Document pass/fail criteria for both tests to avoid disputes later.

Product testing and sample runs

Good suppliers will test your products on the proposed multihead weigher machine and share video and data from those tests. Kenwei offers product testing and customization—if a vendor refuses to test your materials, consider that a red flag.

After-sales service, training and spare parts strategy

Evaluate supplier response times, availability of spare parts, remote support, and on-site service network. Look for training programs for operators and maintenance staff, spare-part kits for wear items, and clear warranty terms. A reliable service contract reduces unplanned downtime and protects throughput.

Local support and spare-part availability

Regional presence or authorized service partners shorten response times. Ask for lead times on critical spares (motors, PLC modules, load cells) and recommended stocking levels so you can plan inventory to keep your multihead weigher machine running when parts wear or fail.

Customization, flexibility and future-proofing

Choose a multihead weigher machine platform that supports future needs: additional heads, wider weight ranges, new recipes, or software upgrades. Modular designs let you expand capacity without replacing the entire machine, lowering long-term costs and making it easier to add new SKUs.

Software updates and recipe portability

Check how the supplier handles firmware updates and whether recipe formats are portable between machines of the same family. A standardized software environment simplifies operator training and enables faster SKU changeovers.

Calculating total cost of ownership (TCO) and ROI

Beyond purchase price, estimate TCO including installation, commissioning, spare parts, energy use, labor savings, and expected reduction in giveaway. Multihead weighers often pay back through increased yield and lower labor costs; request a business-case example showing how accuracy improvements translate to reduced giveaway and payback period.

Hidden costs and energy consumption

Ask about central air requirements, electrical consumption, and preventive maintenance intervals. Energy-efficient drives and optimized feeders can lower operating costs over the machine lifetime.

Safety, compliance and certifications

Verify relevant safety and regulatory certifications: CE, UL, food contact material compliance, and any local standards for machine safety. For food production, confirm compliance with hygiene regulations and traceability features for tracking batches and weights.

Allergen control and GMP alignment

If you produce multiple allergen-containing SKUs, discuss cleaning protocols and separate lines or validated cleaning procedures. A multihead weigher machine designed with quick disassembly speeds up changeovers and reduces cross-contamination risk.

How to evaluate suppliers and choose the right partner

Assess suppliers on technical fit, service capability, reputation, and ability to deliver turnkey solutions. Ask for references in your industry, factory visit opportunities, and case studies showing similar installations. Kenwei, located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province, provides one-stop automated weighing and packaging solutions and supports design, manufacturing, installation, training and after-sales service—important dimensions to evaluate when choosing a supplier.

Decision checklist before purchase

Before signing, confirm these items: documented throughput and accuracy targets; sample test results from FAT; full scope of supply (controls, conveyors, hoppers); warranty and service terms; spare-parts list and lead times; integration plan and timeline; and clear acceptance criteria for SAT. A signed checklist reduces scope creep and ensures predictable commissioning.

Conclusion: Buying a multihead weigher machine with confidence

Selecting the right multihead weigher machine requires a clear understanding of production targets, careful comparison of technical specifications, and evaluation of supplier capability for testing, integration and service. Prioritize machines that deliver the required accuracy with room to handle new SKUs, and choose a partner who offers factory testing, on-site commissioning and fast after-sales support. For manufacturers seeking high-speed, high-precision solutions, Kenwei offers tested multi-head weighers, metal detectors and complete packaging systems with product testing, customization and service to support your line goals—visit https://www.kenweigroup.com/ to request tests or a quotation.

Frequently Asked Questions

Q: What is the typical lead time for a multihead weigher machine?A: Lead time varies by configuration and customization level; standard models often ship within 8–12 weeks, while customized or larger systems can take longer. Confirm lead time with your supplier and include shipping and installation in the schedule.

Q: How do I know how many heads I need on a multi-head weigher?A: The number of heads depends on required throughput, pack-weight range and product variability. Suppliers can model performance using your pack-weight targets; more heads typically improve throughput and reduce giveaway but increase cost.

Q: Can a multihead weigher handle multiple SKUs on one machine?A: Yes—modern machines support multiple recipes and quick changeovers, but very different products (e.g., powders vs. fragile candies) may require physical adjustments. Ask about recipe capacity, changeover time and optional tooling.

Q: Are multihead weighers compatible with checkweighers and metal detectors?A: Yes. Integrating a multihead weigher machine with metal detectors and checkweighers is common for quality control. Ensure your supplier can provide interface compatibility and coordinated reject systems.

Q: What maintenance is required to keep a multihead weigher accurate?A: Regular calibration of load cells, cleaning of feeders, checking for wear on contact parts, and preventive replacement of vibration motors and belts are typical. Follow the manufacturer's maintenance schedule and keep critical spares on hand.

Q: How much accuracy improvement can I expect versus manual filling?A: While outcomes vary, a properly specified multihead weigher machine typically reduces giveaway and variability significantly compared with manual or volumetric filling due to precise combination algorithms and automated feedback. Ask a vendor for sample data using your product.

Q: Do suppliers offer financing or leasing for multihead weighers?A: Many suppliers and third-party financiers provide leasing or financing options. Discuss payment terms, leasing vs. purchase benefits, and include service contracts in financial planning.

Q: What information should I provide suppliers to get an accurate quote?A: Provide product samples, target packs/minute, weight ranges, product dimensions, expected SKUs, line layout or space constraints, required certifications and any integration needs (PLC/MES protocols). This enables precise proposals and FAT planning.

Integrating Economic VFFS with Multihead Weighers: Best Practices

Top 10 Ways to Improve Aluminum Foil Detection Accuracy

Selecting the right sensors and feeders for JW-B12 systems

Procurement Guide: Evaluating JW-B20 Powder Packing Machine

About Product choice

What is the average lifespan of Kenwei products?

Kenwei machines are built for durability and longevity. With proper maintenance, our products are designed to last for many years, even under heavy usage. We offer maintenance services and support to help extend the lifespan of your machines.

What is the difference between a multi-head weigher and a linear weigher?

Multi-head Weigher: Ideal for high-speed and high-precision weighing of products with irregular shapes or varying sizes. It provides multiple weighings in parallel for faster processing.

Linear Weigher: It is suitable for powder and granule. It is typically slower than a multi-head weigher but is effective for certain types of applications that require more continuous flow or controlled weighing.

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

About Cooperation Process

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

What information is needed to get a quote from Kenwei?

For us to provide an accurate quote, please provide the following details:

Type of machinery you are interested in (e.g., multi-head weighers, metal detectors, etc.)

Specifications and customization requirements (e.g., capacity, speed, size, etc.)

Your intended application and industry

Quantity of machines required

Delivery location

Leak Proof Multi Head Combination Weigher for Small Particle&Powder

Discover the Kenwei Leak Proof Multi Head Combination Weigher for Small Particle & Powder. This advanced multihead weigher machine ensures high-precision weighing, leak-proof performance, and efficiency. Ideal for various industries needing accurate combination weigher solutions.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Food Metal Detector Manufacturer For Reject Defective Products G5020

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei