What is multi head combination weigher ?

- What is a Multi Head Combination Weigher? Unlocking Precision in Packaging

- Understanding the Basics of a Multi Head Combination Weigher

- How Does a Multi Head Combination Weigher Work?

- Key Benefits of Using a Multi Head Combination Weigher in Production

- Industries That Rely on Multi Head Combination Weighers

- Why Choose Kenwei for Your Multi Head Combination Weigher Needs?

- The Role of Multi Head Combination Weighers in Automation

- Factors to Consider When Selecting a Multi Head Combination Weigher

- Future Trends in Multi Head Combination Weigher Technology

- Conclusion: Elevate Your Packaging with a Multi Head Combination Weigher

What is a Multi Head Combination Weigher? Unlocking Precision in Packaging

In today’s fast-paced manufacturing and packaging industries, efficiency and accuracy are paramount. This is where the multi head combination weigher comes into play. As a cutting-edge piece of equipment, it has become a cornerstone for businesses looking to optimize their weighing and packaging processes. At Kenwei, a leading manufacturer of multi-head weighers, we specialize in delivering high-speed and high-precision solutions to meet diverse industry needs. Located in Fusha High-tech Industrial Park, Zhongshan City, Guangdong Province, Guangdong Kenwei is dedicated to providing one-stop automated weighing and packaging systems. In this comprehensive guide, we’ll explore what a multi head combination weigher is, how it works, its benefits, and why it’s a game-changer for modern production lines. Visit our website at https://www.kenweigroup.com/ to learn more about our innovative solutions.

Understanding the Basics of a Multi Head Combination Weigher

A multi head combination weigher is a specialized machine designed to weigh products with exceptional accuracy and speed. Often referred to as a combination scale, it uses multiple weighing heads—typically ranging from 10 to 32—to measure and dispense precise portions of a product. These machines are widely used in industries like food, pharmaceuticals, and hardware, where consistent portioning is critical. At Kenwei, our multi head combination weighers are engineered to handle a variety of products, from snacks and confectionery to frozen goods and granular items, ensuring businesses achieve their production goals with minimal waste.

How Does a Multi Head Combination Weigher Work?

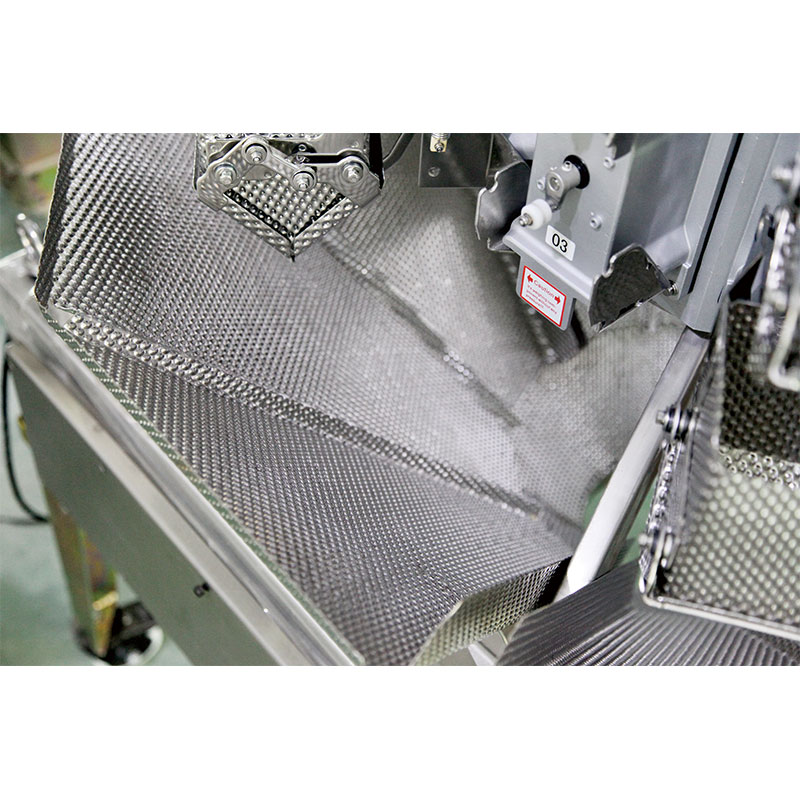

The working principle of a multi head combination weigher is both simple and ingenious. The product is first fed into the machine through a central distribution system. From there, it is distributed to individual hoppers or weighing heads. Each head measures a portion of the product, and a computer calculates the best combination of weights from different heads to achieve the target weight. This process ensures unparalleled precision and speed, making it ideal for high-volume production lines. Kenwei’s multi head combination weighers are designed with advanced technology to minimize product giveaway and maximize efficiency, helping businesses save costs while maintaining quality.

Key Benefits of Using a Multi Head Combination Weigher in Production

Investing in a multi head combination weigher offers numerous advantages for manufacturers. First and foremost, these machines provide unmatched accuracy, ensuring that every package meets the specified weight, reducing overfills or underfills. Secondly, they operate at high speeds, significantly increasing throughput compared to traditional weighing methods. Additionally, their versatility allows them to handle a wide range of products, from sticky to free-flowing items. At Kenwei, our multi head combination weighers are built for durability and ease of use, with features like quick-release parts for cleaning and maintenance, ensuring minimal downtime on your production line.

Industries That Rely on Multi Head Combination Weighers

The multi head combination weigher is a versatile solution adopted by various industries worldwide. In the food sector, it is commonly used for packaging snacks, cereals, nuts, and frozen foods, ensuring consistent portion sizes. The pharmaceutical industry benefits from its precision in weighing pills and capsules, while hardware manufacturers use it for small parts like screws and bolts. According to market research by Future Market Insights, the global multihead weighers market is expected to grow from USD 247.9 million in 2024 to USD 353.8 million by 2034, at a CAGR of 3.6%, reflecting the increasing demand across these sectors. Kenwei is proud to support businesses in these industries with tailored multi head combination weigher solutions to meet their specific needs.

Why Choose Kenwei for Your Multi Head Combination Weigher Needs?

When it comes to selecting a reliable multi head combination weigher, Kenwei stands out as a trusted name in the industry. With years of expertise, we are committed to the development and manufacturing of high-quality weighing and packaging equipment, including metal detectors, linear weighers, and check weighers. Our machines are known for their high speed and precision, and we offer customized solutions to meet unique customer requirements. Based in Guangdong, China, Kenwei has established a strong reputation for thoughtful and fast service, earning a positive brand image in the packaging machinery market. Explore our full range of products at https://www.kenweigroup.com/.

The Role of Multi Head Combination Weighers in Automation

Automation is transforming industries, and the multi head combination weigher plays a critical role in this shift. As the core of intelligent weighing systems, these machines integrate seamlessly with other equipment like vertical form fill seal machines and conveyor systems to create fully automated production lines. This not only boosts productivity but also reduces labor costs and human error. At Kenwei, we provide comprehensive one-stop automated weighing and packaging solutions, helping businesses streamline their operations and stay competitive in a rapidly evolving market. Our vision is to become the world’s leading weighing packing machine manufacturer, and we’re dedicated to making that a reality.

Factors to Consider When Selecting a Multi Head Combination Weigher

Choosing the right multi head combination weigher for your business requires careful consideration of several factors. First, assess the type of product you’ll be weighing—its size, shape, and flow characteristics can influence the machine’s design. Next, consider the required speed and output; high-volume operations may need more weighing heads for faster processing. Additionally, look for features like ease of cleaning, durability, and compatibility with existing equipment. At Kenwei, our team offers expert guidance to help you select the perfect multi head combination weigher, ensuring it aligns with your production goals and budget.

Future Trends in Multi Head Combination Weigher Technology

The future of multi head combination weigher technology is exciting, with advancements aimed at further improving efficiency and sustainability. Innovations like AI integration for predictive maintenance, IoT connectivity for real-time monitoring, and eco-friendly designs are on the horizon. These trends align with the growing emphasis on smart manufacturing and Industry 4.0. Kenwei is at the forefront of these developments, continuously investing in research and design to deliver state-of-the-art multi head combination weighers that meet the evolving needs of our customers. Stay updated on the latest industry innovations by visiting https://www.kenweigroup.com/.

Conclusion: Elevate Your Packaging with a Multi Head Combination Weigher

In summary, a multi head combination weigher is an indispensable tool for businesses seeking precision, speed, and efficiency in their weighing and packaging processes. Whether you’re in the food, pharmaceutical, or hardware industry, these machines offer a reliable solution to meet strict quality standards and boost productivity. At Kenwei, we take pride in being a powerful manufacturer of multi-head weighers, offering high-quality equipment and customized automation solutions. With our comprehensive capabilities in design, manufacturing, and after-sales service, we are your trusted partner in achieving packaging excellence. Ready to transform your production line? Contact us today at https://www.kenweigroup.com/ to learn how our multi head combination weighers can benefit your business.

Frequently Asked Questions (FAQs) About Multi Head Combination Weighers

What is the main purpose of a multi head combination weigher?

The primary purpose of a multi head combination weigher is to accurately and quickly weigh products for packaging. It uses multiple heads to measure portions and combines them to achieve the target weight, minimizing waste and ensuring consistency.

Which industries benefit most from using a multi head combination weigher?

Industries such as food (snacks, cereals, frozen goods), pharmaceuticals (pills, capsules), and hardware (small parts) benefit significantly due to the machine’s precision and versatility in handling various products.

How does Kenwei ensure the quality of its multi head combination weighers?

Kenwei employs advanced technology and rigorous quality control in the design and manufacturing process. Our machines are built for high speed and precision, and we provide comprehensive after-sales support to ensure customer satisfaction.

Can a multi head combination weigher handle sticky or difficult products?

Yes, modern multi head combination weighers, like those from Kenwei, are designed with specialized features to handle sticky, lumpy, or irregular products, ensuring smooth operation and accurate weighing.

How can I get a customized multi head combination weigher for my business?

Contact Kenwei through our website at https://www.kenweigroup.com/. Our team will assess your specific needs and provide tailored solutions to match your production requirements and budget.

Top 10 food packing machine Manufacturers and Supplier Brands

Where to Buy vffs packaging

Top 10 multihead weigher Manufacturers and Supplier Brands in America

Where to Buy vffs packaging machine

About Product choice

Are Kenwei’s products suitable for small-scale or large-scale operations?

Yes! We offer machines that are scalable to meet the needs of both small and large-scale operations.

Are there any additional features available for Kenwei machines?

Yes, we offer a variety of optional features for customization, such as: advanced touchscreen interfaces, multiple language support and so on.

About Cooperation Process

What is the lead time for product delivery?

The lead time depends on the complexity of the order and the level of customization required. Typically, our products are shipped within 4-8 weeks after receiving the order confirmation. However, this can vary, and we will provide an estimated delivery date when you place your order.

About Price and payment

Are the prices for Kenwei machines negotiable?

Prices are generally fixed, but depending on the order volume, long-term partnerships, or special circumstances, we may offer discounts or promotional pricing. Please contact our sales team to discuss your specific situation.

How is the price of Kenwei machines determined?

The price of Kenwei machines depends on several factors, including the type of machine, customization requirements, production volume, and any additional features or integrations. We provide tailored quotes based on your specific needs and requirements.

Multihead Weigher for Frozen food Packing Machine Manufacturers

Kenwei Multihead Weigher is designed for frozen food packing, delivering high speed and precise weighing. Trusted by leading multihead weigher packing machine manufacturers, Kenwei ensures efficiency, reliability, and exceptional performance for your packaging needs.

14 Heads Vertical Single Screw Feeding Pickles Weigher backups

This type of weigher is designed to handle the unique characteristics of pickles, ensuring precise measurements for packaging and distribution. It uses a vertical single screw mechanism to feed the pickles into the weighing system, allowing for efficient and consistent weighing. This technology is particularly useful in food processing and packaging facilities where precise portioning is essential for quality control and customer satisfaction. This specialized equipment is perfect for accurately measuring and dispensing pickles in a production line or packaging facility. The vertical design allows for efficient and precise filling of containers, while the single screw feeding mechanism ensures consistent and reliable weighing.

Vertical Frozen Food Packaging Machine for IQF & Frozen Products JW-B1

Metal Detector for Aluminum Foil in the Food Industry for Accurate Contamination Detection

The 2415 Metal Detector for Aluminum Foil is equipped with high-sensitivity sensors that effectively filter out signals from aluminum packaging, ensuring precise detection of magnetic metal contaminants. Ideal for detecting foreign bodies in aluminum foil-packaged items such as coffee bags, peanuts, dried meats, chocolate, and more. This versatile metal detector offers adjustable settings, with a maximum width of 24mm and height ranging from 20-150mm, making it suitable for a wide variety of aluminum foil packaging applications.

Kenwei

Kenwei

Kenwei multi weigh

Kenwei

Kenwei

Kenwei