Choosing the Right Automatic 8-Track Electronic Counting Machine

- Choosing the Right Automatic 8-Track Electronic Counting Machine

- What is an Automatic 8-Track Electronic Counting and why it matters for a pill counter machine

- Key performance metrics to evaluate in a pill counter machine

- How the Automatic 8-Track compares to other counting approaches

- Why throughput alone shouldn’t be the only selection criterion for a pill counter machine

- Practical checks to validate machine claims

- Design features that matter for pharmaceutical pill counter machine installations

- Environmental and operator safety considerations

- Maintenance, serviceability, and spare parts strategy

- Typical operating costs comparison

- Integration: how the 8-Track machine fits within packaging lines

- Regulatory and validation best practices for pill counter machine deployments

- Validation checklist (high-level)

- Return on investment: how to build a business case for a pill counter machine

- Brand advantages: why choose our Automatic 8-Track pill counter machine

- Common pitfalls and how to avoid them with a pill counter machine

- Frequently Asked Questions (FAQ)

- Q: What types of products can the Automatic 8-Track Electronic Counting and Filling Packaging Machine handle?

- Q: How accurate is the counting process?

- Q: How fast is the machine and does speed affect accuracy?

- Q: How long does changeover take between different bottle heights?

- Q: What validation support is provided?

- Q: Can I integrate vision systems or serialization?

- Next steps — contact sales or view product

- References

Choosing the Right Automatic 8-Track Electronic Counting Machine

What is an Automatic 8-Track Electronic Counting and why it matters for a pill counter machine

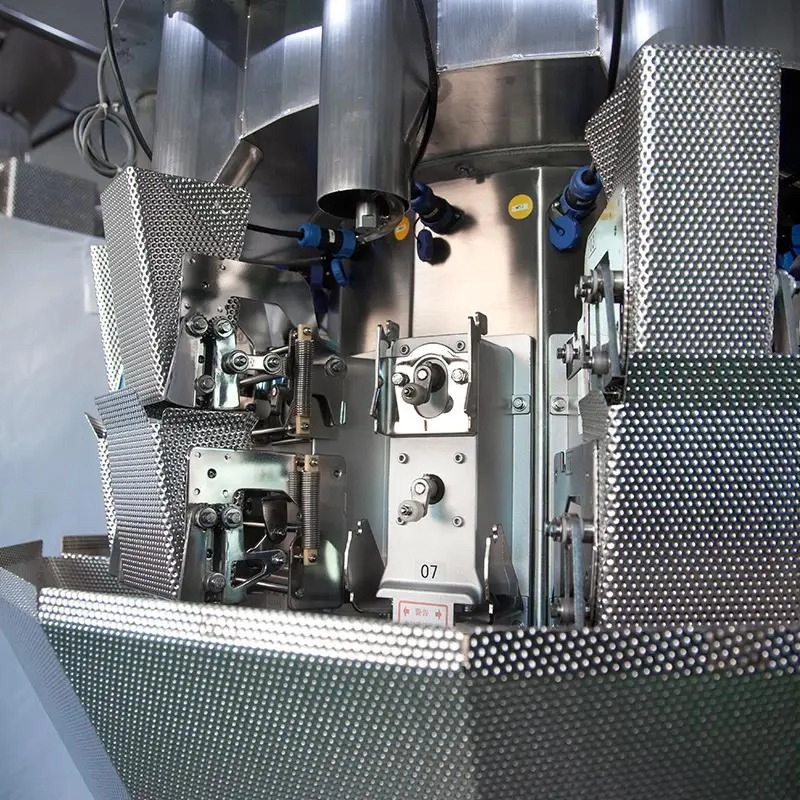

Pill counter machine selection starts with a clear understanding of the machine architecture and the problems it solves. The Automatic 8-Track Electronic Counting and Filling Packaging Machine is a two-channel, eight-track electronic system with adjustable height, supporting bottle heights from 20 to 100 mm. It requires no reset during fast line changes, making it perfect for counting products of various shapes. With a maximum speed of 4,000 particles per minute, it is ideal for pharmaceutical, food, chemical, plastic, healthcare, and other industries, delivering efficient and precise counting.Once you've chosen the right automatic 8-track electronic counting machine, it’s time to evaluate the key features to consider in a pill counter machine. This will ensure you make the most informed decision about your equipment.

Key performance metrics to evaluate in a pill counter machine

When comparing counting machines, focus on measurable metrics that affect throughput, quality, and total cost of ownership. For a pill counter machine these include:

- Throughput (particles per minute) — how many items the machine can count and fill per minute under normal production conditions.

- Accuracy and error rate — percentage of correct counts and how the machine detects and rejects short/overfilled containers.

- Changeover time — time required to switch from one product or bottle size to another; crucial for multi-SKU lines.

- Product handling versatility — ability to handle different shapes (tablets, capsules, softgels, bolts, small molded parts) without jams or damage.

- Footprint and integration — physical space required and the ease of integrating with upstream/downstream equipment.

- Validation and compliance features — audit trails, batch records, and CFR/annex compliance support for regulated industries.

How the Automatic 8-Track compares to other counting approaches

There are multiple approaches to automated counting: mechanical vibratory feeders, vision counting, single-track electronic counters, and multi-track electronic counters. Below is a concise comparison to help you weigh trade-offs for pill counter machine applications.

| Approach | Typical Max Speed (particles/min) | Typical Accuracy | Best Use Cases |

|---|---|---|---|

| 8-Track Electronic Counting (this product) | Up to 4,000 | >99.5% (product-dependent) | High-mix pharma, medium-high volume, variable shapes |

| Single-track Electronic Counter | 1,000–2,500 | >99% | Low-mix, small footprint lines |

| Vision Counting Systems | 1,500–3,500 | >99.9% (with good lighting/setup) | High-precision applications, transparent items |

| Vibratory Feeders | 500–2,500 | Varies widely | Simple geometries and low-cost solutions |

Source: manufacturer technical comparisons and industry packaging reviews (see references below).

Why throughput alone shouldn’t be the only selection criterion for a pill counter machine

Manufacturers often default to selecting the highest throughput machine. While speed matters, consider the whole production ecosystem. A machine that runs at 4,000 particles per minute but experiences frequent jams, rejects, or requires long changeovers can reduce effective line OEE (Overall Equipment Effectiveness). For pharmaceutical and healthcare products, compliance and traceability are equally important — a high-speed machine without appropriate audit trails or IPC interfaces may create downstream regulatory risk.

Practical checks to validate machine claims

Before purchase, request on-site or remote trials with your actual SKUs. Validate the following:

- Real throughput with mixed SKUs and current line pace.

- Accuracy for each SKU and pack size over statistically significant runs.

- Product damage rates (chipping, abrasion) for fragile tablets or softgels.

- Time required for product changeover and height adjustments (20–100 mm bottle range in this model).

Design features that matter for pharmaceutical pill counter machine installations

For regulated environments, prioritize features that reduce risk and simplify validation:

- HMI and recipe management — Clear recipe recall reduces human error during changeovers.

- Electronic audit trail — Data logging of counts, rejects, and operator actions supports batch release.

- Tool-less maintenance — Fast access to tracks and sensors speeds cleaning and reduces downtime.

- Adjustable height and no-reset changeover — The product’s adjustable height (20–100 mm) and no-reset during fast line changes save time and reduce throughput loss.

- Sanitary design — Smooth surfaces, stainless steel, and IP-rated components for easy cleaning.

Environmental and operator safety considerations

Ensure the machine supports dust control, has emergency stops accessible on all sides, and meets local electrical safety standards. For pharmaceuticals, confirm that cleaning protocols are compatible with your detergents and that parts exposed to product can be validated as cleanable.

Maintenance, serviceability, and spare parts strategy

Maintenance drives lifetime operating costs. Seek partners that provide:

- Clear preventive maintenance schedules and calibrated service intervals.

- Fast access to critical spares (sensors, tracks, belts) and recommended spare parts lists.

- Remote diagnostics and software update support to shorten MTTR (Mean Time To Repair).

For the Automatic 8-Track Electronic Counting and Filling Packaging Machine, the multi-track architecture reduces mechanical stress per track and often means lower wear rates compared to single-track high-speed counters.

Typical operating costs comparison

Operating costs vary by utilization, but consider these buckets: labor, maintenance/spare parts, utilities, and validation/documentation. Ask vendors for a 3–5 year TCO (Total Cost of Ownership) estimate that includes downtime assumptions and spare parts consumption.

Integration: how the 8-Track machine fits within packaging lines

Seamless integration reduces line friction. Key integration aspects:

- Conveyor interfaces — standard infeed/outfeed heights and IDs for easy mechanical coupling.

- Control protocols — PLC communication (Ethernet/IP, Modbus, Profinet) to share status and alarms.

- Reject and diversion handling — clear paths for rejects to avoid line stoppages.

- Upstream feeding — reliable hoppers or vibratory feeders to match the counting tracks.

Because the machine supports a wide bottle height range (20–100 mm) and requires no reset during fast line changes, it is specifically designed to minimize mechanical rework when lines handle multiple container formats.

Regulatory and validation best practices for pill counter machine deployments

In regulated industries, validation is non-negotiable. Prepare for IQ (Installation Qualification), OQ (Operational Qualification), and PQ (Performance Qualification) steps. Key activities include:

- Documenting installation and power/environmental conditions (IQ).

- Testing functionality across all recipes and interlocks (OQ).

- Running production-level batches with acceptance criteria for throughput and accuracy (PQ).

Ensure the vendor supplies traceable calibration data for critical sensors and supports electronic batch logging compatible with your MES or batch record system.

Validation checklist (high-level)

- List of recipes and acceptance criteria.

- IQ documentation, certificates of conformity.

- OQ test scripts for every speed, track, and reject function.

- PQ: at least three consecutive successful production runs per SKU (industry best practice).

Return on investment: how to build a business case for a pill counter machine

To justify capital spending, quantify savings and gains:

- Increased throughput (units/hour) leading to faster batch completion.

- Reduced labor costs through automation of counting and filling tasks.

- Fewer packaging mistakes and rework due to higher accuracy.

- Lower shrinkage and product loss from better handling.

Ask vendors for real-world case studies and, if possible, references in your vertical. Use modest assumptions for uptime and quality improvements to avoid overpromising ROI.

Brand advantages: why choose our Automatic 8-Track pill counter machine

When selecting a partner, consider these brand-level advantages that affect long-term satisfaction:

- Proven multi-track expertise — decades of development in multi-track electronic counting reduce design risk and improve reliability.

- Comprehensive service network — fast spare parts and remote diagnostic support minimize downtime.

- Regulatory support — supplied documentation, calibration certificates, and validation templates tailored to pharma customers.

- Modularity and upgrade paths — ability to add vision verification, serialization, or additional tracks for future capacity needs.

These advantages translate into measurable benefits: faster deployment, reduced validation timelines, and stable production performance across SKUs.

Common pitfalls and how to avoid them with a pill counter machine

Several common mistakes cause buyer remorse. Avoid them by:

- Not testing with real product samples — always validate with the worst-case SKU.

- Underestimating changeover complexity — verify the stated no-reset behavior with your operators and practice multiple changeovers.

- Skipping integration testing with upstream/downstream equipment — perform a full line dry-run before commissioning.

Frequently Asked Questions (FAQ)

Q: What types of products can the Automatic 8-Track Electronic Counting and Filling Packaging Machine handle?

A: It is engineered for tablets, capsules, softgels, nutraceuticals, small molded plastic parts, and similar discrete items. The multi-track architecture and adjustable height (20–100 mm bottles) make it versatile for many shapes and sizes.

Q: How accurate is the counting process?

A: Accuracy depends on product shape and feeding conditions. Under normal validated conditions, modern multi-track electronic counters achieve >99% accuracy for most SKUs. For critical pharmaceutical packaging, perform factory acceptance tests and on-site PQ to confirm performance for your SKUs.

Q: How fast is the machine and does speed affect accuracy?

A: The maximum speed is up to 4,000 particles per minute. Speed can affect accuracy if product flow or feeding is inconsistent. Properly configured tracks, feed hoppers, and rejection logic maintain accuracy at higher speeds.

Q: How long does changeover take between different bottle heights?

A: This model supports bottle heights from 20 to 100 mm with adjustable height and is designed for fast line changes without a full-reset. Typical changeovers for trained operators range from a few minutes to under 15 minutes, depending on the number of adjustments required—validate with in-field trials.

Q: What validation support is provided?

A: Our standard deliverables include IQ documentation, recommended OQ test scripts, calibration certificates for sensors, and templates to accelerate PQ execution. Additional on-site validation support can be provided as a service.

Q: Can I integrate vision systems or serialization?

A: Yes. The machine supports modular upgrades including vision inspection, counting verification, serialization and MES/ERP interfaces. Discuss your integration requirements during the specification phase.

Next steps — contact sales or view product

If you’re evaluating a pill counter machine for a new or upgraded packaging line, schedule a product demo or an on-site trial. Our technical sales team can arrange trials with your SKUs, provide a detailed TCO, and supply validation documentation.

Contact our sales team to request a demo, quote, or validation package. View the product page for the Automatic 8-Track Electronic Counting and Filling Packaging Machine or request a specification sheet from our representatives.

References

- U.S. Food & Drug Administration (FDA) — Guidance for industry on manufacturing quality systems and documentation. https://www.fda.gov

- Packaging World — Machinery and automation trends in pharmaceutical packaging. https://www.packworld.com

- International Society for Pharmaceutical Engineering (ISPE) Good Practice Guides — Equipment qualification and validation practices. https://ispe.org

- Industry vendor technical white papers on electronic multi-track counting and changeover techniques.

Note: Performance figures (speeds and typical accuracies) presented in this article are based on manufacturer specifications and industry-standard test conditions. For precise performance on your product SKUs, request an on-site or in-house trial.

Top 10 Features to Look for in Food Industry Metal Detectors

Maintenance Strategies for a 14-Head Vertical Multihead Weigher

Reduce Product Giveaway: Tips to Improve Multihead Weigher Accuracy

Integrating backup systems with 14 head multihead weighers

About Solution suggestions

How do Kenwei’s machines improve my production efficiency?

Kenwei machines enhance efficiency by automating the weighing, packaging, and quality control processes. Our high-speed, high-precision machines ensure accurate measurements, reduce human error, and increase throughput, leading to faster production times and lower operational costs.

About Price and payment

How do I make a payment for Kenwei machines?

We accept several payment methods: T/T, Letter of Credit (L/C)

About products customization

Can I customize Kenwei machines to suit my specific needs?

Yes, Kenwei offers a wide range of customization options to ensure that our machines meet your production requirements.

How long does it take to deliver a customized Kenwei machine?

The lead time for customized machines can vary based on the complexity of the customization, as well as production schedules. Generally, it takes 4-6 weeks to deliver a fully customized machine after design approval.

About Product choice

What types of products does Kenwei offer?

Kenwei specializes in high-precision and high-speed automated machinery for weighing, packaging, and quality control. Our main products include: multihead weigher, linear weigher, checkweighers,food metal detector,vertical packing machine and packing machine accessories.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Food Metal Detector Manufacturer For Reject Defective Products G5020

The G5020 multi-frequency metal detector features a specialized conveyor belt designed to reduce contamination risks, ensure smooth operation, and maintain high detection sensitivity. It is easy to disassemble for convenient maintenance. Ideal for detecting metal contaminants in food, pharmaceuticals, spices, plastics, electronics, textiles, toys, handicrafts, and more.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei