Global Trends and Development Status of the Packaging Machinery Industry: A Comparative Analysis of the US, Germany, Italy, Japan, and China

- 1. United States: Automation and Smart Packaging Innovation

- 2. Germany: Leadership in Automation, Simulation, and Custom Solutions

- 3. Italy: Customization, Flexibility, and Global Reach

- 4. Japan: Compact, Precise, and Highly Automated Packaging Solutions

- 5. China: Rising Potential Amidst Challenges

- Conclusion: The Future of Global Packaging Machinery

The global packaging machinery industry is witnessing intense competition, with key trends moving toward the "Three Highs"—high speed, high efficiency, and high quality. The evolution of packaging equipment increasingly emphasizes low energy consumption, compact design, environmental adaptability, and alignment with operator needs and ecological standards. Countries such as the United States, Germany, Italy, and Japan lead this evolution through advanced technologies and innovative practices.

1. United States: Automation and Smart Packaging Innovation

The U.S. packaging machinery sector has rapidly advanced in forming, filling, and sealing equipment. Traditionally split evenly between the food and non-food industries, the sector has seen significant growth in non-food applications, such as beverages, electronics, and chemicals. New technologies, including microwave packaging and aseptic filling, have been adopted in food packaging.

The U.S. has developed a complete packaging ecosystem, including materials, technology, and machinery, now shifting toward mechatronics, laser scanning, RFID, nanotechnology, and system simplification. Emerging innovations like microelectronics, industrial robotics, intelligent systems, and new materials are driving U.S. packaging machinery toward full automation, energy efficiency, and enhanced productivity.

2. Germany: Leadership in Automation, Simulation, and Custom Solutions

Germany holds approximately 20% of global packaging machinery output and contributes 30% of global exports. German packaging machinery is renowned for its measurement accuracy, technical performance, and automation.

Key development trends include:

-

Full automation of production processes

-

Flexible and modular machine designs

-

Use of computer-aided simulation and digital modeling

German companies design with user input, leveraging simulation software to demonstrate real-time production performance. They also offer remote diagnostics, emphasizing reliability and minimal environmental impact. Germany's focus on high-speed, low-waste beverage packaging systems illustrates its technological leadership.

3. Italy: Customization, Flexibility, and Global Reach

Italy ranks as the fourth-largest producer and second-largest exporter of packaging machinery globally, with about 40% of its equipment used in the food and beverage sector. Italian packaging machinery is celebrated for its excellent performance, elegant design, cost-efficiency, and strong export orientation (80%).

Italian strengths include:

-

Customer customization based on user needs

-

High flexibility and adaptability

-

Use of advanced technology such as programmable controllers, microcomputers, and mechanical metering

-

Specialization in pharmaceutical and food packaging machines

Despite many Italian packaging equipment manufacturers being SMEs or family-owned businesses, they excel in rapid prototyping and personalized system design, enabling strong international competitiveness. Italy is a major supplier to the U.S., China, Africa, and Oceania, with notable brands like Sipa and Ilapak serving global beverage and pharmaceutical markets.

4. Japan: Compact, Precise, and Highly Automated Packaging Solutions

Since the 1960s, Japan has been a major force in the global packaging machinery industry, ranking second only to the U.S. Japanese packaging systems are known for being compact, precise, easy to operate, and highly automated.

Key innovations include:

-

Introduction of computer technology and servo motors

-

Development of microcomputer-controlled forming, filling, and sealing machines

-

Integration of heat pipe technology to improve energy efficiency and sealing performance

Japan emphasizes safety, sanitation, and standard compliance, driven by strict national regulations. Over 400 manufacturers focus primarily on food packaging, which accounts for over 50% of total output. Although exports remain modest, Japan's advanced automation and system integration provide strong global competitiveness.

![]()

5. China: Rising Potential Amidst Challenges

China's packaging machinery sector has developed rapidly since the 1980s, driven by the growth of the commodity economy and stricter government regulations on food and pharmaceutical safety. However, the industry still faces several challenges:

Current Challenges:

-

Low R&D investment (0.2–0.3% of sales revenue)

-

High product homogeneity and low automation

-

Weak integration between research institutions and manufacturing companies

-

Limited use of new technologies and materials

Despite these hurdles, regional leaders like Guangdong Kenwei Intellectualized Machinery Co., Ltd. have made significant progress. Kenwei has collaborated with academic institutions on “multi-material mixing” technologies, receiving provincial science and technology awards. This cooperation has helped improve market share and technological capability in combination weighing systems.

Recommended Countermeasures for Industry Progress:

-

Promote coordinated regional development

-

Foster large-scale enterprise groups

-

Strengthen technology transfer and independent R&D

-

Encourage foreign capital investment

-

Establish testing centers for applied research

-

Improve quality control systems

-

Expand scientific and technical talent development

With a focus on technological innovation, strategic investment, and industry-academia collaboration, China is well-positioned to transition from being a manufacturing giant to a global leader in food and packaging machinery.

Conclusion: The Future of Global Packaging Machinery

The future of packaging machinery lies in integration, intelligence, automation, flexibility, and sustainability. Developed countries are continuously leveraging cutting-edge technologies—such as AI, robotics, smart sensors, and green materials—to maintain their lead. Meanwhile, emerging economies like China are striving to close the gap through innovation, collaboration, and government support.

As demand for diversified, high-quality packaging solutions grows, the global industry will increasingly rely on automated, eco-friendly, and smart packaging machinery to meet consumer expectations and sustainability goals.

About Product choice

What types of products does Kenwei offer?

Kenwei specializes in high-precision and high-speed automated machinery for weighing, packaging, and quality control. Our main products include: multihead weigher, linear weigher, checkweighers,food metal detector,vertical packing machine and packing machine accessories.

About Price and payment

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

About products customization

Can I customize Kenwei machines to suit my specific needs?

Yes, Kenwei offers a wide range of customization options to ensure that our machines meet your production requirements.

About Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

About After Sales Support

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

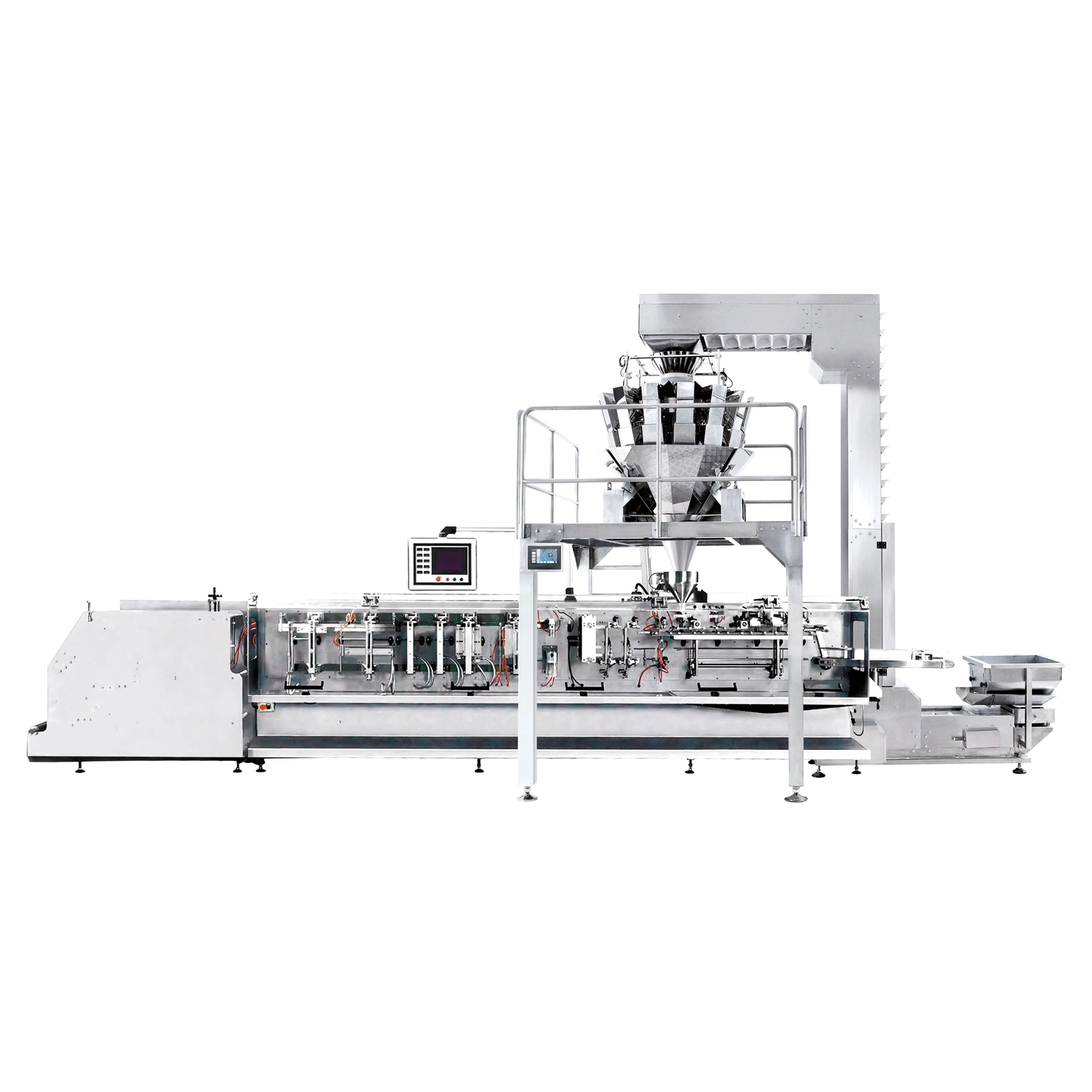

The JW-B13 Standard Pre-Made Bag Packing Machine is an advanced weighing and packing system ideal for granules, slices, and irregular products like snacks, nuts, pet food, and hardware. This fully automated line includes a vibrator feeder, Z conveyor, working platform, multihead weigher, and horizontal packing machine. It ensures high weighing accuracy, fast packing speed, and premium bagging quality—perfect for efficient, stable, and precise packaging.

The Kenwei JW-B16 Two Outlet Semi-Auto Sugar Weighing and Packaging Machine delivers high-precision, automated weighing for granules, slices, and irregular products like candy, coffee beans, and pet food. With a compact, cost-effective design and excellent price-performance ratio, it supports unique bag types and boosts efficiency. Optional add-ons like check weighers, metal detectors, and conveyors ensure quality control and seamless integration. Ideal for food and hardware industries.

The economical vertical form fill seal (VFFS) packaging machine offers a variety of models designed with a sturdy 304 stainless steel frame. It is equipped with safety door protection and supports multiple bag types, including pillow bags, angle belt bags, printed bags, and triangle bags. This versatile machine is ideal for packaging a wide range of materials, such as snacks, frozen foods, coffee beans, oats, sugar, salt, rice, small hardware components, and more. Affordable and cost-effective, it provides reliable performance and efficiency for diverse packaging needs.

The parallel manipulator features a 4-axis linkage structure and a high-precision servo control system, ensuring accurate and reliable operation. It can be integrated with a vision system or onboard conveyor, supporting customized conveying solutions with flexible configuration options. This system is ideal for automated handling of various materials across industries such as food, pharmaceuticals, condiments, plastics, handicrafts, electronics, and more.

Contact Kenwei

Our company is located in areas with convenient transportation and developed economy. Our products are supplied in a timely manner. In the course of business operation, we always focus on customers.Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei