Maintenance Checklist for Semi Automatic Powder Packing Machines

- Maintenance Checklist for Semi Automatic Powder Packing Machines

- Why regular maintenance matters for your Powder Packing Machine

- Daily maintenance checklist for the JW-B20 Powder Packing Machine

- Weekly maintenance: Calibration and mechanical checks for your Powder Packing Machine

- Monthly maintenance: Lubrication, filters and software backup

- Quarterly and annual maintenance: Professional servicing and parts replacement

- Preventive vs corrective maintenance (quick comparison)

- Calibration procedure for the JW-B20 linear weigher

- Cleaning and sanitation best practices for powder and food environments

- Common problems, root causes and fixes for Powder Packing Machines

- Recommended spare parts and inventory levels

- Maintenance log template and KPIs to track for your Powder Packing Machine

- Why choose Kenwei JW-B20: Brand advantages in maintenance and operation

- Frequently Asked Questions (FAQ)

- Authoritative references and further reading

Maintenance Checklist for Semi Automatic Powder Packing Machines

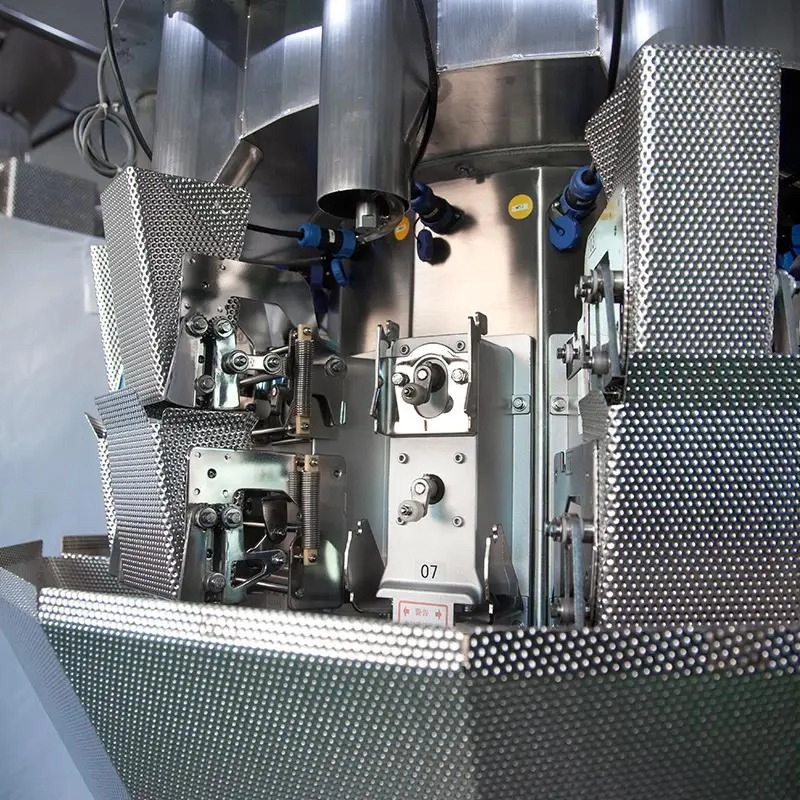

The Kenwei JW-B20 Semi-Automatic Multi-Function Packaging Machine with Linear Weigher is ideal for powders and granules like sugar, salt, rice, coffee, and milk powder. It automates feeding, weighing, and output with high accuracy and efficiency. Compact and cost-effective, it suits various bag types not supported by standard machines, making it perfect for flexible, space-saving packaging needs.

Why regular maintenance matters for your Powder Packing Machine

Regular maintenance of a Powder Packing Machine—especially the Semi Automatic Multi-Function Single Bucket Conveying Powder granule food Packaging Machine With Linear Weigher JW-B20—reduces unscheduled downtime, preserves weighing accuracy, ensures food safety, and extends service life. For food and powder applications, even small deposits or loose fasteners can change weight accuracy or contaminate product. A consistent maintenance routine protects product quality, lowers per-package cost, and supports regulatory compliance (HACCP, local food safety laws).

Daily maintenance checklist for the JW-B20 Powder Packing Machine

Perform these checks at the start and end of every production shift. These tasks are quick but essential to catch early issues.

- Visual inspection of the entire machine for leaks, dust build-up, or loose components.

- Clean hopper, funnel, and weighing buckets from powder residues (dry brushing or vacuum appropriate for product).

- Confirm sensors (photoelectric/weight sensors) are free of dust and correctly aligned.

- Check bag feeding/holding fixtures and sealing area for crumbs or misalignment.

- Run a sample batch of 5–10 packages; verify average weight and standard deviation meet specification.

- Check pneumatic pressure and look for slow leaks in hoses/fittings.

- Ensure emergency stop and safety guards operate correctly.

- Log any anomalies in the maintenance log with time and operator name.

Weekly maintenance: Calibration and mechanical checks for your Powder Packing Machine

Weekly tasks dig deeper into mechanical integrity and weighing performance.

- Perform a more thorough calibration check of the linear weigher using certified test weights or a traceable reference weight set.

- Inspect and tighten mechanical fasteners, mounting bolts and bracketry to manufacturer torque recommendations.

- Inspect conveyor belts, chain drives, and bearings for wear; tension belts as specified.

- Check motor mounts, couplings and gearboxes for vibration or unusual noise.

- Inspect vibratory feeders/augers for product build-up and wear; remove obstruction and document wear areas.

- Clean and inspect electrical enclosures for dust and moisture; ensure cable glands are tight.

Monthly maintenance: Lubrication, filters and software backup

Monthly tasks keep components running smoothly and protect critical control data.

- Lubricate bearings, chains and sliding points with manufacturer-recommended lubricants; avoid over-lubrication that attracts powder.

- Replace or clean air filters and vacuum filters where fitted.

- Inspect and replace sealing gaskets and inlet screens if signs of wear or cracking appear.

- Verify grounding and electrical connections for corrosion and tightness.

- Backup PLC and HMI configuration files off-machine; store backups in a change-controlled location.

- Review and update the maintenance log and trend any drift in weighing accuracy.

Quarterly and annual maintenance: Professional servicing and parts replacement

Schedule professional preventive maintenance at least once per year (quarterly for high-use lines). Tasks typically performed by trained technicians include:

- Full calibration and certification of the linear weigher to traceable standards (recommended for food-grade weighing accuracy).

- Replacement of consumable wear parts: seals, belts, actuators, sensor heads and proximity switches.

- Firmware and software updates; functional testing of all safety interlocks and emergency stops.

- Comprehensive electrical panel inspection and thermal imaging to detect hotspots.

- Performance qualification (PQ) testing to confirm the machine meets speed, accuracy and sanitation requirements for your product line.

Preventive vs corrective maintenance (quick comparison)

| Aspect | Preventive Maintenance | Corrective Maintenance |

|---|---|---|

| Goal | Prevent failure, ensure accuracy and safety | Restore function after failure |

| Cost | Planned, lower long-term cost | Often higher due to downtime and expedited parts |

| Downtime | Planned and minimized | Unplanned, may be lengthy |

| Impact on accuracy | Maintains consistent weighing performance | Accuracy compromised until fixed |

Calibration procedure for the JW-B20 linear weigher

Accurate calibration keeps the Powder Packing Machine within specification. Follow this simplified calibrated check; adapt to your in-house validation procedures and regulatory requirements.

- Warm-up the machine for the recommended period (15–30 minutes) under normal operating load.

- Ensure the weighing bucket and hopper are empty and clean.

- Place certified test weights on the weighing platform or use a traceable calibration kit. For example, test at 25%, 50%, 75% and 100% of the target bag weight.

- Record displayed weights and compare to test weights. Acceptable deviation typically depends on product and tolerance (e.g., ±0.5–1% for many food powders). Consult product specs.

- If calibration drift exceeds tolerance, follow manufacturer recalibration steps (adjust scale calibration coefficient or perform span calibration via HMI), then re-test.

- Document calibration results, technician name, date, and any adjustments made.

Cleaning and sanitation best practices for powder and food environments

Cleaning a Powder Packing Machine used for food powders must balance thoroughness with avoiding moisture where not appropriate. Follow these principles:

- Prefer dry-cleaning methods (vacuum, dry brushing) for hygroscopic powders before any wet cleaning.

- Where wet cleaning is required, follow EHEDG guidelines: isolate electrical components, use appropriate detergents and ensure full drying before restart.

- Disassemble removable contact parts (hoppers, funnels, weighing buckets) for deep cleaning according to the manufacturer’s instructions.

- Use food-grade cleaning agents and document cleaning cycles in your HACCP plan.

- After cleaning, run a product-change verification (rinse or fill run) to confirm no cross-contamination.

Common problems, root causes and fixes for Powder Packing Machines

Knowing frequent failure modes shortens fault-finding time:

- Inaccurate weights: Causes—sensor drift, product build-up on scale, loose mounting. Fix—clean weighing bucket, recalibrate, tighten mounts.

- Product bridging in hopper: Causes—static, moisture, poor hopper angle. Fix—install agitator, anti-bridging inserts, or increase vibration; control humidity.

- Poor bag seal: Causes—contaminated sealing jaws, incorrect temperature/pressure. Fix—clean/replace jaws, check heater control and air supply.

- Sensors not reading: Causes—dust obscuring photo sensors, wiring fault. Fix—clean sensors, check connectors, replace faulty sensors.

- Intermittent stoppages: Causes—loose encoder, intermittent pneumatic supply. Fix—secure encoders, service air compressors and regulators.

Recommended spare parts and inventory levels

Keep these spares on hand to reduce downtime for typical operations:

- Sealing jaws and heater elements: 2 sets

- Weight sensor/load cell: 1–2 units

- Photoelectric sensors and proximity switches: 2 each

- Minor wear parts—belts, gaskets, O-rings, solenoid valves: 5–10 pieces each depending on usage

- Emergency electronic component kit (fuses, relays, PLC spare module): 1 set

Maintenance log template and KPIs to track for your Powder Packing Machine

Track these KPIs monthly to evaluate maintenance effectiveness:

- Mean Time Between Failures (MTBF)

- Mean Time To Repair (MTTR)

- Percentage of packages within weight tolerance (yield)

- Unplanned downtime hours

- Calibration drift per month (grams or %)

Sample maintenance schedule (quick view):

| Task | Daily | Weekly | Monthly | Quarterly/Annual |

|---|---|---|---|---|

| Visual inspection & cleaning | ✔ | ✔ | ✔ | ✔ |

| Calibration check | Quick test | Partial | Full check | Certified calibration |

| Lubrication | ✔ | ✔ | ||

| Software/backup | ✔ | ✔ |

Why choose Kenwei JW-B20: Brand advantages in maintenance and operation

The Kenwei JW-B20 Powder Packing Machine is designed for low-maintenance, high-accuracy operation. Key advantages include:

- Compact modular design that simplifies cleaning and reduces areas where powder can accumulate.

- Linear weigher technology for reliable, repeatable weighing—reducing calibration frequency when correctly maintained.

- Compatibility with a variety of bag types and flexible packaging formats, minimizing changeover time.

- Cost-effective construction that balances durable components with easily replaceable wear parts.

- Simple HMI and PLC logic that make configuration backups and troubleshooting straightforward for operators.

Frequently Asked Questions (FAQ)

- Q: How often should I calibrate the JW-B20 linear weigher?

- A: Perform a quick calibration check daily and a full calibration weekly or monthly depending on production volume. Certified calibration should be performed at least annually or per regulatory requirements.

- Q: Can I wet-clean the machine if I package milk powder?

- A: Wet cleaning is acceptable if the machine and electrical parts are isolated and protected, and you follow EHEDG guidance. Prefer dry cleaning first and only wet-clean removable food-contact parts. Ensure full drying before restart.

- Q: What is the most common cause of weight drift?

- A: Product build-up on the weighing bucket or loose mounting hardware are common causes. Regular cleaning and tightening mounts often resolve drift issues.

- Q: Which spare parts should be stocked to minimize downtime?

- A: Keep seals, belts, heater elements, a spare load cell, sensors, and critical electronic spare modules on hand. Quantities depend on production volume.

- Q: How do I document maintenance to satisfy auditors?

- A: Use a dated maintenance log that records daily checks, calibration records (with test weights and results), cleaning cycles, spare part replacements and any corrective actions taken. Keep software backup records and technician sign-offs.

For product inquiries, spare parts, or to schedule professional maintenance for the Semi Automatic Multi-Function Single Bucket Conveying Powder granule food Packaging Machine With Linear Weigher JW-B20, contact our sales and service team or view the product page.

Contact Sales / View Product: Please contact your local Kenwei representative or visit the product page to request a quote and maintenance service schedule.

Authoritative references and further reading

- EHEDG — European Hygienic Engineering & Design Group: https://www.ehedg.org/

- Codex Alimentarius — Food safety standards: http://www.fao.org/fao-who-codexalimentarius/en/

- NIST — Weights and Measures Calibration Guidance: https://www.nist.gov/

- ISO 9001 — Quality Management Systems: https://www.iso.org/iso-9001-quality-management.

- Wikipedia — Packaging Machinery: https://en.wikipedia.org/wiki/Packaging_machine

Top 10 multihead weigher Manufacturers and Supplier Brands in America

Calibrating Multihead Weighers for Accurate Food Packing

Troubleshooting common issues with a 14 head multihead weigher

Comparing Single Bucket vs Multihead Powder Packing Solutions

About After Sales Support

What after-sales support does Kenwei offer?

Kenwei provides comprehensive after-sales support, including product installation, training, maintenance, troubleshooting, and technical assistance. Our team is dedicated to ensuring your machines operate at their best throughout their lifecycle.

How can I get technical support for my Kenwei machine?

You can contact Kenwei's technical support team via email, phone, or through our website.

How do I claim warranty service?

To claim warranty service, please contact our customer support team with your machine’s product code and a description of the issue. If applicable, we may request photos or videos of the issue to facilitate troubleshooting.

About Solution suggestions

How can Kenwei solutions help reduce waste in my production process?

Kenwei solutions improve accuracy in weighing, packaging, and quality control, reducing the chances of overfill or underfill. This leads to less product waste and higher operational efficiency.

About products customization

Can Kenwei machines support multiple languages?

Yes, we can customize the software interface to support multiple languages, making it easier for operators from different regions to use the machine.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Semi Automatic Vacuum Feeding Linear Weigher System for Powder and Small Granules Weighing JW-B19

The Kenwei JW-B19 Semi-Automatic Vacuum Feeding Linear Weigher is ideal for precise weighing of powders and small granules like sugar, salt, rice, coffee, and milk powder. With full automation, high accuracy, and space-saving design, it boosts efficiency while reducing labor and cost. Perfect for industries needing reliable, flexible, and compact weighing solutions.

Economical Linear Weighing and Vertical Packaging Machine for Powder Products JW-B7

The JW-B7 Economical Linear Weighing and Vertical Packaging Machine is ideal for packaging small granules and powder materials such as sugar, salt, rice, sesame, milk powder, coffee, and seasoning powder. This compact, cost-effective system automates feeding, weighing, filling, and bagging with date printing and output. It reduces labor costs, enhances efficiency, and is perfect for businesses with moderate speed requirements.

Combined weighing and packaging machine with screw feeder for powder materials

The Kenwei combined weighing and packaging machine with screw feeder is ideal for powder packaging. This advanced weighing and packaging machine of powder ensures high precision and efficiency, making it your top choice power packaging machine for powder materials.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei