Reducing Waste and Cost with Accurate Powder Packing Tech

- Reducing Waste and Cost with Accurate Powder Packing Tech

- Why precision matters in Powder Packing Machine operations

- The JW-B20 Powder Packing Machine: designed for accurate, flexible packing

- How linear weighing reduces waste compared to traditional methods

- Key contributors to waste in powder packing and how accurate machines solve them

- Practical cost-savings: numbers and comparison

- Operational strategies to maximize waste reduction with your Powder Packing Machine

- Maintenance and hygiene practices for powders

- Case uses: who benefits most from JW-B20 and similar Powder Packing Machine solutions?

- Brand strengths: why choose the Kenwei JW-B20 Powder Packing Machine

- Integration and scalability

- Choosing the right specs: practical checklist for purchasing a Powder Packing Machine

- FAQ — Common questions about Powder Packing Machine accuracy and the JW-B20

- Next steps — see the JW-B20 in action and reduce your packaging waste and cost

- Authoritative references

Reducing Waste and Cost with Accurate Powder Packing Tech

Why precision matters in Powder Packing Machine operations

In powder and granule packaging, small deviations per package multiply quickly across production volumes. Even a 0.5% overfill on a single 1 kg bag becomes 5 kg lost per 1,000 bags. Over time this drives material waste, inflates cost of goods sold, and erodes margins. Accurate Powder Packing Machine systems minimize giveaway (overfilling) and reduce rejects (underfilling), both of which carry direct and indirect costs—from wasted raw material to rework, customer complaints and regulatory non-compliance. Cost savings achieved through precision can only be sustained with proper upkeep, highlighting the importance of a solid maintenance checklist for semi automatic powder packing machines.

The JW-B20 Powder Packing Machine: designed for accurate, flexible packing

The Kenwei JW-B20 Semi-Automatic Multi-Function Packaging Machine with Linear Weigher is ideal for powders and granules like sugar, salt, rice, coffee, and milk powder. It automates feeding, weighing, and output with high accuracy and efficiency. Compact and cost-effective, it suits various bag types not supported by standard machines, making it perfect for flexible, space-saving packaging needs.

How linear weighing reduces waste compared to traditional methods

Linear weighers, like the JW-B20's linear weigher, use a one-by-one dispensing and weighing approach. Compared with volumetric fillers or simple cup fillers, accurate weighing directly measures product mass for each fill, eliminating density-related volume errors (common with powders that compress or aerate). For manufacturers handling multiple SKUs or hygroscopic powders, linear weighing is more reliable at achieving target fills with tighter tolerances—translating to measurable reductions in giveaway and rejected packs.

Key contributors to waste in powder packing and how accurate machines solve them

- Product variability: Powders can clump, bridge or aerate—accurate feeding and weighing systems detect and compensate for flow changes.

- Line speed vs accuracy trade-off: Modern linear weighers maintain accuracy at practical line speeds, so operators don't have to slow production to avoid giveaway.

- Human error: Semi-automatic machines reduce manual scooping and adjustments, lowering under/overfill risk and operator-dependent variability.

- Changeover losses: JW-B20's compact, adaptable design minimizes setup time for different bag types, reducing start-up scrap during SKU changeovers.

Practical cost-savings: numbers and comparison

To assess the business case for a Powder Packing Machine like the JW-B20, compare common metrics: giveaway (g/bag), throughput (bags/min), and scrap rate. The table below provides a representative comparison between manual packing, a basic volumetric filler, and the JW-B20 with linear weighing. Numbers are typical industry figures to illustrate potential savings; real results depend on product and operations.

| Metric | Manual Packing | Volumetric Filler | JW-B20 (Linear Weigher) |

|---|---|---|---|

| Giveaway per 1 kg bag | 10–20 g | 5–12 g | 1–5 g |

| Throughput (bags/min) | 5–10 | 10–30 | 8–25 (depending on SKU) |

| Start-up scrap during changeover | 5–10% of first batch | 3–6% | 1–3% |

| Typical accuracy (± g) | ±10–20 g | ±3–10 g | ±1–3 g |

Example ROI scenario: For a line producing 20,000 1 kg bags/month, reducing giveaway from 8 g to 3 g saves 5 g per bag, or 100 kg/month. If raw material costs $2.50/kg, that's $250/month saved—$3,000/year. When combined with labor reduction, fewer rejects, and lower rework, payback on a compact semi-automatic machine like the JW-B20 becomes compelling for small-to-medium operations.

Operational strategies to maximize waste reduction with your Powder Packing Machine

Installing accurate equipment is only the first step. To realize full savings, pair the JW-B20 with operational best practices:

- Regular calibration: Schedule daily or shift-based calibration checks using traceable test weights to keep the linear weigher accurate.

- Material handling: Control humidity and use appropriate hopper agitation to prevent bridging and ensure consistent feed.

- Operator training: Train staff on changeover procedures, cleaning, and quick diagnostics to reduce downtime and start-up scrap.

- Data monitoring: Track fill statistics (mean, std deviation, rejects) to detect drift and optimize setpoints—many modern machines export this data for SPC analysis.

- Packaging compatibility: Match bag type and sealing parameters to reduce seal rejects—JW-B20 accommodates various bag styles to reduce mismatches and scrap.

Maintenance and hygiene practices for powders

Powders demand attention to hygiene to avoid contamination and flow problems. Use smooth-walled hoppers, accessible surfaces for CIP or wipe-downs, and follow a documented cleaning schedule. Routine maintenance—greasing bearings, checking vibratory feeders, and inspecting load cells—preserves weighing accuracy and minimizes unplanned downtime that causes waste.

Case uses: who benefits most from JW-B20 and similar Powder Packing Machine solutions?

The JW-B20 particularly benefits businesses that require:

- Flexible packaging for multiple powder/granule SKUs (small-to-medium batches)

- Space-constrained production areas seeking compact, semi-automatic solutions

- High accuracy at moderate throughput where a full multihead weigher is not cost-justified

- Food producers (sugar, milk powder, coffee), chemical powders, salt, spices, and nutraceuticals

Brand strengths: why choose the Kenwei JW-B20 Powder Packing Machine

The JW-B20 blends accuracy, flexibility and cost-effectiveness. Key brand advantages include:

- Compact design: Suited to facilities with limited floor space where a full-scale multihead weigher cannot fit.

- Multi-function capability: Integrates feeding, weighing and discharge for diverse powders and granules without extensive custom tooling.

- Ease of changeover: Supports different bag formats quickly, minimizing start-up scrap and downtime.

- Cost-efficient: Lower capital outlay than full automated systems while delivering significant waste and cost reduction.

Integration and scalability

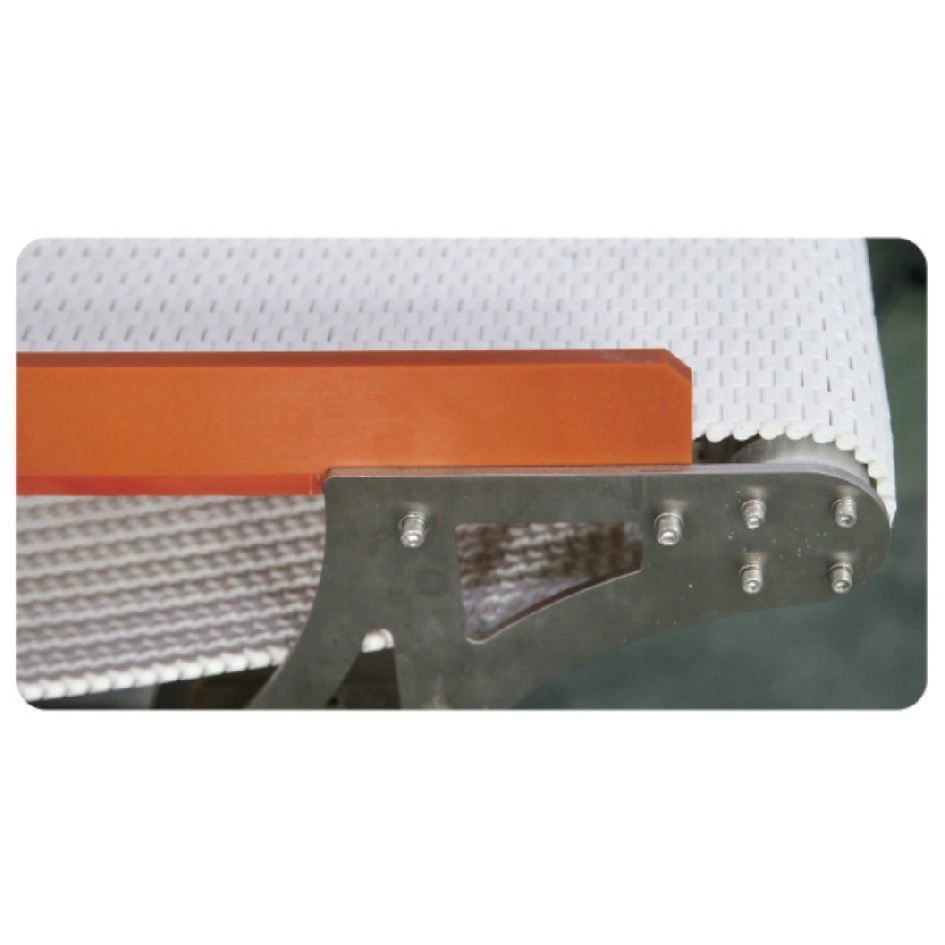

The JW-B20 can be deployed as a standalone semi-automatic station or integrated into a semi-automated line with conveyors and sealers. This makes it an excellent stepping stone—businesses can start with a JW-B20 and later scale to higher-capacity systems if volumes increase.

Choosing the right specs: practical checklist for purchasing a Powder Packing Machine

When evaluating machines, prioritize these items to ensure minimal waste and cost:

- Expected accuracy and repeatability ranges for your target pack weights

- Compatibility with product flow properties and required bag types

- Throughput relative to your production plan

- Ease of cleaning and hygienic design

- Data output capabilities for quality control (e.g., CSV, Ethernet)

- After-sales support and availability of spare parts

FAQ — Common questions about Powder Packing Machine accuracy and the JW-B20

Q: How much does accurate weighing reduce giveaway?

A: Typical reductions range from 2–10 g per 1 kg bag when moving from volumetric or manual filling to a precise linear weigher like the JW-B20. Exact savings depend on product and current process variability.

Q: Can the JW-B20 handle hygroscopic or sticky powders?

A: The JW-B20 is optimized for many powders and granules. For sticky/hygroscopic materials, modifications such as agitation, anti-bridging devices, or special coatings may be recommended—consult technical support for product-specific solutions.

Q: What is the expected accuracy of the JW-B20?

A: Typical achievable accuracy is ±1–3 g for 1 kg fills under well-controlled conditions. Calibration and good material flow management are essential to maintain this performance.

Q: Is the machine suitable for small batch or seasonal production?

A: Yes. Its semi-automatic, compact design and fast changeover capability make the JW-B20 well-suited for smaller or variable-volume operations.

Q: How quickly will the machine pay for itself?

A: Payback depends on throughput, giveaway reduction and material cost. For many operations, combining reduced giveaway, lower labor costs and fewer rejects yields payback within 1–3 years. Conduct a site-specific ROI assessment for accurate figures.

Next steps — see the JW-B20 in action and reduce your packaging waste and cost

If you are evaluating solutions to reduce giveaway and packaging cost, request a live demo or a trial run with your product. Our technical team can help size the JW-B20 for your SKU mix, run sample fills and provide an ROI estimate based on your data.

Contact sales to schedule a demo or view product specifications:

Authoritative references

- Packaging machine — Wikipedia: https://en.wikipedia.org/wiki/Packaging_machine

- Packaging Machinery Manufacturers Institute (PMMI): https://www.pmmi.org/

- Food and Agriculture Organization (FAO) — Food packaging guidance: https://www.fao.org/3/y4355e/y4355e05.htm

- International Organization for Standardization — Packaging (ICS 71): https://www.iso.org/ics/71

- National Institute of Standards and Technology (NIST): https://www.nist.gov/

For a personalized quote, demo or technical consultation on the Kenwei JW-B20 Semi Automatic Multi-function Single Bucket Conveying Powder granule food Packaging Machine With Linear Weigher, contact our sales team today.

Where to Buy checkweighers

Procurement Guide: Evaluating JW-B20 Powder Packing Machine

Food Packing Machine Solutions for Fresh Produce

ROI of Investing in Good Metal Detectors for Food Safety

About products customization

Can I customize Kenwei machines to suit my specific needs?

Yes, Kenwei offers a wide range of customization options to ensure that our machines meet your production requirements.

About Logistics

How long does logistics delivery take?

Shipping times depend on your location and the shipping method you choose. Generally speaking, international shipping can take anywhere from a few weeks to a few months.

How are large machines handled during shipping?

Large machines are typically shipped via sea freight using containerized shipping.

About After Sales Support

Can I get remote troubleshooting assistance?

Yes, Kenwei offers remote troubleshooting for certain issues. Our technical team can guide you through diagnostics and help resolve issues via phone, video call, or online messaging.

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Combined Check Weigher and Metal Detector for Food Industrial Weighing and Sorting

Kenwei’s Combined Checkweigher and Metal Detector for food industrial weighing and sorting ensures precise weight control and superior safety. This advanced food metal detector integrates high-speed check weighing, delivering accuracy and reliability for quality assurance.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei