Selecting the right sensors and feeders for JW-B12 systems

- Optimizing feeding and sensing for high-speed packaging

- Why sensors and feeders matter for throughput and accuracy

- Key performance targets to define before selection

- Choosing the right sensors for precision and reliability

- Common sensor types and when to use them

- Selecting sensors by product category

- Selecting feeders: dual-feeder strategies for irregular products

- Feeder types and matching to the JW-B12 dual-feeder layout

- Dual-feeder strategies

- Practical feeder selection checklist

- Integration, testing and maintenance for sustained performance

- Sensor and PLC integration best practices

- Commissioning and acceptance testing protocol

- Maintenance schedule and spare parts planning

- Comparisons, ROI and real-world examples

- Sensor-feeder combos by product type (quick reference)

- Return on investment considerations

- Brand advantages and why JW-B12 is a strong platform choice

- Integrated design for Rotary Packing Machine environments

- Engineering strengths and service support

- Case example (anonymized)

- FAQ

- Which sensor type is best for powdered vs particulate snacks?

- Can the JW-B12 handle two different products simultaneously (dual-feed mixing)?

- How often should load cells be calibrated on the JW-B12?

- What are the top causes of false sensor triggers and how to avoid them?

- Can vision systems be retrofitted to the JW-B12?

This article provides practical guidance for choosing sensors and feeders for the Double feeder horizontal packaging and weighing system JW-B12. It focuses on matching sensor technology and feeder design to product characteristics, production targets and hygiene requirements to optimize performance on high-speed packaging lines, including rotary packing machine applications. Where appropriate, links to authoritative references are included to support recommendations.

Optimizing feeding and sensing for high-speed packaging

Why sensors and feeders matter for throughput and accuracy

The JW-B12 Double feeder horizontal packaging and weighing system combines a multihead weigher with dual feeders to achieve rapid, high-precision bagging of snacks, puffed foods, nuts, candies, hardware and irregular-shaped materials. Sensors and feeders are the front-line components that control product flow into the weighing system. A mismatch between sensor type, feeder geometry and product behavior causes underfills, overfills (giveaway), line stoppages and inconsistent seals—directly impacting yield, cost and customer satisfaction.

Key performance targets to define before selection

Before selecting sensors and feeders, define measurable targets: target throughput (bags/min), acceptable weight tolerance (e.g., ±1.0% or ±2.0%), product fragility, particle size distribution, and hygiene/IP level. These targets frame trade-offs: e.g., higher throughput often requires faster sensors and more aggressive feeder agitation, which may increase breakage for delicate snacks.

The JW-B12 Double Feeder Horizontal Packaging and Weighing System is designed for high-speed, high-precision packaging of snacks, puffed foods, nuts, candies, hardware, and irregular-shaped materials. With a multihead weigher and dual-feeder setup, it delivers efficient, fully automated feeding, weighing, and bagging for a wide range of products—ensuring secure seals and professional premade bag packaging.

Choosing the right sensors for precision and reliability

Common sensor types and when to use them

Understanding sensor strengths helps match technology to the JW-B12 application. The most common options are:

- Photoelectric/optical sensors — fast, non-contact detection ideal for counting pieces and detecting flow/no-flow for opaque and transparent products. They are widely used on rotary packing machines and feeders to detect presence and control gates. However, they are sensitive to dust and product spray.

- Proximity sensors (inductive/capacitive) — inductive sensors detect metal parts (hardware) reliably; capacitive sensors can detect non-metal or bulk material levels, useful for powders or low-dielectric materials, but require calibration for different products.

- Load cell weight sensors — essential at the weighing stage for accuracy. High-resolution load cells are used on each multihead weigh bucket to guarantee weight precision; ensure compatibility with the JW-B12 multihead weighing sub-system.

- Vision systems — machine vision can inspect product orientation, count pieces, and detect foreign materials or broken pieces for high-value snacks and confectionery. Vision systems are slower and more costly but add quality control on-line.

- Infrared or laser distance sensors — useful for level detection in hoppers and continuous product flow monitoring. Lasers perform well in dusty environments compared to simple photoelectrics.

Selecting sensors by product category

Match sensor choice to the product handled by JW-B12:

- Fragile, lightweight snacks (puffed foods): use gentle feeders + optical sensors with debounce logic to avoid false triggers from dust. Avoid aggressive vibrations that break product.

- Nuts and candies: optical and load cells for counting and weighing; consider vision if size/shape sorting is needed.

- Hardware (screws, bolts): inductive proximity sensors for metal detection, robust hoppers and anti-jam feeders, and heavy-duty photoelectrics for piece counting.

- Irregular-shaped items: multihead weighers paired with dual feeders and photoelectric or laser sensors for flow detection to ensure even distribution to weigh buckets.

For general background on weighing and sensor principles see the Wikipedia overview on weighing scales: https://en.wikipedia.org/wiki/Weighing_scale, and on sensor fundamentals: https://en.wikipedia.org/wiki/Sensor.

Selecting feeders: dual-feeder strategies for irregular products

Feeder types and matching to the JW-B12 dual-feeder layout

The JW-B12 uses a double feeder horizontal layout to feed two multihead inputs or to provide staged feeding into one multihead weigher. Feeder options include:

- Vibratory feeders — commonly used for small to medium parts (snacks, nuts, candies). They provide gentle, controllable flow and are easy to tune for speed vs. gentleness.

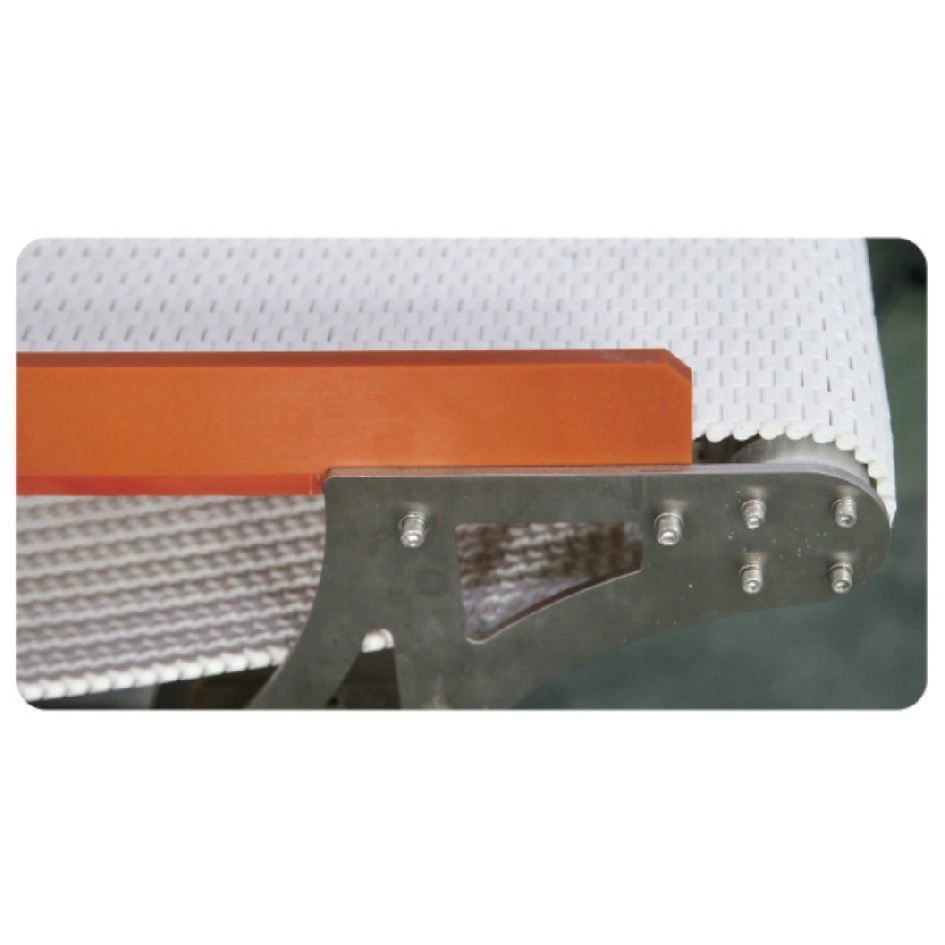

- Belt feeders — ideal for sticky or oily products, or when positive conveyance and spacing are required for rotary packing machine infeed. Belts can be fitted with pockets or separators for portioning.

- Air-assisted feeders — useful for very light, voluminous items (puffed snacks) where controlled puffed flow is needed; requires integration with dust control and air management.

- Inclined or stepped feeders — help align and singulate irregular or bulky items before they reach the vibrator/belt section.

Dual-feeder strategies

Using two feeders on the JW-B12 opens strategic options:

- Alternating feed — feeders alternate to allow continuous weighing while one feeder is refilling, reducing downtime for high-speed lines.

- Parallel feed — both feeders feed simultaneously into different weigh heads to maximize throughput on rotary packing machines when the multihead weigher supports parallel distribution.

- Product staging — one feeder provides bulk flow while the second provides top-ups or different product components (e.g., mix of nuts and dried fruit), enabling multi-component mixes without manual changeovers.

Practical feeder selection checklist

When specifying feeders for the JW-B12, verify:

- Compatibility with product abrasiveness, oiliness and dust generation.

- Adjustability of vibration amplitude, belt speed, or air flow for tuning.

- Hygienic design, washdown rating and materials (stainless steel options) if used in food environments.

- Integration points for sensors, gates and actuators; ensure sensor mounting positions avoid false triggers from vibration.

- Spare parts availability (liners, belts, motors) and local service support to minimize Mean Time To Repair (MTTR).

Integration, testing and maintenance for sustained performance

Sensor and PLC integration best practices

Ensure sensors interface cleanly with the JW-B12 control logic and the plant's PLC/SCADA when used on a rotary packing machine line. Important considerations:

- Use shielded wiring and proper grounding to avoid electrical noise from vibratory feeders corrupting photoelectric signals.

- Implement debounce and validation logic in PLC to filter spurious sensor pulses, especially where dust and product spray are present.

- Synchronize encoder feedback from rotary equipment with sensor timing to coordinate gates and reject cycles accurately.

Commissioning and acceptance testing protocol

Create a commissioning protocol covering these steps:

- Baseline test with known-weight samples to validate load cell calibration and multihead combinations; record variance and calculate Cpk.

- Throughput ramp-up tests: start at low speed and incrementally increase conveyor/feeder speeds while monitoring weight accuracy and bag integrity.

- Contamination and false-trigger tests: introduce common dust or oil conditions in a controlled way to verify sensor robustness and PLC debounce settings.

- Product changeover test: time required to switch feeders, change sensor settings and validate weights should meet the expected changeover time targets.

Maintenance schedule and spare parts planning

Preventive maintenance reduces downtime. Recommended schedule:

| Interval | Task | Notes |

|---|---|---|

| Daily | Clean sensors and hopper inlets; check belts and visual for jams | Wipe photoelectrics, ensure no dust build-up |

| Weekly | Check load cell zero and span; inspect feeder liners and vibration mounts | Record zero drift; replace worn liners |

| Monthly | Test sensor alignment and PLC signal integrity; lubricate bearings | Run diagnostics and update firmware if available |

| Quarterly | Full calibration against certified weights; inspect mechanical wear and electrical connections | Keep calibration certificates for audits |

Comparisons, ROI and real-world examples

Sensor-feeder combos by product type (quick reference)

| Product | Recommended Feeder | Recommended Sensors | Notes |

|---|---|---|---|

| Puffed snacks | Air-assisted or gentle vibratory feeder | Laser/optical level sensors, load cells | Minimize drop height; dust control needed |

| Nuts & candies | Vibratory feeder or belt with pockets | Photoelectric sensors, load cells, optional vision | Vision helps with broken piece rejection |

| Hardware (metal) | Robust vibratory feeder or belt | Inductive proximity sensors, load cells | Inductive sensors are reliable for metal detection |

| Irregular shapes | Inclined + vibratory feeder | Photoelectric or laser, load cells | Dual-feed staging often improves distribution |

Return on investment considerations

Investing in the right sensors and feeders reduces giveaway, improves uptime and lowers labour costs for manual corrections. Typical ROI drivers:

- Reduced giveaway: accurate load cells and well balanced feeders cut product giveaway by 0.5–2% which can add up quickly on high-volume lines.

- Increased throughput: dual feeders and fast sensors keep the multihead weigher supplied to achieve rated bags/min on rotary packing machine systems.

- Lower scrap/rejects: vision systems and robust feeders prevent damaged product from entering the bag.

For industry context on multihead weighers and packaging technology, consult manufacturer resources such as ISHIDA on multihead weighers: https://www.ishida.com/global/products/multihead-weigher and PMMI industry information: https://www.pmmi.org.

Brand advantages and why JW-B12 is a strong platform choice

Integrated design for Rotary Packing Machine environments

The JW-B12 Double Feeder Horizontal Packaging and Weighing System is engineered to integrate with rotary packing machine lines. Its dual-feeder configuration supports continuous high-speed operation with minimized downtime for hopper refills and product staging. Built-in interfaces for standard sensors, encoders and PLC protocols ease integration into existing plant automation systems.

Engineering strengths and service support

Key brand advantages to highlight when selecting the JW-B12 platform:

- Modular feeder options (vibratory, belt, air-assisted) allow a tailored solution for snacks to hardware.

- High-precision load cell and multihead weigher integration reduce giveaway and improve weight distribution on premade bag packaging.

- Hygienic stainless steel construction options and IP-rated sensors for washdown environments.

- Local service networks and spare parts provisioning reduce MTTR and ensure continuity of production.

Case example (anonymized)

A high-volume snack producer upgraded from single-feeder vibratory infeed to the JW-B12 with dual vibratory feeders and laser level sensors. Results after commissioning: 18% throughput uplift (bags/min), 1.4% reduction in product giveaway, and 35% fewer stoppages due to improved hopper control. These results underline the value of matching feeder dynamics and sensor robustness to product characteristics.

FAQ

Which sensor type is best for powdered vs particulate snacks?

For powders, capacitive sensors or laser distance sensors combined with load cell feedback work well because photoelectrics are often affected by dust. For particulates like chips, optical sensors plus load cell weighing are optimal.

Can the JW-B12 handle two different products simultaneously (dual-feed mixing)?

Yes. The JW-B12’s dual-feeder design supports staged feeding and multi-component mixes when the system is configured to sync feeders and weigh heads. Proper sensor and PLC logic must be implemented to ensure correct ratios.

How often should load cells be calibrated on the JW-B12?

Calibration frequency depends on regulatory requirements and production intensity. A practical schedule is monthly zero checks and quarterly full calibration against certified weights, with records retained for audits.

What are the top causes of false sensor triggers and how to avoid them?

Top causes: dust buildup, vibration coupling, electrical noise and poor alignment. Mitigation: regular cleaning, sensor damping mounts, shielded cables and PLC debounce logic.

Can vision systems be retrofitted to the JW-B12?

Yes. Vision systems can be added for quality checks, counting and foreign material detection. Ensure the vision camera mount, lighting and conveyor timing are coordinated with the JW-B12 control system.

Optimized components not only improve control but also support energy-efficient rotary packing machine practices for factories focused on long-term operating cost reduction.For more detailed specifications, commissioning templates, or to arrange an on-site trial, contact our sales team or view the product page for the Double feeder horizontal packaging and weighing system JW-B12.

Top food pouch packing machine Manufacturers and Suppliers in China

Calibration Tips for Accurate Metal Detection in Food Lines

ROI of Investing in Good Metal Detectors for Food Safety

Multihead Weigher Technology Trends 2026

About After Sales Support

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

About Price and payment

How is the price of Kenwei machines determined?

The price of Kenwei machines depends on several factors, including the type of machine, customization requirements, production volume, and any additional features or integrations. We provide tailored quotes based on your specific needs and requirements.

About Product choice

Can Kenwei's machines be used in my industry?

Kenwei’s equipment is highly versatile and can be used across a wide range of industries, including:Food,Pharmaceuticals,Chemicals,Plastics and Agriculture.

Plastics If you're unsure whether our products are suitable for your industry, please contact us, and we can provide you with specific solutions tailored to your needs.

What types of products does Kenwei offer?

Kenwei specializes in high-precision and high-speed automated machinery for weighing, packaging, and quality control. Our main products include: multihead weigher, linear weigher, checkweighers,food metal detector,vertical packing machine and packing machine accessories.

About Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Combined Check Weigher and Metal Detector for Food Industrial Weighing and Sorting

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei