The combination weigher Cost Guide

- Introduction: Why a Combination Weigher Cost Guide Matters

- Understand combination weigher price before you buy

- What is a Combination Weigher and Why Cost Varies

- Definition and commercial value of multi-head weighers

- Typical Price Ranges for Combination Weighers

- Entry-level, mid-range, and high-end multihead weigher costs

- Key Cost Drivers for Combination Weighers

- Head count and weighing accuracy influence cost

- Product handling and feed systems affect pricing

- Control systems, software and integration costs

- Material of construction and sanitary design

- Optional accessories and compliance features

- Ancillary and Hidden Costs to Budget For

- Installation, commissioning, and site preparation

- Training, spare parts, and after-sales service

- Shipping, taxes, and duties

- Performance Factors That Affect Cost-effectiveness

- Speed versus accuracy trade-offs for ROI

- Uptime, reliability and total cost of ownership

- Budgeting Examples: Realistic Scenarios

- Small start-up snack producer

- Medium bakery or frozen food line

- High-capacity turnkey packaging line

- How to Reduce Combination Weigher Costs Without Sacrificing Quality

- Buy standard configurations and modular upgrades

- Consider leasing, used equipment, or financing options

- Negotiate service levels and spare parts bundles

- Checklist: Questions to Ask When Requesting a Quote

- Critical commercial questions to include in an RFQ

- Return on Investment: Simple ROI Example

- How to estimate payback time on a multi-head weigher

- Why Choose Kenwei for Your Combination Weigher

- Kenwei: proven multi-head weigher manufacturer with full-line solutions

- Conclusion: Making an Informed Purchase Decision

- Balance price with long-term value

- Frequently Asked Questions

Introduction: Why a Combination Weigher Cost Guide Matters

Understand combination weigher price before you buy

Choosing a combination weigher (also called a multi-head weigher) is a strategic investment for any food, snack, or packaged goods business. Buyers are usually searching for clear cost expectations, factors that drive price, and how to achieve a fast ROI. This guide explains realistic cost ranges, what influences the price of a combination weigher, and how Kenwei’s experience can help you optimize both budget and line performance.

What is a Combination Weigher and Why Cost Varies

Definition and commercial value of multi-head weighers

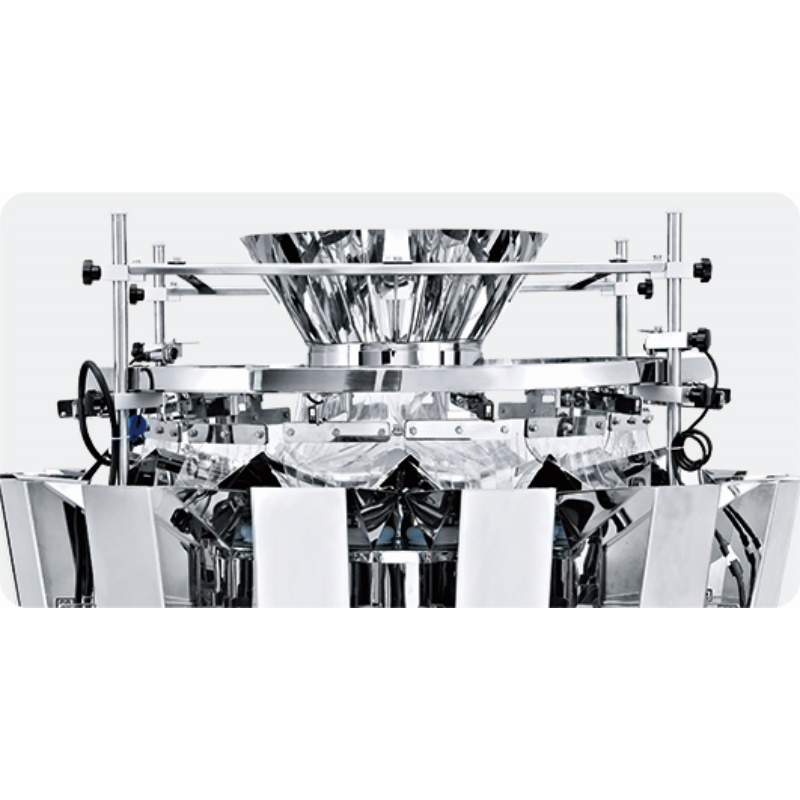

A combination weigher is an automated multi-head weighing system that uses multiple weighing heads and combination algorithms to achieve precise pack weights at high speed. The commercial intent behind buying a combination weigher is usually to increase throughput, reduce giveaway, and improve product accuracy — all of which affect long-term costs and profitability.

Typical Price Ranges for Combination Weighers

Entry-level, mid-range, and high-end multihead weigher costs

Combination weigher price ranges depend on head count, construction, and options. Typical price brackets you should expect:

- Entry-level machines (6–10 heads): $18,000–$45,000 — suited to small manufacturers and low-to-medium speeds.

- Mid-range machines (10–14 heads): $40,000–$90,000 — common for medium plants looking for higher accuracy and throughput.

- High-capacity machines (14–24+ heads and special models): $80,000–$200,000+ — target high-speed production lines and challenging products.

Full turnkey packaging lines that include a combination weigher integrated with vertical form fill seal (VFFS) machines, conveyors, metal detectors, and checkweighers typically range from $80,000 to $400,000 depending on capacity, automation, and custom features.

Key Cost Drivers for Combination Weighers

Head count and weighing accuracy influence cost

Head count is a principal cost driver. More heads provide finer combinational options and faster pack rates, but increase machine complexity and price. For lightweight, high-speed products, more heads can reduce giveaway and improve yield.

Product handling and feed systems affect pricing

Specialized infeed, vibratory feeders, bucket elevators, or coating-resistant surfaces for sticky or hot products increase the bill of materials and engineering time. If you handle fragile or irregular-shaped items, expect to pay more for gentler feeding and custom tooling.

Control systems, software and integration costs

Advanced PLC/HMI systems, recipe management, remote diagnostics, and Industry 4.0 connectivity add to the cost but improve uptime and reduce long-term service costs. Integration to your existing MES or ERP system also increases engineering and commissioning time.

Material of construction and sanitary design

Stainless steel grades (304 vs 316), IP protection, dust-tight designs, and washdown capability affect pricing. Food-safe finishes and CIP-compatible designs cost more initially but lower cleaning time and compliance risks.

Optional accessories and compliance features

Options such as special hoppers, enrobers, dust extraction, metal detector integration, checkweigher pairing, bagmakers, and custom conveyors will add to the total investment. Compliance features for export markets (CE, UL) also contribute to the final price.

Ancillary and Hidden Costs to Budget For

Installation, commissioning, and site preparation

Installation and commissioning typically add 5–15% to equipment cost, depending on travel, electrical/mechanical work, and control integration. Site modifications like foundations, air or chilled water lines, or raised platforms should be budgeted separately.

Training, spare parts, and after-sales service

Operator and maintenance training ensure proper use and reduce downtime; this is usually a line item in proposals. Annual spare parts and service budgets commonly range from 3–10% of the machine’s purchase price depending on runtime and critical part lead times.

Shipping, taxes, and duties

Freight for large machines and packaging lines varies by origin and destination — inland transportation, port handling, and customs duties can be significant. Always verify whether quotes are EXW, FOB, or DDP to understand total landed cost.

Performance Factors That Affect Cost-effectiveness

Speed versus accuracy trade-offs for ROI

High speed without adequate accuracy increases giveaway and product loss. Conversely, over-specifying accuracy for simple products increases capital cost. Analyze your target speed (packs per minute) and acceptable weight tolerance to find the economically optimal machine.

Uptime, reliability and total cost of ownership

Total cost of ownership (TCO) includes energy, downtime, labour savings, and giveaway. Machines from reputable suppliers like Kenwei offer higher initial cost but can deliver lower TCO through service coverage, faster spare parts delivery, and proven reliability in harsh production environments.

Budgeting Examples: Realistic Scenarios

Small start-up snack producer

Scenario: 6–10 head combination weigher integrated with a small VFFS bagger for snack packs, low batch complexity. Estimated cost: $30,000–$60,000 for equipment + $5,000–$10,000 installation and commissioning. This setup provides immediate automation benefits and scalable productivity for growing businesses.

Medium bakery or frozen food line

Scenario: 10–14 head weigher with hygienic design, special feed for irregular products and integration to a mid-speed bagger. Estimated cost: $70,000–$150,000 inclusive of conveyors, basic metal detection, and commissioning. The investment addresses higher throughput and stricter accuracy needs.

High-capacity turnkey packaging line

Scenario: Multiple high-head weighers, robotic picking systems, multi-lane VFFS, checkweighers, and metal detectors. Estimated cost: $150,000–$400,000+ depending on automation level and custom engineering. This solution targets large manufacturers and contract packers requiring maximal throughput and compliance.

How to Reduce Combination Weigher Costs Without Sacrificing Quality

Buy standard configurations and modular upgrades

Choosing standard models with modular upgrade paths reduces initial capital outlay while preserving future scalability. Kenwei designs modular systems that can be upgraded with additional heads, feeders, or connectivity features as your business grows.

Consider leasing, used equipment, or financing options

Equipment leasing or financing helps spread capital cost and preserve working capital. Certified used machines from reputable manufacturers can be cost-effective for lower-risk applications, but factor in refurbishment and spare parts availability.

Negotiate service levels and spare parts bundles

Bundling service agreements and spare parts can lower long-term costs and ensure predictable maintenance budgets. Ask suppliers for clear SLAs, response times, and optional training packages to reduce downtime costs.

Checklist: Questions to Ask When Requesting a Quote

Critical commercial questions to include in an RFQ

When requesting quotes, include these items to get comparable, realistic pricing:

- Target pack weight range and tolerance

- Desired throughput (packs per minute) and shift patterns

- Product characteristics: size distribution, fragility, moisture, temperature

- Required sanitary standards and surface materials

- Integration needs: baggers, metal detectors, checkweighers, robots

- Service, warranty, and spare parts expectations

- Delivery terms and commissioning responsibilities

Return on Investment: Simple ROI Example

How to estimate payback time on a multi-head weigher

Example: A mid-range combination weigher costing $80,000 reduces giveaway by 1.5% on a product with annual sales value of $1,200,000. Annual savings from reduced giveaway = $18,000. If labour savings and productivity improvements add $12,000 annually, total annual benefit = $30,000. Simple payback = $80,000 / $30,000 ≈ 2.7 years. This shows why improved accuracy and throughput can justify higher initial cost.

Why Choose Kenwei for Your Combination Weigher

Kenwei: proven multi-head weigher manufacturer with full-line solutions

Kenwei is a powerful manufacturer of multi-head weighers headquartered in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province. We design and manufacture multi-head weighers, metal detectors, linear weighers, and checkweighers. Kenwei provides one-stop automated weighing and packaging solutions, with capabilities across design, production, installation, commissioning, training, and after-sales service. Our machines emphasize high speed and high precision — delivering measurable ROI for customers worldwide. Visit https://www.kenweigroup.com/ to learn more.

Conclusion: Making an Informed Purchase Decision

Balance price with long-term value

Combination weigher cost is just the start of the purchasing decision. Evaluate total cost of ownership, integration ease, service responsiveness, and expected accuracy improvements. Use the checklist above to get comparable quotes, and consider Kenwei’s experience for high-quality multihead weighers and turnkey packaging solutions that lower TCO and increase productivity.

Ready to get an accurate quote tailored to your product and throughput? Contact Kenwei for a consultation and detailed proposal that aligns price with performance.

Frequently Asked Questions

How much does a combination weigher cost to maintain annually?Maintenance budgets vary, but plan for 3-10% of the equipment price per year for spare parts, labour, and scheduled servicing. High-usage lines or harsh environments may require more frequent maintenance.

What is a reasonable lifespan for a multi-head weigher?With proper maintenance and periodic parts replacement, a well-built combination weigher can last 10–15 years or more. Useful life depends on runtime, environment, and maintenance discipline.

Can a combination weigher handle fragile products like chips or pet treats?Yes. With appropriate feeders, gentler product handling options, and tailored tooling, combination weighers are commonly used for fragile snacks, pet food, and other delicate products. Discuss product specifics with the manufacturer for best results.

Is it better to buy or lease a combination weigher?Leasing preserves capital and can be attractive for fast-scaling businesses. Buying often yields lower lifetime cost if you have long-term stable demand. Assess cash flow, depreciation, and expected equipment lifespan before deciding.

What warranty and service should I expect from Kenwei?Kenwei provides warranty terms and after-sales service with clear SLAs. Exact terms depend on the machine and region. Always confirm warranty period, response times, and spare parts availability in your quote.

The latest trends for linear weigher packaging machine

What are the application scenarios of food packaging machines?

Sanitation and IP Rating: Protecting Metal Detectors in Plants

Procurement Guide: Evaluating JW-B20 Powder Packing Machine

About Solution suggestions

Can Kenwei machines handle products with irregular shapes or sizes?

Yes, multi-head weighers are particularly effective for handling products with irregular shapes and sizes.

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

About Product choice

How do I choose the right product for my business?

Choosing the right machine depends on several factors:

Product Type: Different machines are suited for different products (e.g., powder, granules, etc.).

Production Capacity: Consider the volume of products you need to process and the speed requirements.

Customization: If you have specific needs, such as the need for unique features or sizes, we offer customization options.

About After Sales Support

What do I do if I encounter a malfunction in the machine?

If you encounter a malfunction, first check the user manual and troubleshooting guide for common issues. If the problem persists, contact our technical support team for further assistance.

About products customization

Can Kenwei machines be customized for different industries?

Yes,According to the material characteristics and requirements of different industries, we developed various machine types for counting (small pouches into big bag), noodles, frozen foods, peppers, stick-shaped products, product -mixing, cheeses, salads and so on.

10-Head Standard No-Spring Multihead Weigher 1.6L for Precise Weighing

The standard no-spring combination scale features a patented spring-free hopper design, making it ideal for weighing a variety of products such as melon seeds, peanuts, nuts, almonds, grapes, candies, pistachios, potato chips, shrimp chips, and more. The double-support feeding tray is easily adjustable, while the feeding hopper is designed for easy disassembly, ensuring convenience and cleanliness. With a maximum weighing speed of up to 120 bags per minute, the 14-head standard no-spring combination scale is an economical, versatile, and cost-effective solution.

Standard Multihead Weigher with New Springless Actuator for Food Weighing Machine

The Standard Multihead Weigher features a high-speed, spring-free hopper with a new aluminum shell design, ensuring stable and fast weighing performance. The integrative welding of the mouthpiece case and middle seat enhances the overall machine strength. Ideal for weighing granular products like melon seeds, peanuts, nuts, almonds, raisins, candies, and pistachios, this 14-head multihead weigher offers hopper options of 1.6L and 2L. With a maximum weighing speed of 120 packs per minute, it delivers rapid and accurate results for high-volume operations.

14-Head High-Speed Springless Multihead Weigher for Accurate Weighing

The high-speed weigher features a new spring-free aluminum shell design with double chute feeding and dual high-speed hopper alternating feeding, significantly boosting feeding speed. It is ideal for weighing materials such as melon seeds, peanuts, nuts, almonds, raisins, candy, pistachios, and more. The 18-head high-speed weigher is equipped with 2L hoppers, achieving a maximum weighing speed of up to 180 bags per minute.

16-Head Multihead Weigher with 1.6L Three-Layer Hopper for Accurate Weighing

The Kenwei 16-Head Multihead Weigher with a 1.6L Three-Layer Hopper provides precise and efficient weighing with a maximum speed of 240 packs per minute, optimizing your production line. The main vibrating pan supports two types of mixed materials, offering versatility and consistent performance. This advanced multihead packing machine is ideal for a wide range of products, including nuts, raisins, candies, potato chips, and other snack foods, as well as hardware and plastic materials. It ensures reliable performance and high accuracy in various industries.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei